stertil-KONI ST 1055 Operation manual

Mobile Column Lifts

ST 1055

ST 1060

ST 1072

Installation - operation - service

325-58-990A

PLEASE DELIVER TO THE LIFT ALL OPERATION, INSPECTION AND MAINTENANCE MANUALS AND ALL

OTHER INSTRUCTIONAL MATERIAL FURNISHED WITH THE LIFT, TO THE LIFT

OWNER/USER/EMPLOYER.

PLEASE READ AND UNDERSTAND ALL INSTRUCTIONS IN THIS MANUAL

BEFORE INSTALLING, OPERATING OR MAINTAINING THIS LIFT

DIRECTIONS ASSEMBLY AND SERVICING MANUAL

FOR THE 10,000/16,000 LBS STERTIL-KONI HYDRAULIC MOBILE COLUMN LIFTS

MODEL

ST 1055 / ST 1060 ST 1072

Starting at Serial Number

TN 72000 TH 49869

This document belongs with mobile column lift no.:

TN................... TH...................

Date first used:

……………….

Date: 01-10-2003

EC DECLARATION OF CONFORMITY in application of the European 'Machines' Directive (98/37/EC)

Manufacturer : Stertil B.V., Postbox 23, 9288 ZG KOOTSTERTILLE

Holland

Machine : Hydraulic mobile column lifts

Make : STERTIL-KONI

Model : ST 1055 / ST 1060 / ST 1072

Version : Primary column and Secondary column

Variants : Widened model ST 1072 V

: Extended forks and base leg length for

recreational vehicles ST1055-RV

The undersigned, H. Claus, Director, for this purpose authorised by Stertil BV, hereby declares that the mobile column lift described above, has been designed according to

the 'Machines' Directive and has been found to meet the fundamental safety requirements stipulated by this directive.

This Wheel Engaging Mobile Automotive Lifts are approved by: Stertil, Kootstertille

ETL, Testing Laboratories, Inc. - Lexington, H. Claus

KY 40510 USA, under report no.: J99024825 Director

Signature:

Date, 14-05-01

1

Contents Page

PREFACE ........................................................................................................................................................................................ 3

STATEMENT OF WARRANTY................................................................................................................................................... 4

1. GENERAL............................................................................................................................................................................ 5

1.1 MANUFACTURER'S INFORMATION........................................................................................................................5

1.2 SPECIFICATIONS.........................................................................................................................................................5

2. DIRECTIONS ...................................................................................................................................................................... 6

2.1 SCOPE............................................................................................................................................................................6

2.2 LIABILITY ....................................................................................................................................................................6

2.3 GUARANTEE................................................................................................................................................................6

2.4 SAFETY MEASURES...................................................................................................................................................7

3. DESCRIPTION OF THE LIFTING SYSYEM................................................................................................................. 9

3.1 STRUCTURE OF THE COLUMN LIFT.....................................................................................................................10

4. INSTALLATION ............................................................................................................................................................... 11

4.1 UNPACKING AND HANDLING THE LIFTING COLUMN ....................................................................................11

5. GENERAL USE ................................................................................................................................................................. 12

5.1 CONTROL ...................................................................................................................................................................12

5.2 CONNECTING LIFTING COLUMNS........................................................................................................................13

5.3 DESCRIPTION OF THE MOBILE COLUMN LIFT SYSTEM .................................................................................14

5.4 WHEEL ADAPTERS...................................................................................................................................................16

5.5 LENGTHENED WHEEL ADAPTERS ..........................................................................................................................16

5.6 USING OUTDOORS ...................................................................................................................................................17

6. OPERATION ..................................................................................................................................................................... 18

6.1 PREPARATION...........................................................................................................................................................18

6.2 RAISING AND LOWERING ALL LIFTING COLUMNS.........................................................................................18

6.3 RAISING AND LOWERING OF TWO LIFTING COLUMNS (ONE VEHICLE AXLE); PAIRED OPERATION.18

6.4 RAISING AND LOWERING A SINGLE LIFTING COLUMN.................................................................................18

6.5 EMERGENCY RELEASE ...........................................................................................................................................18

7. INSPECTION AND MAINTENANCE............................................................................................................................ 19

7.1 GENERAL ...................................................................................................................................................................19

7.2 DAILY (BY OPERATOR)...........................................................................................................................................19

7.3 MONTHLY (BY OPERATOR) ...................................................................................................................................19

7.4 ANNUALLY (BY SERVICE DEPARTMENT)..........................................................................................................20

7.5 MAINTENANCE SWITCHES ....................................................................................................................................21

7.6 REMOVAL/INSTALLATION OF THE LIFTING CYLINDER.................................................................................21

7.7 ADJUSTING THE PALLET JACK MECHANISM (ONLY ST 1072)......................................................................22

8. SERVICE............................................................................................................................................................................ 22

8.1 GENERAL ...................................................................................................................................................................22

8.2 TROUBLE-SHOOTING ..............................................................................................................................................24

8.3 IDENTIFICATION ......................................................................................................................................................27

2

9. LIST OF PARTS AND APPENDICES ............................................................................................................................ 27

9.1 PARTS LIST ................................................................................................................................................................27

9.2 ORDERING SPARE PARTS.......................................................................................................................................27

APPENDICES AND FIGURES

FIG. A - MOBILE LIFTING COLUMN............................................................................................................................28

FIG. B - PALLET JACK MECHANISM (OPTION).........................................................................................................30

FIG. C - HYDRAULIC UNIT 60 HZ.................................................................................................................................32

FIG. D - HYDRAULIC CYLINDER .................................................................................................................................33

FIG. E - CONTROL BOX (MASTER COLUMN)............................................................................................................34

FIG. F - ELECTRICAL DIAGRAM CONTROLBOX (PRIMARY)................................................................................35

FIG. G - CONTROL BOX (SECONDARY COLUMN)....................................................................................................36

FIG. H - ELECTRICAL DIAGRAM (SECONDARY COLUMN)....................................................................................37

FIG. I - CONNECTION CABLE......................................................................................................................................38

FIG. J - LABEL LOCATIONS .........................................................................................................................................39

FIG. K - HYDRAULIC SCHEME .....................................................................................................................................40

FIG. L - WHEEL ADAPTORS & EXTENDED ARM (OPTION ONLY ST 1055 / ST 1060) .......................................41

FIG. M - DIMENSIONAL DRAWING..............................................................................................................................42

INSPECTION CHECK LIST ...................................................................................................................................................... 43

3

PREFACE

Prior to the operation of your Stertil-Koni mobile lift make sure that you read the instructions thoroughly. These instructions are found in this

manual. Please note that your warranty can be voided if you do not read the manual and understand its content

If you have any questions, concerning operation, safety or application of your mobile lift, please contact Stertil Koni USA at the following

toll-free number: 800 336 6637 or call 410 643 9001. The address for Stertil Koni USA Inc. is 200 Log Canoe Circle, Stevensville, Maryland

21666.

An automotive lift operator shall have certain qualifications before he/she can safely operate a Stertil Koni mobile lift and these include ability

in written or oral communications as demonstrated by either a high school diploma or certificate of equivalency, aptitude test or job experience.

He/she must also have the ability to understand the mathematical, mechanical and electrical principles of automotive lifts as demonstrated by

one of, or a combination of aptitude test, training program, technical vocational school or job experience.

The owner/employer of the Stertil Koni mobile lift must ensure that the operator of the mobile lift must be instructed and trained in the safe use

and operation of the lift using the manufacturer-provided instructions and warning labels and the Automotive Lift Institute Publications, "Lifting

It Right" and "Safety Tips".

The lift that has been delivered to you contains the supply operating instructions, general safety information, safety tips and warning labels on

the master control console. As an owner, or employer, it is requested that you display these materials in a conspicuous location in the lift

operating area.

The owner or employer shall appropriately document operator training by completing an operator training log which shall be part of the

management documentation.

The operator shall operate the automotive lift only after being properly instructed or trained in accordance with manufacturer supplied

instructions found in the this manual.

The operator shall use all applicable safety features provided on the automotive lift and operate the lift in accordance with the instructions

provided by Stertil-Koni.

The lift operator or employer shall take all appropriate steps to follow the recommended inspection procedures of the lift manufacturer but in no

event shall the lift operator fail to inspect or take notice of the following features on a daily basis.

1. accessibility and readability of the operating procedures, safety tips and generic safety material

2. accessibility and readability of safety warning labels

3. readability of the rated load capacity of the lift

4. proper operation of the lift controls, restraints and locking devices

5. deformation or excessive wear of any of the lift structural components

6. deformation or excessive wear of other components such as hoses, electrical wires

7. evidence of hydraulic leaks

8. unusual noises

If any of the conditions described above are observed before, during or after operation of the lift, the operator shall stop using the lift and report

the condition to the supervisor, employer or owner. If any of the conditions listed above are observed, then the lift shall not be used until the

cause of the problem has been determined and the appropriate repairs made by qualified Stertil Koni service authorized personnel. In order to

ensure that the lift is not used until the repairs have been effected, the lift shall be locked out or tagged in accordance with ANSI/Z244.1-1982.

The owner or employer shall establish a periodic preventive maintenance procedure in accordance with the recommendations listed in this

manual.

Stertil-Koni USA shall not be responsible for any actions not specifically called out for in this manual or in this notice.

Please note that there shall be no modifications or reconstruction made to the Stertil Koni mobile lift without the express written permission of

the manufacturer.

Please make sure that caution labels are not frayed and are on the lift. Please call the manufacturer if these caution labels have been removed or

through age are no longer on the lift.

Please read and understand the attached Statement of Warranty for the Stertil Koni mobile lift.

Thank you for the purchase of your Stertil Koni product.

4

STATEMENT OF WARRANTY

Stertil KONI USA lifting systems are warranted for a period of two (2) years for parts and labour commencing from the effective

date of acceptance by the Customer. During the warranty period, equipment that is found to be defective will be repaired or

replaced (at the option of Stertil-KONI USA) without charge.

The equipment must be returned and freight charges prepaid, with proof of delivery date to a Stertil-KONI USA Authorized

Service Center. The repaired or replaced equipment will be returned with freight charges prepaid by Stertil-KONI USA.

Hydraulic cylinders are warranted for a period of five (5) years. There is a lifetime warranty on nylon guide rollers used in

Stertil-KONI lifting products that utilize such rollers.

This warranty does not apply where equipment has been damaged due to abnormal wear, misuse, overloading, accident

(including shipping), improper maintenance, alteration, improper fluid maintenance, or other causes not the result of defective

materials or workmanship.

Repair or replacement is the exclusive remedy for allegedly defective equipment under this warranty, and Stertil-KONI USA

will not be liable for any consequential or incidental damages for breach of any express or implied warranty on this equipment.

Stertil-KONI USA is not responsible for claims not made by persons other than Stertil-KONI USA authorized service or sales

representatives.

Please contact Stertil-KONI USA for the location of authorized Service Centers throughout the United States.

Stertil-Koni USA Inc.

200 Log Canoe Circle

Stevensville, Maryland 21666

tel. 00 1 410 643 9001

fax. 00 1 410 643 8901

Toll-free number: 800 336 6637

Column Serial Numbers: _______________________ _______________________

_______________________ _______________________

_______________________ _______________________

_______________________ _______________________

___________________________________________________________________________________________

Signature Date

5

1. GENERAL

1.1 MANUFACTURER'S INFORMATION

Stertil BV Kootstertille (NL)

Westkern 3, 9288 CA Telephone 31(0)512334444

Postbus 23, 9288 ZG Telefax 31(0)512334430

Website: www.stertil.nl

1.2 SPECIFICATIONS

Also see type plate on the mobile column lift.

Model ST 1055

ST 1060 ST 1072

Capacity 10,000 lbs 12,000 lbs 16,000 lbs

Pressure relief valve 3,200 psi (sealed ex-works

with plastic cap)

3,800 psi (sealed ex-works with

plastic cap)

3,800 psi (sealed ex-works

with plastic cap)

Electrical power

3 Phase

1 Phase

3 HP

1,5 HP

3 HP

1,5 HP

3 HP

1,5 HP

Mains supply

3x208/230V 60 Hz

3x460V 60 Hz

3x575V 60 Hz

1x208/230V 60 Hz

3x phase, 1x earth, 1x zero

3x phase, 1x earth

3x phase, 1x earth

1x phase, 1x earth

3x phase, 1x earth, 1x zero

3x phase, 1x earth

3x phase, 1x earth

1x phase, 1x earth, 1x zero

3x phase, 1x earth, 1x zero

3x phase, 1x earth

3x phase, 1x earth

1x phase, 1x earth

Mains fuse

3x208/230V 60 Hz

3x460V 60 Hz

3x575V 60 Hz

1x208/230V 60 Hz

See Amperage Power

Supply Consumption table

30 A (slow)

15 A (slow)

10 A (slow)

30 A (slow)

See Amperage Power Supply

Consumption table

30 A (slow)

15 A (slow)

10 A (slow)

30 A (slow)

See Amperage Power Supply

Consumption table

30 A (slow)

15 A (slow)

15 A (slow)

30 A (slow)

Operational voltage 24 V= 24 V= 24 V=

Stroke 71" 71" 68 7/8"

Lifting speed 3 Phase

1Phase

62"/min

30"/min

62"/min

30"/min

50"/min

24"/min

Lifting/lowering time

3Phase

1Phase

71 sec/57 sec

142 sec/57 sec

71 sec/57 sec

142 sec/57 sec

83 sec/60 sec

170 sec/60 sec

Noise level max 73 dB(A) max 73 dB(A) max 73 dB(A)

Set-up Indoors / outdoors Indoors / outdoors Indoors / outdoors

Weight 900 lbs 900 lbs 1050 lbs

Electrical supply cable

length

62' – 4" 62' – 4" 62' – 4"

Lifting column

interconnection

cable length

39' - 4" 39' - 4" 39' - 4"

Maximum distance

between

lifting columns

29' - 6" 29' - 6" 29' - 6"

Maximum floor pressure 5800 psi 7000 psi 8000 psi

Maximum floor load (per front wheel)

4200 lbs

(per front wheel)

5000 lbs

(per front wheel)

6750 lbs

6

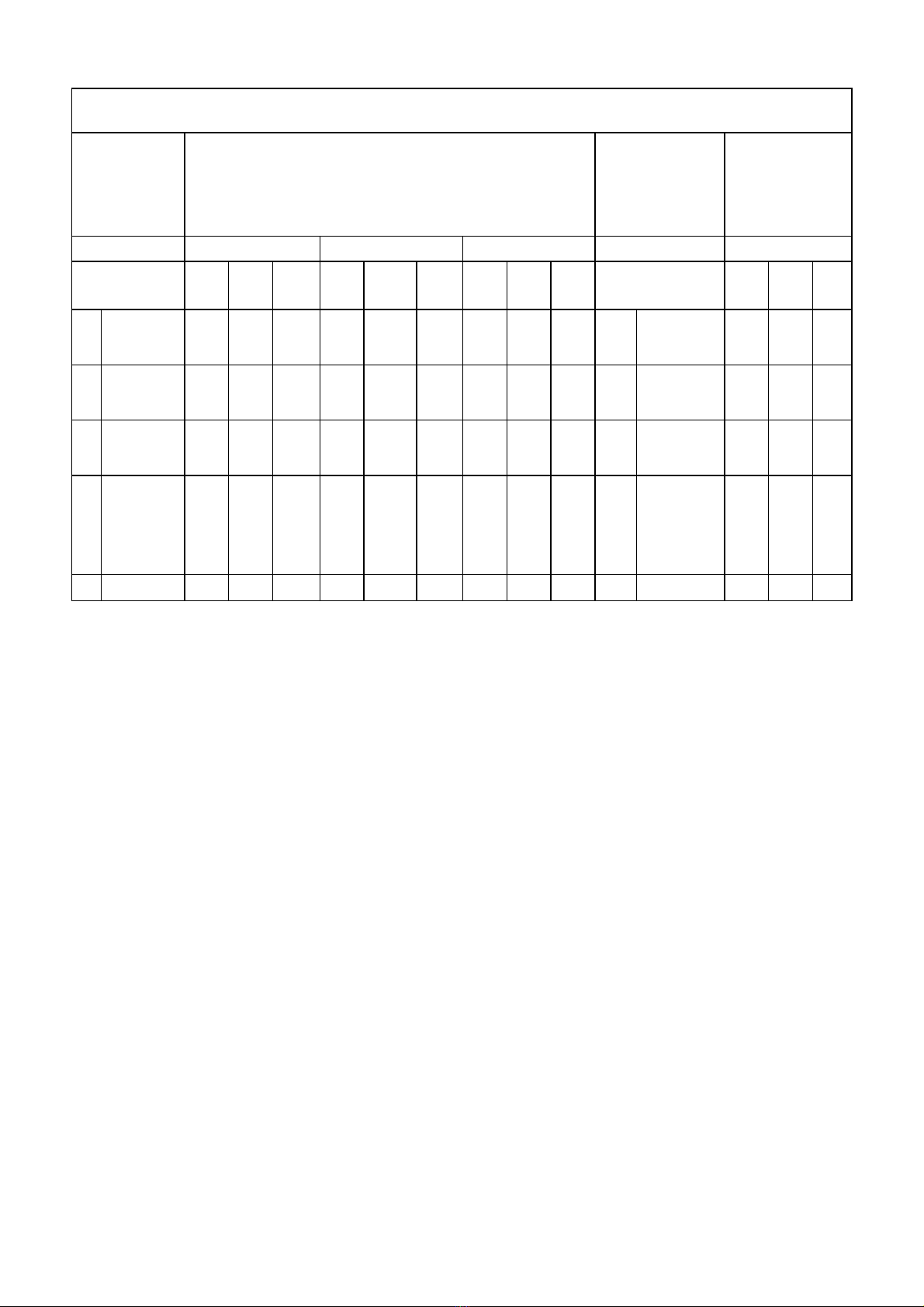

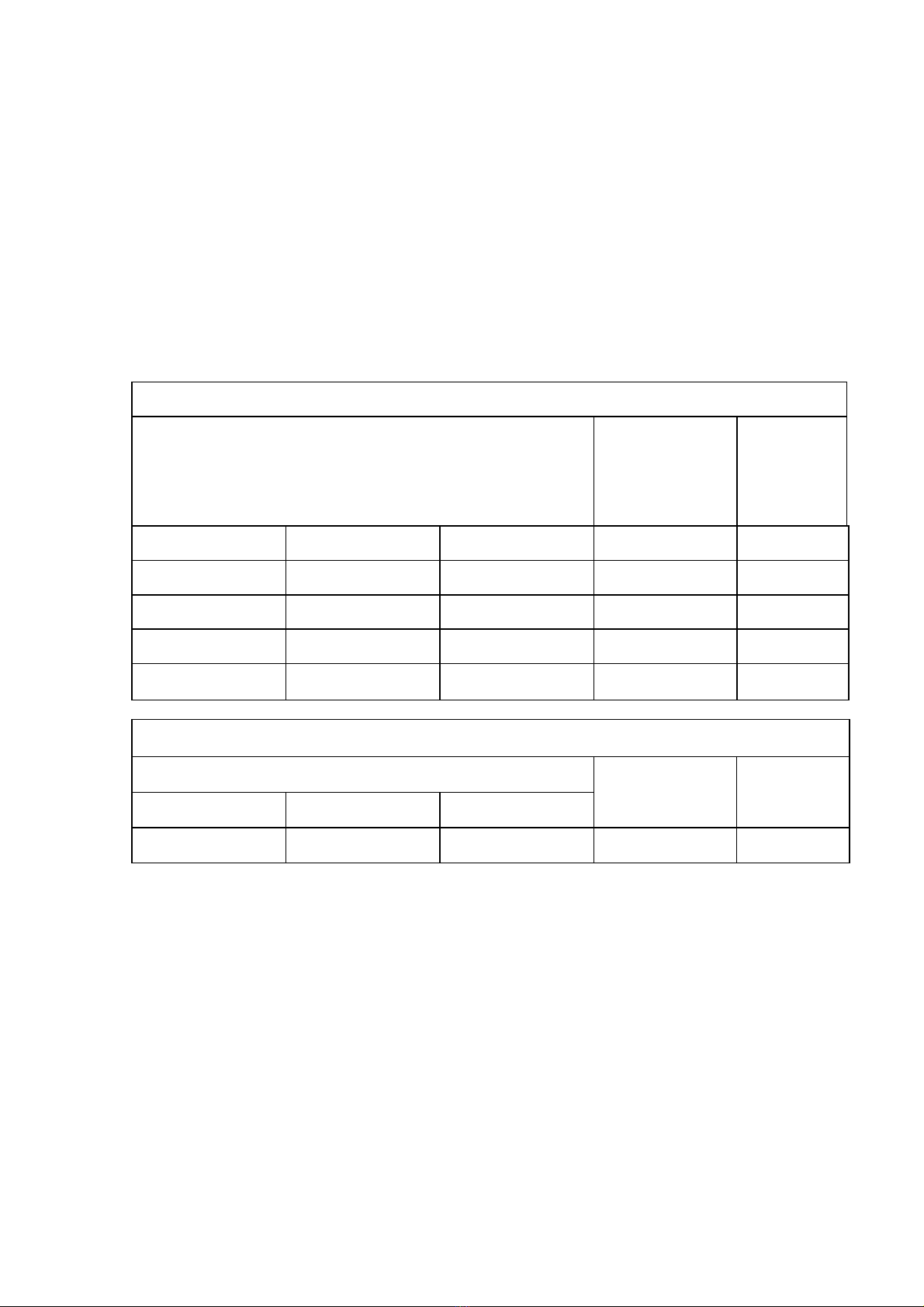

Amperage Power Supply Consumption

Number of lifting

columns:

max. 3 additional

columns

at 1 (one) primary

column;

see instruction

Supply Voltage

3 Phase

Number of lifting

columns:

max. 1 additional

columns

at 1 (one) primary

column;

see instruction

Supply Voltage

1 Phase

Total Composition 208/230 V 460 V 575 V Total Composition 208/230 V

ST1055

(Amps)

ST1060

(Amps)

ST1072

(Amps)

ST1055

(Amps)

ST1060

(Amps)

ST1072

(Amps)

ST1055

(Amps)

ST1060

(Amps)

ST1072

(Amps)

ST1055

(Amps)

ST1060

(Amps)

ST107

2

(Amps

)

2:

1 Primary +

1 Additional

column 12 14,5 16 5 6,5 7 4 5 6 2:

1 Primary +

1 Additional

column

13 15,5 17,5

3:

1 Primary +

2 Additional

columns

18 21 24 8 10 11 6 8 9

3:

2 Primary +

1 Additional

column

13 +

7

15,5

+ 7,5

17,5

+ 9

4:

1 Primary +

3 Additional

columns

24 29 32 10 13 14 8 10 12

4:

2 Primary +

2 Additional

column

2 x 13 2 x

15,5

2 x

17,5

6:

1 Primary +

3 Additional

columns

1 Primary +

1 Additional

column

24

12

29

14,5

32

16

10

5

13

6,5

14

7

8

4

10

5

12

6

6:

etc

etc.

2. DIRECTIONS

2.1 SCOPE

This manual refers to the Mobile Column Lift.

This manual contains useful and important information for proper functioning and maintenance of the lifting system. It

also contains important instructions to prevent accidents and serious damage prior to and during operation of the lifting

system, and it enables the product to perform as safely and flawlessly as possible. Read this manual carefully before

using the lifting system, familiarize yourself thoroughly with the functioning and operation of the lifting system and

strictly observe the directions given.

2.2 LIABILITY

The data published in this manual are based on the latest information available. They are subject to future modification.

We reserve the right to change the construction and/or design of our products, without being obliged to adapt earlier

supplies accordingly.

2.3 GUARANTEE

The guarantee conditions stated in our terms of delivery, which are in your possession, are applicable to this product.

The guarantee on your lifting system will become null and void if:

- service and maintenance are not carried out strictly in accordance with the instructions, repair work is not carried out by

our personnel or has been performed without our prior consent in writing;

- the lifting system has been modified without our prior consent in writing;

- non-original parts are used;

- the lifting system is used inexpertly, incorrectly, carelessly or not in accordance with its nature or intended use.

Wearing parts are not covered by the guarantee.

7

2.4 SAFETY MEASURES

The lifting system is provided with safety and protection features. Even so, caution is required when using the lifting

system.

Work safely!

Stertil B.V. have made every effort to inform you as correctly and completely as possible on any dangers associated

with operation of the lifting system. You must ensure and are responsible for compliance with these behavioural

guidelines.

The buyer/user is obliged to familiarise operating, cleaning and maintenance personnel with these instructions.

Upon their arrival, check deliveries for:

- any damage and/or missing parts due to transport. Make sure that the carrier draws up a transport damage report

on the spot.

- correctness and completeness; have all parts (additionally) and or accessories ordered been supplied?

In the event of damage always contact Stertil B.V. or the supplier.

All worn or broken parts need to be replaced with genuine lift manufacturer supplied parts.

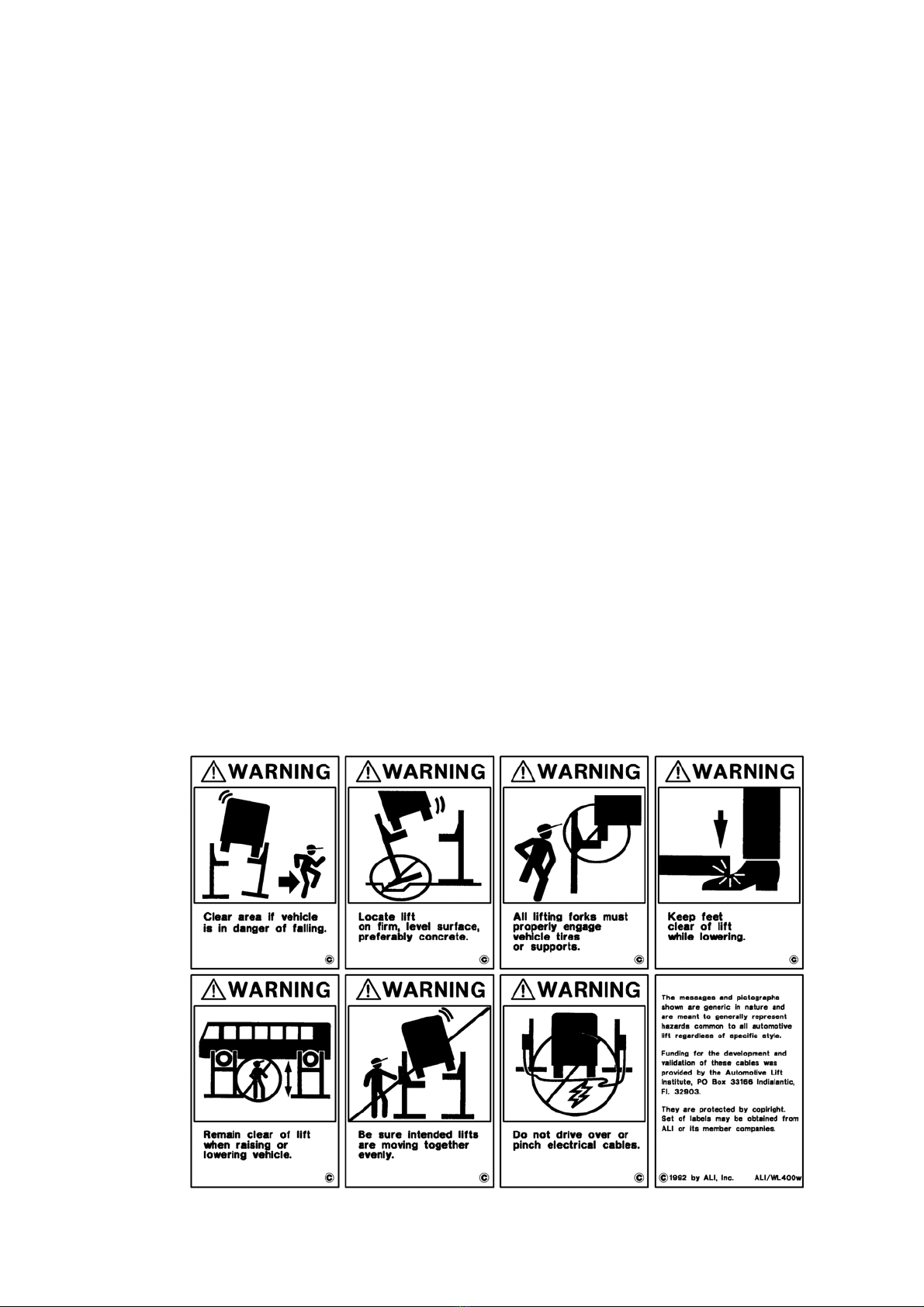

MANUFACTURERS INSTRUCTIONS TO THE LIFT OWNER/EMPLOYER

The owner/employer shall ensure that lift operators are qualified and that they are trained in the safe use and

operation of the lift using the manufacturers operating instructions; ALI/SM 93-1, ALI Lifting it Right safety

manual; ALI/ST-90, ALI Safety Tips card; ANSI/ALI ALOIM, American National Standard for Automotive Lifts-

Safety Requirements for Operation Inspection and Maintenance; ALI/WL Series, ALI Uniform Warning Label

Decals/Placards.

The owner/employer shall establish procedures to periodically inspect the lift in accordance with the lift

manufacturers instructions; ANSI/ALI ALOIM, American National Standard for Automotive Lifts-Safety

Requirements for Inspection and Maintenance; and the employer shall ensure that lift inspectors are qualified and

that they are adequately trained in the inspection of the lift.

The owner/employer shall maintain the periodic inspection and maintenance records recommended by the

manufacturer or ANSI/ALI ALOIM, American National Standard for Automotive Lifts-Safety Requirements for

Inspection and Maintenance; and the employer shall ensure that lift inspectors are qualified and that they are

adequately trained in the inspection of the lift.

The owner/employer shall display the lift manufacturers operating instructions; ALI/SM 93-1, ALI Lifting it Right

safety manual; ALI/ST-90, ALI Safety Tips card; ANSI/ALI ALOIM, American National Standard for Automotive

Lifts-Safety Requirements for Operation Inspection and Maintenance; in a conspicuous location in the lift area

convenient to the operator.

The owner/employer shall provide necessary lockout/tagout means for energy sources per ANSI Z244.1-1982

(R1993), Safety Requirements for the Lockout/Tagout of Energy Sources, before beginning any lift repairs.

The owner/employer shall not modify the lift in any manner without the prior written consent of the manufacturer.

IMPORTANT SAFETY INSTRUCTIONS

- Read all instructions.

- If an extension cord is necessary, a cord with a current rating equal to or more than the equipment must be

used. Cords rated for less current than the equipment may overheat. Care should be taken to arrange the

cord so that it will not be tripped over or pulled.

- Always unplug equipment from electrical outlet when not in use. Never use the cord to pull the plug from

the outlet. Grasp plug and pull to disconnect.

- Let equipment cool completely before putting away. Loop the cord loosely around equipment when storing.

- To reduce the risk of fire, do not operate equipment in the vicinity of open containers of flammable liquids

(gasoline).

- Adequate ventilation should be provided when working on internal combustion engines.

8

- Keep hair, loose clothing, fingers and all parts of the body away from moving parts.

- To reduce the risk of electrical shock, do not use on wet surfaces or expose to rain.

- Use only as described in this manual. Use only manufacturers recommended attachments.

- ALWAYS WEAR SAFETY GLASSES. Everyday eyeglass only have impact resistant lenses, they are not

safety glasses.

- Use by untrained people could result in serious injury and/or damage.

- Do not use the lifting system outdoors if the wind velocities mentioned in paragraph 5.5 are exceeded

- If the lifting system is used outdoors do not leave the vehicles unattended in the lifted position. The wind

speed may change and exceed the safety limits.

- Danger of getting injured by electrical shock.

- Only remove the covers to carry out maintenance, ensure that the lifting system is disconnected from the

power supply.

- Care must be taken as burns can occur from touching hot parts.

- Prevent damage to the power feed cables on account of driving over or heavy or falling objects.

- Do not drive over interconnecting cables. Always disconnect interconnecting cables and remove from

vehicle travel path before moving vehicle.

- Do not operate equipment with a damaged cord or if the equipment has been dropped or damaged until it

has been examined by a qualified serviceman.

- In case of using one or two lifting columns (in paired operation), be sure that this will not result in stability

risks. In case of doubt, consult your superior. Unsafe lifting can result in serious injury and damage to the

lifting system and/or vehicles.

- This lifting system should only be used for lifting of vehicles and not for other applications. The positioning

of the lifting system must be done in a way that a safe working area will be obtained above and around the

lifting columns, thereby creating escape paths for emergency situations (leave passageways of at least 600

mm, 24").

- If a vehicle is in the lifted position, its air suspension system may not be used in a view of possible change of

track width and/or wheel base.

- Use the lifting columns only on a hard and level floor with sufficient bearing capacity,

see 1.2 Specifications for floor pressure and floor load.

- Once desired height has been reached, it is recommended but not required that the lift be lowered into the

mechanical locks.

SAVE THESE INSTRUCTIONS

9

3. DESCRIPTION OF THE LIFTING SYSYEM

For the hydraulic system diagram see figure K.

The mobile column lift is a movable electrically driven hydraulic column lift used for lifting heavy vehicles. At

least two lifting columns are required for lifting a vehicle. The number of lifting columns required depends on the

weight of the vehicle and the number of axles.

The main components of the mobile column lift are shown below:

Usually, a set of four lifting columns are used consisting of one primary column and three secondary columns.

The power supply is connected to the primary column. The primary column and secondary columns are

interconnected so as to form a ring circuit. All power supplies and the control signals are through the

connecting cables.

The primary column can be set to function as a secondary column when more than one primary column is used.

The control system on the lifting columns ensures that the columns are raised or lowered synchronically.

Each lifting column is equipped with a position sensor which transmits the height positions to the control system.

The control system controls and protects the lifting system during lifting or lowering as follows:

- At a difference in height between the lifting columns of over 5/8" mm and less than 1 1/4"mm, an

extra adjustment valve in the hydraulic system opens and remains open until the difference has been cancelled out.

Fig. 3.1

ST 1072

Each lifting column has a lifting

capacity of 16,000 lbs.

Consequently, four columns

have a total lifting capacity o

f

64,000 lbs. The total lifting

capacity can be increased by

adding lifting columns.

ST 1055

Each lifting column has a lifting

capacity of 10,000 lbs.

Consequently, four columns

have a total lifting capacity o

f

40,000 l

b

s. The total lifting

capacity can be increased by

adding lifting columns.

ST 1060

Each lifting column has a lifting

capacity of 12,000 lbs.

Consequently, four columns

have a total lifting capacity o

f

48,000 lbs. The total lifting

capacity can be increased by

adding lifting columns.

10

- At a difference in height of over 1 1/4" and less than 2 3/8", lowering is interrupted. A lifting

fork may be blocked; the cause of the failure must then be traced first. Lifting is still possible, the adjustment

valve in the hydraulic system will open and remain open until the difference has been cancelled out.

- At a difference in height of over 2 3/8" mm, the control voltage is switched off, thus blocking all

movements. The cause of the failure can then be traced.

In addition, the control system has been designed so that:

- Each lifting column can be operated separately

- Any pair of axles can be handled separately

Also see section 6, Operation

3.1 STRUCTURE OF THE COLUMN LIFT

Each lifting column consists of (see figure 3.1):

- a column and a lifting cylinder

- a hydraulic unit

- a control box

- a pallet jack lifting mechanism

- a mechanical safety lock

• Hydraulic unit

The hydraulic system consists of an electrically driven pump, flow control valves, control valves and a liquid

reservoir.

• Column and lifting cylinder

The column and lifting cylinder form the major part of the mobile column lift. In the U-section of the column

are a guide block and rollers. The rollers enable the guide block to move along the full length of the column.

The hydraulic lifting cylinder provides the lifting capacity.

• Control box

The control box has all the functions controlling the use of the lifting column. The control box of the primary

column is provided with a three-position switch allowing the lifting column to be used as a secondary column if

necessary.

The control box components and functions have been specified in sections 5 and 6.

• Pallet jack mechanism

The two-wheel pallet jack mechanism serves to move the lifting column. The two wheels protect the lifting

column from being turned over at the back when it is moved. The pallet jack mechanism lifts the back of the

column off the ground so that the column can be easily moved.

The pallet jack mechanism is operated by means of the handle bar and the handle inside the bar.

The handle can be set in three positions:

1. When the handle is set in the upper position, the pallet jack mechanism is lowered.

2. The middle setting is the neutral position; the column can be moved without the system being lifted or lowered.

3. When the handle is in the lower position, the pallet jack mechanism can be raised by moving the handle up and

down.

• Mechanical safety lock

If the hydraulic pressure fails while a vehicle is on the lifting system or is lifted or lowered,

a mechanical safety lock ensures that it cannot drop.

The characteristic clicking of the safety lock indicates that it has been activated.

During lowering the pawl is retracted by a solenoid.

11

4. INSTALLATION

Remark: Only move the lifting column with the correct type of lifting equipment.

Only raise the lifting column at the correct points. Damage to lifting column and/or injury to

persons may occur if the lifting column is not moved in the correct manner.

4.1 UNPACKING AND HANDLING THE LIFTING COLUMN

1. Transport the lifting column to the place of use.

2. Remove the cover from the crate or, when using a stand, remove the straps.

Remark: Do not stand under the lifting column when it is suspended from the lifting equipment. If it falls it

will cause serious injury.

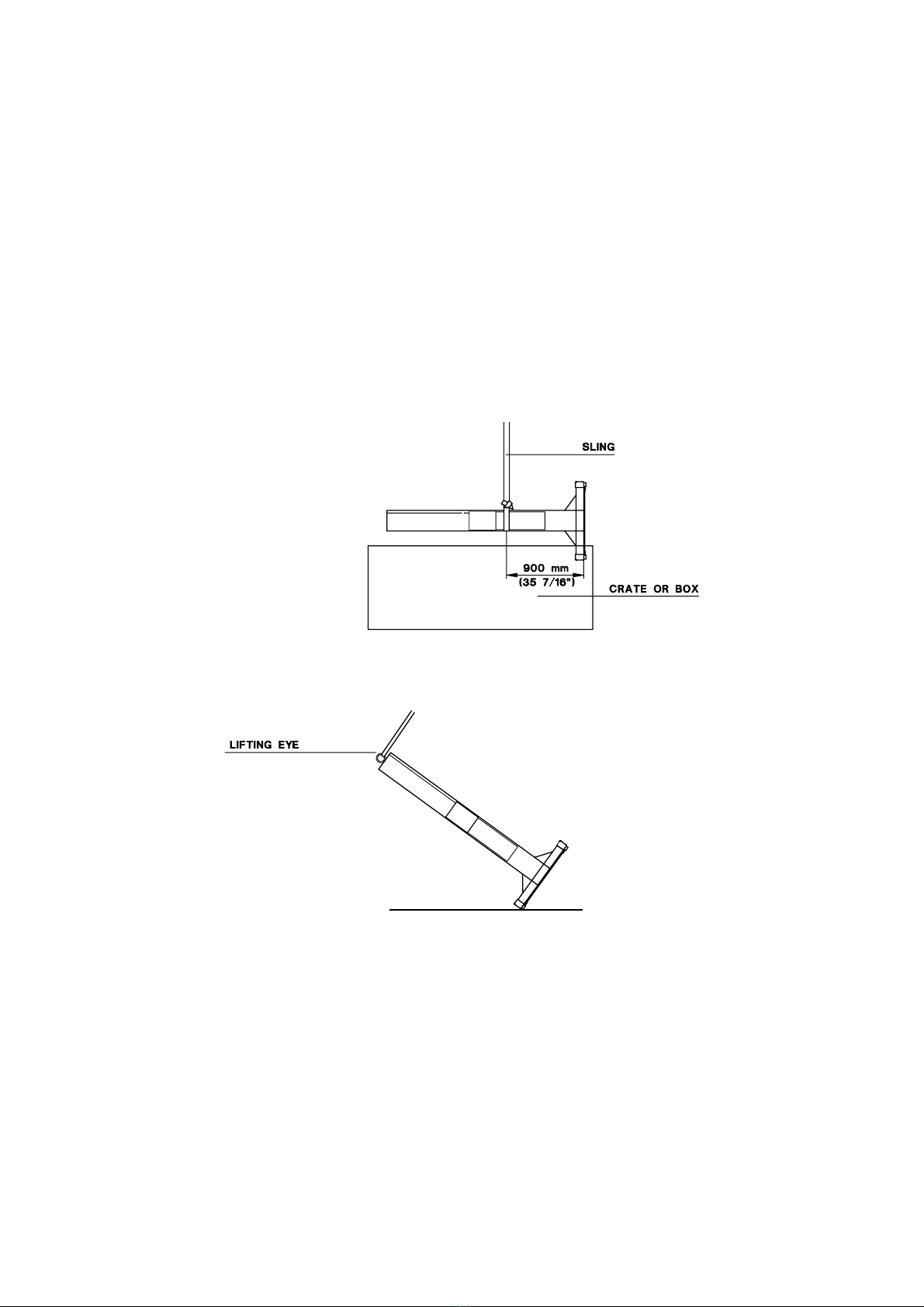

3. Fasten a sling with a hoisting capacity of at least 480 kg (1065 lbs) around the lifting column and lift the

column from the crate (see fig. 4.1).

Fig 4.1

4. Carefully lower the lifting column to the floor.

5. Attach a hook to the lifting lug at the top of the column.

6. Lift the column to the upright position.

7. Remove the hook from the lifting lug.

8. Remove the cover from the hydraulic unit

Remove the plug from the fill opening and install the breather cap. Install the cover on the hydraulic unit.

9. Check for oil leakage.

10. Repeat the procedure for each column.

12

5. GENERAL USE

5.1 CONTROL

All functions of the lifting system are controlled from the controlpanel on the column.

There are two types of controlpanels:

- Primary column controlpanel.

- Secondary column controlpanel.

These two control boxes are pracically identical. Only the control box of a secondary column is not provided with a main

switch and a mains feed cable.

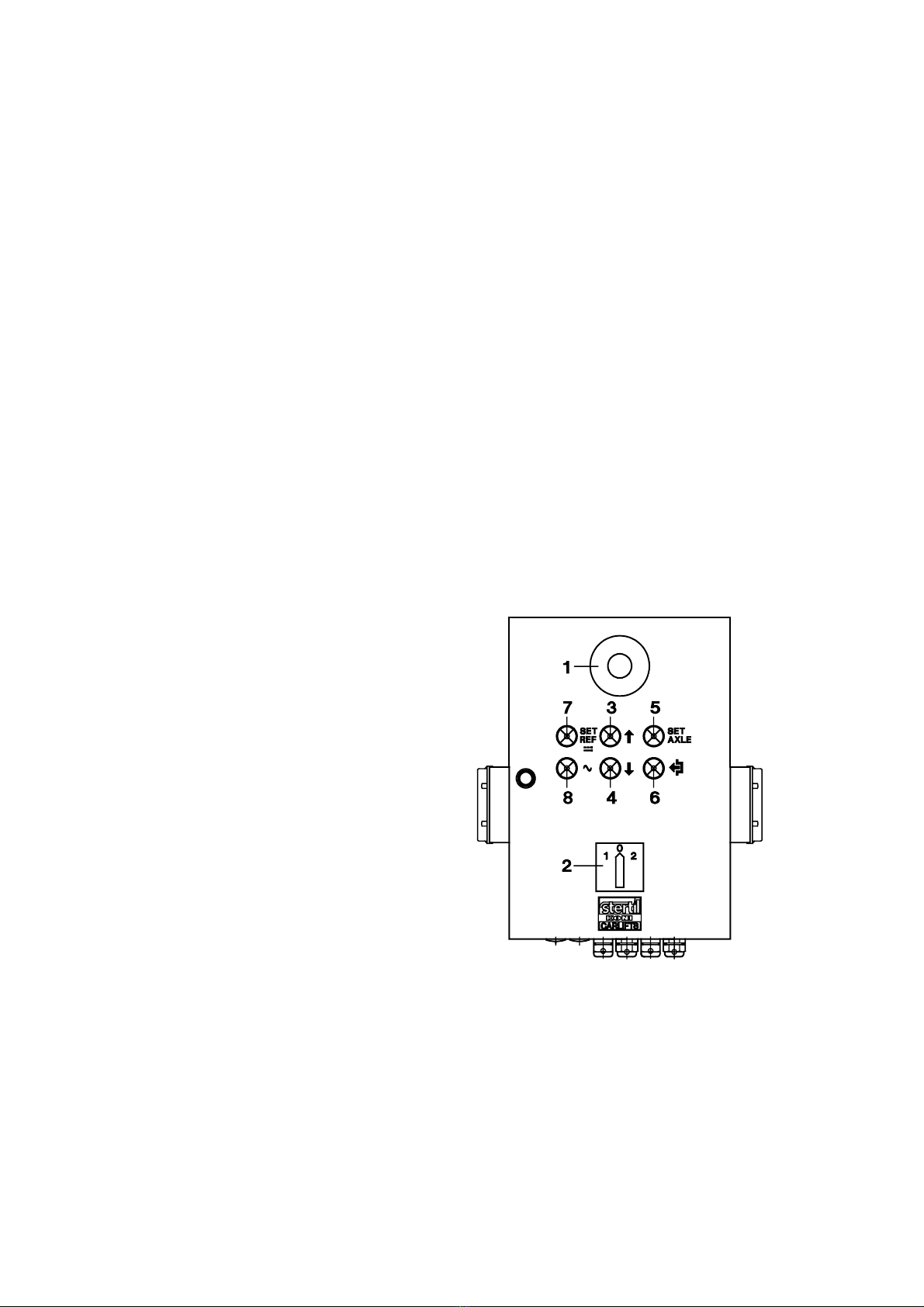

The functions of the switches on the primary control panel are described below (see Fig. 5.1).

1. Emergency release knob; Pressing this all movements (lifting or lowering) are immediately stopped.

2. Main switch; Controls the power to the lifting columns. The switch has three positions:

0 (OFF); removes electrical power from the lifting column(s)

1 (ON); switches on power to the lifting column(s);

2 (SECONDARY COLUMN); allows the primary column to be used as a secondary column, if the mobile column lift

has more than one primary column.

3. ×(UP) button; Controls the lifting of the columns.

4. Ø(DOWN) button; Controls the lowering of the columns.

5. “SET AXLE” button. This button serves to select the axle functions. These functions are descibed in paragraph 5.3.6.

6. Unlock button. This button controls, in combination with the lowering button, the lowering of the columns.

7. “SET REF” button. This button has several functions. These are descibed in paragraph 5.3.5.

8. Mains voltage indication light. This will go on when the internal control voltage relay is switched on.

Remark: The main switch is not fitted to the secondary column control box.

1. Emergency release knob

2. Main switch

3. Lifting ×

4. Lowering Ø

5. “SET AXLE”-button

6. Unlock button

7. “SET REF”-button/control voltage

indication.

8. Control power indicator light.

Fig. 5.1, Control box

13

5.2 CONNECTING LIFTING COLUMNS

A fully closed ring circuit consists of a minimum of two and a maximum of 32 lifting columns (single phase a min.

of 2 and a max. of 4 lifting columns).

A column circuit requires at least 1 (one) primary column. The position of a primary column in a circuit is

irrelevant, but preferably should be located near the power supply. If in a column circuit there is one primary

column, this circuit is called a "set".

A set can consist of 2, 3, 4, 5 or 6 etc. up to 32 lifting columns (single phase 2, 3 or max. 4 lifting columns).

A set has a maximum lifting capacity of 40,000/48,000/64,000 lbs (this is the maximum lifting capacity of a standard

set of 4 lifting columns of 10,000/12,000/16,000 lbs each). For higher lifting capacities, "sets" are to be combined in

a column circuit as specified in the table below (also see fig. 5.2).

3 Phase

Lifting capacity in lbs

Minimum

number of

primary

columns

Maximum

number of

secondary

columns

up to 40,000 up to 48,000 up to 64,000 1 5

40,000 to 80,000 48,000 to 96,000 64,000 to 128,000 2 (2 sets required) 10

80,000 to 120,000 96,000 to 144,000 128,000 to 192,000 3 (3 sets required) 15

120,000 to 160,000 144,000 to 192,000 192,000 to 256,000 4 (4 sets required) 20

etc. etc. etc.

etc.

etc.

1 Phase

Lifting capacity in lbs

ST 1055 ST 1060 ST 1072

Minimum number

of primary

columns

Maximum

number of

secondary

co

l

u

mn

s

up to 40,000 lbs up to 48,000 lbs up to 64,000 lbs 2 2

Primary columns are arranged in a circuit so that the weight of the load of the "set" (primary column followed by the

secondary columns up to the next primary column) does not exceed 40,000/48,000/64,000 lbs. To increase the

flexibility of a system, it is possible to select a primary column as a secondary column.

To ensure safety, each primary column is provided with a thermal relay preventing a set from being overloaded and

protecting the lifting system against power overloads.

14

5.3 DESCRIPTION OF THE MOBILE COLUMN LIFT SYSTEM

The mobile column lifts are designed in such a way as to offer maximum flexibility and convenience.

A lifting system can consist of a minimum of 2 and a maximum of 32 lifting columns.

The control system is equipped with the following features:

- simultaneous operation of all lifting columns

- operation of one pair of lifting columns (per vehicle axle): the so-called paired operation

- operation of one lifting column

Each lifting column is provided with these control functions without selector switches having to be set.

The control system of the mobile column lift is set-up as follows:

1. Connect the lifting columns in a full circuit as indicated in 5.2, Connecting Lifting Columns.

- The column sequence in this circuit can be selected at random; primary columns or secondary columns can be

positioned at any place, provided the maximum lifting capacity of 40,000/64,000 is not exceeded as described

in 5.2.

- A system must have at least one primary column (single phase must have at least 2 primary columns).

- The maximum number of lifting columns in a system is 32 (single phase a max. of 4 columns).

2. With respect to all primary columns:

- Eensure that the main switch is in the O (OFF) position, then connect the feed cable to the right mains

connection.

- Set the main switch to 1 (ON).

If the circuit consists of more than one primary column, ensure that all other main switches have been

set to 1(ON) or 2 (SECONDARY COLUMN).

- If the switch of another primary column has been set to 1, this column also has to be connected to the mains.

- When the column has been set to 2, it will function as a secondary column and does not need to be connected

to the mains.

Fig. 5.2, Connecting lifting columns

15

3. Take care that the emergency stop button of each lifting column has been released.

4. Press the "SET REF" button.

The light in button 8 (feed) will come on indicating that:

- the system control has been checked for its proper functioning

- the sequence of all lifting columns has been stored in the system memory

- the primary column in the system has been connected to the mains.

5. Press the "SET REF" button again.

The light in this button will come on indicating that:

- the height position of each lifting column has been stored in the system.

- the lifting columns can now be activated.

All functions are possible now except paired operation.

6. Setting paired operation (only possible with an even number of lifting columns):

- Select the primary columns at one axle to set this function (e.g. the front wheel axle).

- Press the "SET AXLE" button on one of the lifting columns belonging to the selected axle for approx. 3

seconds.

- The "SET AXLE" button will flash indicating that the setting procedure has been selected.

- Within 30 seconds press the "SET AXLE" button of the control panel of the lifting column on the other side

of the axle and also keep it pressed for 3 seconds.

The "SET AXLE" buttons of all lifting columns will go on indicating that paired operation has been set.

When setting paired operation, the other pairs of axles in the control system are automatically selected as pairs.

This only works satisfactorily if all lifting columns have been connected in a closed circuit as described in 5.2.

All system functions are now available by pressing:

- button 3 ⇑, all columns are raised;

- button 4 ⇓, lowered and locked;

- buttons 6 and 4 ⇓, all columns are lowered;

- buttons 5 (SET AXLE) and 3 ⇑, one axle is raised (2 lifting columns);

- buttons 5 (SET AXLE) and 4 ⇓, one axle is lowered (2 lifting columns);

- buttons 7 (SET REF) and 3 ⇑, one column is raised;

- buttons 7 (SET REF) and 4 ⇓, one column is lowered.

This manual suits for next models

2

Table of contents

Popular Lifting Column manuals by other brands

Linak

Linak TECHLINE ELEVATE - LC3 IC user manual

progressive automations

progressive automations FLT-03-2-1 user manual

RK Rose+Krieger

RK Rose+Krieger Multilift I Assembly instructions

Phoenix Mecano

Phoenix Mecano RK Rose+Krieger Multilift II Assembly instructions

MSH equipment

MSH equipment EASY LIFT 3000 manual