When running this cable, a few simple guidelines must be followed

•All speakers should be home-run. That is, wire should be run directly from each speaker, back to

the sound source

•Speaker wire should be kept away from AC wiring to prevent noise. If AC wiring and speaker wire

must cross paths, it is best to have them cross at a 90º angle, minimizing the common surface

area between the two

•Speaker wire and AC lines should NEVER pass through the same hole in studs or joists

Installation

1. For this type is installation, a stud finder such as MCM #22-9346 is highly recommended. This device

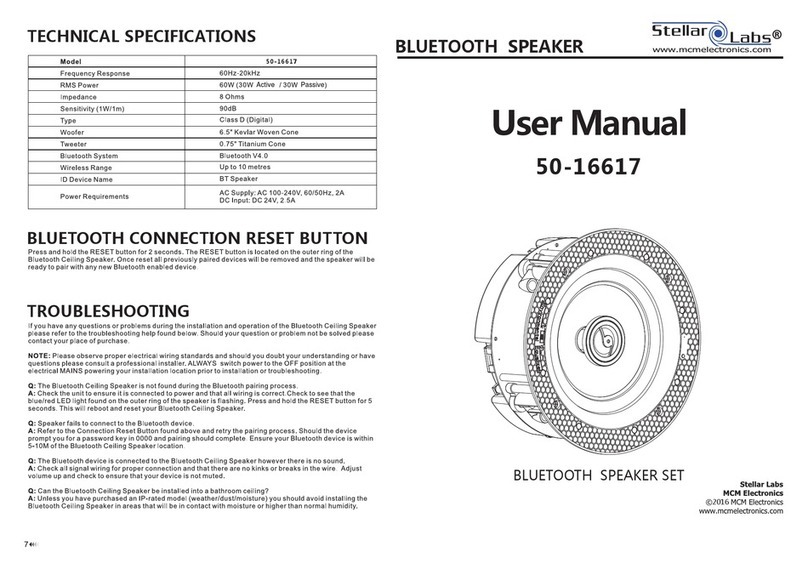

will not only accurately located both edges of the stud, but will provide a warning of nearby electrical

wiring.

2. When deciding on a final location to install speakers, extreme care should be taken to ensure that

obstructions do not exist, such as air ducts, plumbing and electrical wiring.

3. Locate the studs in the wall between which the speaker will be mounted. Using a pencil, mark a spot

directly in the center of the two studs

4. Locate the cardboard mounting template, included with the speaker, and using a tape measure,

determine its exact center point.

5. Poke a small hole in the template, and place the template on the wall, lining up the hole with the spot

marked on the ceiling. Using a level, make sure the template is level and plumb on the wall.

6. Trace the outer perimeter of the template with a pencil.

7. Using a wallboard saw, similar to MCM #22-7597, cut around this circumference. This type of saw is

especially useful, as its rigid design and sharp point allow it to “plunge” into the wall with no need to drill

a pilot hole.

8. Remove the rectangular section of drywall from the wall.

9. Remove the front grille from the speaker to be installed. This is most easily accomplished by rotating the

plastic mounting clips outward, and pressing then towards the front speaker frame. This will cause the

screw heads, behind the grill, to push the grill out from inside. In some cases, it may be necessary to

gently pry the grill from the front. This may be done with a small knife blade or micro size flat blade

screwdriver. In this case, extreme care should be taken not to damage the plastic frame around the

grill.

10. When looking at the rear of the speaker, rotate the six mounting clips clockwise as far as they well go,

so as not to obstruct the frame. If necessary, loosen the six mounting screws, from the front of the

speaker, to allow these clips to rotate freely within their bracket.

11. Locate the green terminal strip on the rear of the speaker, connections marked ( – ) and ( + ). This is a

two-part terminal strip, with the screw terminals being detachable from the PC board. Unplug the screw-

connector portion of the strip, allowing easy access to the screws. Strip ¼" of insulation from the end of

the speaker wire, insert into the terminal strip, and tighten the screws. Take care to observe correct

polarity. Then plug the terminal strip back into the PC board on the rear of the speaker.

12. Fully insert the speaker into the wall opening and begin to tighten the six mounting screws. Care should

be taken when tightening these screws. Make sure the screwdriver is secure in the head of the screw

and does not slip out and damage the speaker cone.

13. As screws are tightened, the plastic mounting clips will rotate clockwise and draw in against the inside of

the wallboard. If using a drill to tighten screws, tighten all six until the speaker frame just makes contact

with the ceiling. From there, it is best to use a hand screwdriver to fully tighten. This will prevent

breakage of the plastic mounting clips.

14. Once all screws are tightened, the grill may be reinstalled on the front of the speaker.

15. The other end of the speaker wire is now ready for connection to the sound source