2.

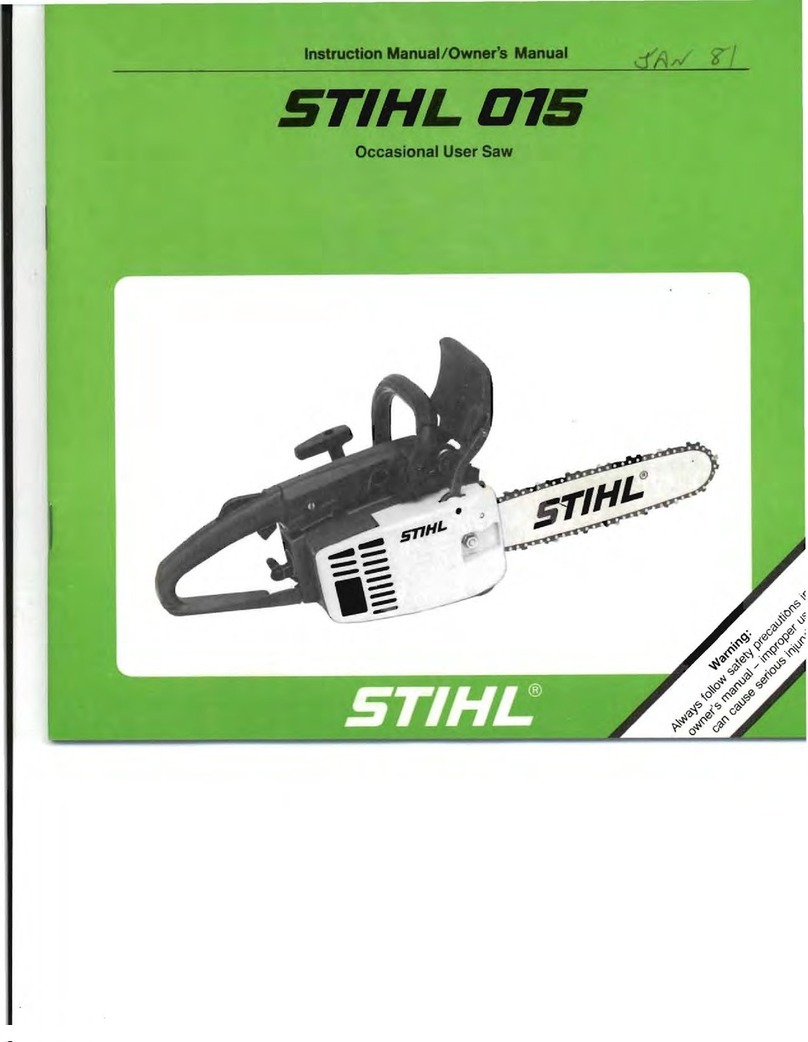

CLUTCH,

CHAIN DRIVE AND

CHAIN BRAKE

2

..

1 Construction and

Operation

2

..

1

..

1 Clutch and Chain Sprocket

The transmission of

power

from the

engine to the

saw

chain is effected

via a centrifugal clutch

..

O~

"Quick-

stop"

models, the centrifugal clutch

incorporates an isolating clutch

which

isactuated

bythechainbrake.

On the Quickstop version the hub

screwed to the crankshaft is the

clutch element which absorbs the

torque and acceleration of the

crankshaft.. It is essential that the

hub is always tightened down to the

specified torque

..

The clutch

spider

is supported on the hub

by

a needle

sleeve and located axially with a

circlip

..

The driving plate is located

on

thethree

lugs ofthe clutch

spider

and can move axially while remai-

ning in

constant

mesh with the

spider

..

The flat spring between the

spider and driving plate pressesthe

driving plate against the release

plate; this means

that

the internal

teeth ofthe driving plate are always

in mesh with the teeth of the hub

when the chain brake is released,

and thus provides positive

trans-

mission of engine torque to the

clutch

spider

..

When thechain brake

is actuated, the release plate

dis-

engages the driving plate from the

hUb

..

The clutch

spider

and hub can

then rotate independently.

On the standard version the clutch

spider assumes the function of the

hub and must therefore always be

tightened to the specified torque

..

Chain

brake

engaged

The centrifugal clutch has three

clutch shoes

without

linings

..

The

clutch drum and chain sprocket are

separate components. The

spur

gear

which drives the oil pump is a

ring-gear,

positively

mountedto the

hub of the clutch drum

..

The chain

sprockethastwointegrallycastlugs

which engage in corresponding re-

cesses on the drum hub

..

As the lugs

have odd sizes, the chain sprocket

can only be fitted in one position

..

When the engine is running at idle

speed the clutch shoes are also in

the idle position, because the

ten-

sion of the clutch spring is

greater

thanthecentrifugalforce

..

Asengine

speed increases, centrifugal force

presses the clutch shoes outwards

against the clutch drum and thus

transmit engine torque

positively

via

the chain

sprocket

to the saw

chain

..

The preload and strength of the

clutch spring are designed so

that

7

Chain

brake

released

the clutch shoes begin to make

con-

tact with the clutch drum at an en-

gine speed of approx

..

3100 rpm

(engagement speed)

..

The clutch

engagesfullyabovethisspeed

..

The

correct idle setting on the

carbure-

tor

is therefore essential in

order

to

insure that the clutch engagement

speed is not reached when

the

en-

gine is idling

..