INDEX

1. INTRODUCTION ........................................................................................................ 2

2. INSTALLATION INSTRUCTIONS .............................................................................. 3

2.1 EMC Requirements .................................................................................................. 3

2.2 Unit Mounting ........................................................................................................... 3

2.3 Connections General ................................................................................................ 4

2.4 Internal Controls ....................................................................................................... 5

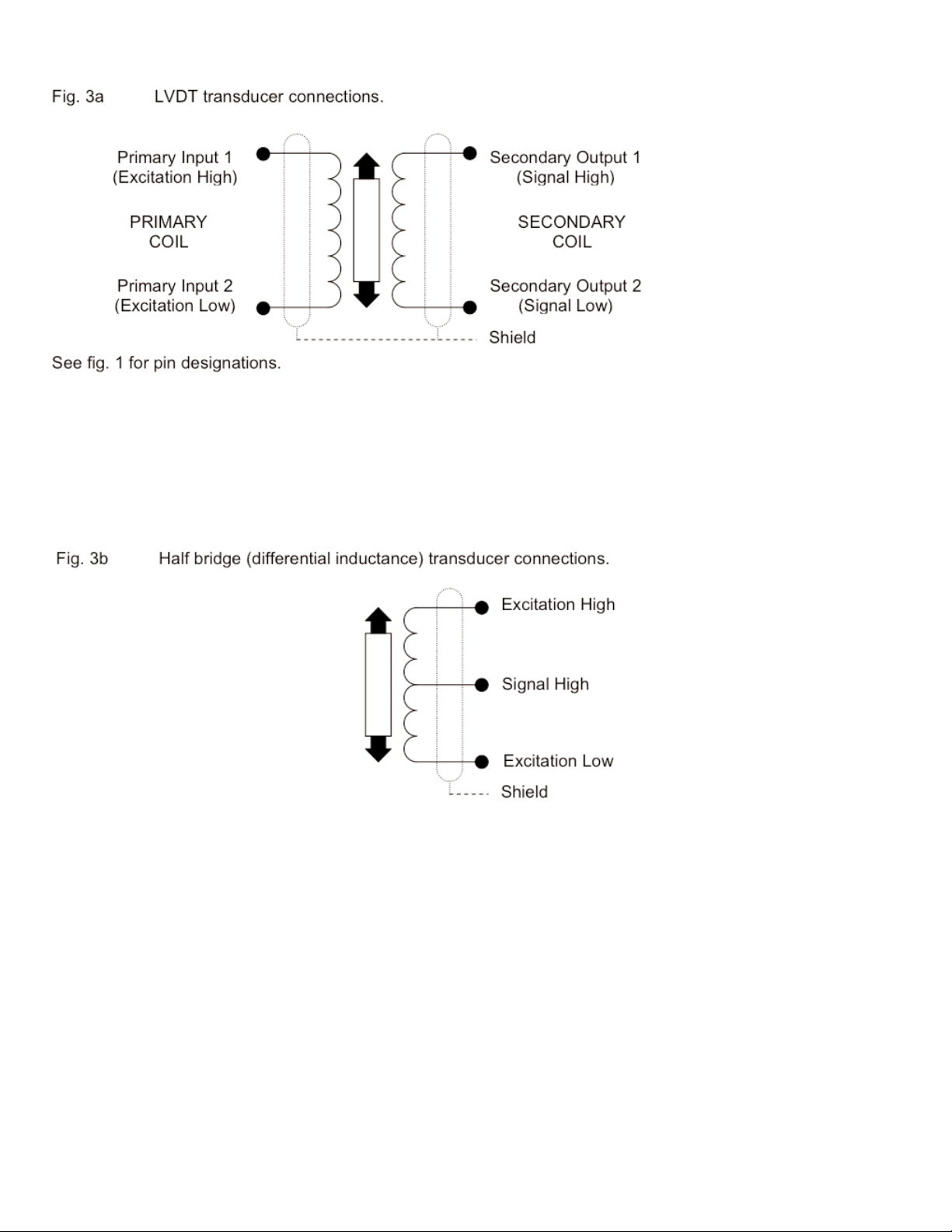

2.5 Transducer connections (LVDT and half bridge) ...................................................... 6

3. CONTROLS ................................................................................................................ 6

3.1 Voltage/Current Output ............................................................................................. 6

3.2 Coarse Gain Selection ............................................................................................. 6

3.3 Fine Gain (On front panel, labelled GAIN) ............................................................... 6

3.4 Coarse Zero ............................................................................................................. 6

3.5 Zero Input .................................................................................................................7

3.6 Fine Zero (On front panel, labelled ZERO) .............................................................. 7

3.7 Over-Range Indicator ............................................................................................... 7

3.8 Excitation Voltage ..................................................................................................... 7

3.9 Excitation Frequency ................................................................................................ 7

3.10 Master/Slave ........................................................................................................... 7

4.0 SETTING UP PROCEDURES ................................................................................. 8

4.1 LVDT & Half Bridge (Differential Inductance) Transducers ...................................... 8

5. SPECIFICATION ........................................................................................................ 9

6. WARRANTY ...............................................................................................................10

1. INTRODUCTION

The AP5102 is a single channel signal-conditioning unit for use with transducers requiring

AC excitation and synchronous demodulation, producing a DC output voltage or current.

The AP5102 incorporates a DC-DC converter ensuring that the output of the unit is

electrically isolated from the supply.

Units may be master-slaved in systems where carrier frequency beating is a problem.

The unit is housed in a DIN-rail mounting thermoplastic case with recessed screw-clamp

terminals for all connections and 25-turn front-panel-accessible span and zero

adjustments.

All other controls are internal including coarse gain and zero switches, a zero input switch

and jumper links for master/slave setting and excitation frequency setting.

The unit is suitable for use with the complete range of STI LVDT transducers.

2