GS 461

English

5

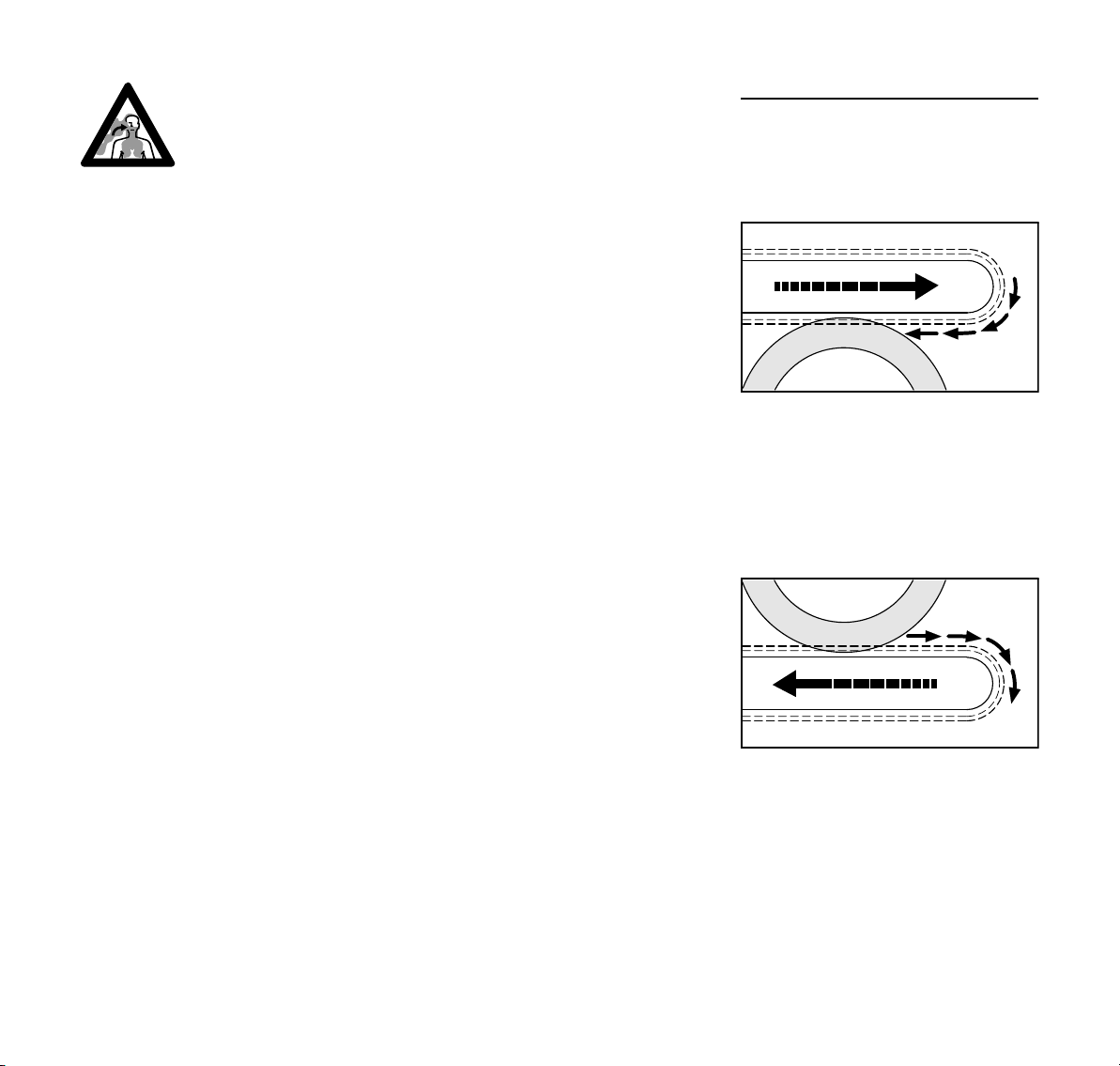

–The diamond abrasive chain must

be suitable for the material to be cut.

It must be in good condition and

fitted correctly (direction of running).

–Correctly tensioned diamond

abrasive chain

–Both the accelerator lever and its

locking to move smoothly – the

accelerator lever has automatically

to return to its idle run position.

–Master control lever can be moved

to STOP or 0

–Check that the spark plug boot is

secure. A loose boot can lead to

flying sparks which may ignite the

escaping fuel/air mixture – risk of

fire!

–Never attempt to modify the controls

or safety devices in any way

–Keep the handles dry and clean,

free from oil and dirt – important for

safe control of the concrete cutter

The concrete cutter should only be used

if it is in full working order – risk of

accident!

Starting the engine

Move at least 3meters away from the

place at which the machine was refueled

and never start the machine in enclosed

spaces.

The machine may only be used on level

ground. Ensure a firm and secure

footing and hold the machine firmly. The

diamond abrasive chain must not touch

any objects or the ground and must not

be in the cut, because it may begin to

rotate when the machine is started.

The engine-driven device is operated by

a single person only – do not allow any

person to stay within the working area –

nor with starting.

Do not drop-start the engine – start as

described in the Instruction Manual.

Before starting, open the shut-off valve

completely and ensure a supply of water

to the diamond abrasive chain – do not

allow diamond abrasive chain to run dry.

Holding and controlling the machine

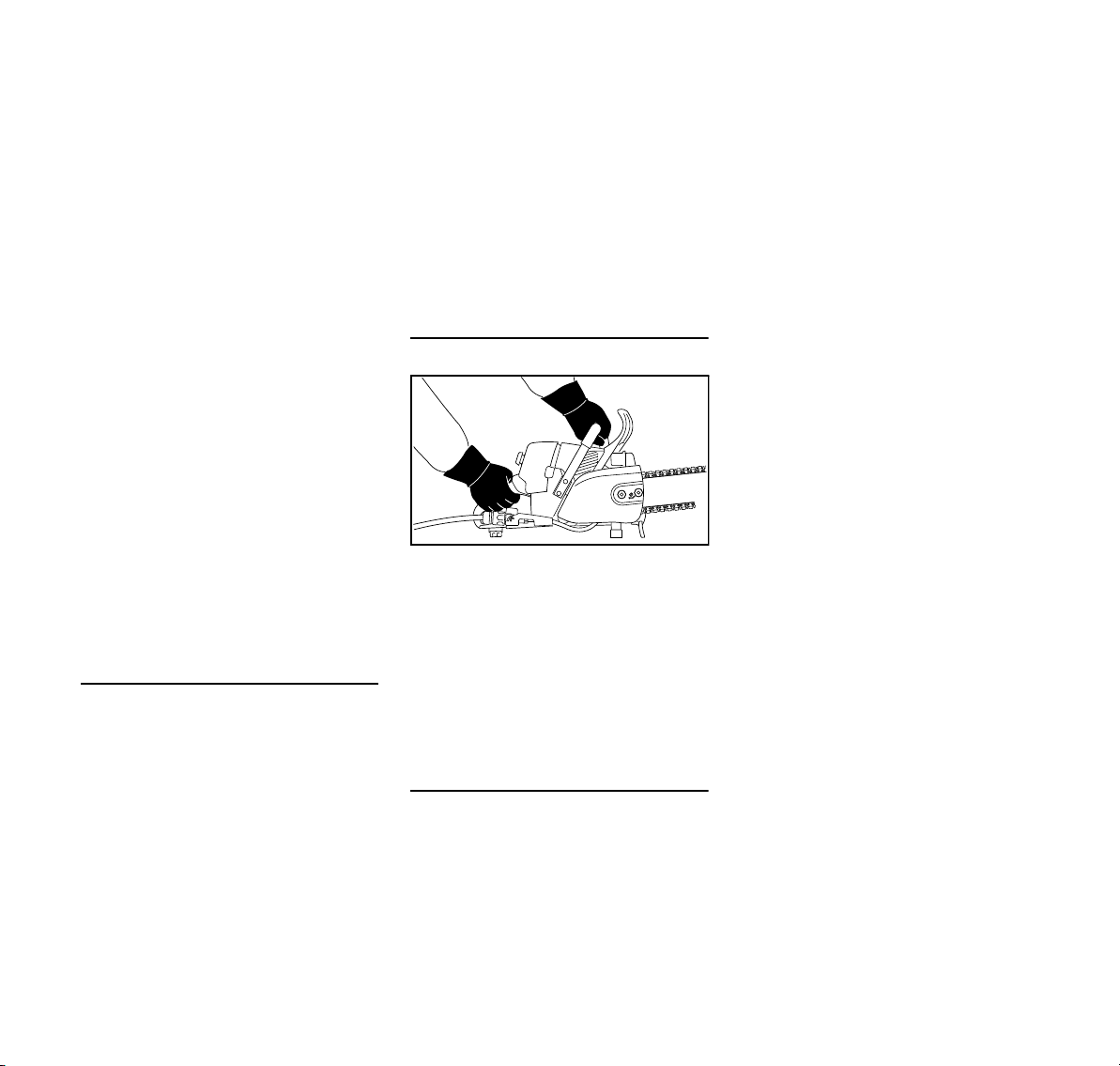

Always hold the machine firmly with both

hands: Right hand on the rear handle –

even if you are left-handed. To ensure

reliable control, wrap your thumbs tightly

around the handlebar and handle.

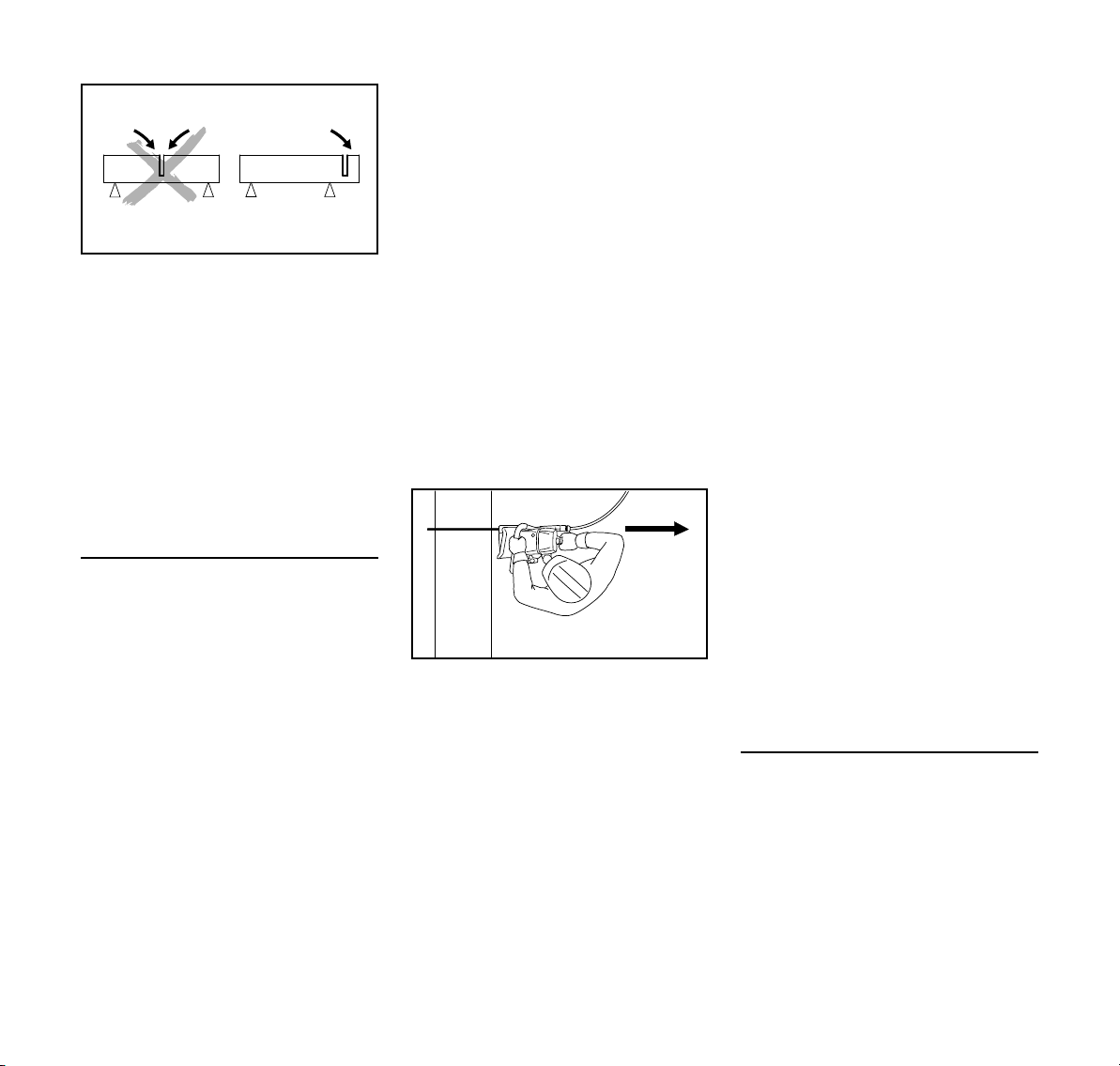

The object to be parted-off has to be

firmly supported. Always guide the

device towards the workpiece – never in

reverse.

During operation

Ensure you always have a firm and safe

footing.

In the event of impending danger or in

an emergency, switch off the engine

immediately by moving the master

control lever to STOPor0.

The machine is operated by only one

person. There should not be any other

person within the working area.

Use extreme caution with openings,

recesses, etc., someone could be

standing behind them – look

beforehand.

Never let the machine run unattended.

When the engine is running: The

diamond abrasive chain continues to run

for some time after the throttle trigger

has been released – Risk of injury due to

coasting effect!

Beware of slipping on ice, water, snow

or uneven ground!

Don not work while standing on a ladder

– not at unstable places – not over your

shoulder height – not with one hand only

– risk of accident!

Keep clear the working area – bear in

mind obstacles, holes and pitches.

Never work alone – stay always in

earshot to other persons, who can

render first aid in case of emergency.

More care and attention than usual are

required when wearing ear protection –

warning sounds (shouts, alarms, etc.)

cannot be heard properly.

Take a break in good time to avoid

tiredness or exhaustion – risk of

accidents!

Keep easily combustible materials away

from hot exhaust gases and hot mufflers

– risk of fire! Mufflers with catalytic

converters can become especially hot.