Steridose STERIFLANGE User manual

1

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

STERIFLANGE®

Welding Guide

Welding the flange intoposition

Thisweldingguideshould beread carefully

beforeunpackingtheSteriflange®

OrderNo.____________

2

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

Table ofContents

1. ABOUTTHEWELDING GUIDE.............................................................................3

2. GENERAL...................................................................................................................4

3. POSITIONING AND ORIENTATIONOFSTERIFLANGE……………….........4

3.1 ORIENTATION OFSTERIFLANGE....................................................................................4

3.2 DISTANCE BETWEEN WELDS.............................................................................................5

3.3 DISTANCE FROMOUTER EDGE........................................................................................5

4. OPTIMUMALIGNMENTOFSTERIFLANGE®.....................................................6

5. MAKINGAND PREPARATIONOFHOLEINTHEGABLE...............................6

6. WELDING (TIG), TACK WELDING THESTERIFLANGE..................................7

7. FINAL WELDING......................................................................................................9

8. AFTER WELDING.....................................................................................................10

3

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

1. AbouttheWeldingGuide

Theweldingproceduredescribedin thisguideisusedforweldingflange in tovessels.The

guidelinesreferonlytothetechnicalaspectsofweldingoperations.Pleasenotethatalldatawith

regardtoweldingcurrent,timeetcareapproximateand mayvaryin practice.Referencesaremade

totheSwedishcodeforpressurevessels,TKN87. Ensurethattherelevantstandardsforpressure

vesselsarecomplied withthevessel.

RoplanABs liabilityforpossiblefaultsareregulatedbyECE 188. ThisimpliesthatRoplanABis

responsibleforfaultspresentin theproductatthetimeofdelivery.

RoplanABisnotresponsibleforfaultsthatoccurduetoconditionsthatariseafterdelivery,for

examplefaultyhandling,weldingorfitting.

Asastepin RoplanABs qualityassurance,eachflange isinspectedpriortodeliverytoensure

conformance withregardtosize and otherrequirementsoftheRoplanABs drawings.Acertificate

isenclosed with each delivery.

Thisprocedureensuresthattheprobabilityofan original faultisverysmall. Faultsthatdooccurcan

normallybetraced to incorrecthandling, weldingorfitting.

RoplanABs experience isthatthegreatestriskofafaultoccurringisdeformation in connection

with weldingtheflange into thegableend ofthevessel.

Tominimisetheriskoffaultsoccurringafterdeliveryfrom RoplanABitisessentialthatthis

weldingguideisstudiedand thatonlyproperlytrainedand experiencedpersonnelareemployedin

theweldingoperations.

Forothercountriesthan Sweden, pleasemakesurethattherelevantstandardsforthatcountryare

complied with.

Thepurposeofthismanual isto avoid deformation oftheSteriflange dueto releaseoftension

forcesin thegable.

Thismanual should onlyberegarded asan aid in theweldingwork and notoverridethelegal

obligations.

4

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

2. General

TheSteriflange maybeweldedintothevesselbeforeit’sweldedtogether.Itcanalsobeweldedin

an alreadyfinished vessel.

Itisvitalthatall otherweldingonthelowergableend iscompletedbeforemakingaholeforthe

flange.Examplesofsuchweldingthatmayberequiredarebottom outletvalves,connection

adaptersforsensorsand sampleportsetc.

3. Positioningand Orientation ofSteriflange

3.1 Orientationof Steriflange

In orderto connectpipe, etc. into theSteriflange, ensurethatno otherequipmentwill bein conflict

with theassembled parts. Also makesurethatthere'senough space to mount/dismountthelocking

ring.

5

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

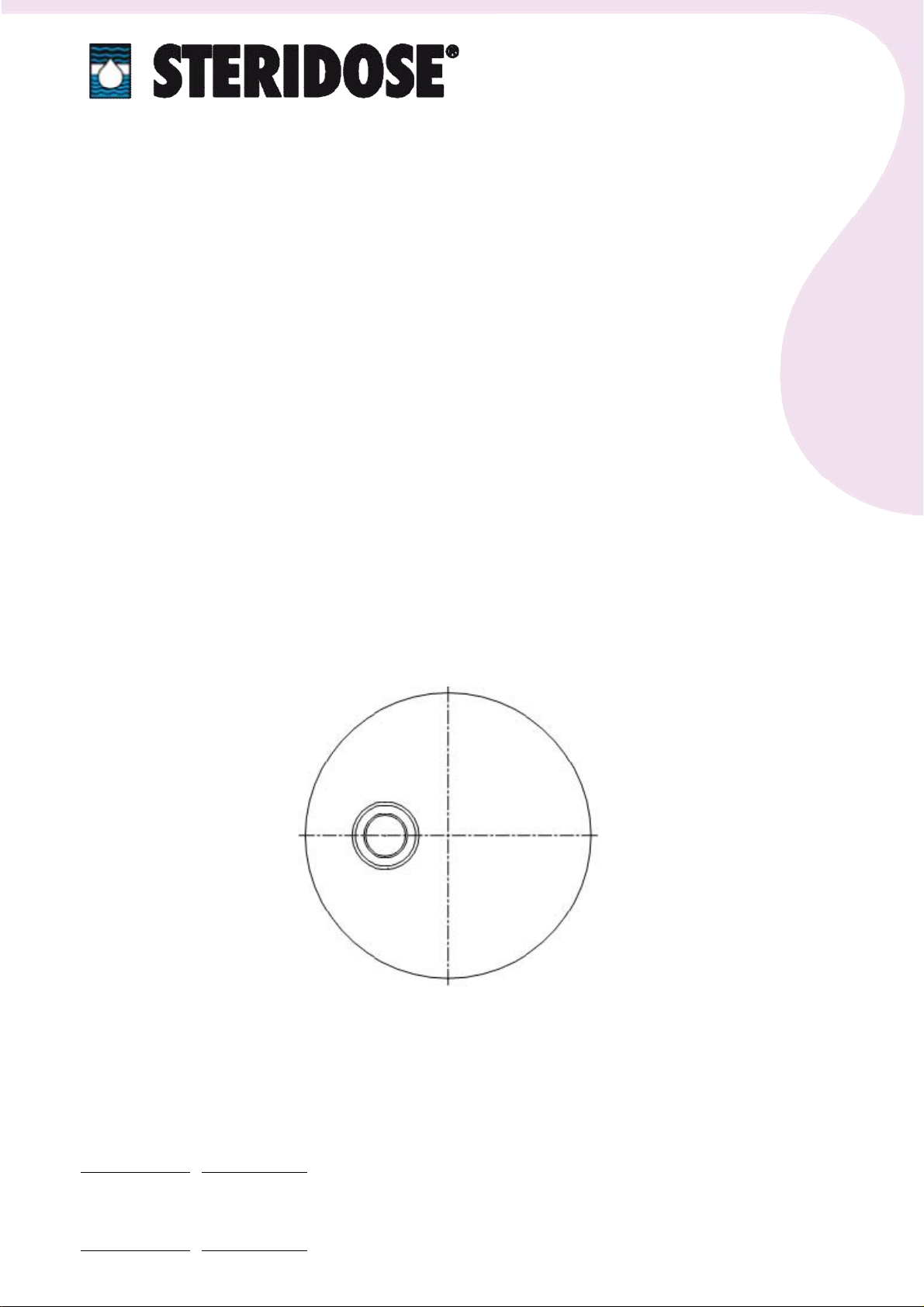

3.2 DistancebetweenWelds

Thesmallestpermissibledistance betweentheweldseamofaflangeandanyotherweld isthree

timesthethicknessofthematerialofthegableend, 3xt,accordingtothe1987 Swedishstandards

forpressurevessels,TKN87.

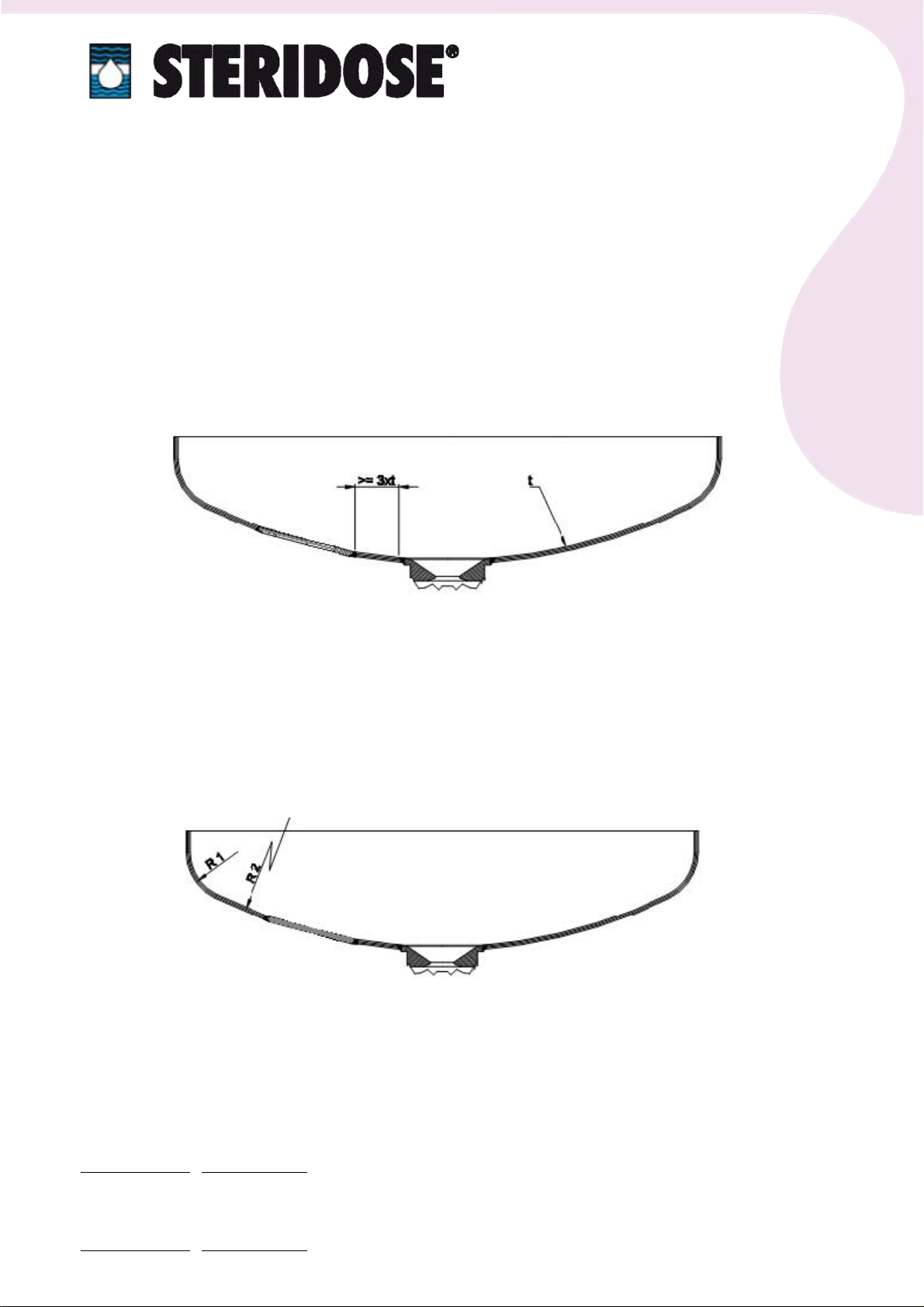

3.3 DistancefromOuter Edge

Theflange mustbepositionedin suchaway thatnopart ofitsweld liesoutsidethelarge radiusR2,

see figure. Weldinginsidethesmall radiusR1 isnotpermitted, accordingto TKN 1987.

6

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

4. Optimum AlignmentofSteriflange®

Since theSteriflangeshall beweldedinto agable. Makesurethatitwill bewelded flush with the

innersurface.

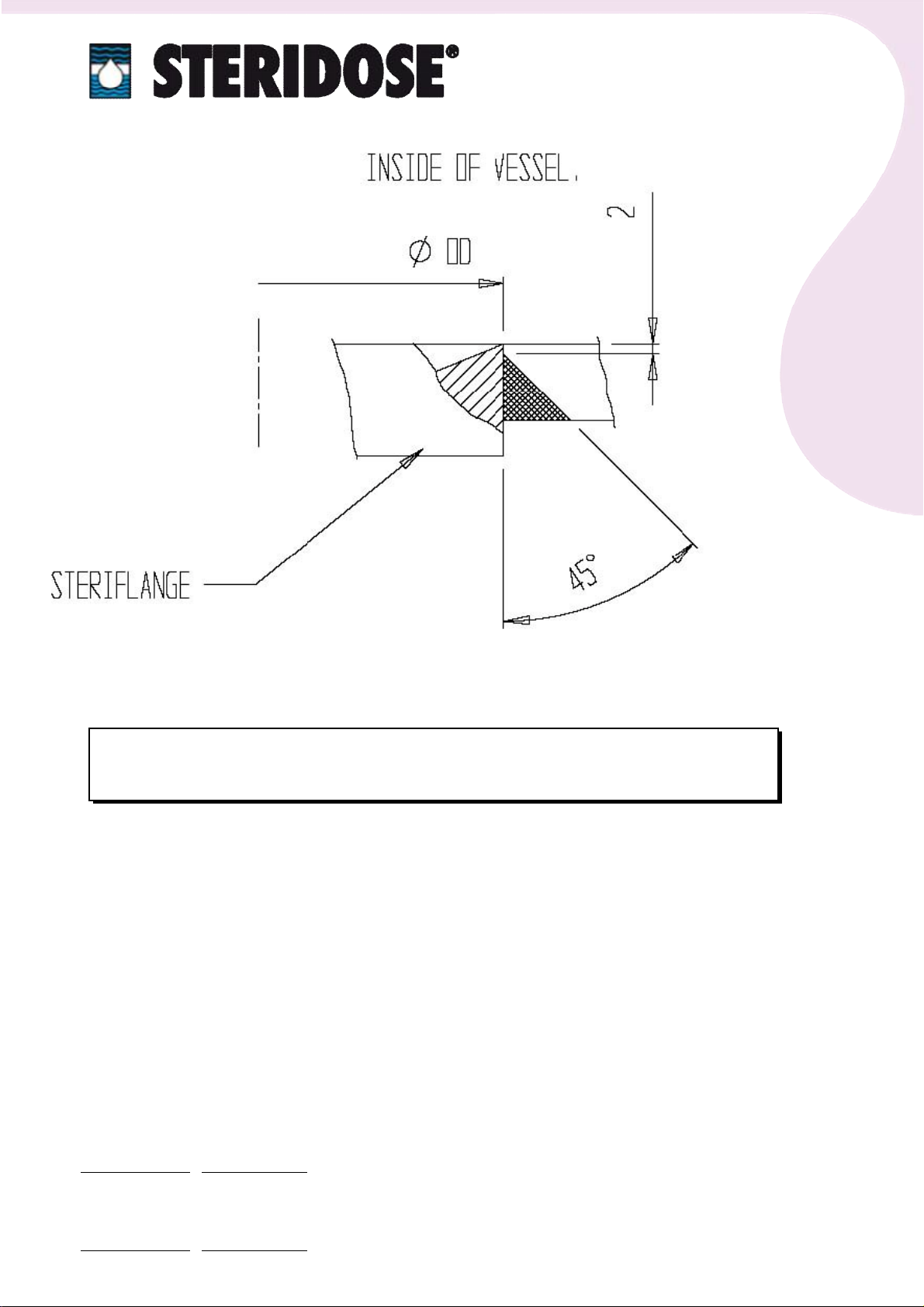

5. Makingand Preparation ofHolein theGable

1. MeasuretheouterdiameteroftheSteriflange.

2. Mark outthemeasured diameteron theoutsideofthelowergableend.

3. Cutaholewith theaid ofaplasmacutter, followingthemarked size on thegableend.

4. Prepareasuitableweld gapbetweenthegableendand theflangebygrindingtheedgeofthe

hole. Thisweld grooveshould bekeptassmall aspossible. Theflange can beused asatemplate.

5. Preparetheholeforweldingbygrindinga45°angle,slopingoutwards,seethefigurebelow.A

straightedge about2 mm should beleft towardstheinsideofthevessel.

6. Welding(TIG), tack weldingtheSteriflange

7

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

IMPORTANT!

Allowthegableand theflange to cool slowlyon completion ofwelding.

No coolingmedium, otherthan airhasto beused.

1. Check thatstampedchargenumberon theSteriflange isidentical to thenumberon certificate.

2. Position theflange in theholeso thattheinnersurface isflush with theinnergablesurface.

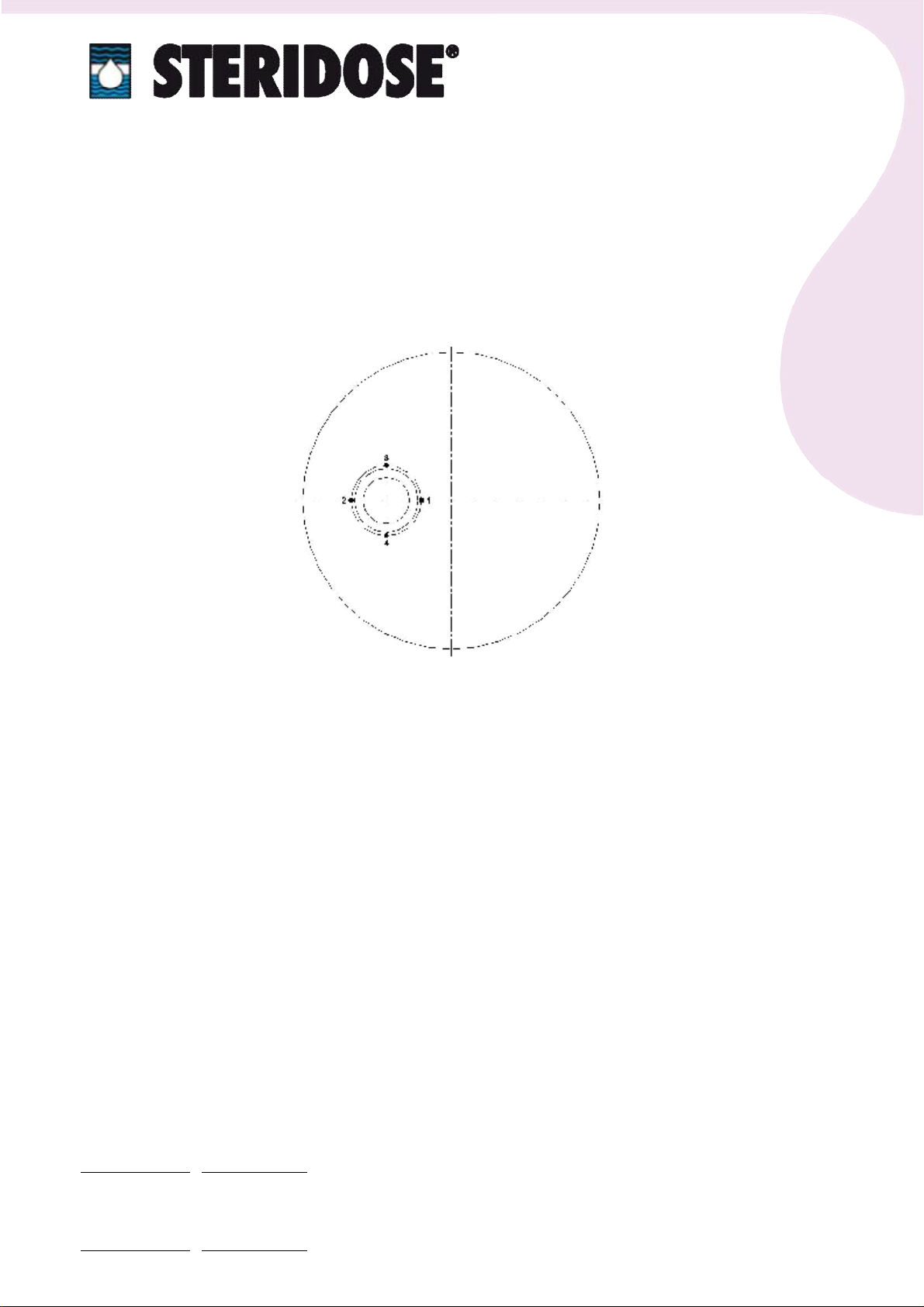

3. Tackweld theflangewithaTIGwelderattwopointson theinside,(point1and point2inthe

figurebelow).Thecorrectfillerdependson thematerialin thegableandflange.Foragableand

flange of316LfillerAvesta316L(SKR), 316L-Si/SKR-Si orsimilarisrecommended.

8

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

4. Check howtheflange isfitted, itmustlieflush with theinsideofthelowergableend.

5. Tackweld theflange attwomorepointsfromtheinside(3and 4in accordance withthebelow

figure).

6. Turnoverthegableand place iton aflatbench. Sealitbetweenthebenchand gableend with

theaid oftapeetc.Fill thegableend withargon gas.Itwill normallytakeabout3or4minutes

to replace theairwith theinert argon gas. Keep acertain gasflowingduringthewelding.

7. Tack weld theflange from theoutside. Thesequence 5-16 asshown in thefigurebelowis

followed.

9

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

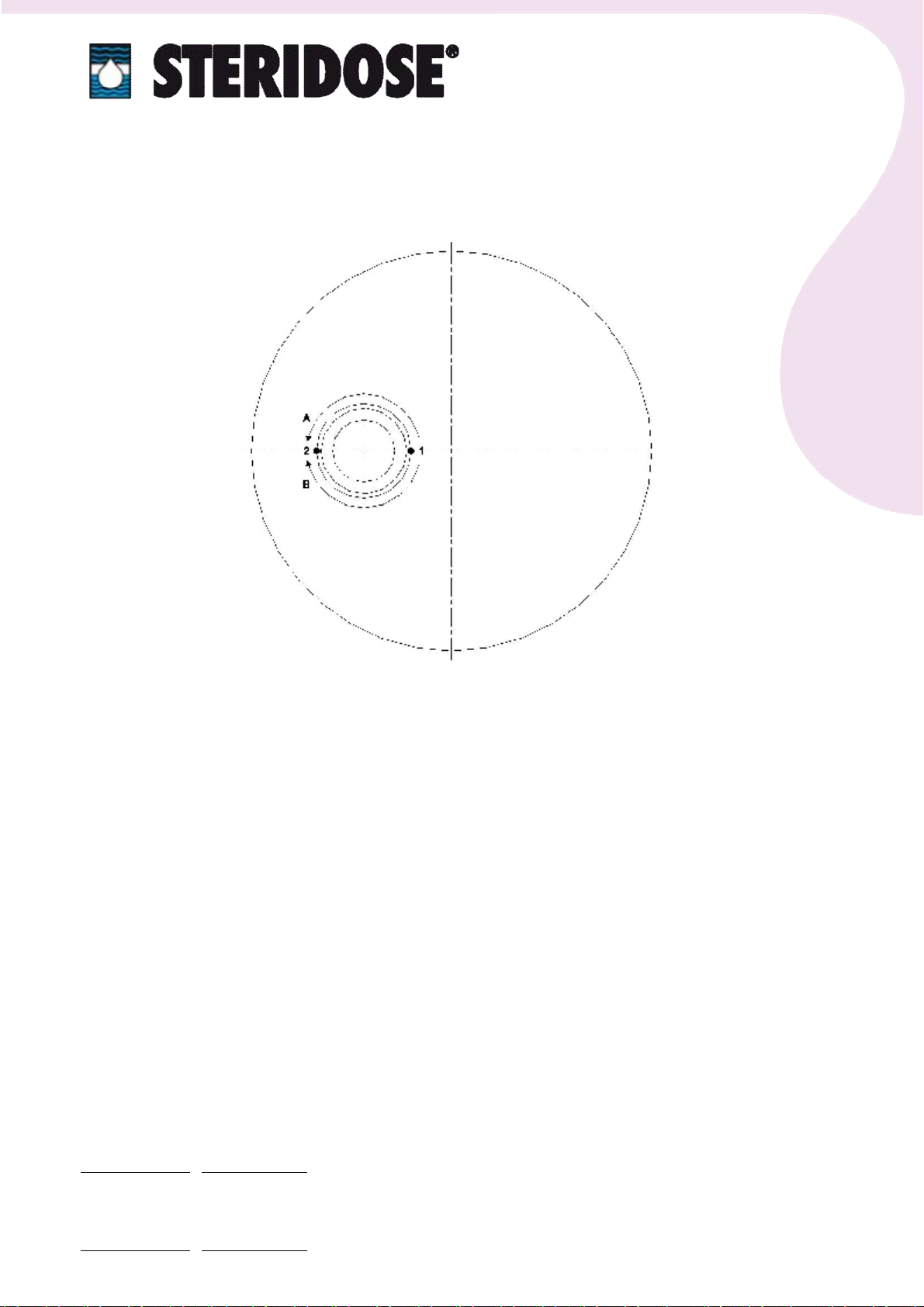

7. Final Welding

IMPORTANT!

Allowthegableand theflange to cool slowlyon completion ofwelding.

No coolingmedium, otherthan airhasto beused.

Thefinalweldingstartsnearesttothecentreofthegable.Itshould beweldedcontinuouslyfrom

point1topoint2(alongpathAasshownin thefigurebelow).A1,0 mm wireand weldingcurrent

should beusedwhen weldinga5mm thickgable.Thefillermaterialshould bethesameasthatused

previously.

Weldingshould bedonewithoutinterruption. Thesecond halfofthecirclefrom point1topoint2

butalongpath Bisnowwelded. Otherwisethesameasabove.

Theweldingisfinishedwiththesameprocedureasabovefrom point1topoint2(butalongpath

A),from 1to2(alongpathB),from 1to2(alongpathA),from 1to2(alongpathB).......... until the

weld ditch isfilled.

Thegableshould beinvertedagain and weldedfrom theinsidetoevenouttheweld joint.ATIG

qualified weldermustbeused throughoutforwelding.

10

STERIDOSESALES

HeadOffice

Himmelsbodavägen 7·P.O.Box120 ·SE-147 22 TUMBA ·SWEDEN

Phone:+46-844999 00 ·Fax: +46-8449 99 90

info@steridose.com · www.steridose.com

RegionalOffice

5020 WorldDairyDrive ·Madison,WI53718 ·USA

Phone:+1-608 229 5225 ·Fax:+1-608 227 9599

info@steridose.com · www.steridose.com

8. AfterWelding

1. Allowthegableand theflange tocool slowlyoncompletion ofwelding.Nocoolingmedium,

otherthan airhasto beused.

2. Grind and polish theinsideand outsideoftheweld to therequired finish.

Steriflange®isaregistered trademark.

Table of contents

Popular Welding System manuals by other brands

ESAB

ESAB Aristo Mig U5000i 400 V instruction manual

STAYER WELDING

STAYER WELDING M40.18Multi operating instructions

Miller Electric

Miller Electric 230Volt owner's manual

ESAB

ESAB DTG 405 Service manual

Eastwood

Eastwood VERSA-CUT 60 Assembly & operating instructions

Miller

Miller Auto-Continuum 350 CE owner's manual