© stilum GmbH, Gewerbegebiet Larsheck, D-56271 Kleinmaischeid • Tel. +49 (0) 2689 92790-0 • Alle Rechte und Produktmodikationen vorbehalten

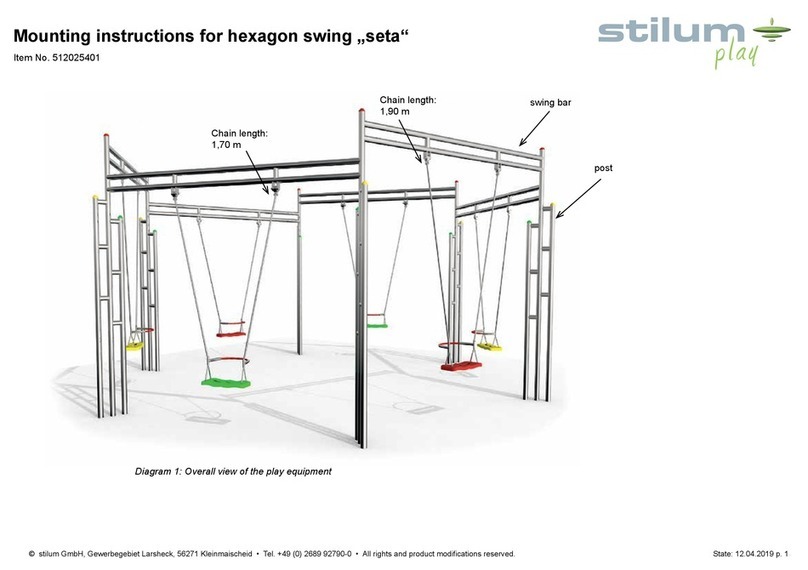

Mounting instructions for hexagon swing „seta Robinie“

Item No. 51 2025 601

State: 17.08.2020 p. 4

In order to preserve a good visual appearance of your stilum playground equipment

over a long period one should take care of maintenance of the stainless surface

even despite of their corrosion resistance.

Especially areas, which can not be reached by rainfall should be frequently cleaned

from dirt and deposits due to air pollution and dirt caused by the atmosphere.

Light soiling can easily be romoved by using a high pressure cleaner.

For persistent deposits use a clean cloth moistened with a special liquid cleaner

(e.g. on phosphoric acid) and rinse o with clear water after a short application time.

During cleaning with mild abrasive components, only wipe over stainless steel sur-

face in polishing direction.

For heavily soiled surfaces, polishes can be used (e.g. for cleaning chrome on cars)

or for greasy and oily dirt alcoholic cleaning agents and solvents (e.g. ethyl alcohol,

isopropyl alcohol or acetone).

However, it should be noted that the dissolved soiling is not spread over the surface

again.

Do not use any chlorid or hydrochloric containing cleaning products nor scouring

powder, bleaching - or silver polish cleaner. Cleaning intervals depend on type and

degree of soiling as well as on demands made on optical characteristics. Therefore

cleaning is advisable at intervals of six to twelve months – whereby in the case of

strong soiling it is appropriate to clean the playground equipment at intervals of three

to six months.

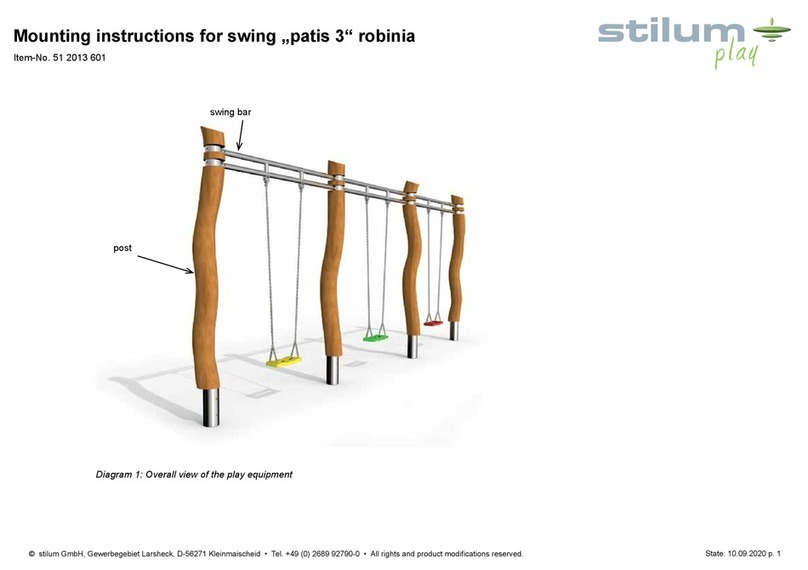

WOOD

NOTE: For all play equipment with wooden elements, it cannot be ruled out that dry

cracks may develop. These natural changes of wood are dependent on climate con-

ditions as well as on the age and usage of the play equipment. Longer dry periods

may lead to more dry cracks.

This development, however, does not represent a quality defect. Static properties of

the equipment are not impaired.

See EN 1176 Bbl 1:2019-01 4.2.7.6: Dry cracks in wood elements as a conse-

quence of weather conditions are not to be considered as dangerous openings in

terms of the standard due to the fact that the shape of the cracks (tapering towards

the inside) makes it almost impossible for ngers to get trapped in them.

MAINTENANCE: To ensure a long life of stilum playground equipment, wooden

surfaces should be regularly re-glazed. This provides the wooden surfaces with the

necessary protection and preserves the look. Areas which are not exposed to rain

should be regularly freed from deposits.

The cleaning intervals depend on the degree and type of soiling as well as on the

exigencies on cleanliness. It is recommended to clean and / or glaze at every 6

to 12 months, or to shorten the cleaning interval to 3 to 6 months if the wheather

conditions are bad.

LASUR: Use a soft and at brush or / and a glaze application roll to paint.

The wood should be cleaned a few hours before glazing. That can be done with

mild javel water, which should in any case be rubbed o afterwards. For resistant

dirt use a wood cleaner. Eventually a light abrasion is necessary. If water-based de-

tergents are used for cleaning, please ensure that the wood elements are thorough-

ly dried before the glazing is done.

Always brush in one direction, so that the glaze can spread evenly. Apply very

thinly!

Remove glaze with a soft cotton cloth.

Then let the freshly glazed wood dry for at least one day and prohibit the use of the

equipment for this duration.