StoneAge Big Pig User manual

1

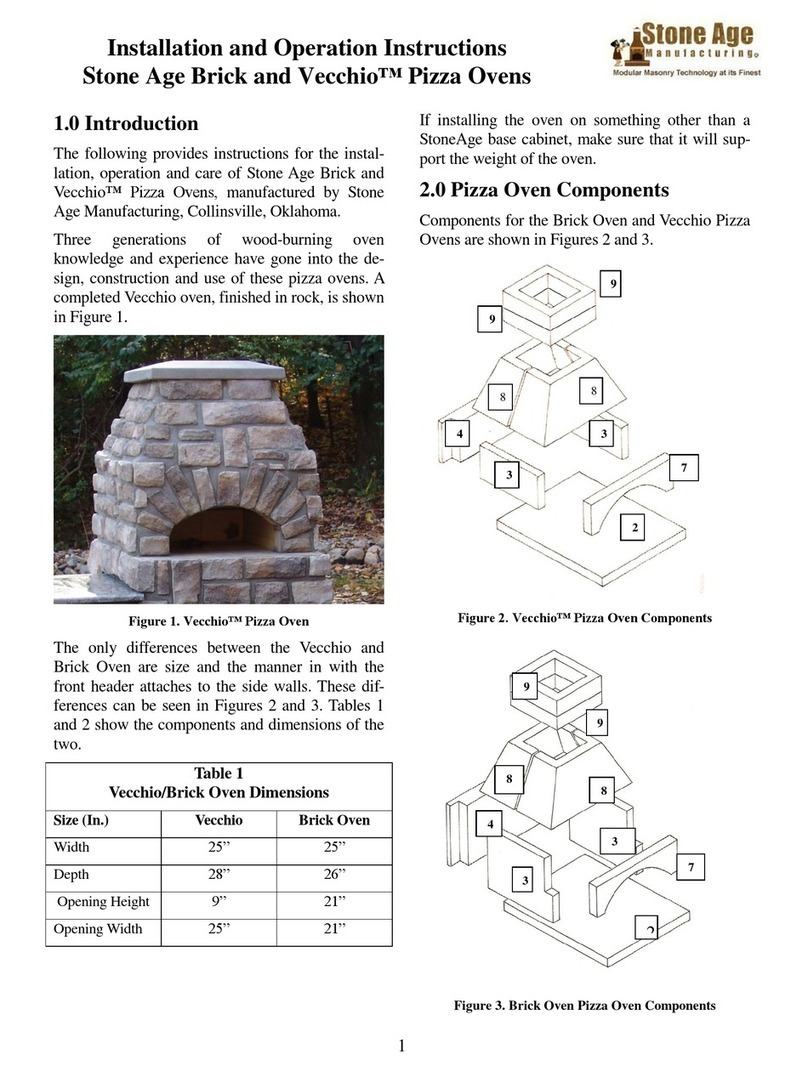

Installation and Operation Instructions

Stone Age Big Pig™ and Little Pig™ Smoker Ovens

1.0 Introduction

The following provides instructions for the installa-

tion and operation care of Stone Age Big Pig™ and

Little Pig™ (SA-SM-BP8 and SA-SM-LP6)

Smoker Ovens, manufactured by Stone Age Manu-

facturing, Collinsville, Oklahoma.

Three generations of wood-burning masonry con-

struction experience have gone into the design and

construction of these smoker oven kits. A com-

pleted Little Pig oven, finished in natural stone, is

shown in Figure 1.

Stone Age smokers are unique in that they are the

only masonry/metal smoker units which can be

covered in the same masonry finish material as the

rest of your outdoor kitchen.

Figure 1. Little Pig™ Smoker Oven

The key differences between the Big Pig™ and

Little Pig™ ovens are their size and weight. Table

1 shows the weights of the two Smokers.

Table 1. Smoker Weights (lbs)

Big Pig™ Little Pig™

Refractory Kit

Weight 2,850 2,600

Metal Smoker

Insert 700 500

Complete Kit 3,550 3,100

Note: Weights do not include footing platform or

exterior finish

2.0 Installation

Smokers are offered as kits or assembled with

stone or brick veneer finishes. Kit weights are

listed in Table 1.

If your smoker is received in kit form, it will arrive

on two pallets, one containing the metal frame and

the other containing the outer wall components,

shown in Figure 2.

Metal Frame Outer Wall Components

Figure 2. Smoker Kit

Smoker assembly and installation is not specifical-

ly designed as a “do-it-yourself” project. This is

2

primarily because of component weight (see Table

1) and the care required when applying mortar.

However, it can be done if one has the necessary

weight lifting equipment, and can use a mortaring

trowel. We recommend that you contract with a

professional rock/brick mason to install and finish

your installation.

2.1 Site Selection and Preparation

Consult local building codes before selecting a site,

as local code may prescribe specific minimum

clearances to a combustible structure. In such case,

follow local code if it is more stringent than the

factory recommendations.

Select a location at least 8 feet away horizontally

from any combustible materials, i.e., outside wall,

trellis, etc. If the smoker will be built under a

combustible covered area or structure, ensure the

area is open enough to allow smoke to dissipate

when the unit is in operation, and that the struc-

ture is open on at least 3 sides, with a minimum of

6’ clearance to combustibles overhead.

Site preparation should include pouring a rein-

forced concrete footing for placement of the unit.

Depth of the footing and specific reinforcement

requirements, such as piering, should be deter-

mined based on size and weight of the unit, finish

material to be applied, soil stability and building

customs. Table 2 provides minimum guidelines.

Table 2. Minimum Footing Requirements (in.)

Finish Front

(in.) Side

(in.) Depth

(in.)

Thin: Fabricated

stone, stucco, stain or

tile 43 37 8-10

Thicker: Full veneer,

natural stone or brick 48 43 18-24

2.2 Smoker Assembly

A. After the footing has cured, set the base plate,

checking for level, and square it with the footing,

shown in Figure 3. Use high quality refractory

cement such as Stone Age Multi-Purpose Ready-

Mix for construction of the smoker kit.

Figure 3. Set the Base Plate

B. Align the metal framework, centering it from

side to side as shown in Figure 4.

Figure 4. Center Framework Side to Side

C. Position the front of the frame with a 1 ½-inch

overhang from the base plate to expose the

expansion channel for stone/brick finish, as

shown in Figure 5.

Figure 5. Provide Overhang at the Front

D. Install firebrick floor inside of the metal

framework. Start at the front edge and cover the

entire floor. Use refractory cement to adhere the

1 ½” Overhan

g

3

bricks to each other and to the base plate. See

Figure 6. Use level to make sure floor is even.

Figure 6. Lay Floor

E. After the floor is completed, brick the side and

back walls to the bottom of the moisture chamber

by laying the bricks on their side, as shown in

Figure 7. Four layers of brick are required.

Figure 7. Install Brick Walls

F. When this part (firebox) is completed, it will

look like Figure 8, looking from the back.

Figure 8. Firebox Completed

G. Begin outer wall construction. Start with the

larger, 2-piece L-shaped sections to create the

first layer, and then alternate with the smaller, 3-

piece sections, as shown in Figure 9. Install on

3/8”- inch bed of mortar with the components

mortared together.

Figure 9. Outer Wall Components

H. Installed, the components will look like Figure

10. Alternate layers until all pieces are used.

Note that mortar is not applied between the lower

layers and the firebrick in the firebox area, and

there will be a small gap, creating an airspace be-

tween the firebrick and the outer walls.

First Layer

Second La

y

er

4

Figure 10. Outer Wall Components Installed

I. Add the roof section as shown in Figure 11.

Note that the opening for the chimney flue will be

to the rear of the oven.

Figure 11. Add Roof Section

J. Add the chimney kit assembly, as shown in

Figure 12.

Figure 12. Add Chimney Section

You are now ready for exterior finishing. Note that

the channel around the metal front allows the finish

material, stone or thin brick, to run behind the main

frame edge, permitting a clean finish. If using stuc-

co, fill in the channel with mortar and finish. Refer

to Figure 5 on page 2.

In order to reduce the possibility of moisture

saturation, it is recommended that the oven be

treated with a water sealer after completion of the

exterior. Always finish the smoker with a chim-

ney cap.

3.0 Safety

Working around an oven that can operate at tem-

peratures up to 500°F can be dangerous if proper

tools and clothing are not used. Also, combustible

materials in the vicinity of the oven may be at risk

of fire.

WARNING: When working around a smoker

oven, make sure that proper

clothing is worn and proper tools

are used. Make sure that com-

bustible materials not necessary

for operation of the oven are

kept away from the oven.

3.1 Clothing

A. It is advisable that long-sleeved shirts be

worn when inserting and removing items in-

to/from the oven.

B. Use a non-combustible oven mitt when stok-

ing and adding wood to the fire.

5

C. Use the non-combustible mitt when inserting

and removing items from the oven.

4.0 Building a Fire

Familiarize yourself with the main sections of the

Stone Age smoker before operation, as shown in

Figure 13. Each section has a separate door, with

the firebox at the bottom, the drip shelf in the mid-

dle area, and the smoking chamber in the upper

area of the unit.

The owner should wait a minimum of 28 days after

construction is completed to build the first fire. It is

important that all moisture be gone from the smok-

er oven before the first fire is laid. After that, the

first three fires should be small to gently season

and break in the smoker.

WARNING: Do not start a fire in a unit that

has been exposed to excessive

moisture.

To protect from moisture, keep the smoker doors

closed when the oven is not in use.

4.1 Selection of Wood

Any cured wood that is suitable for smoking meats

can be used in the Little Pig and Big Pig Smokers.

Hickory, pecan and mesquite wood are good. Oak

is good for heating ovens and generating a bed of

coals. Flavored wood such as apple and cherry

fruitwoods, soaked in water, can be used for smok-

ing when the cooking starts.

Charcoal and natural lump charcoal are also an

option for smoking along with fruitwood chips for

flavor.

Avoid use of green uncured wood as it will have a

much stronger smoke flavor which can be over-

bearing, and will produce more soot and oils.

Caution: Do not use paper, trash, synthetic logs,

or wood treated with petroleum or other

chemicals. Do not use accelerants such

as charcoal lighter fluid or other fuels

with the smoker.

4.2 Starting and Keeping a Fire

It takes time and experience to learn the nature of a

wood-fired smoker oven. There are a lot of varia-

bles affecting cooking such as type and quantity of

wood, ambient temperature, size of oven and the

dish.

5.0 Smoking

Little Pig and Big Pig Smokers have a large ca-

pacity for smoking. The Big Pig has five shelves

and the Little Pig three. Figure 14 shows the large

amount and variety of meats that can be smoked at

the same time, even with two of the shelves re-

moved.

Figure 13. Main Section Layout

(Outer Walls omitted for clarity)

Figure 14. Multiple Cooking Shelves Showing

Sunday Afternoon Dinner

Firebox

Drip Shelf

Smoking

Chamber

Rear View Front View

This manual suits for next models

1

Table of contents

Other StoneAge Oven manuals

Popular Oven manuals by other brands

Brandt

Brandt FC 222 user manual

aumate

aumate TOA20M04N-1E instruction manual

Maytag

Maytag CWE4100AC - 24" Single Electric Wall Oven Dimension Guide

Kernau

Kernau KBO 1076 S PT B instruction manual

Bosch

Bosch HB 37 N Series User manual and installation instructions

Electrolux

Electrolux EOD5420AA user manual