1 - PRECAUTIONS

4

E

N

G

L

I

S

H

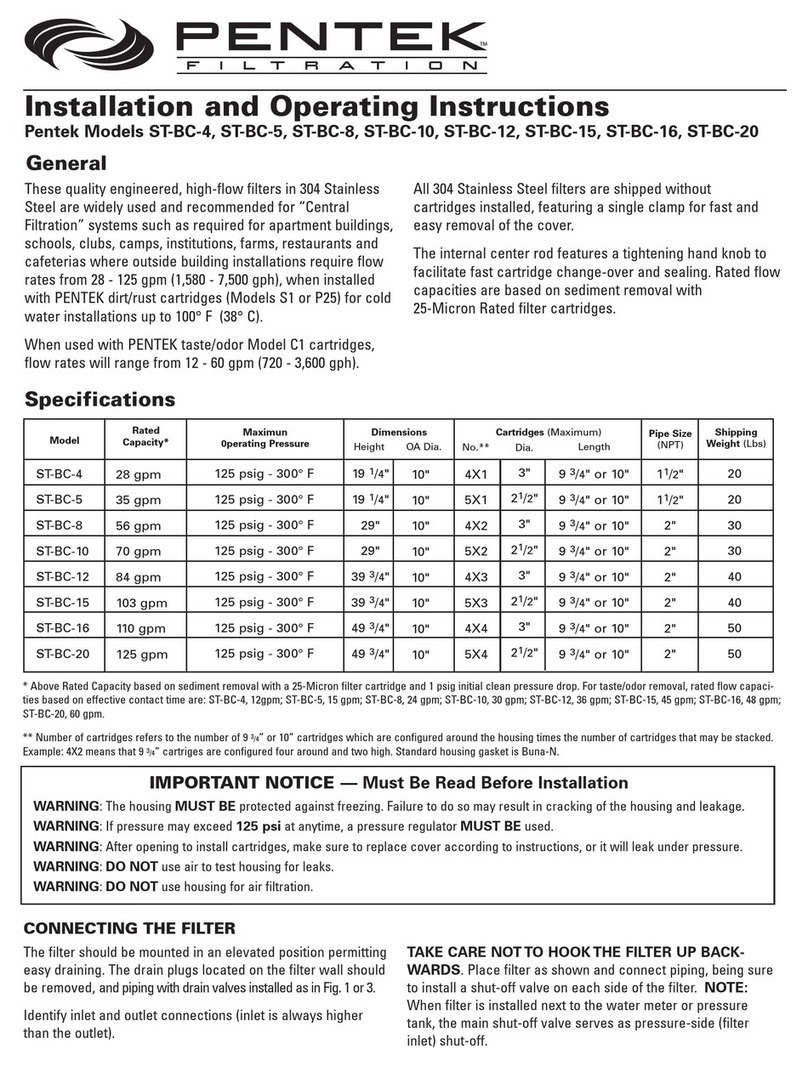

General

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system.

CAUTION: Filter must be protected against freezing, which can cause cracking of the filter and water leakage.

CAUTION: Because of the product’s limited service life and to prevent costly repairs or possible water damage,

we strongly recommend that the bottom of all plastic housings be replaced every five years for clear

and ten years for opaque. If the bottom of your housing has been in use for longer than this period,

it should be replaced immediately. Date the bottom of any new or replacement housing to indicate

the next recommended replacement date.

NOTE:

• Your water must be within required limits for satisfactory operation. If not, your membrane life may be shortened

and your warranty will be voided (see chapter “Specifications”).

• This reverse osmosis system will not protect against disease-causing bacteria or remove naturally-occurring

harmless bacteria.

• Install on cold water line only.

• Do not use wicking or sealer to fit connections into the cap of the filter. Teflon® tape is recommended.

• Make certain that installation complies with all state and local laws and regulations.

• The replacement cartridges and reverse osmosis membrane included with this system have limited service lives.

Changes in taste, odour, and colour of the water being filtered indicate that the cartridge should be replaced (see

chapters “Replacing the Pre- and Post- Filters” and “Replacing the Membrane”).

• After prolonged periods of non-use (such as during a vacation) it is recommended that the system be flushed for

5 minutes before it is used.

• A drinking water cartridge may contain carbon fines (very fine black powder). After installation, flush the

cartridge for 5 minutes to remove the carbon fines before using the water.

• It is recommended that you run the tap at least 20 seconds prior to using water for drinking or cooking purposes.

• The contaminants or other substances removed or reduced by this water treatment device are not necessarily

present in your water.

Ro membrane precautions

CAUTION: Chlorine will destroy the TFM-36 membrane. If you use the RO-2500 with a chlorinated or

periodically-chlorinated water supply, it is ABSOLUTELY NECESSARY to use a carbon pre-filter

(included with the system). This carbon pre-filter should be changed at least every 3 months to avoid

chlorine bypass. See Warranty for disclaimers and limitations that apply to the TFM-36 membrane.

NOTE:

• To make sure no chlorine is present in the water that reaches the membrane, you may want to use a chlorine test

kit to check the brine/reject water that flows from the membrane to the drain. No chlorine should be detected.

• The TFM-36 membrane is resistant to naturally-occurring bacteria.

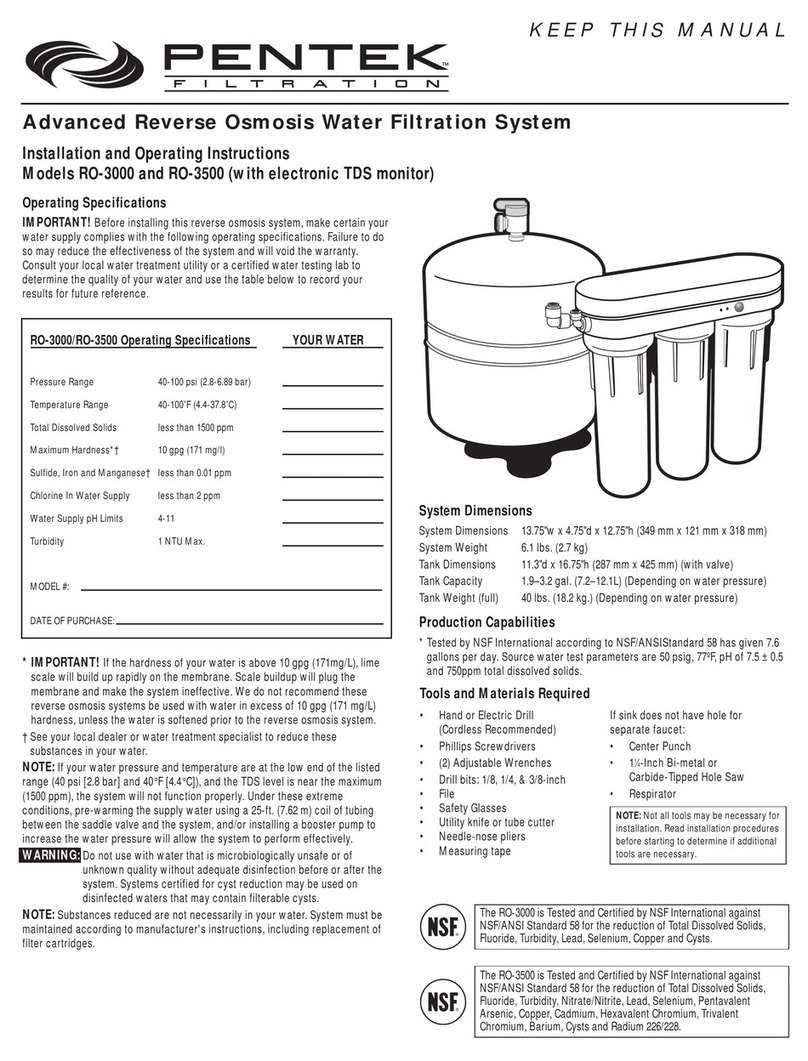

How reverse osmosis works

The RO-2500 Reverse Osmosis (RO) System uses a semi-permeable membrane to reduce dissolved salts and

minerals, improving the taste and odour of your water. The RO membrane is made of layers of micron-thin film

wound around a hollow centre core. Water molecules can pass through the membrane, but dissolved salts and

minerals are rejected.

The RO-2500 Reverse Osmosis System features 4-stage filter action. Your water supply is pre-filtered to reduce dirt

and chlorine that may foul the membrane. The RO membrane separates this pre-filtered water into PRODUCT

WATER and DRAIN or REJECT WATER. Incoming water pressure forces the product water through the membrane

and into the storage tank. Dissolved solids and other contaminants cannot pass through the membrane and are

sent to the drain as reject water. When you open the drinking water faucet, product water is drawn from the

storage tank through an activated carbon post-filter, providing you with cleaner, great-tasting water.

For each liter of water produced, several liters are discharged as reject water. The storage tank can hold up to 4.9

L (1.3 gallons) of water at a time, for drinking and cooking needs. When used under the chapter “Specifications”

of the manual, your Reverse Osmosis membranes should last 12-24 months.

Basic installation procedure guidelines

• For standard, under-sink installation on 10 mm (3/8”) steel, brass or copper cold water line.

• Please read all instructions and precautions before installing and using your RO-2500.

• Numbered diagrams correspond with numbered steps.