4

2.2SHIPMENTANDTRANSIT

Thefreezerhasbeenassembled,operatedandinspected

at the factory. Upon arrival at the final destination, the

completefreezermustbecheckedforanydamagewhich

mayhaveoccurredduringtransit.

With the method of packaging used, the freezer should

arriveinexcellentcondition.THECARRIERISRESPON-

SIBLE FOR ALL DAMAGE IN TRANSIT, WHETHER

VISIBLEORCONCEALED.Donotpaythefreightbilluntil

thefreezerhasbeencheckedfordamage.Havethecarrier

note any visible damage on the freight bill. If concealed

damageand/orshortageisfoundlater,advisethecarrier

within10daysandrequestinspection.Thecustomermust

place claim for damages and/or shortages in shipment

withthecarrier.Stoelting,Inc.cannotmakeanyclaims

against the carrier.

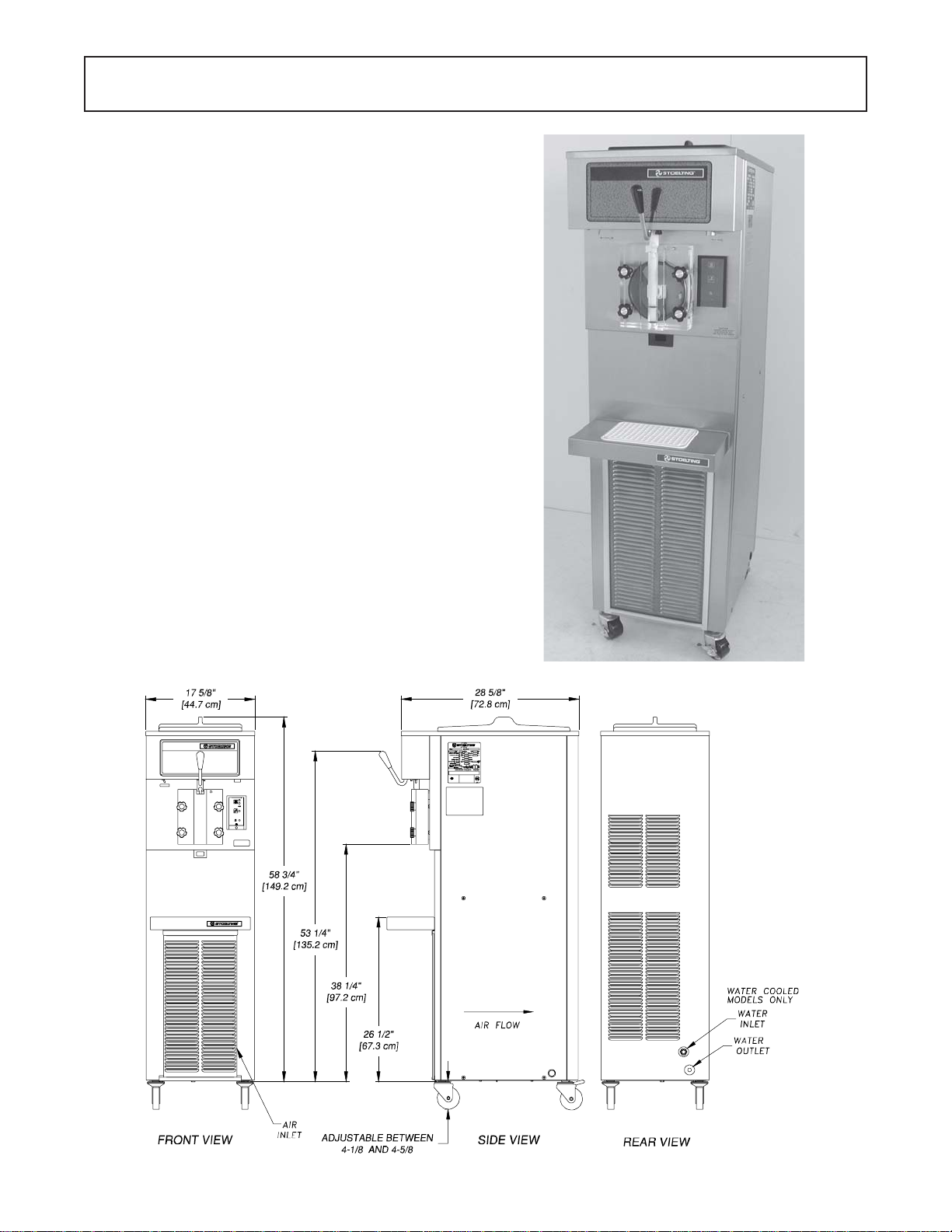

2.3FREEZERINSTALLATION

Installationofthefreezerinvolvesmovingthefreezerclose

to its permanent location, removing all crating, setting in

place,assembling parts,and cleaning.

A. Uncratethefreezer.

B. Accuratelevelingisnecessaryforcorrectdrainage

offreezerbarrelandtoinsurecorrectoverrun.Place

a spirit level on top of the freezer at each corner to

checkforlevelcondition.Ifadjustmentisnecessary,

level the freezer by turning the caster in or out and

tighten the locknut. (Fig. 4).

Figure 7. Installing Tray and Cover

Figure 4. Leveling

C. Thefreezerisequippedwithanaircooledcondenser

andrequirescorrectventilation.Thefrontofthe

freezeristheairintakeandtheback discharge. Both

front and back must have a minimum of 3" of

clearance.(Fig.5).

CAUTION

FAILURE TOPROVIDEADEQUATEVENTILATION

WILL VOID WARRANTY!

D. PlacetheOFF-ONswitchintheOFFposition.(Fig.10).

Figure 5. Space and Ventilation Requirements

E. Connectthepowercord.Theplugisdesignedfor208

or230volt/20ampduty.Checkthenameplateonyour

freezerforpropersupply.Theunitmustbeconnected

toaproperlygroundedreceptacle.Theelectricalcord

furnishedaspartof the freezerhasathree prong

groundingtypeplug(Fig.6).Theuseofanextension

cord is not recommended, if necessary use one with

asize12gaugeorheavierwithgroundwire.Donotuse

anadaptertogetaroundgroundingrequirement.

CAUTION

DONOTALTERORDEFORMPLUGINANYWAY!

F. Installthedriptray,draintray,hoppercoverandother

miscellaneous parts on the freezer. (Fig. 7).

Figure 6. Electrical Plug