3

WARNING: DO NOT USE LEGS FOR AN

INDOOR INSTALLATION. IN

THIS INSTALLATION, THE

VOID BELOW THE FIREBOX

COULD INADVERTANTLY BE

USED FOR STORAGE OF

COMBUSTIBLE MATERIALS,

WHICH COULD CREATE A

FIRE HAZARD.

Select a high temperature fire clay or refractory

cement and mix according to manufacturer’s

instructions. Several companies in the U.S. and

Canada sell refractory cement or fire clay including

Stone Age Manufacturing.

Once the fireplace is constructed you must wait at

least 28 days before building a fire to give the

cement adequate time to cure. This will provide

ample time for any water residue to evaporate,

eliminating the adverse reaction of the combination

of water and fire.

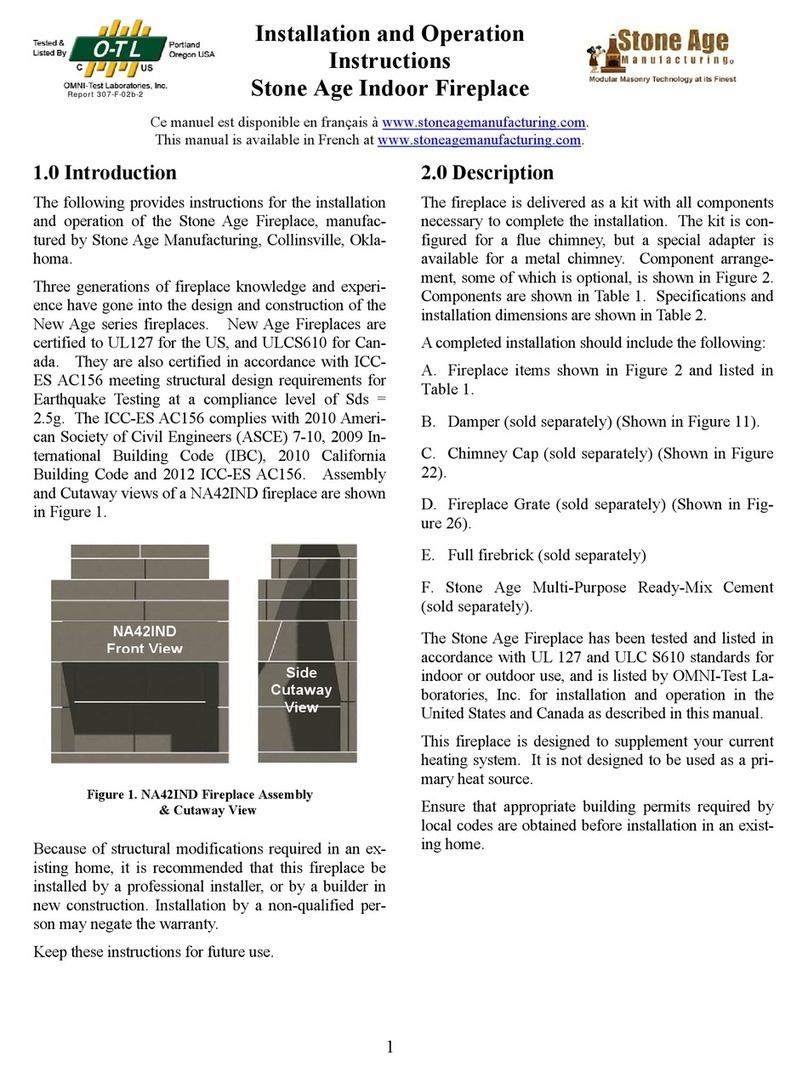

3.2 Assembly of Components

A. When the base is level and square, set the

baseplate (2). Level it from side to side and

front to back.

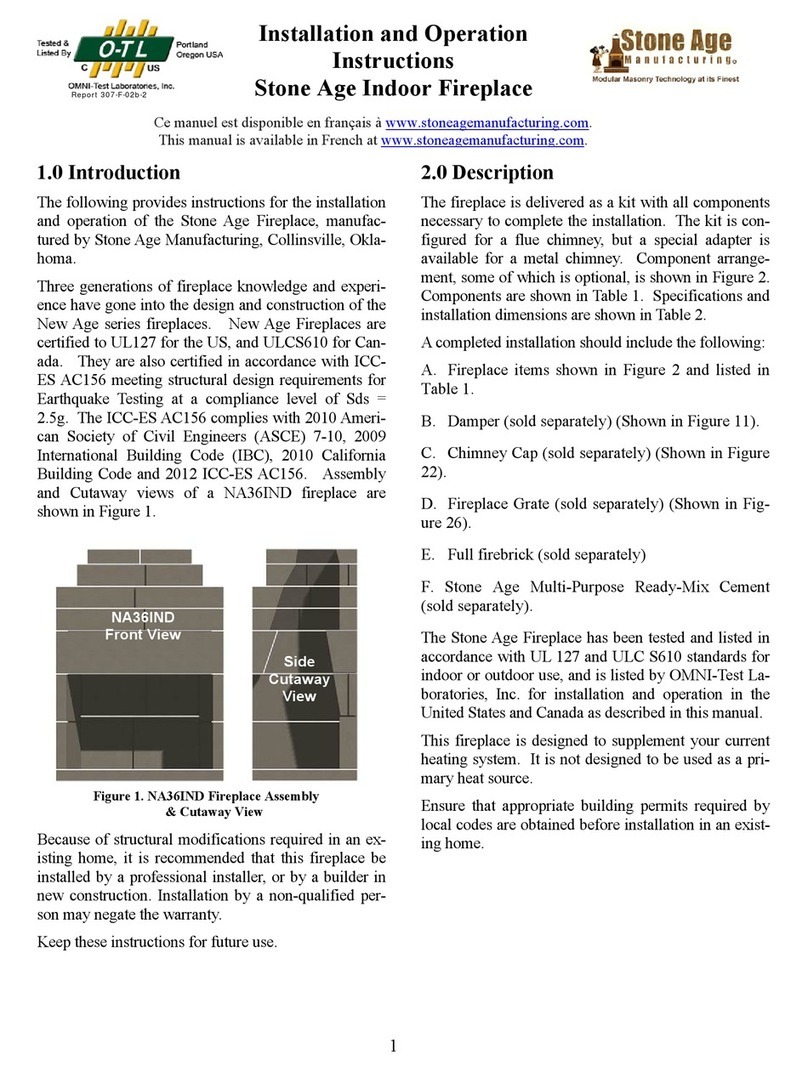

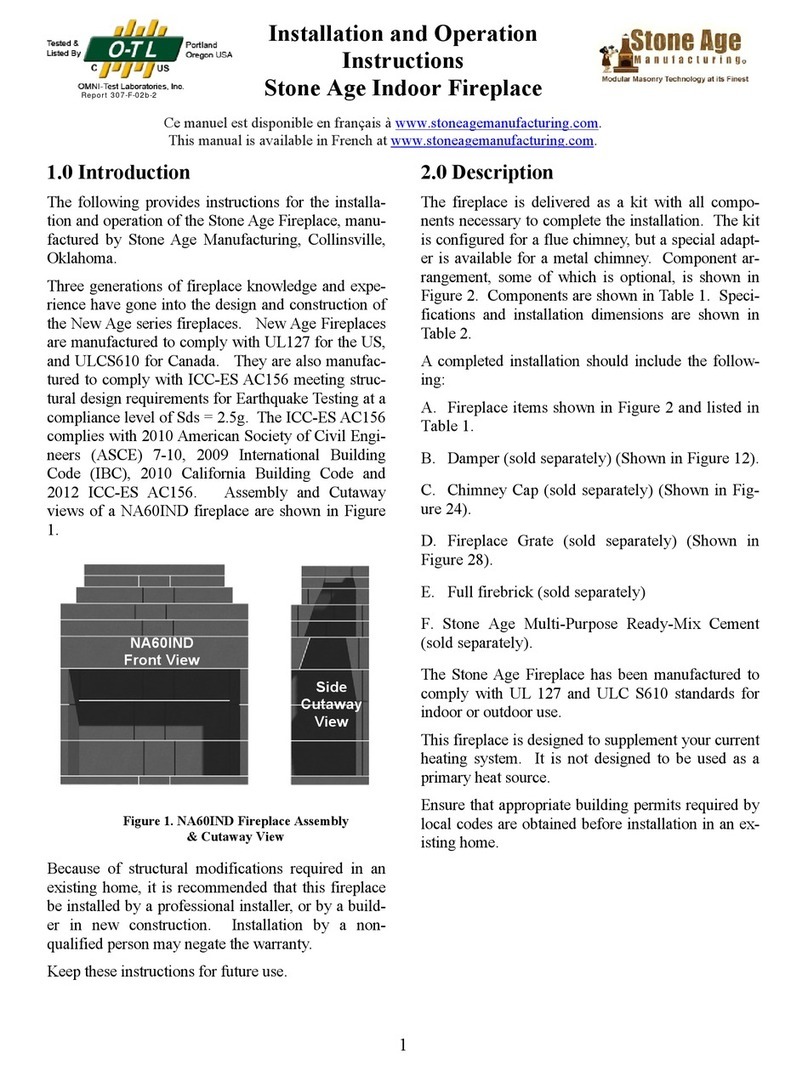

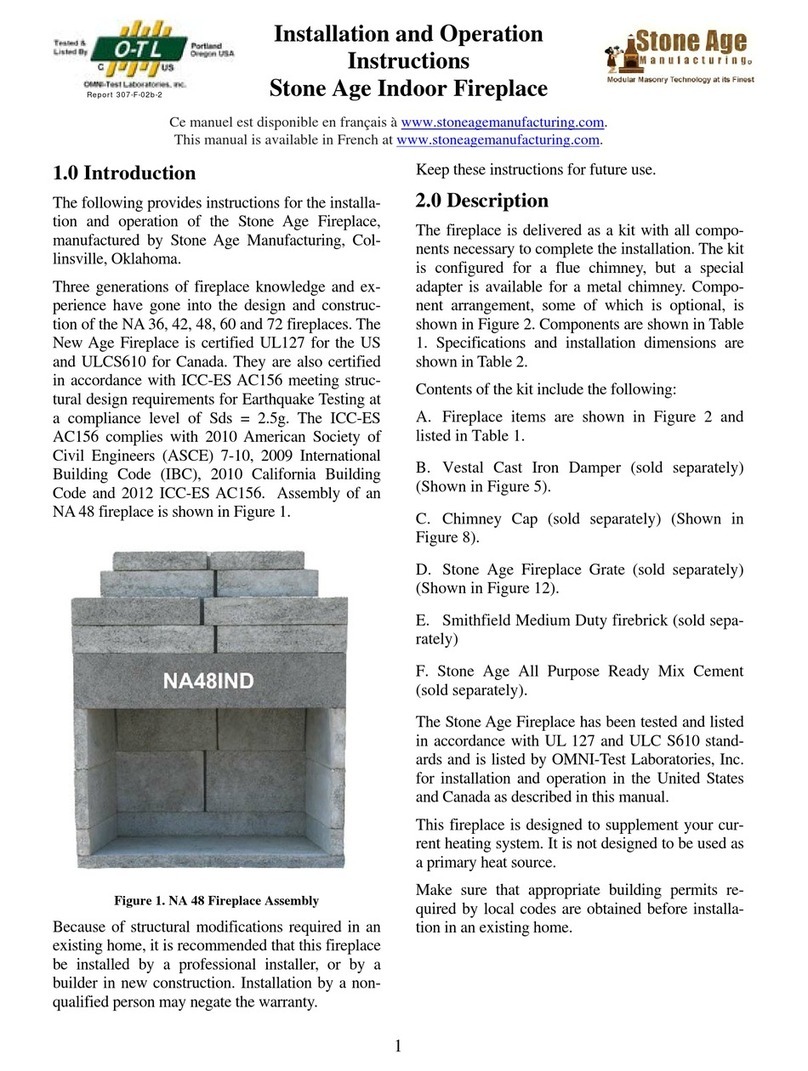

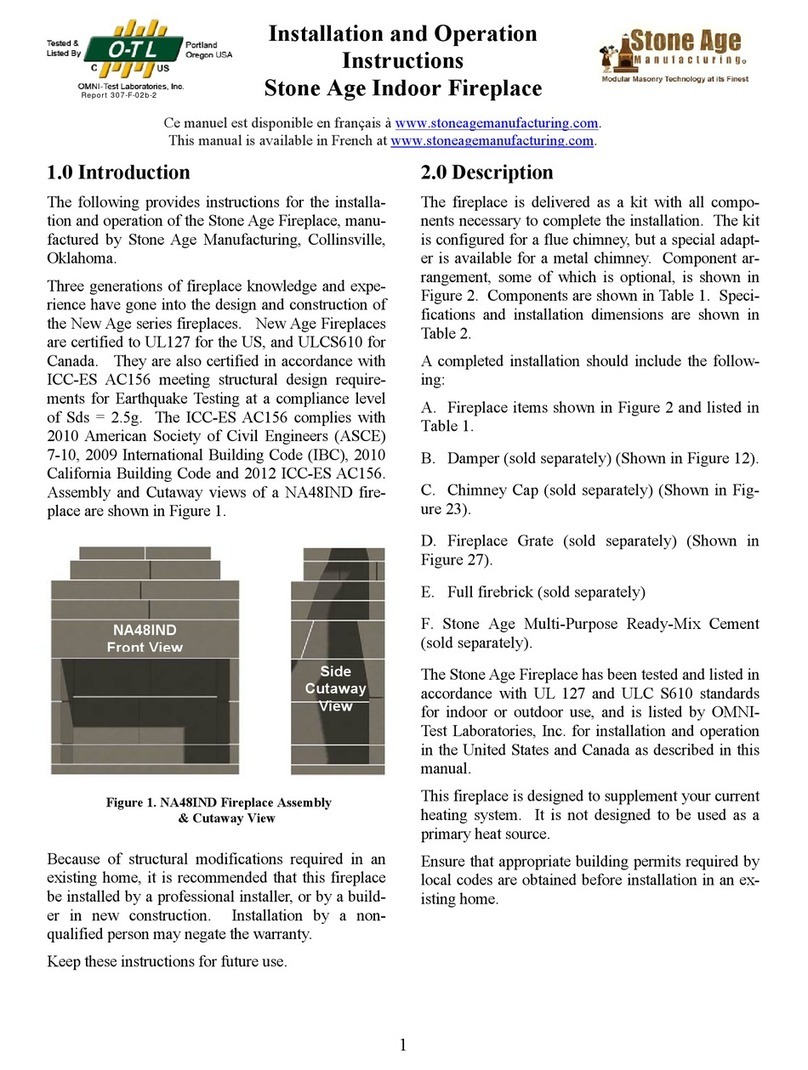

B. As shown in Figure 1, install the four sidewall

pieces (3) and the back header (6). Use one-

half inch of mortar between each section.

Smooth out mortar and make sure sections

remain level.

C. After installation of the back header (6), install

the firebrick inside the firebox. Line the floor,

then the back and then the sides. Apply

approximately ¼ to ½ -inch thick layer cement

to the back of the brick, and approximately 1/4

–inch mortar joint around the brick.

D. Continue with the installation with front

header, throat and flue (7, 8 and 9). The front

header (7) can be arched or straight. Add as

many flue sections (9) to reach desired

chimney height.

E. If installing the SA 48-inch fireplace, install

the throat-to-flue adapter, item 11, shown in

Figure 2 and listed as item 11 in Table 2. It is

installed between items 8 and 9.

F. If installing a mantel and side trim, especially if

it is wood or other combustible materials,

make sure the minimum distances shown in

Table 2 are met.

G. Install the hearth (10). You are now ready to

install the exterior.

3.3 Installation of Additional Equipment

A decorative gas appliance (gas log) may be

installed in this fireplace if it meets the following

requirements.

A.A hole may be cut or drilled in the side, floor or

back wall to install piping for a gas supply.

B. The gas log must have an automatic shutoff

device.

C. Installation must comply with the Standard for

Decorative Gas Appliances for Installation in

Vented Fireplaces, ANSI Z21.60 (1991) or

American Gas Association draft requirements

for Gas-Fired Log Lighters for Wood Burning

Fireplaces, Draft No. 4 dated August, 1993.

D. It must also be installed in accordance with the

National Gas Fire Code, ANSI Z223.1.

3.4 Exterior finishing

The exterior finish may be either fabricated stone,

thin veneer or full bed depth natural stone, stain,

tile, brick, stucco or any material that is compatible

with concrete or masonry.

If exterior finish is going to be stucco, stain, tile or

manufactured thin stone, wrap outside of firebox

with metal lathe. Attach lathe to fireplace using

concrete nails or tapcons. Full bed depth or thin

veneer natural stone, full size brick, concrete

pavers or CMU block etc. do not require metal

lathe.

Make sure same refractory mortar is used.

4.0 Installation of Chimney

The chimney is completed by stacking as many

flue sections (9) as necessary to reach chimney

height. Chimney plumbing can either be straight

through the ceiling and through the roof, or if the

fireplace is installed on an outside wall, the

chimney can be external to the house.

WARNING: THIS FIREPLACE HAS NOT

BEEN TESTED FOR USE

WITH GLASS DOORS. TO

REDUCE THE RISK OF FIRE