9

Steps 7-12 are for the Pneumatic Extractor only. For the Manual Extractor,

proceed to step 13.

7. Make sure Air Valve (F) is in the closed position. Connect the air hose to

the Air Valve and turn on the air compressor.

8. Turn Air Valve (F) to the open position and press the Push Button (E).

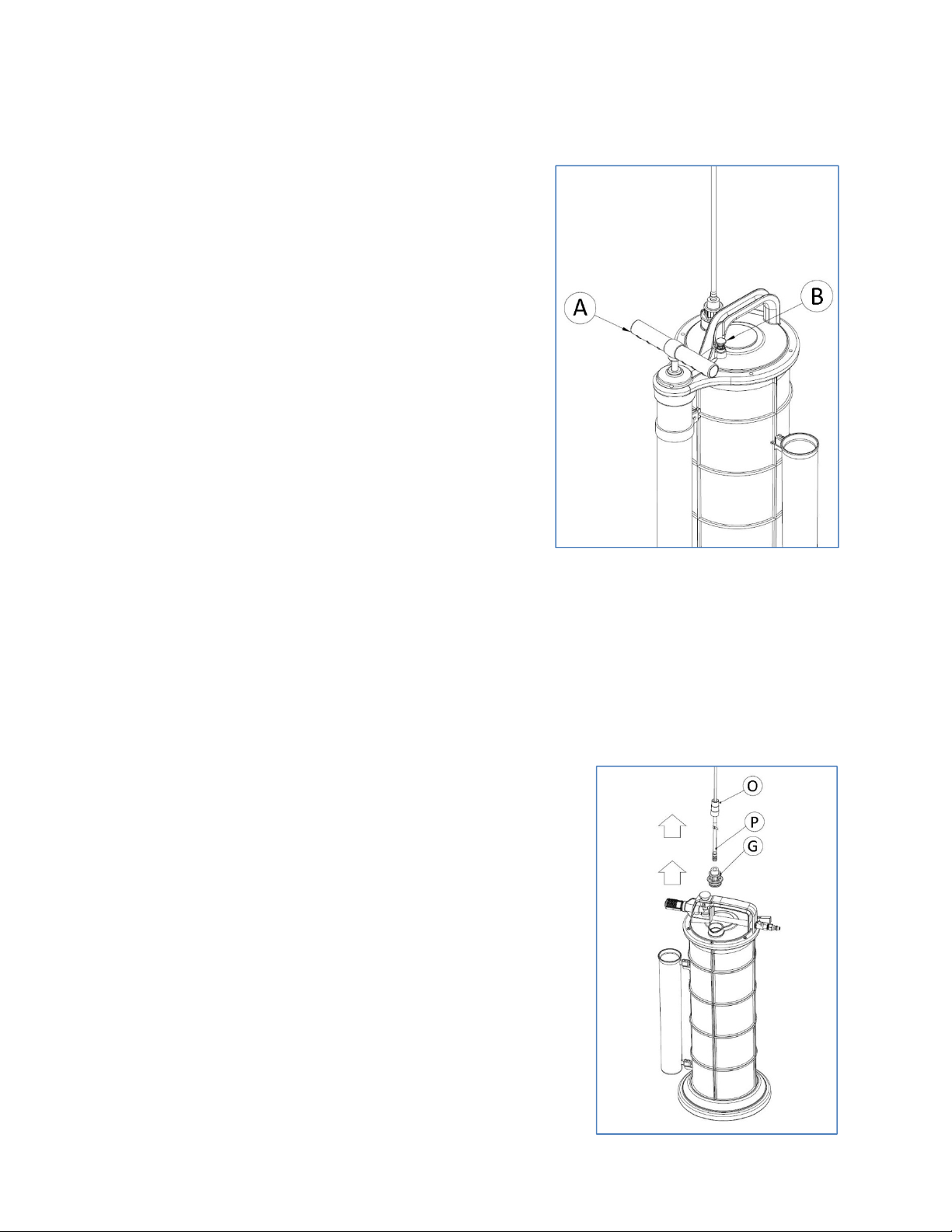

9. Open the bleeder screw slightly, just enough to cause fluid to flow into

the Brake Bleeding Tube (N).

10. Evacuate fluid until no air bubbles are present in the clear tube and then

tighten the bleeder screw.

11. Top off master cylinder reservoir and proceed to next brake according to

manufacturers bleeding order. Repeat until bleeding of all brakes has

been completed.

12. When the Reservoir Tank (J) is full, the extractor will automatically shut

off. If extractor does not become completely full, turn the Air Valve (F) to

the off position in order to stop the extractor. Proceed to Step 18.

Steps 13-17 are for Manual Extractor only.

13. Open the bleeder screw slightly, just enough to cause fluid to flow into

the Brake Bleeding Tube (N).

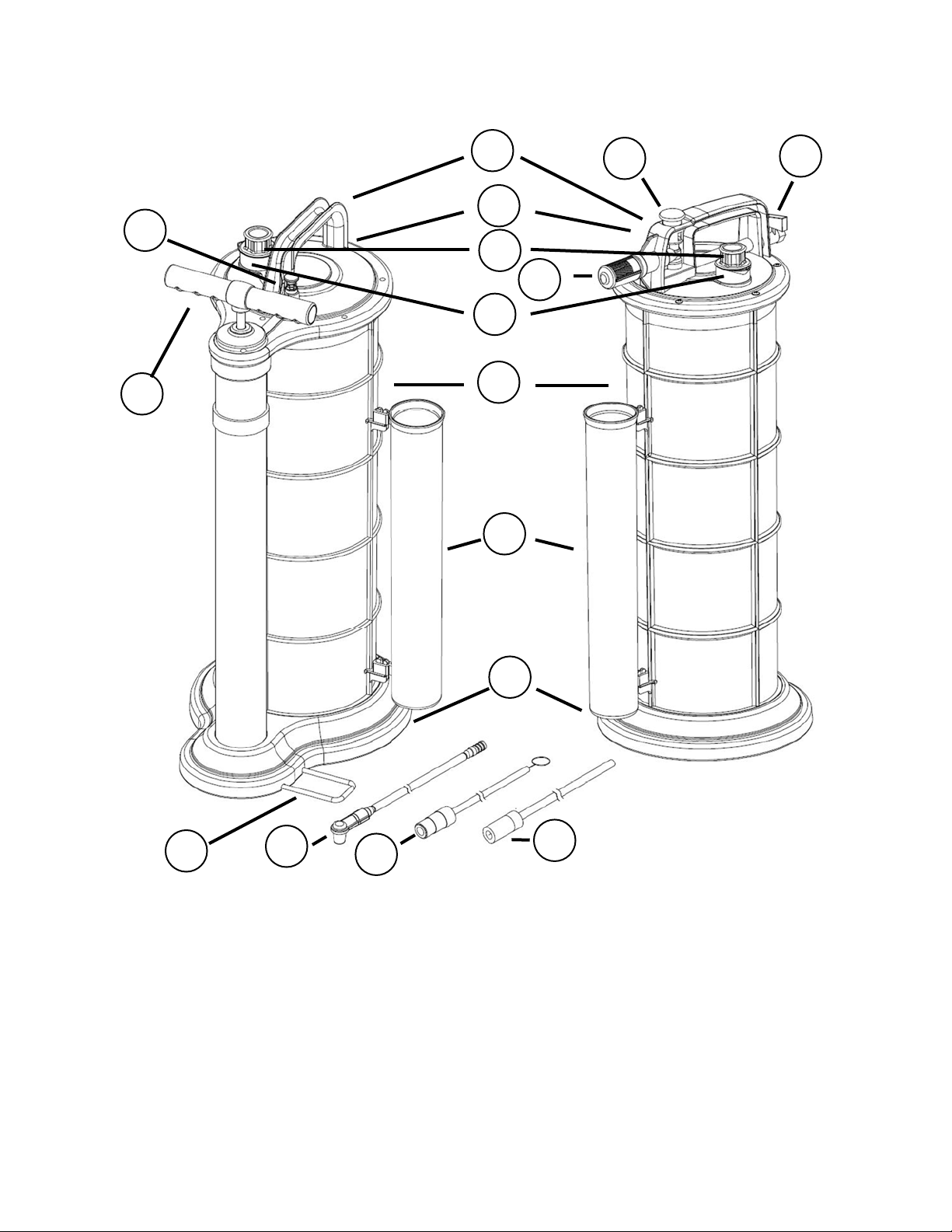

14. Lift Handle (A) to top position and return back to bottom position. Repeat

this pumping action to create vacuum in the Reservoir Tank (J). Brake fluid

will begin transferring into Reservoir Tank (J).

15. Evacuate fluid until no air bubbles are present in the clear tube and then

tighten the bleeder screw.

16. Top off master cylinder reservoir and proceed to next brake according to

manufacturers bleeding order. Repeat until bleeding of all brakes has

been completed.

17. When brake fluid in Reservoir Tank (J) reaches “full” position, the Handle

(A) of the hand pump will become difficult to depress due to back-

pressure in the Reservoir Tank (J). Press the Release Button (E) to return

the Handle (A) to its bottom position.