STODDART SPWA.PCRO1 User manual

REVERSE OSMOSIS (RO) SYSTEM

SPWA.PCRO1

SPECIFICATION, INSTALLATION

AND OPERATION MANUAL

READ ALL INSTRUCTIONS BEFORE USE

Revision: A - 13/03/2023 - 02

Page Intentionally Left Blank

Page 1

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 2

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

1.0 Introduction

1.1 Your New Stoddart Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Australia and New Zealand Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Warranty Period

1.2.2 Warranty Registration

2.0 Specification

2.1 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.2 Components

2.1.2 Operating Specifications

3.0 Installation

3.1 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Water Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Maintenance

4.1 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.1 Filter Life

4.1.2 Filter Replacement (for 1st, 2nd and 4th Stage)

4.1.3 RO Membrane Replacement

4.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 3

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

1.0 Introduction

Carefully read this instruction booklet, as it contains important advice for safe installation, operation and maintenance. Keep this

booklet on hand in a safe place for future reference by other operators or users.

Stoddart design, manufacture & distribute Food Service Equipment (appliances) exclusively for the commercial market.

This appliance is not designed nor intended for household or domestic use and must not be used for this purpose.

This product is intended for commercial use, and in line with Australian electrical safety standards the following warnings are provided:

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the product by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the product

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid

a hazard

The manufacturer/distributor cannot be held responsible or liable for any injuries or damages of any kind that occur to persons, units or

others, due to abuse and misuse of this unit in regards to installation, removal, operation, servicing or maintenance, or lack of conformity

with the instructions indicated in this documentation.

Disclaimer

All units made by the manufacturer/distributor are delivered assembled, where possible, and ready to install. Any installation, removal,

servicing, maintenance and access or removal of any parts, panels or safety barriers that is not permitted, does not comply in

accordance to this documentation, or not performed by a TRAINED AND AUTHORISED SPECIALIST will result in the

IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer/distributor cannot be held responsible or liable for any unauthorised modifications or repairs. All modifications or

repairs must be approved by the manufacturer/distributor in writing before initiating. All modifications or repairs performed to this unit

must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Thank you for choosing this quality Stoddart product.

All Stoddart products are designed and manufactured to meet the needs of food service professionals. By caring for and maintaining this new

Stoddart product in accordance with these instructions, will provide many years of reliable service.

Stoddart is a wholly Australian owned company, which manufactures and/or distributes a comprehensive range of food service equipment for

kitchens, food preparation and presentation. Stoddart products are manufactured and engineered to provide excellent results whilst offering

value-for-money, ease-of-use and reliability.

1.1 Your New Stoddart Product

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty & Registration

Page 4

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

1.0 Introduction

Carefully read this instruction booklet, as it contains important advice for safe installation, operation and maintenance. Keep this

booklet on hand in a safe place for future reference by other operators or users.

Stoddart design, manufacture & distribute Food Service Equipment (appliances) exclusively for the commercial market.

This appliance is not designed nor intended for household or domestic use and must not be used for this purpose.

This product is intended for commercial use, and in line with Australian electrical safety standards the following warnings are provided:

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the product by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the product

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid

a hazard

The manufacturer/distributor cannot be held responsible or liable for any injuries or damages of any kind that occur to persons, units or

others, due to abuse and misuse of this unit in regards to installation, removal, operation, servicing or maintenance, or lack of conformity

with the instructions indicated in this documentation.

Disclaimer

All units made by the manufacturer/distributor are delivered assembled, where possible, and ready to install. Any installation, removal,

servicing, maintenance and access or removal of any parts, panels or safety barriers that is not permitted, does not comply in

accordance to this documentation, or not performed by a TRAINED AND AUTHORISED SPECIALIST will result in the

IMMEDIATE LOSS OF THE WARRANTY.

The manufacturer/distributor cannot be held responsible or liable for any unauthorised modifications or repairs. All modifications or

repairs must be approved by the manufacturer/distributor in writing before initiating. All modifications or repairs performed to this unit

must be performed at all times by a TRAINED AND AUTHORISED SPECIALIST.

Thank you for choosing this quality Stoddart product.

All Stoddart products are designed and manufactured to meet the needs of food service professionals. By caring for and maintaining this new

Stoddart product in accordance with these instructions, will provide many years of reliable service.

Stoddart is a wholly Australian owned company, which manufactures and/or distributes a comprehensive range of food service equipment for

kitchens, food preparation and presentation. Stoddart products are manufactured and engineered to provide excellent results whilst offering

value-for-money, ease-of-use and reliability.

To register your new product, Follow the below Link/QR code.

www.stoddart.com.au/warranty-information

All Stoddart manufactured and distributed products are covered by Stoddart’s standard Australia and New Zealand Product Warranty (minimum

12 month on-site parts and labour, terms and conditions apply). Further to this standard warranty, certain products have access to an extended

warranty. Full terms, conditions and exclusions can be found using the below Link/QR code.

Warranty & Registration

1.2.2 Warranty Registration

1.2.1 Warranty Period

1.2 Australia and New Zealand Warranty

Page 5

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

2.0 Specification

2.1 Product Overview

2.1.2 Operating Specifications

2.1.2 Components

B

1

A

2

4

3C

D

E

F

G

H

IK

J

Model SPWA.PCRO1

W x D x H (mm) 380 x 220 x 445

Weight 20kg

Power 240VAC / 50-60Hz / 7A

10A plug & lead

Temperature 4-40°C (Cold Water Only)

Pressure 206 - 413 kPa

Total Dissolved Solids <800 ppm maximum

Maximum Hardness 250 ppm

RO Output 4540 LPD / 3.1 LPM

AMounting Bracket

BPressure Gauge

CPower Switch

DPower Socket

EBooster Pump

11st Stage: FG82 - 5 Micron High Capacity

22nd Stage: FG92 - 5 Micron Carbon Block

33rd Stage: 600GPD RO Membrane x 2

44th Stage : FG92 - 5 Micron Carbon Block

FFiltered Water Outlet

GDrain Outlet

HWater Inlet

IHigh Pressure Switch

JSelf Piercing Solenoid

Page 6

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

3.0 Installation

3.1 Electrical Connection

This unit must be installed in accordance with AS/NZS 60335.1

Some procedures in this manual require the power to the equipment to be turned o and

isolated. Turn the power OFF at the power point and unplug the power supply lead by the plug

body. If the power point is not readily accessible turn the equipment o at the isolation switch

or the circuit breaker in the switchboard. Attach a yellow “CAUTION-DO NOT OPERATE” tag.

This must be performed where relevant unless the procedures specify otherwise.

FAILURE TO DO SO MAY RESULT IN ELECTRIC SHOCK.

WARNING

Single Phase Units:

• Supplied and fitted with an appropriately rated plug and lead, indicated as:

- 10amp transformer with lead and plug

Notes:

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a

hazard. Please contact Stoddart for parts and we will advise how to do this in order to avoid any electrical hazard

• The power cable should be dry and/or isolated from moisture or water

Page 7

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

3.0 Installation

OVEN

WASH

SYSTEM

OVEN

STEAM

GENERATION

COLD WATER CONNECTION

WITH ISOLATION VALVE

(EXISTING CONNECTION)

DRAIN

COMBI

WATER SUPPLY

K

K

M

J

E

L

I

E

C C

C

A

B

D

G

F

H

N

J

Note: After connections are complete, close the 3/8 three way manifold “L” to the combi and flush the system for 5

minutes. After 5 minutes open the 3/8 three way manifold “L”.

3.2 Water Connection

IMPORTANT

This unit must be installed in accordance with AS/NZS 3500.1

The unit must be installed with the supplied Water Filters and

Pressure Limiting Valve

The RO unit is to be installed using the supplied fittings and combi oven plumbing kit.

Item Description Supplied

with Oven

Supplied

with RO Kit Total Qty.

ADual Check Valve 1 --- 1

BFour Way Manifold 1 --- 1

C3/4” Bsp To 3/8” Tube Connector --- 3 3

D1/2” Bsp To 3/8” Tube Connector --- 1 1

E3/8” John Guest Stem Elbow --- 2 2

FPressure Limiting Valve 300-350 Kpa --- 1 1

GPressure Limiting Valve 350-600 Kpa --- 1 1

HNipple, 3/4” Male 1 --- 1

IBlue 3/8 Tube ‘Filtered Water’ (to be cut to length) --- 1 1

JWhite 3/8 Tube ‘Unfiltered Water’ (to be cut to length) --- 1 1

KRed 1/4 Tube ‘Drain’ (to be cut to length) --- 1 1

L3/8” John Guest Three Way Manifold (For filter flushing) --- 1 1

MJohn Guest Locking Clip --- 12 12

MSpare outlet (Hand Shower) --- --- ---

Page 8

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

3.0 Installation

3.3 Installation

1. Connect the dual check valve to the cold water supply

2. Attach four way manifold and two connectors to the dual check valve

3. Connect the two PLV’s to the connectors on manifold

4. Connect to the oven wash system with 3/8 white tube, John guest elbow and connector

5. Attach 3/8 white tube to the PLV and connect to the water supply connection on the RO

6. Attach 3/8 blue tube to the COMBI connection on the RO. Attach the three way manifold to the tube then run tube to the oven steam

generation connection using a John guest elbow and connector

7. Connect the 1/4 red tube to the DRAIN connection on the RO and run to the tundish. Connect 3/8 blue tube to the third connection on

the three way manifold and run to the tundish (this is used as the flush hose

8. Close the three way manifold “L” to the combi and flush the system for 5 minutes. After 5 minutes open the manifold

OVEN

STEAM

GENERATION

DRAIN

COMBI

WATER SUPPLY

OVEN

WASH

SYSTEM

1

5 6

7 8

2 3 4

K

I

I

I

J

J

J

J

E

E

L

C

C

C

A

B

D

G

F

H

Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Note: After changing a filter, close the 3/8 three way manifold “L” to the combi and flush the system for 5 minutes. After 5 minutes open the

3/8 three way manifold “L”.

1. Isolate from power supply

2. Unplug

3. Turn off water supply to the RO

4. Close the 3/8 three way manifold “L” to the combi

5. Unscrew the filter to be replaced

6. Replace with new filter

7. Screw new filter into position

2 3 4

1

OFF

57

6

LOOSEN TIGHTEN

4.1.2 Filter Replacement (for 1st, 2nd and 5th Stage)

4.0 Maintenance

4.1 Filters

4.1.1 Filter Life

Note: The life of the cartridges depend on the water volume used and the substances in the water. The following is a general guide.

Part No. Filter Stage Description Replacement

SPWA.PFG82 1st Stage FG82 - 5 Micron High Capacity 6 - 12 Months / 12,000 L

SPWA.PFG92 2nd Stage FG92 - 5 Micron Carbon Block 6 - 12 Months / 12,000 L

SPWA.PFRO 3rd Stage 600GPD RO Membrane x 2 12 - 24 Months

SPWA.PFG92 4th Stage FG92 - 5 Micron Carbon Block 6 - 12 Months / 12,000 L

Replacement cartridge part numbers for Re-Ordering through appliance dealer or Stoddart customer service.

Page 10

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

4.1.3 RO Membrane Replacement

4.0 Maintenance

Note: After changing the RO membrane, close the 3/8 three way manifold “L” to the combi and flush the system for 5 minutes. After 5 minutes

open the 3/8 three way manifold “L”.

1. Unscrew and remove the top cover

2. Unscrew and remove the back cover

3. Pull the RO housing out of the bracket

4. Remove the PE tubes

5. Using the supplied tool unscrew the RO housing cap

6. Using pliers remove the RO membrane. Once removed clean the housing

7. Place the new RO membrane into the housing

8. Re-install the RO housing cap and tighten using the supplied tool

9. Reconnect the PE tubes

10. Push the RO housing back into the bracket

11. Re-install the back cover

12. Re-install the top cover

1 2 3 4

5 6 7 8

9 10 11 12

Page 11

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

4.2 Troubleshooting

4.0 Maintenance

Problem Possible Cause Solution

Pump not working

No power supply Check the power supply

Transformer is burnt out

Replace transformer

(A possible reason is a pump leak causing the bearing to jam, so the

transformer burns out. The pump and the transformer should be checked at

the same time)

Pump bearing jammed Replace pump

Bad wire connection Check wire connection

Bad electrical connection inside pump Replace pump

High / low pressure switch is damaged Replace high/ low pressure switch

Pump switches on and off

repeatedly

Low pressure switch switches on and off repeatedly because of

low feed water pressure

Increase feed water pressure. (If you are sure of a consistent feed water

pressure, a short circuit around the low pressure switch could be made)

Bad electrical connection inside pump Replace pump

Bad wire connection Check all wire connection

Pump keeps running

Air in the tubes causes the pump to not reach sufficient pressure

to shut off the pump

Disconnect the outlet tube of the pump to discharge air and reconnect to

run with water in the tube

The torque of the pump has decreased, so sufficient pressure

cannot be reached to turn off the high pressure switch

Replace pump

High pressure switch is damaged Replace high pressure switch

The check valve cannot close properly, thus pressure cannot reach

shut off point

Replace check valve

Pump is leaking

Diaphragm seal is worn or split Replace pump

Feed water pressure is too high (> 40psi) Install a pressure regulator or shut off pump to allow the system to run at

natural feed water pressure

Pump is noisy RO membrane or post is clogged Replace RO membrane or post filter

Pump bearing is worn Replace pump

TDS value of permeated

water is rising (rejection

rate is lower than 90%)

Working pressure is lower than 40 psi: Air in the tubes pre-vents

pump from reaching sufficient pressure to permeate properly

Disconnect the outlet tube of the pump to discharge air and reconnect to

run with water in the tube

Working pressure is lower than 40 psi: RO membrane or post filter

is clogged

Replace RO membrane or post filter

The ratio of permeate water to drain water is less than 1:3 Flow restrictor is clogged. Clean it, or replace it

RO membrane is worn Replace RO membrane

Output of permeate water

decreases

RO membrane is clogged Replace RO membrane.

(If clogging is frequent, increase the drainage ratio of the flow-restrictor or

install a softener to extend the lifespan of the RO membrane)

Pump is worn, decreasing the working pressure Replace pump

No permeate or drain water

is produced

The solenoid valve coil is burnt out Replace solenoid valve

Bad electrical connection in solenoid valve Replace solenoid valve

Solenoid valve is clogged inside, thus unable to turn on Replace solenoid valve

Shut-off valve is worn Replace shut-off valve

System drains at full tank

when pump is not running

Feed water pressure is too high to turn off the shut-off valve Install a pressure regulator

The shut-off valve or solenoid valve is clogged. Clean the valve or replace it

Check valve is worn and causes permeate water in the storage

tank to reverse flow to drain

Replace check valve

Solenoid valve is noisy

The solenoid valve coil is not in place Fix the coil in its place

Feed water pressure is too low, causing the low pressure switch

and the solenoid valve to turn on and off repeatedly

Increase inlet water pressure. (If you are sure of a consistent feed water

pressure, a short circuit around the low pressure switch could be made)

Page 12

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

4.0 Maintenance

Problem Possible Cause Solution

System does not run

High / low pressure switch is worn Replace high / low pressure switch

Feed water pressure is lower than 5 psi (If you are sure of a consistent feed water pressure, a short circuit around

the low pressure switch could be made)

No power Check power source

Pump or transformer is worn See trouble shooting for pump

System runs at full tank

when faucet is turned off

Check valve is worn and- causes permeate water in the storage

tank to reverse flow to the drain. The high pressure switch senses

pressure decrease and turns on

Replace check valve

High pressure switch is worn Replace high pressure switch

Page 13

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

Page 14

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

www.stoddart.com.au

International

Sales

Tel: +617 3440 7600

Email: [email protected]

Service / Spare Parts

Tel: +617 3440 7600

Email: [email protected]

Email: [email protected]

Service Request

www.stoddart.co.nz

New Zealand Business Number: 6837694

New Zealand

Sales

Tel: 0800 79 1954

Email: [email protected]

Service / Spare Parts

Tel: 0800 935 714

Email: [email protected]

Email: [email protected]

Service Request

www.stoddart.com.au

Australian Business Number: 16009690251

Australia

Sales

Tel: 1300 79 1954

Email: [email protected]

Service / Spare Parts

Tel: 1300 307 289

Email: [email protected]

Email: [email protected]

Service Request

Revision Date: 13/03/2023

Table of contents

Popular Water Filtration System manuals by other brands

Survivor Filter

Survivor Filter L600D Product guide

Spirotech

Spirotech SPIROVENT Installing and operating instructions

Pentek

Pentek RO-2500 Installation and operating instructions

Mitsubishi

Mitsubishi STERAPORE 5600 FF Series instruction manual

Minarik

Minarik CE24PWM installation guide

EHEIM

EHEIM 2227 manual

Grunbeck

Grunbeck GENO-OSMO-X 180 Operation manual

NTF

NTF ALH Series instruction manual

Veolia

Veolia Hydrotech Discfilter HSF 26-2F Series Operation and maintenace manual

Pond Boss

Pond Boss 52387 manual

amiad

amiad Filtomat MG110 Installation, operation and maintenance instructions

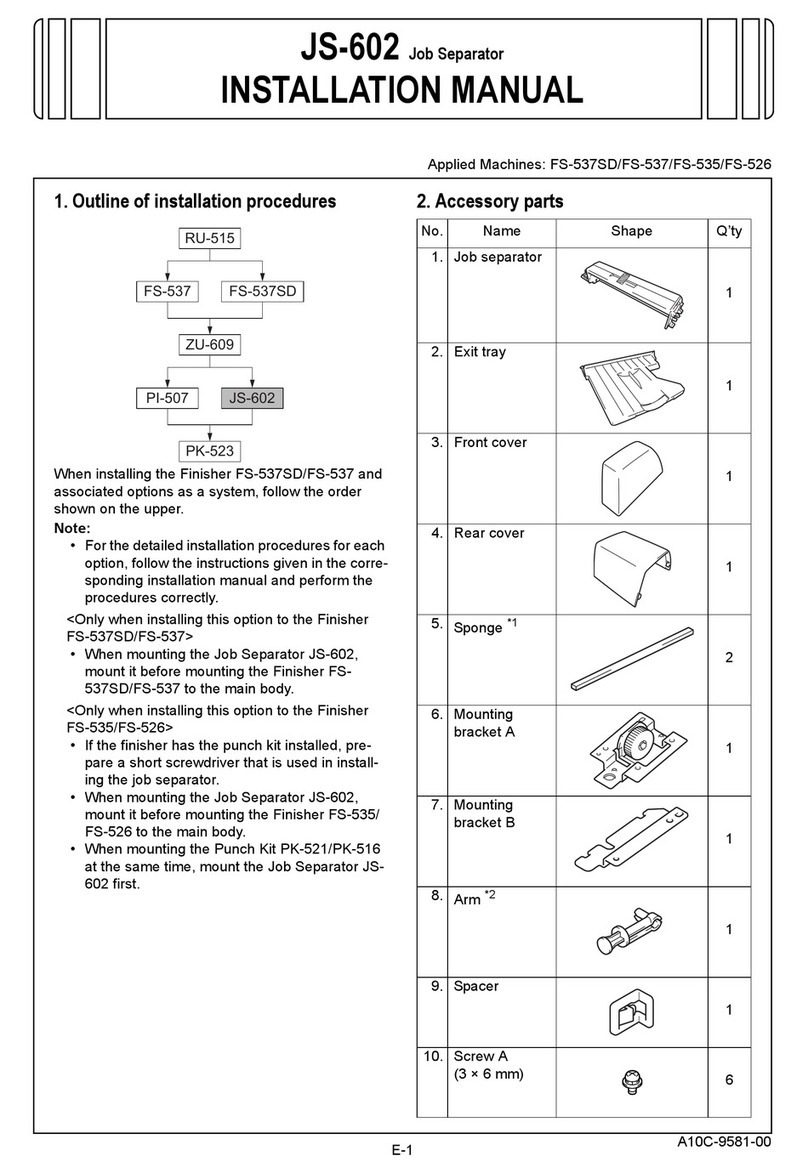

Develop

Develop JS-602 installation manual