STIHL TS 400 2

1. INTRODUCTION

This Repair Manual contains a

detailed description of all the typical

repair work required for this series of

cut-off machines. Repairs to be

undertaken on standard parts and

assemblies which are used in several

STIHL power tool series are described

in separate repair manuals. Attention

is drawn to these instructions at the

relevant points in this Manual.

The illustrated spare parts lists should

also be consulted when carrying out

repairs, for they show the installed

position and sequence of assembly

for the individual parts.

The latest edition of the respective

parts lists should always be used

when determining the part numbers of

the required replacement parts.

Microfilms are more up-to-date than

printed replacement parts lists!

Faults in the cut-off machine may be

due to several causes. Note the

"Summary of faults" in the manual

"Troubleshooting, standard repairs"

for all function groups.

Note the "Technical Information"

sheets, for they describe technical

changes implemented after publication

of this Repair Manual. The Technical

Information sheets supplement the

replacement parts list until a new

edition is published.

The special tools mentioned in the text

are listed in the last chapter of this

Manual. The tools can also be

identified in the manual of "STIHL

tools" on the basis of this part number.

The manual lists all tools available

from STIHL.

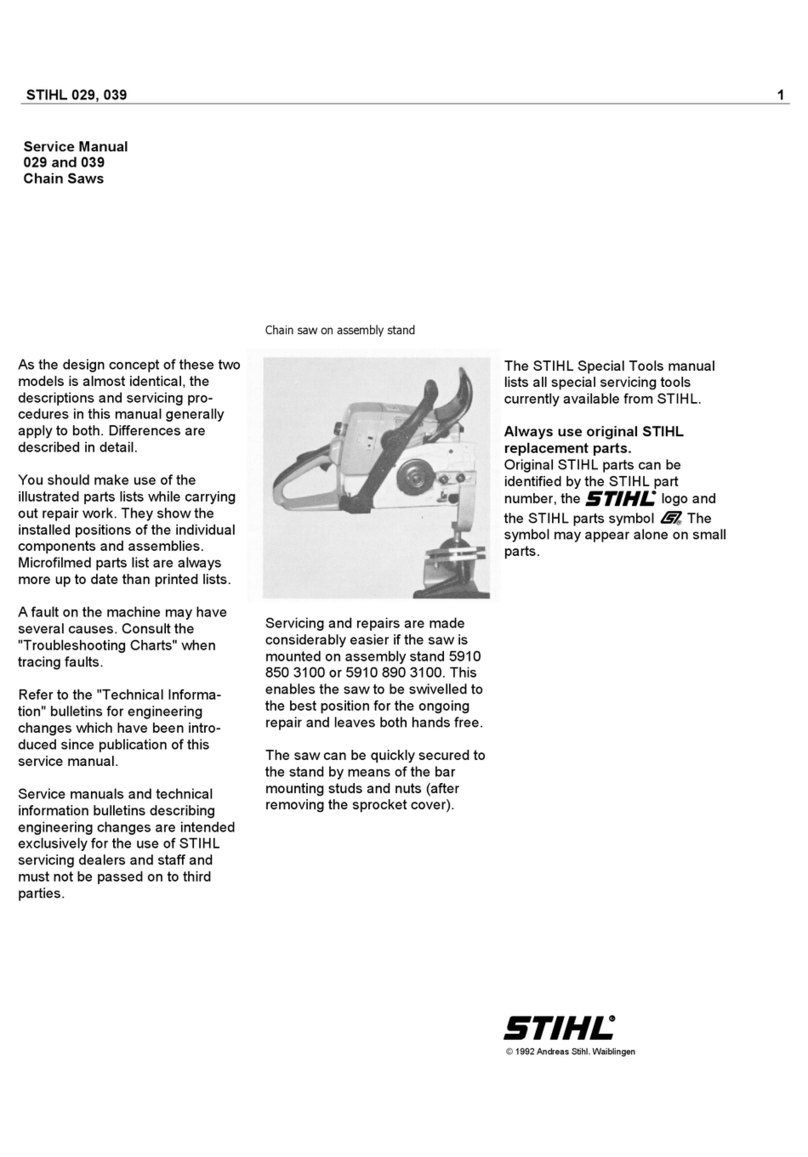

Repairs can be carried out more easily

by mounting the cut-off machine on an

assembly stand (1). It is attached to

the cast arm with two hex bolts (2)

M8x25 after removing the bearing with

guard.

The cut-off machine can then be

swivelled into the most suitable

working position, leaving both

hands free for the work itself.

Repair Manuals and Technical

Information sheets should always be

on hand wherever repairs are carried

out. They must not be passed on to

third parties.

The following graphic symbols are

used in the text and illustrations in

order to make this Manual easier to

use and understand:

In the text:

• = Activity to be carried out;

corresponds to the activity in the

picture above the text.

- = Activity to be carried out, but is not

shown in the picture above the text.

In the illustrations:

= Arrow indicating: Note

= Arrow indicating: Go to

Always use original STIHL

replacement parts. Original STIHL

parts can be identified by the STIHL

part number, the

STIHl

logo

and the STIHL parts symbol (.

The symbol may appear alone on

small parts.