Stinson Voyager 150 Operation manual

OWNER'S

OPERATING

MANUAL

for

STINSON

VOYAGER

150

1947

FOREWORD

In the

Ow

ner's OPerating Manual

for

the

Sfinso'n

Voya

g

f'

r 150 a large

amount

of

engineeri

ng

and

re-

se

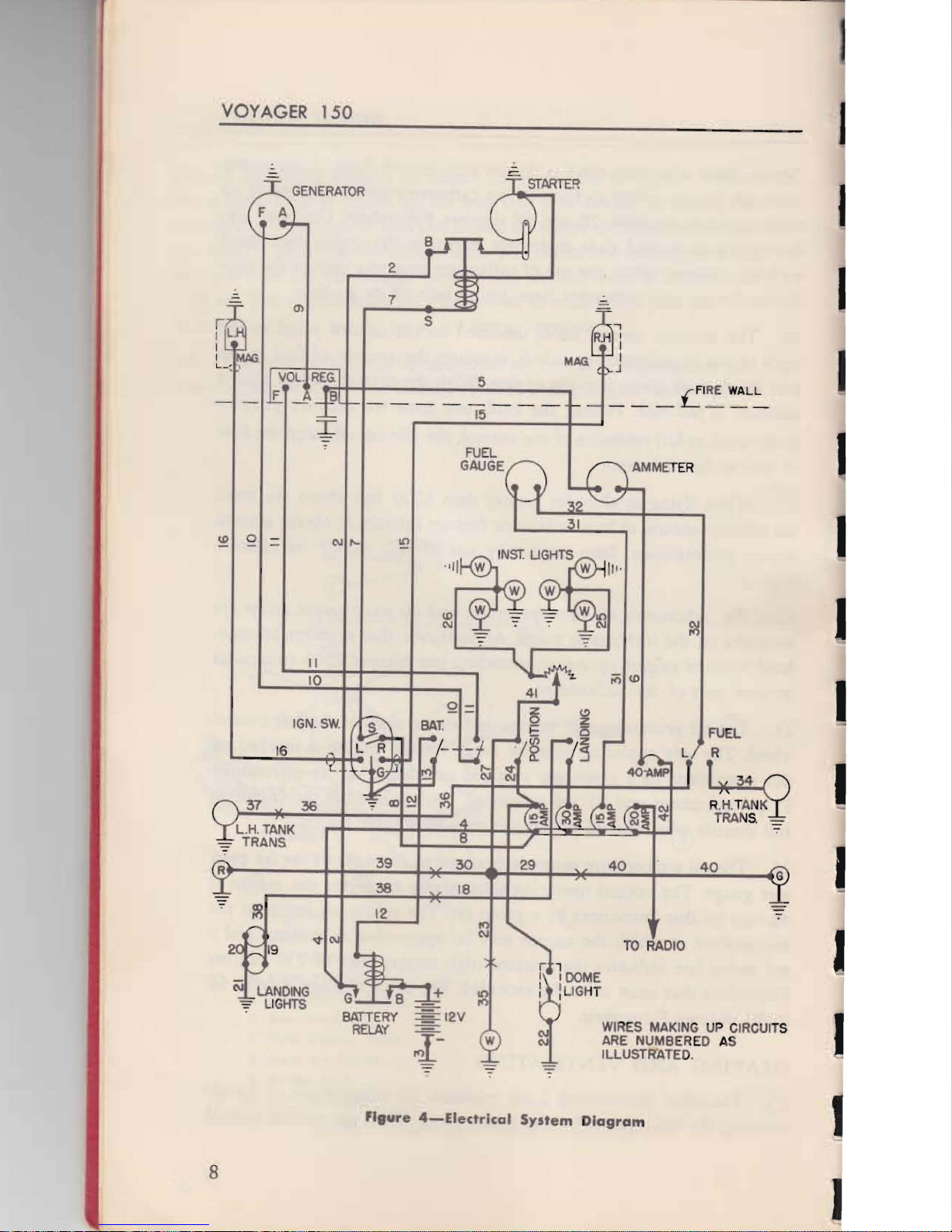

arc

h da a

h

a~

been

reduced

to

an e

as

ily

understood

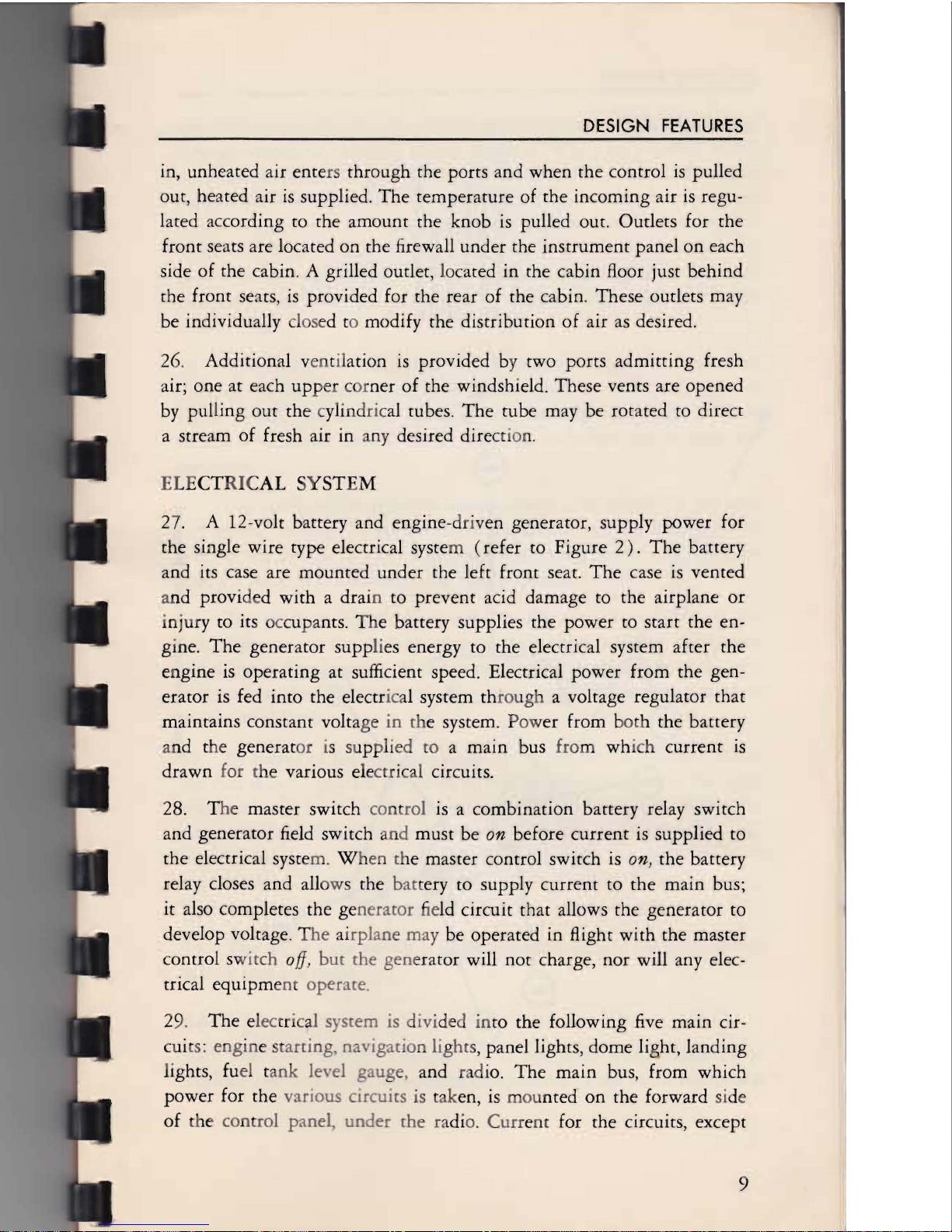

reference

sou

rc

e

th

at will c

ont

ribu

te

to

I

ng

life

an

d econ

omi

cal op

eration

of

the

airplane.

The

manual

is

on

e

of

t

wo

books available to the owner.

The

ot

her

is the General

SC

rl

l;CC Manllal, whi h

is

a o

nvenicntly

arra

nged,

au

th

or

itat

ive

guide

t

constr

uc

tion

detail

s

and

maintenan

e

rcqu

ir me

nt

s

for

t

he

airplane

. Care-

ful

study

of

b

oth

man uals will

provide

the

informati

on

needed

to

keep

the

Stins

on

Voyager

150

oper

ating

eco

no

m

ically

at

top

efficie

ncy.

TA

BLE

OF

CON

TE

NTS

Page

CHAPTER I

Design Features ..................................

..

...

........................................... 1

C

HAPT

ER II

Operating Instruc

ci

ons

..

.......................

...

..................

....

....................

21

CHAPTER III

Operating Limitations

..

......

..

........

..

......

..

..

................

..

.

...

.................

..

.

33

N <

o

-<

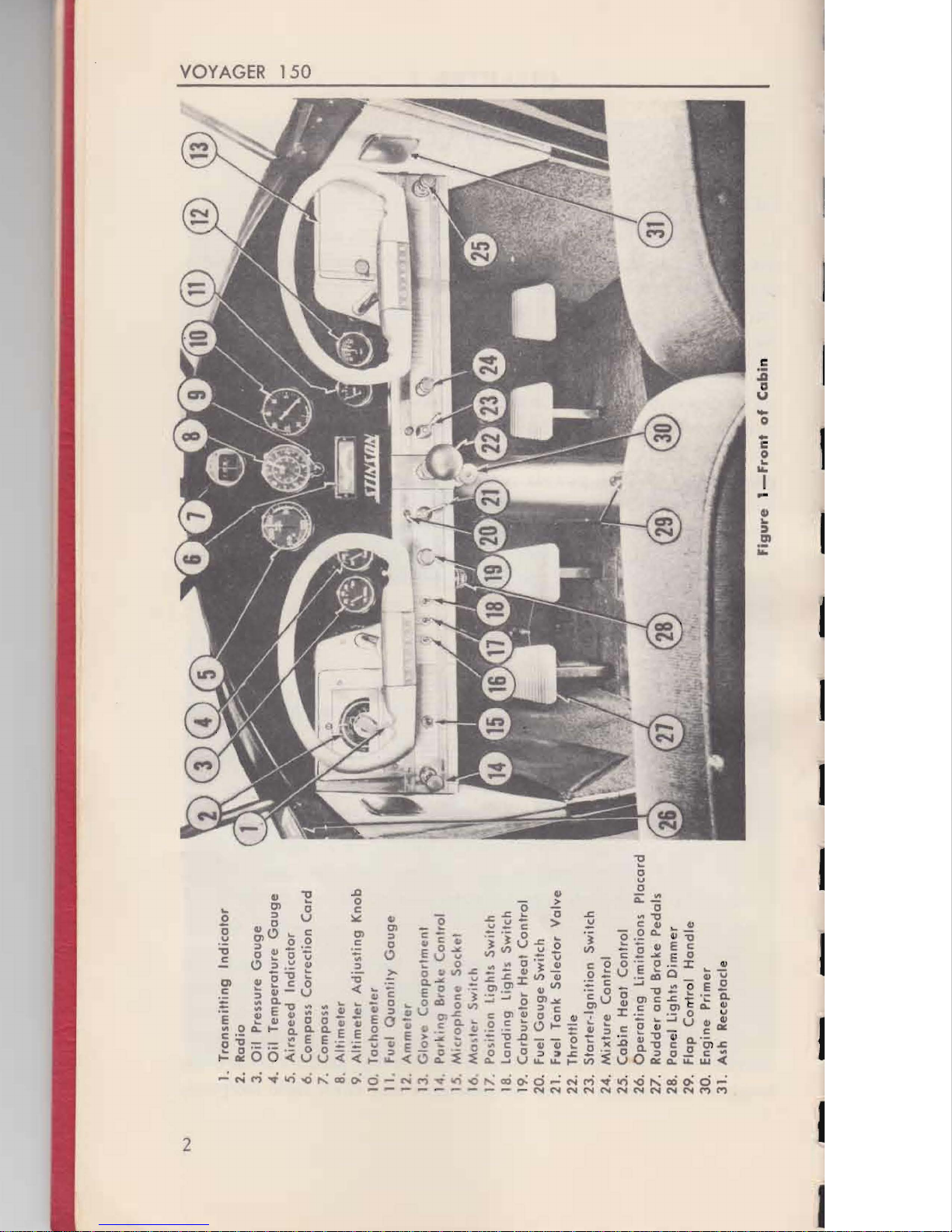

1.

Transmitting

Indicator

>

2.

Radio

C>

3.

Oil

Pressure

Gouge

QI

4.

Oil

Temperature

Gauge

5.

Airspeed

Indicdtor

VI

o

6. Compass

Correction

Card

7. Compass

8.

Altimeter

9

Altimeter

Adjusting

Knob

10

.

Tachomeler

I I. Fuel

Quantity

Gauge

12.

Ammetor

13

.

Gloy,

:

Comportment

I ".

P(II~

i

f'l9

IhCJk~

Canlrol

1,5. Mi

crophon

e Sockel

16

Ma

~

IN

Swilch

11

Po

s

ition

L

ights

Switch

18

.

Landing

Lights Switch

19.

Carburetor

Heat

Control

20

. Fuel

Gauge

Switch

21. File! Tank

Selector

Valve

22.

Throttle

23.

Slarter·lgnition

Switch

24.

Mixture

Control

25.

Cab

in Heat Conl

rol

26.

Operati

ng

Limitations

Placard

27. Rudder

and

Brake Pedals

28. Panel

lights

Dimm

er

29.

Flap

Co

rrt

rol

Handle

30.

En

g

ine

Primer

31. Ash Rece

ptacl

e

.......

---

Figure

1-

Front

of

Ca

bi

n

DESI

GN

FEA

lURES

SURFACE CONTROLS

AN

D BRAKES

6.

Th

e ailero

ns

and elevator are operated

by

dual control wheels and

shafts.

The

full up travel of the elevator

is

obtained only when the flaps

are lowered. W hen the

fl

aps are r

ai

sed, a stop

on

the el

ev

ator push-pull

tube engages tbe lower arm

of

tbe

fl

ap handle

ont

rol assembly, limit-

ing the elevator up t

1"a1)el

co

approximately nine degr

es

less than full

up travel.

7.

Th

e

fl

aps are operated by a comrol lever located between the

twO

fro

nt

seats. A three-position locking d

ev

ic

e in the control mechanism

allows the flaps

to

be

sec

in ny one of rhree positions: raised, take-off,

or landing. The

fl

aps are raised fully when the control lever

is

in the

posicion neare t

th

e BOOL

Di

sengage the locking dev

ice

by

pressing the

but

tO

n on the end of the control lever.

Do

not

fl

y at spee

ds

greater than

88

mph

with flaps down.

8.

The eleva

ro

r trim tab is operated

by

a hand crank located overhead.

Th

ere is a tab p

osiC

ion indicator on the pl

aca

rd of the crank assembly.

Th

is

control

is

prov

id

ed to correct the airplane for nose heavy or tail

heavy conditio

ns,

us

ua

ll

y caused by variations

of

loadi

ng

arrangements

or powe

r.

9.

The rudder and steerable tail wheel are controlled by both sets of

pedals.

Th

e brake

ro

e-

peda

ls

are attached

ro,

and extend abo

ve,

the left

set of

ru

dder peda

ls.

The

br

akes

ca

n be set for parking by pulling out

the parking brake control knob while the brakes are de

pr

es

se

d.

Th

e

br

akes

ca

n be used for curning the airplane while taxiing, but to avoid

exce

ss

ive brake wea

r,

the steerable tail wheel should be used

as

the

principal means of turning when

on

the ground.

FLI

GHT

INSTRUMENTS

1

0.

The altimeter, the airsp

ee

d indicato

r,

and the

co

mpa

ss

are mounted

on the instrument pane

l.

Th

e d

ia

l of the altimeter can be rotated and

set to the proper pressure altitude

by

turning the adjusting knob at the

b

ase

of the dial.

11. The airspeed indICator

is

marked with colured lines and letters

to

show the various speed range limitatio

ns

of the airplane. The green arc

ind

ic

ates the normal operating range.

Th

e white arc, inscribed along-

side the green arc mclicates (he permissib

le

speed range with the flaps

dow

n.

A

ye

llow arc mdicates the speed range at which the airp

la

ne

3

4

VOYAGER

150

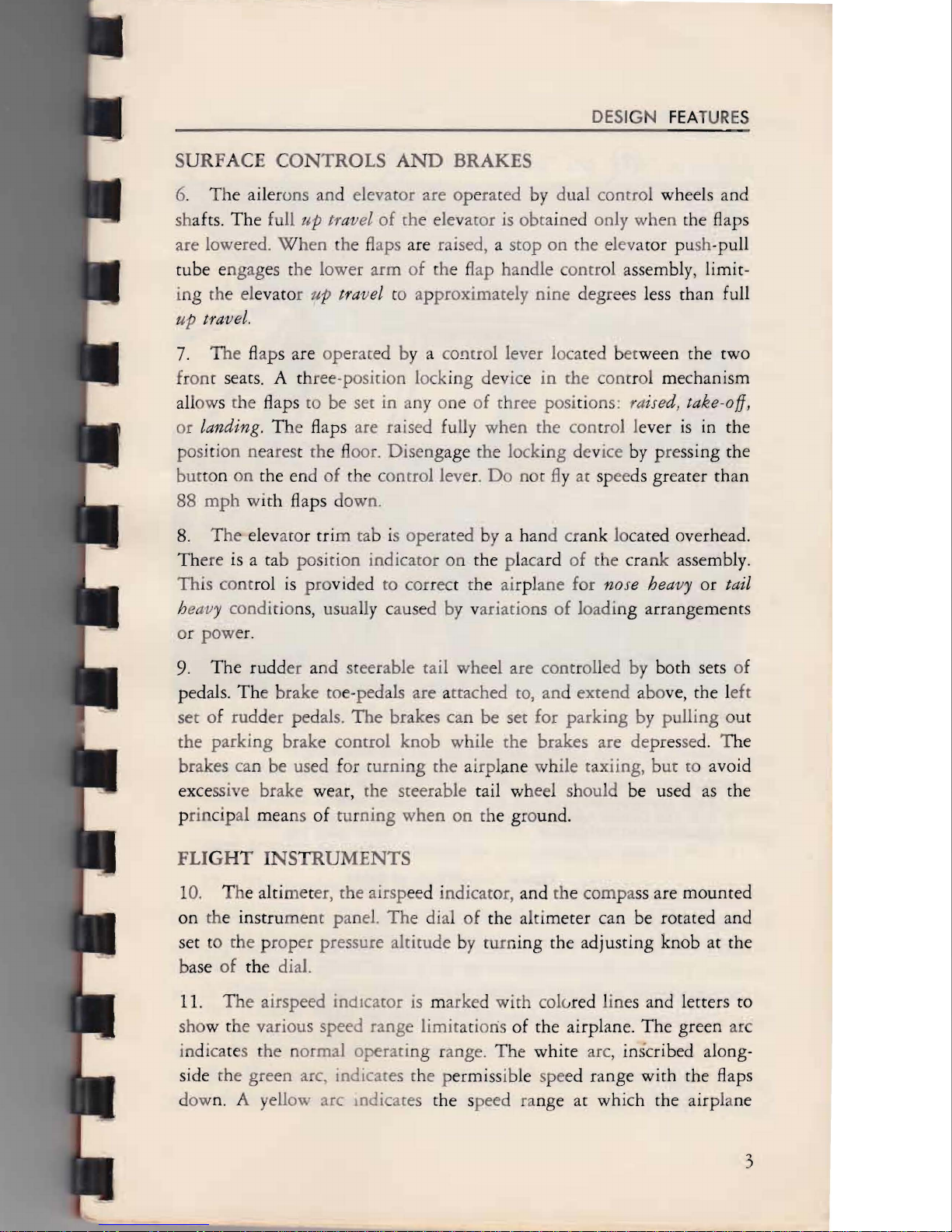

7. Ash Rece

ptacle

8.

Ba

gga

ge

li

m

itation

Placard

9.

Do

or

Ha

nd

le

10. Door

lo

ck

11.

Wind

ow

Lock

12. Air

craft

Data File

1.

Aileron

and

Fl

ap

C

ontrols

Access

Zipper

2. Dome Light Switch

J.

Radio

loud-Speaker

4. Trim

Tab

Control Access

Zipper

5. Elevator Trim Tob Control

6.

Cabin

Ventil

ator

Figure

2-Left

Side

of

Ca

bi

n

should be operated with caution

to

av

oid abru

pt

maneuvers. Red radial

lines and letters on the instrument indica

te

maximum speeds permis-

sible: "

N"

for maximum speed in the normal category (gross weight

between ]925 and 2230

pounds);

and "

U"

for maximum speed in the

utility ategory gross weight 1925 pounds or less).

12. The compass can be adjusted for eviation by turning the com-

pensatjng screws on the face of [he instrument with a non-magnetic

screw driver. T e compensating screws are located at the extreme

tOp

DESIGN

FEATURES

of the inst

rument

and are marked "N

-S

" and "E-

W"

to indicate the

ad

justment that can be made by

tu

rning the screws.

The

compass cor-

rection card is beneath the compas

s.

EN

GIN

E

CON

TROLS

AND

INDIC

AT

ORS

13. All of the power pla

nt

co

nt

rols and indicators, except the oil level

dip stick, are mounted on the control and instrume

nt

panels.

The

control

panel, beneath the main panel, exten

ds

the width of the cabin.

The

oil

level dip stick

is

on the right rear side of the engine crankcase, inside

the engine b

afHes.

14.

Th

e throttle concrol, located in the center of the control panel,

is

the push-pull

typ

e.

A

knu

rled loc

ki

ng nut adjusts the friction applied

to the push-pull rod and determines the ease with which the throttle

control can be adjusted. By turning the nut clockwise, the throttle con-

trol can

be

locked in any positio

n.

Engine speed

is

increased

by

pushing

the throttle control toward the control panel.

15.

The

fuel selector valve, mounted on the aft side of the firewall,

is

operated by a torque rod and a combination handle and pointer

on

the

control pane

l.

The

position of the valve deter

min

es from

wh

ich tank

fuel can flow to the

en

gine.

The

valve can

be

se

t to

anyone

of three

positions:

lef

t tank, right t

ank

,

or

off. W hen the valve handle

is

turned

to the off position, all fuel

is

sh

ut

off from the engine at the val

ve.

16.

The engine primer control

kn

ob

is

on the lower edge of the con-

rrol panel, below the throttle control.

To

prime the engine,

turn

the

co

nt

rol knob counter clockwise; pull the knob out

as

far

as

possible,

then push it back to the normal position.

When

the primer

is

not being

us

ed,

it

must

be

lo

cked securely

in

th

e normal position.

17.

The

combination starter and ignition switch

is

mounted on the

co

ntt

ol panel

to

the right

of

the throttle control. A stop incorporated

within th

is

swiech prevents the switch from being turned to start posi-

tion unless the button direccly above the handle

is

depressed.

The

switch

is

spring loaded and will return

to

the both magnetos position from the

start positi

on

when the switch

is

released. Both magnetos are on with

the switch in start position.

18. The carburetor heat control knob

is

mounted

on

the control panel

to the left

of

the fuel selector valve control. As the control knob is pulled

5

6

VOYAGER

150

ouc,

an increasing amount of heated air enters the carburetor.

When

the control knob

is

pu

lled all the way out, only heated air enters the

carburetor. A mixture of cold and heated air enters the carburetor when

the knob

is

set

at

intermediate points.

The

carburetor heat control can

be locked in any position to provide any desired mixture of hot and

cold air. The concrol knob m

us

t be turned to unlock the push-pull rod

before the control can be

se

t at the desired position.

19.

Th

e primary purpo

se

of carburetor air heat

is

to eliminate or pre-

vent carburetor icing. Use carburetor heat during engine warm-up and

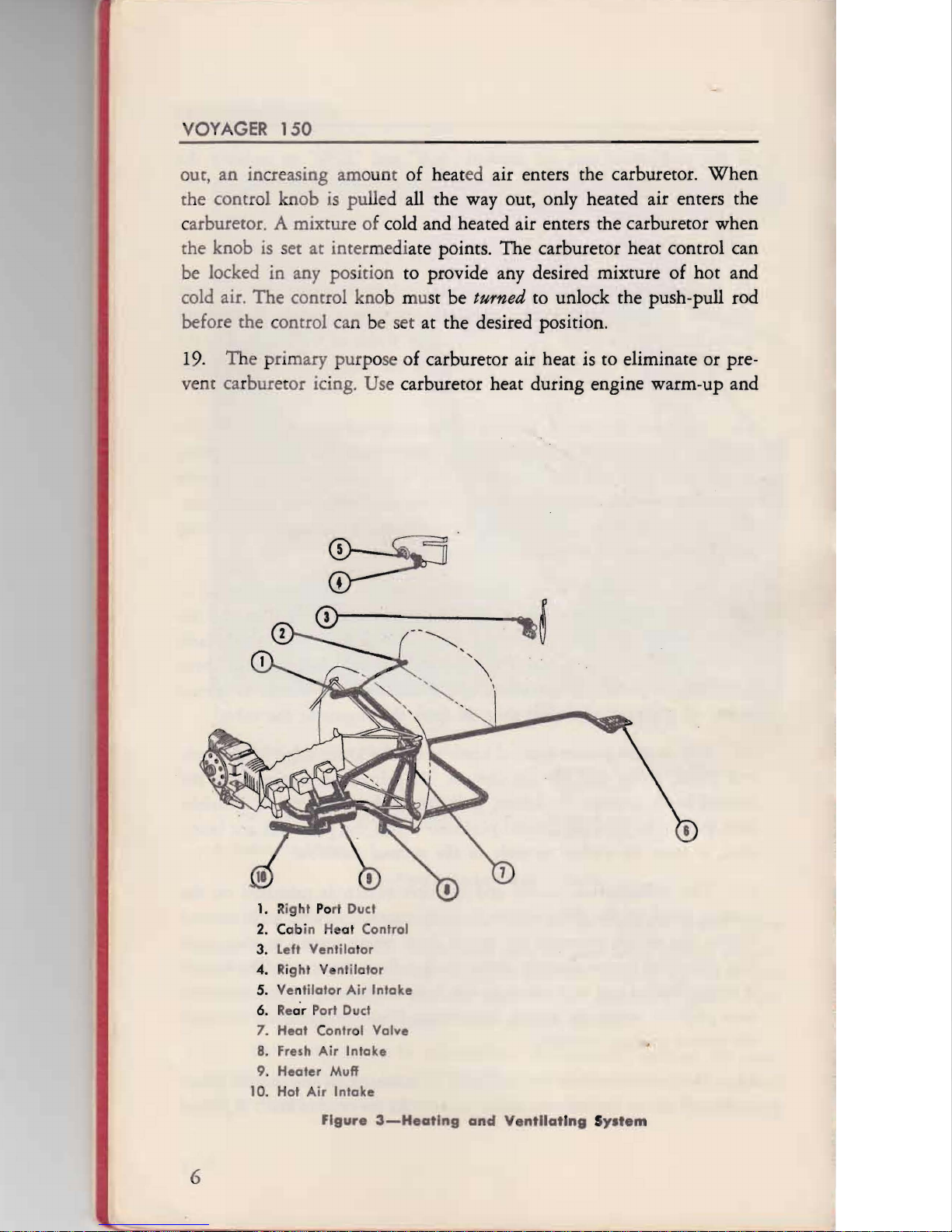

1.

Ri

gh

t

Po

rf Duct

2.

Cabin He

at

Control

3.

left

Ventila

t

or

4. Ri

gh

t Ve

ntilator

5.

Ve

ntilator

Air

Intake-

6.

Re

o'r

P

ort

Duct

7. Heat C

ontr

ol Valve

8. Fresh Air

Intake

9.

Heater

Muff

10. Hat

Air

Intoke

Figure

3-Heatlng

and

Ventilat

i

ng

5y

.te

m

DESIGN

FE

AT

URES

during climb whenever there

is

danger that

ice

will form in the carbu-

retor. Ice

is

most likely to form in the carbure

tOr

when the outside air

temperature

is

between 20 and 68 degrees Fahrenheit. Use heat also

during any prolonged glide or descent. Any time the engine loses speed

without apparent cause, the use of carburetor heat may correct the con-

dition.

Do

not use carburetor heat during take-off or landing.

20. The mixture control knob, mounted on the control panel to the

right of the ignition-starrer switc

h,

regulates the amount of fuel in the

fuel-air mixture going into the engine.

With

the control pushed in, the

mixture

is

full rich. Pulli

ng

the knob out leans the mixture progres-

sively until, at full extension of the control, the idle cut-off stops the flow

of fuel at the carburetor.

21.

When

flying at altitudes greater than 3000 feet above sea level,

use mixture control to lean carburetor fuel-air mixture to obtain smooth

engine performance. Stop engine by use of idle cut-off on mixture

control.

22. The t

ac

hometer, oil pressure gauge, and oil temperature gauge are

mounted on the instrument pan

el.

An

ind

ic

ator that registers accumu-

lated hours

of

engine operation, recordi

ng

one ho

ur

at 2566 rpm,

is

an

integral part

of

th

e tachometer.

23. The oil pressure gauge

is

mounted to the rig

ht

of

the left control

wheel.

Th

e sa

fe

operating pressure range for the engine is marked on

this instrument by a green arc with red radial lines at its extremities,

35

psi mini

mum

and 55 p

si

maximum.

Do

not operate the engine at

full throttle when the oil pressure

is

outside of these limits.

24. The oil temperature gauge is mounted to the right of the oil pres-

sure gauge.

The

normal operating temperature range for the engine

is

marked

on

this instrument by a green arc.

The

yellow arc indicates the

temperature at which the engine m

ay

be operated with caution, and a

red radial line indicates the extreme high temperature of 230 degrees

Fahrenheit that must never

be

exceeded. The caution range

is

from 60

to 80 degrees Fa

ru

enheit.

HEAT

IN

G

AND

VENTILAT

ING

25.

Th

e cabin heat concrol knob regulates the temperature of the air

ent

ering the cabin through three heater

po

r

ts.

W ith the control pushed

7

VOYAGER

150

R

7

II

10

16

'ST

36

L.H.

TANK

TRANS

~

19

N

LANDING

LIG

HTS

G

5

15

FU

EL

GAUGE

BATTERY

§

12Y

RELAY

-

{-

FU

EL

R

l~:

N~

T

RA

NS.

-=

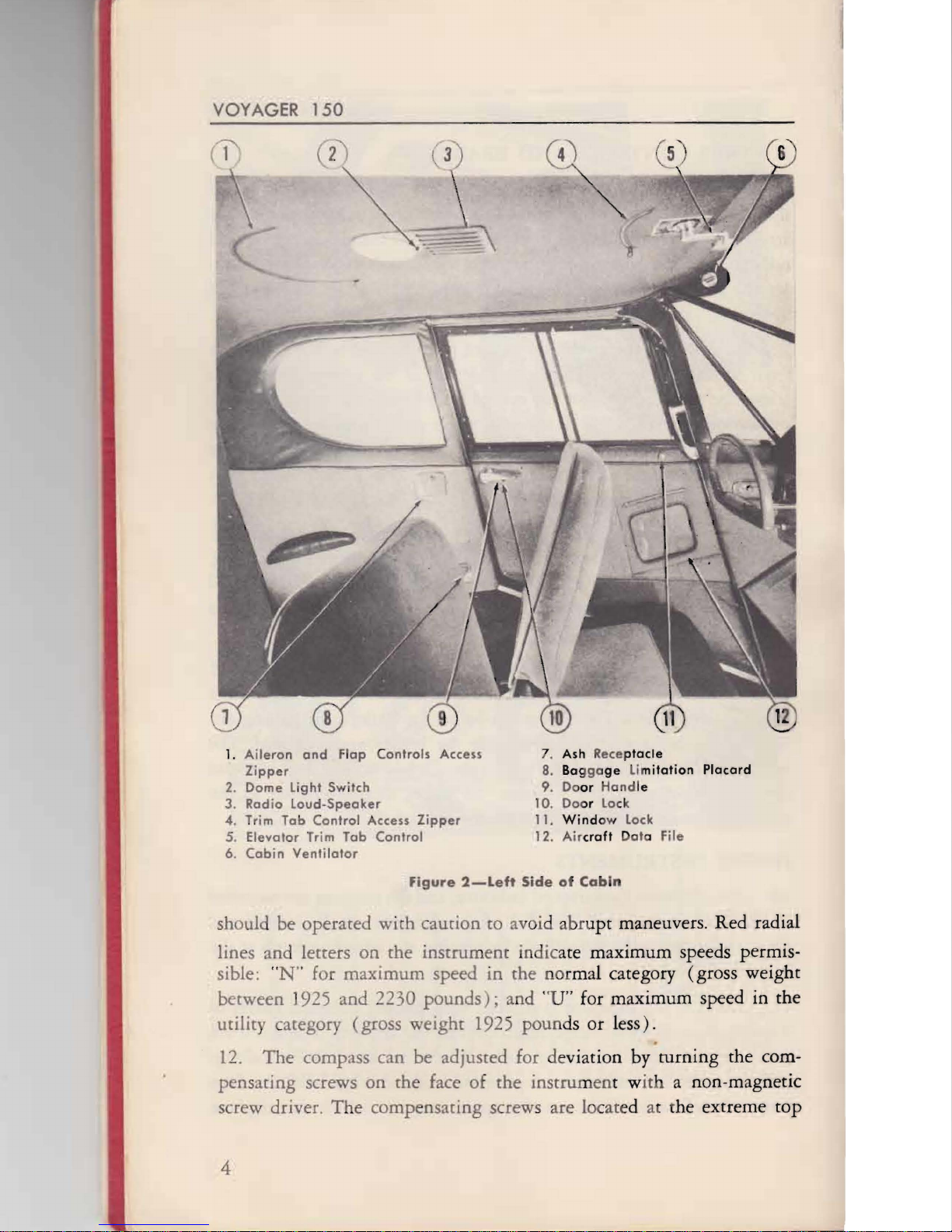

Figure

4-Electrlcal

System

D

iagram

8

DESIGN

FEATURES

in, unheated air enters throLlgh the ports and when the control

is

pulled

out, heated air

is

supplied.

The

temperature of the incoming air

is

regu-

lated according to the amount the knob

is

pulled out. Outlets for the

front seats are located on the firewall under the instrument panel

on

each

side of the cabin. A grilled outlet, located in the cabin floor just behind

the front seats,

is

provided for the rear of the cabin. These outlets may

be individually lased to modify the distribution

of

air

as

desired.

26. Additional ventilation

is

provided by two ports admitting fresh

air; one at each

up

per c rner of the windshield. These vents are opened

by pulling

out

the cylindrical tubes.

The

tube may be rotated to direct

a stream of fresh air in any desired direction.

E

LE

CT

RIC

AL

SY

ST

EM

27. A 12-volt battery and engine-driven generator, supply power for

the single wire type electrical system (refer to Figure

2).

The

battery

and its case are mounted under the left front seat.

The

case

is

vented

and provided with a drain to prevent acid damage to the airplane

or

inj

ur

y to its occupants. The battery supplies the power to start the en-

gine.

The

generator suppli

es

energy to the electrical system after the

engine

is

operating at sufficient speed. Electrical power from the gen-

erator

is

fed into the electrical system through a voltage regulator that

maintains constant voltage

in

the system. Power from b

ot

h the battery

an

d the generator is supplied

to

a main bus from which current

is

drawn for the various electrical circuits.

28. The master switch co

nt

rol

is

a combination battery relay switch

and generator field switch and must be

on

before current

is

supplied to

the electrical system. W hen the master control switch

is

on) the battery

relay closes and allows the

ba

tt

ery

to

supply current to the main bus;

it also completes the generator

fiel

d circuit that allows the generator

to

develop voltage. T

he

airplane may be operated in flight with the master

control switch off)

but

the generator will not charge, nor will any elec-

trical equi

pm

em opera

te.

29.

The

electrical system is divided i

nt

o the following five main cir-

cuits: eng

in

e starting, na igarion lights, panel lights, dome light, landing

lights,

fu

el ta

nk

level gauge, and radio.

The

main bus, from which

power for the vanous

Clf

CUHS

is

taken,

is

mounted

on

the forward side

of

the co

nt

rol panel. under the radio. Curre

nt

for the circuits, except

9

12

J

)

1

VOYA

GE

R

150

are a transmitter-receiver unit, a loudspeaker, and a

microphon~.

Two

jac

ks

are provided, one for the microphone and the other for head-

phone

s.

Headphones are not normally required because of the loud-

speaker installation.

j6

. The airplane

is

equipped with two antennas, an extern!ll

~ntenn~

that extends from the top of the tabin to the verdcal stabilizer, apd a

fixed

loop antenna inside the fuselage, aft of the cabin

(ref~r

to

Fig~

ure 5).

Th

e loop

is

perpen<1icular

to· the longitudinal axis of the

air,.

plape

so

that homing

is

accomplished

by

tuning the null.

37.

Transmission

may

be

accomplished at any setting of the radio

contro

ls

as long

as

the radio

is

operating. The transmitter

is

activated

NOTE:

R

iO

ht

and

UIt

Tonka

en

SImIlar

1.

Vent

6.

Le'ft

Wing

'Tank

2. F

ill

er Cap 7.

Selector

Vaivi

l1andl.

3. R

ig

ht Wing Tank 8. Primer Pump

4.

Dr

ain

Pl

ug 9. Fuel

Strainer

On

Firewall

5. Fuel

Stra

i

ner

in

Wing Tan k 10. Fuel

Strainer

in C

arbur.tor

1"I.t

Fi

gu

re

6-F

u

el

Sys

te

m

J

DES

IGN F

EAT

URES

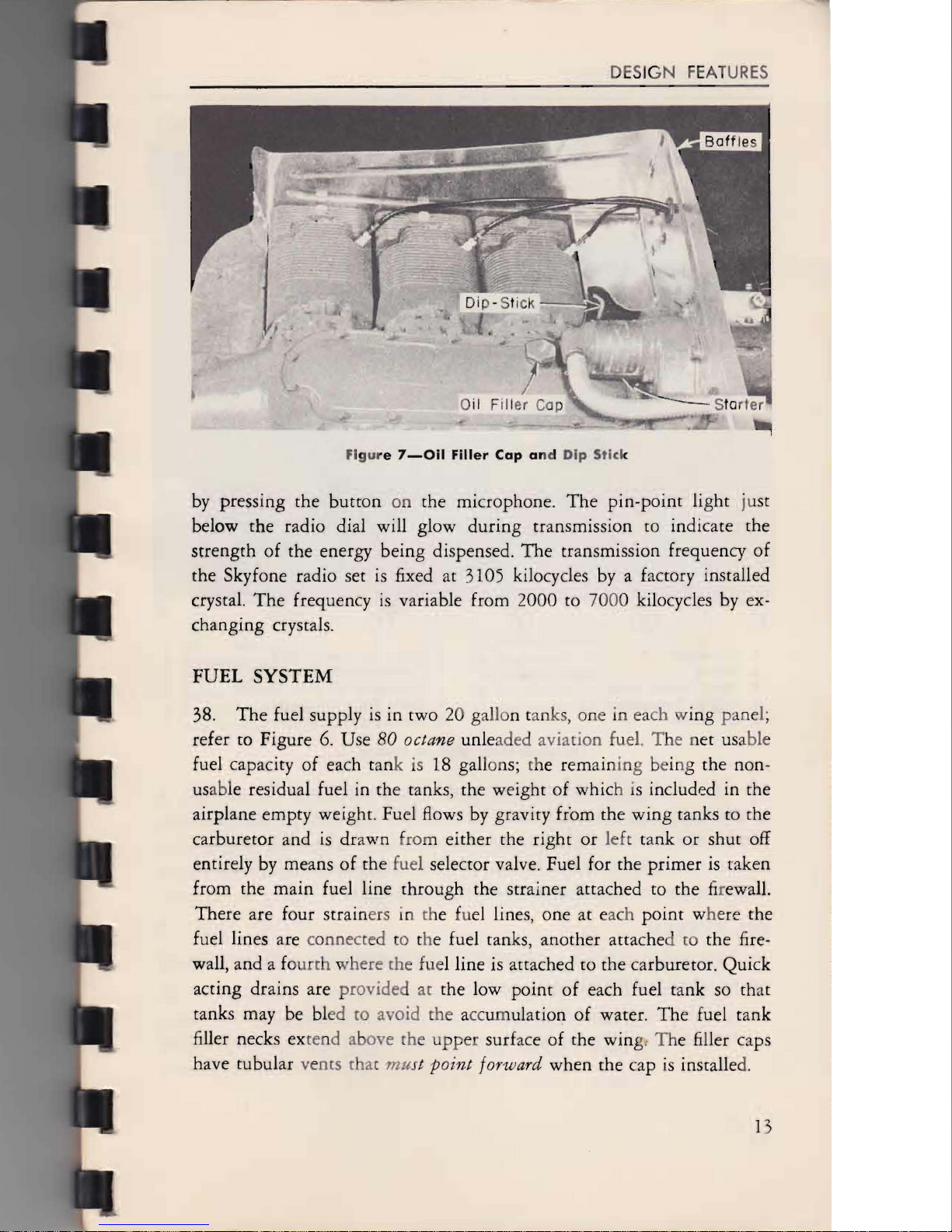

Fi

gur

e

7-0il

Filler

Cap

an

d

Dip

Stick

by

pressing the

button

on

the microphone.

The

pin-point

light just

below the radio dial will glow

during

transmission to indicate the

strength

of

the energy being dispensed.

The

transmission frequency

of

the Skyfone radio set

is

fixed at 3105 kilocycles by a factory installed

crystal.

The

frequency

is

variable from 2000 to 7000 kilocycles by ex-

changing crystals.

FUEL

SYSTEM

38.

The

fuel supply

is

in two 20 gallon tanks, one in each wing

pa

nel;

refer to Figure

6.

Use

80

octa

ne

unleaded aviation fuel. The net usable

fuel capacity of each tank

is

18 gallon

s;

the

rem

aining being the non-

us

able residual fuel in the tanks, the weight

of

which is included in the

airplane empty weight. Fuel Bows by gravity fr'om the

wing

tanks to the

carburetor and

is

drawn from either the

right

or left tank or shut off

entirely by means

of

the fuel selector valve. Fuel for the

primer

is

taken

from the

main

fuel line through the strainer attached to the

fi

rewall.

There are four strainers

in

the fu

el

lines, one at each

point

where the

fuel lines are connected to the fuel tanks, anOther attached

to

the fire-

wall, and a fo

urth

where the fuel line is attached to the carburetor. Quick

acting drains are provided

at

the low

point

of each fuel tank so that

tanks may be bled

ro

avoid the accumulation

of

water.

The

fuel tank

filler necks extend above the

upper

surface of the wing:

Th

e filler caps

have tubular vents that

mu

st p

oint

fo

rw

ard when the cap is installe

d.

13

VOYAGER

150

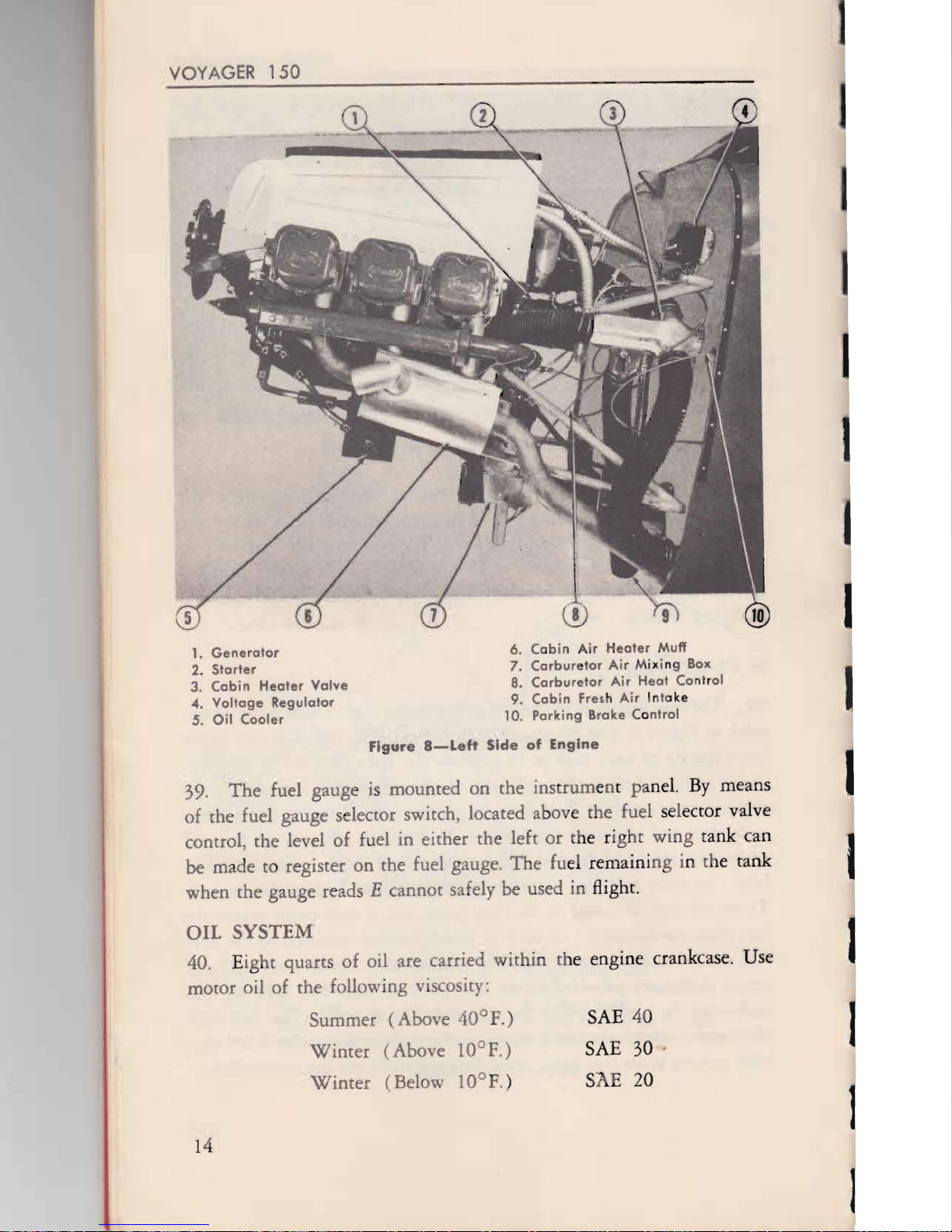

1.

Generator

2.

Starter

3.

Cabin

Heater

Valve

4.

Voltage

Regulator

S.

Oil

Cooler

39.

The

fuel gauge

is

mounted

on

the

instrum

e

nt

panel.

By

means

of

the fuel

gauge

selector switch, located above the fuel selector valve

control, the level

of

fuel

in

either the left

or

the ri

gh

t

wing

t

ank

can

be

made to register

on

the fuel gauge.

The

fu

el

remaini

ng

in the

tank

when

the gauge reads E

cannot

safely be used in flight.

OIL

SYSTEM

40. Eight quarts

of

oil are carried

within

the engine crankcase. Use

motor

oil

of

the

following viscosity:

Summer

(Abo

e

40°F.)

SAE 40

Wincer

(Above

lOoF.)

SAE 30

Winter

(Below

lOoF.) ShE

20

14

6.

Cabin

A

ir

Healer

Muff

7.

Carbur

e

tor

Air

Mixing Box

8.

Carburetor

Air

Heat Conlr

ol

9.

Cabin

Fres

h

Air

In

to

ke

10. Parking Broke Control

Figure

8-Left

Side

of

Engine

DESIGN

FEATURES

1.

C

abin

He

ater

Duct 7.

Mixture

Co

ntro

l

2.

Gen

er

a

to

r 8. C

ar

bu

re

to

r

3.

Ri

ght M

agn

eto

9. Thro

ttle

Con

tro

l

-t.

Starter

10. Primer Line

5. Engine Shock M

ount

11.

Carburet

or

Air

Heater

Muff

6. Fuel

St

r

ain

er

Fi

gur

e

9-Rlght

S

id

e

of

Engine

A dip-sti k for measuring the quantity of oil in the engine

is

acces-

sible upon lifting the right engine cowl panel. The stick

is

on the top

right side of the engine crankcase, inside the baffles. Never operate the

engine with less than 4 quarts of oil in the crankcase. Oil pressure and

temperature gauges are mounted on the instrument panel (see para-

gr

aphs

23

and

24).

EN

GI

NE

A

ND

ENGINE

AC

CES

SORIES

41. The power plant

is

an ai

r-

co

le

d,

six-cylinder, horizontally op-

posed

15

0 ho

rs

epower Franklin engine.

Th

e rated maximum contin-

uous engine s

pe

ed

is

2600 pounds rpm. The propeller '

is

mounted

directly on the crankshaft.

15

16

VOYAGER

150

Lock Release

I

I

I

I

Figure

10-

Sea'

L.ock

Relea$e

42. The engine accessories include a starter, a generator, two mag-

netos, a carburetor, a carburetor air filter, an oil cooler, and a carburetor

heater muff. Refer to Figures 8 and

9.

The starter

is

mounted on the

top aft end of the engine crankcase. The magnetos are below and on

each side of the starter, and the generator

is

directly below the starter

and magnetos. The carburetor

is

attached to the lower aft end of the

engine. The oil cooler and carburetor air

fi

lter are mounted

ben~ath

the forward end of the engine. The carburetor heater muff

is

attached

to

the right exhaust manifold and the muff for cabin heat

is

on the left

exhaust manifold.

ACCOMMODATIONS

43. Seats are provided for four persons. The from seats are adjustable

and can

be

moved forward or back

by

releasing a locking device (see

Figure

10).

The backs of both front seats fold forward permitting en-

trance to the rear seats.

44. The rear

se

ats are the hammock type and are not adjustable. Three

straps support

ea

ch of the rear sea

ts,

and either or both seats can

be

removed easily. Each seat

is

provided with a safety belt. Inasmuch

as

the lower cushions are not

sec

ured, it

is

recommended that the safety

belts be strapped across the rear seat cushions when these seats are

not occupied.

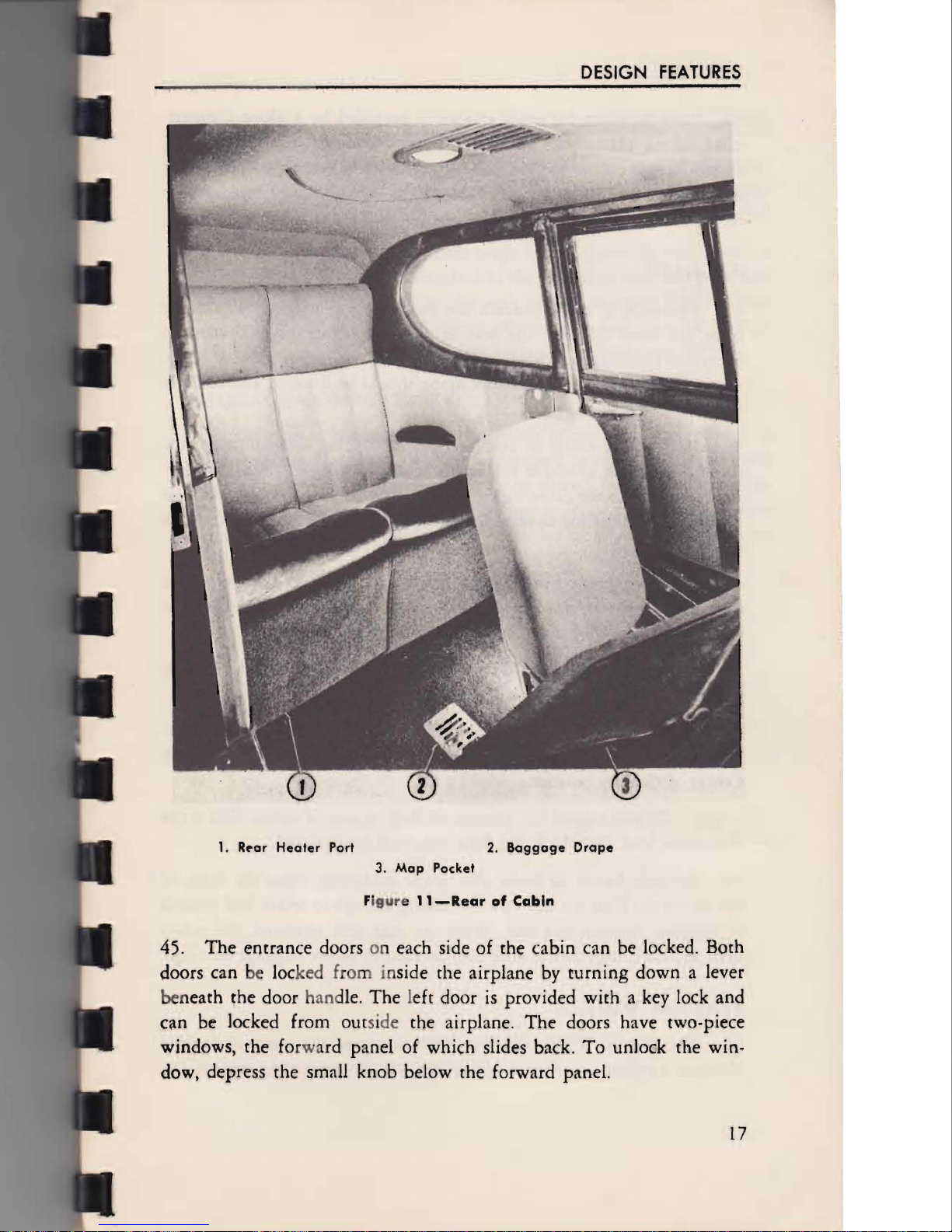

DESIGN

FEATURES

1.

Rpar

Heater

Port

2.

Baggage

Drape

3.

Map

Pocket

F

igur

e

ll-Rear

of

Cabin

45.

The

entrance doors on each side

of

the cabin can be locked. Both

doors can be locked from inside the airplane

by

turning

down a lever

beneath the door hand

le.

The left door

is

provided with a key lock and

can be locked from outside the airplane.

The

doors have two-piece

windows, the forward panel of which slides back.

To

unlock the win-

dow, depress the small knob below the forward panel.

17

VOYAGER

150

46. Stowage space for small articles

is

provided by a glove comP

tt

Ft-I

ment

on

the instrument panel, and by

twO

pockets in the upholstery.

One

pocket

is

on the back of the right front seat and another

is

on

the

left side of the cabin just forward of the cabin door. There are ash

receivers

at

the side of each seat.

BAGGAGE

47. Provi

si

on

is

made beneath the rear seat for baggage.

The

drape

from the fro

nt

edge of the seat

is

attached to the floor

by

curtain

fasteners. Unsnapping these fasteners will allow access to this space.

After the baggage

is

in place, the drape should be lowered and securely

fastened to the floor.

48. Removal of either or both sections of the rear seat will make the

rear of the cabin available for larger baggage

or

light cargo.

Th

e)

()r-

ward tube across the

ca

bin may also. be removed.

To

remove either seat

section, lift off the lower seat cushion and unlock the canvas hammqfk

straps.

49. Any combination of baggage, passengers, and

fuel

may be

carr

~

~d

that does not exceed

anyone

of the following limitations.

The

rear seat I

cannot be occupied during the performance

of

maneuvers.

(a)

Do

not exceed 2230 pounds gross weight.

See

Actual

Weight

and Balance sheets for airplane weight empty. . I

(b)

.

Do

not exceed most rearward Center of Gravity posit

ien

.per-

missible. See Operating Limitations Manual for effect of baggage

on

Center of Gravity position.

(c)

Do

not exceed 350 pounds on floor in rear of cabin. This

is

the

maximum load for which the floor structure

is

approved. I

50

. Securely fasten all loads.

The

drape extending from the front

of

the seat to the floor has been proven strong enough to retain 100 pounds

of baggage beneath the seat.

Wi

th the rear seat removed, the safety

belts and their lugs on the floor may be used to secure baggage

or

cargo. I

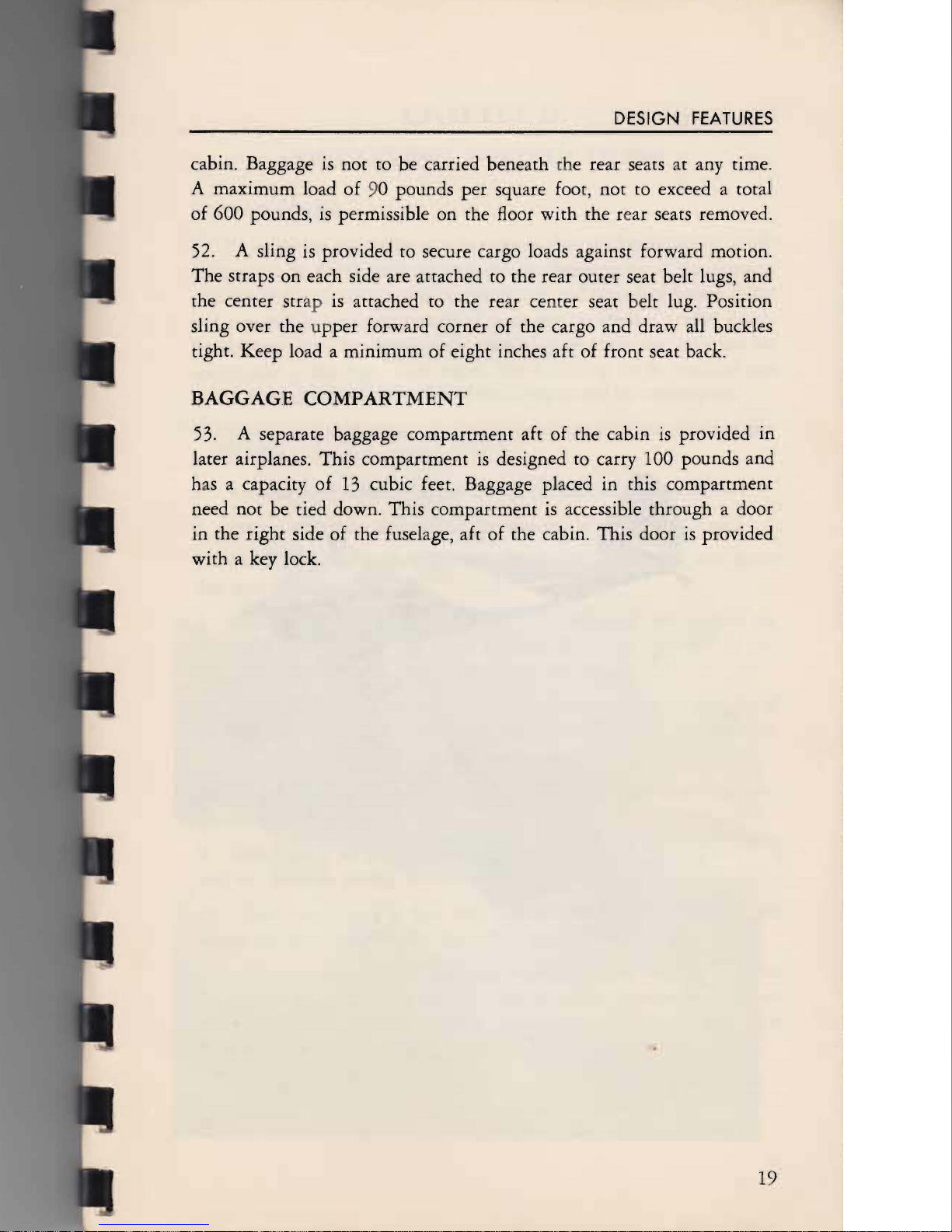

STATIO

N W A

GON

51.

The

Station

Wagon

loading limitations are the ,same

as

for the I

standard airplane

as

given in paragraph 49, except for the rear

of

the I

18

DESIGN

FEATURES

cabin. Baggage

is

not to be carried beneath the rear seats at any time.

A maximum load of 90 pounds per square foot, not to exceed a total

of 600 pounds,

is

permissible on the floor with the rear seats removed.

52. A sling is provided to secure cargo loads against forward motion.

The straps on each side are attached to the rear outer seat belt lugs, and

the center strap

is

attached to the rear

ce

nter seat belt lug. Position

sling over the

up

per forward corner of the cargo and draw all buckles

tight. Keep load a minimum of eight inches aft of front seat back.

BAGGAGE COMPARTMENT

53. A separate baggage compartment aft of the cabin

is

provided

1ll

later airplanes. This compartment

is

designed to carry 100 pounds and

has a capacity of

13

cubic feet. Baggage placed in this compartment

need not be tied down. This compartment

is

accessible through a door

in the right side of the fuselage, aft of the cabin. This door

is

provided

with a key lock.

19

This manual suits for next models

1