Important Safety Precautions

for Chain Saw Users

A. Kickback Safety Precautions

Warning!

Kickbackmay occurwhen the nose ortip ofthe guide

bar touches an object, orwhen thewood closes in and

pinches the saw chain in the cut. Tip contact in some

cases may cause a lightning fast reverse reaction,

kicking the guide bar up and back towards the

operator. Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back to-

wards the operator. Either of these reactions may

cause you to lose control of the saw which could re-

sult in serious personal injury.

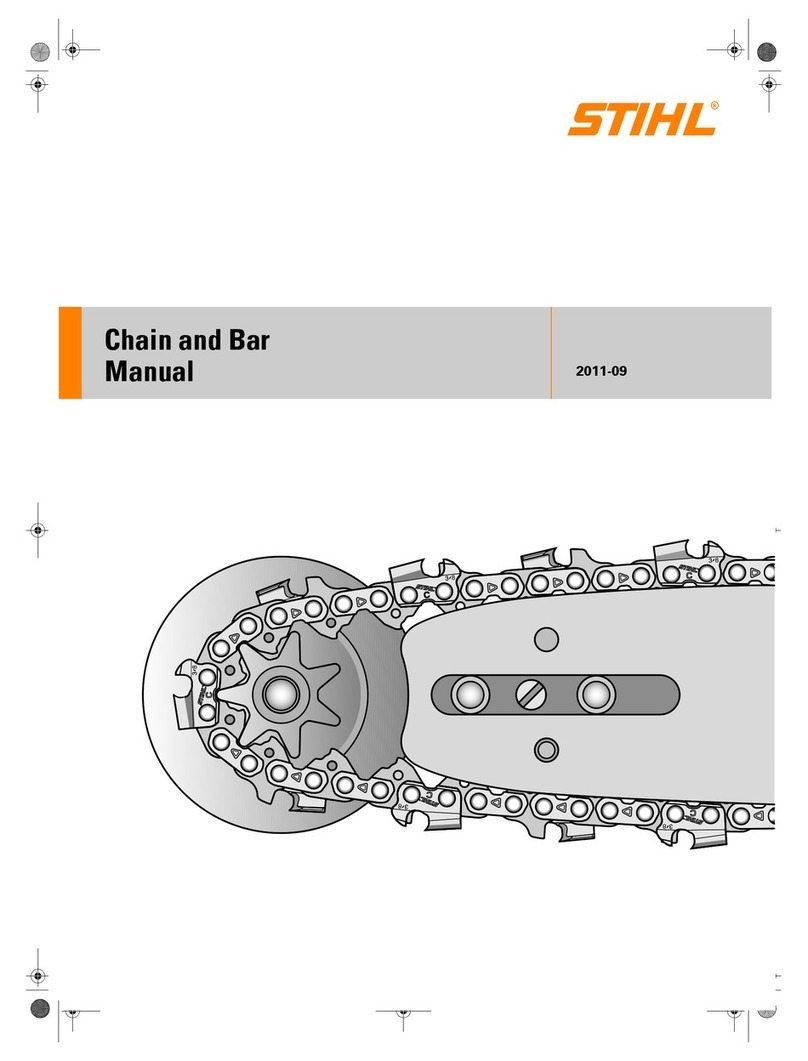

Section 4.12 of ANSI B 175.1-1985 sets certain perfor-

mance and design criteria related to chain saw kick-

back. STIHL has developed a color code system using

green and yellow to help you select a powerhead, bar

and chain combination thatcomplies with the kickback

requirements ofthe ANSI Standard. See the sections

entitled "Safety Precautions" and "Specifications" of

this Manual.

Do not rely exclusively upon the safety devices built

into your saw. As a chain saw user, you should take

several steps to keep your cutting jobs free from acci-

dentor injury.

1. With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sud-

den surprise contributes to accidents.

Keep a good firm grip on the saw with both hands,

the right hand on the rear handle, and the left hand

on the front handle, when the engine is running.

Use a firm grip with thumbs and fingers encircling

the chain saw handles. A firm grip will help you re-

duce kickback and maintain control of the saw.

Don't let go.

Make sure that area in which you are cutting is free

from obstructions. Do not let the nose of the guide

bar contact a log, branch, or any other obstruction

which could be hit while you are operating the saw.

Cut at high engine speeds.

Do not overreach or cut above shoulder height.

Follow manufacturer's sharpening and mainten-

ance instructions for the saw chain.

Only use replacement bars and chains specified

by the manufacturer or the equivalent.

B. Other Safety Precautions

Do not operate a chain saw when you are fatigued.

Use safety footwear; snug-fitting clothing; protec-

tive gloves; and eye, hearing, and head protection

devices.

Use caution when handling fuel. Move the chain

saw at least 10 feet (3 m) from the fueling point

before starting the engine.

continued on the back inside cover