StoneAge RPT-P8 User manual

RAPTOR

SELF ROTARY SWIVELS

(RPT-P8, RPT-MP9, RPT-M24)

USER MANUAL

PL 543 REV A

(01/2019)

2866-795-1586 • WWW.STONEAGETOOLS.COM

TABLE OF CONTENTS

This manual must be used in accordance with all applicable national laws. The manual shall be

regarded as a part of the machine and shall be kept for reference until the nal dismantling of the

machine, as dened by applicable national law(s). Updated manuals can be downloaded at:

https://www.stoneagetools.com/manuals

MANUFACTURER’S INFORMATION ...........................................................3

SPECIFICATIONS FOR ALL MODELS .....................................................3

KEY FEATURES FOR ALL MODELS .......................................................3

TOOL DESCRIPTION AND INTENDED USE ...............................................3

WARNING AND SAFETY INSTRUCTIONS .....................................................4

RAPTOR (RPT-P8, RPT-MP9, AND RPT-M24) .................................................5

TOOL CONFIGURATION...................................................................5

NOZZLE AND PLUG LOCATIONS .........................................................6

OPERATION ...............................................................................7

TROUBLESHOOTING .....................................................................8

TOOL SERVICE INFORMATION ...........................................................9

FLUID REPLACEMENT ....................................................................9

HIGH PRESSURE SEAL REPLACEMENT..................................................10

DISASSEMBLY ............................................................................11

ASSEMBLY ................................................................................13

PART NAMES/NUMBERS .................................................................17

MAINTENANCE KITS ......................................................................17

RAPTOR ACCESSORIES .......................................................................18

TERMS AND CONDITIONS AND WARRANTY .................................................20

3

866-795-1586 • WWW.STONEAGETOOLS.COM

MANUFACTURER’S INFORMATION

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge Europe

Unit 2, Britannia Business Centre

Britannia Way

Malvern WR14 1GZ

United Kingdom

Phone: +44 (0) 1684 892065

DESCRIPTION OF EQUIPMENT

AND INTENDED USE

The Raptor self-rotating pipe cleaning tool is ideal

for cleaning process drains, totes, closed head

drums, water well screens, ducts and exhaust

stacks.

The Raptor handles ows up to 60 gpm to cut

through heavy deposits in pipes as small as 2.25

inches (57 mm) in diameter. Combined with a

centralizer, it cleans pipes as large as 12 inches (305

mm).

FEATURES

• Wide operating range- Better match your pump

capacity for more versatile cleaning capabilities

of heavy to light deposits with one tool.

• Multiple head options- Same tool pairs with

multiple heads, saving the cost of a purchasing

a second specialized tool.

• Pulling ring option available- Clean vertical or

extra long horizontal lines, a feature not widely

available on similar tools.

• Two speed ranges- Maximize cleaning by

choosing slower speeds for hard to clean or

plugged pipes, and faster speeds for polishing

easy to clean pipes with a single tool.

• Jetting options to match the work required-

Same tool can be re-jetted to match a variety

of cleaning applications — great for when you

need more pulling force vs. forward hitting

power.

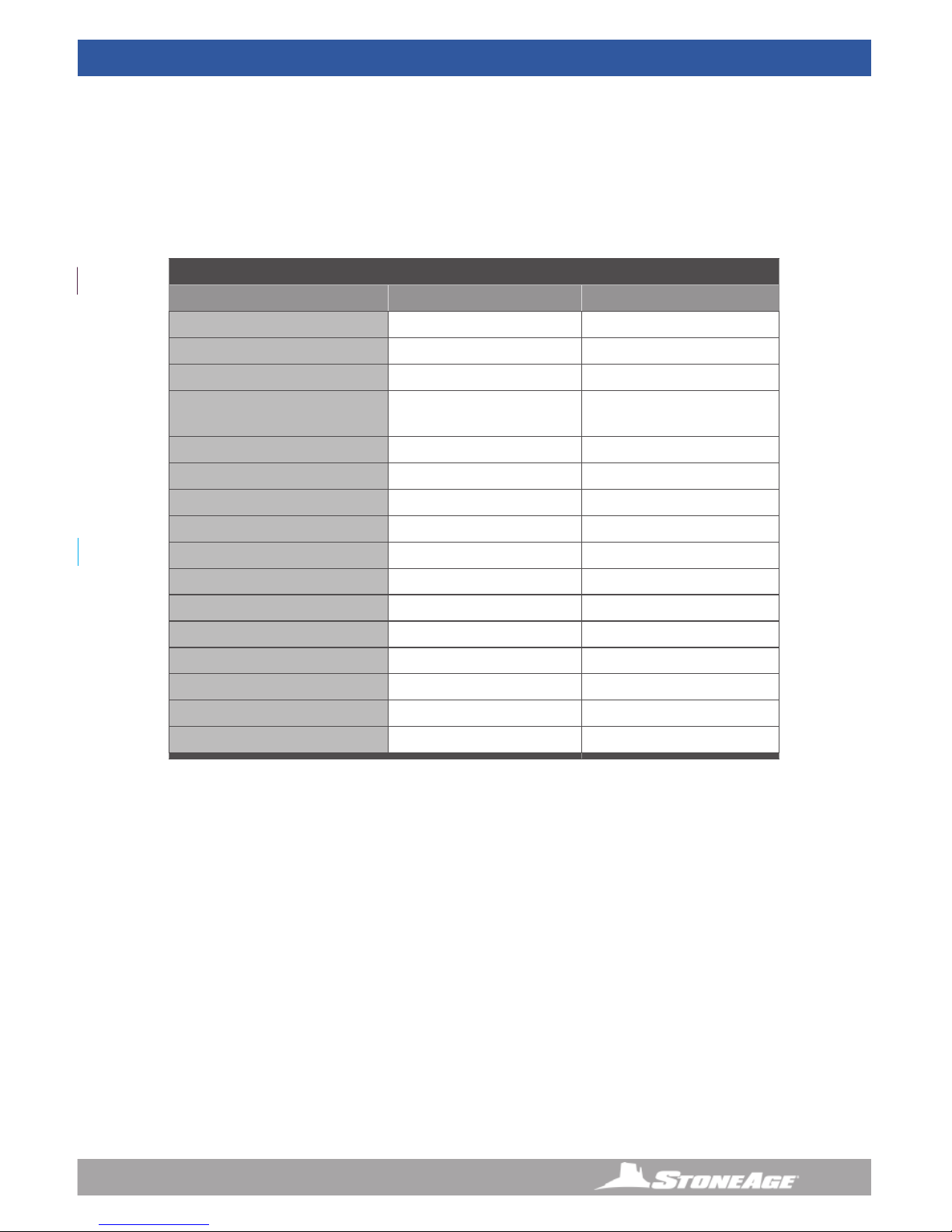

Raptor Model Specifications

Model RPT-P8 RPT-MP9/RPT-M24

Pressure Range 2–15k psi (140–1000 bar) 2–22k psi (140–1500 bar)

Flow Range 10–60 gpm (38–227 l/min) 10–60 gpm (38–227 l/min)

Flow Coefcient 2.3 Cv 2.3 Cv

Rotation Speed 15-60 rpm (Slow Fluid)

50-250 rpm (Fast Fluid)

15-60 rpm (Slow Fluid)

50-250 rpm (Fast Fluid)

Inlet Connection 1/2 NPT 9/16 MP, M24

Port Size 1/8 NPT (P2), 1/4 NPT (P4) 1/8 NPT (P2), 1/4 NPT (P4)

Extension Port Size 1/4 NPT (P4) 1/4 NPT (P4)

Nozzle Type AP2, AP4, APF4 AP2, AP4, APF4

Plug GP 025-P2SS GP 025-P2SS

Extension Plug GP 025-P4SS GP 025-P4SS

Swivel Diameter 2 in. (51 mm) 2 in. (51 mm)

Swivel Length 9.5 in. (240 mm) 9.5 in. (240 mm)

Swivel Weight 4.2 lb (1.9 kg) 4.2 lb (1.9 kg)

Head Diameter 2.0-2.5in (51-64mm) 2.0-2.5in (51-64mm)

Head Weight 1.1–2.4 lb (0.5–1.1 kg) 1.1–2.4 lb (0.5–1.1 kg)

Maximum Water Temperature 160 ºF (70 ºC) 160 ºF (70 ºC)

4866-795-1586 • WWW.STONEAGETOOLS.COM

WARNING AND SAFETY INSTRUCTIONS

WARNING

Raptor Models can turn around in large pipes and come back at the operator at a high rate of

speed. If cleaning larger pipes, a rigid “stinger” should be used between the hose and the tool. It is

recommended that the rigid length of the tool including hose end is 1-1/2 times the inside diameter of

the pipe being cleaned (see below).

Make sure there is an operator controlled dump in the system, operated by the person closest to the

cleaning job. Flush out the high pressure hoses before connecting the Raptor. It is recommended that

the hose be marked a few feet from the end with a piece of tape so the operator knows when to stop

when retracting the tool. Position the tool in the pipe opening. Close the dump and slowly bring up to

pressure the rst time to make sure no nozzles are plugged and the jet thrust is correct. The Raptor

should begin to slowly rotate. Once operating pressure is reached, feed the tool into the pipe to begin

the cleaning job. Allow the jets time to do their work by feeding the hose out at a controlled rate. The

StoneAge ABX-500 Hose Control Device can be used to achieve consistent feed rates for pipe cleaning.

When the work is complete and the tool is disconnected from the hose, blow out all water to prolong

the life of the tool. A small amount of oil can be blown into the tool as well as an added measure to

maximize tool life.

It is strongly recommended to use a backout prevention device. Please see the “Accessories”

section of this manual for a list of backout preventers available through StoneAge Tools.

DANGER

Operations with this equipment can be potentially hazardous. Caution must be exercised prior to and

during machine and water jet tool use. Please read and follow all of these instructions, in addition to

the guidelines in the WJTA Recommended Practices handbook, available online at

www.wjta.org.

Deviating from safety instructions and recommended practices can lead to severe injury and/or death.

Rigid

Stinger

IMPROPER USE:

Raptor will turn around in

large diameter pipe

VERY DANGEROUS!

PROPER USE:

Raptor with rigid “stinger”

to prevent turnaround.

1-1/2 times

pipe ID

Rigid

Stinger

5

866-795-1586 • WWW.STONEAGETOOLS.COM

TOOL CONFIGURATIONS

HEAD SELECTION

There are two standard head congurations for Raptor tools. Custom heads are available on request. The

correct head specication is based on the pressure and ow of the pump and the required port size.

The following table lists head selection approximations of common jetting scenarios.

See the next page for Head and Swivel combinations based on common pressures and ows.

7-PORT

1 @ 15º, 2 @ 45º, 1 @ 80º, 1 @ 100º,

2 @ 135º

45º

45º

15º

100º

135º

135º

80º

6-PORT

2 @ 45º, 1 @ 80º, 1 @ 100º,

2 @ 135º

45º

45º

100º

135º

135º

80º

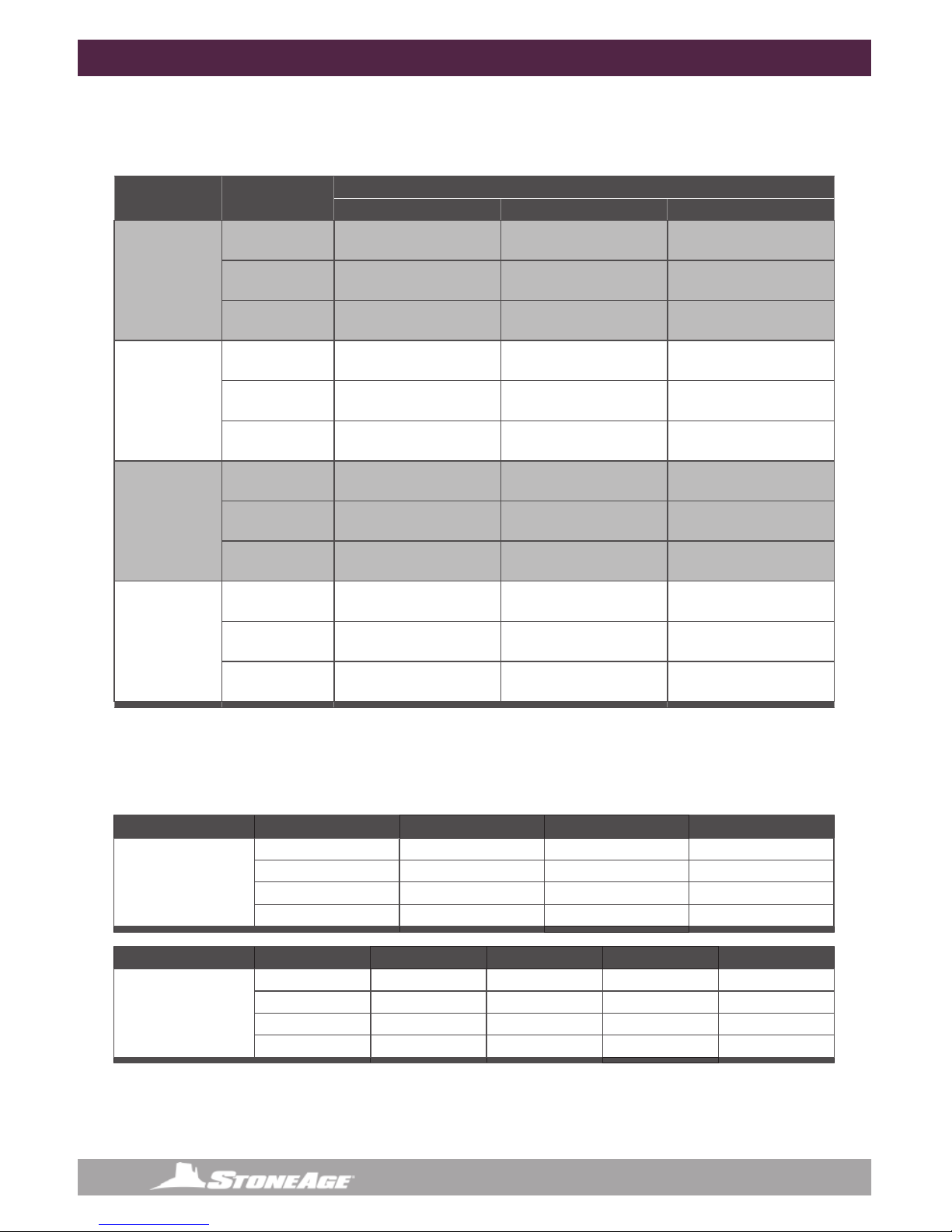

SWIVEL SELECTION

There are six Raptor swivel options available. The correct swivel is selected based on the maximum working

pressure, inlet connection and required rotation speed.

Maximum Pressure Inlet Connection Swivel Part ID Based on Rotation Speed

SLOW (15-60 rpm) FAST (50-250 rpm)

15k psi

1000 bar 1/2 NPT Female RPT-P8-S RPT-P8-F

22k psi

1500 bar

M24 Female RPT-M24-S RPT-M24-F

9/16 MP Female RPT-MP9-S RPT-MP9-F

RAPTOR TOOL CONFIGURATION

Nozzle HeadSwivelHose Adapter.

if required

6866-795-1586 • WWW.STONEAGETOOLS.COM

NOZZLES AND PLUG LOCATIONS

Raptor tool heads can be congured differently depending on the application. The thrust of the jets can be

used to pull the tool through a pipe. Little or no pull is needed for cleaning vertically downward, but more pull is

needed if cleaning horizontally or climbing upward.

The table below shows suitable nozzle/plug congurations for the Raptor tools.

Head Style 45º Port 80º Port 100º Port 135º Ports

6 Port

2 x Nozzle 1 x Nozzle 1 x Nozzle 2 x Nozzle

2 x Plug 1 x Nozzle 1 x Nozzle 2 x Nozzle

2 x Plug 1 x Nozzle 1 x Nozzle 2 x Plug

2 x Plug 1 x Plug 1 x Plug 2 x Nozzle

Head Style 15º Port 45º Port 80º Port 100º Port 135º Ports

7 Port

1 x Nozzle 2 x Nozzle 1 x Nozzle 1 x Nozzle 2 x Nozzle

1 x Nozzle 2 x Plug 1 x Nozzle 1 x Nozzle 2 x Nozzle

1 x Nozzle 2 x Nozzle 1 x Plug 1 x Plug 2 x Nozzle

1 x Nozzle 2 x Plug 1 x Plug 1 x Plug 2 x Nozzle

The nozzle sizes should be selected based on proportioning the total ow rate between the forward and

backward jets to achieve the pulling force needed, but still applying enough power to the material being

removed ahead of the tool. Use the StoneAge Jetting App to determine the nozzle sizes:

http://jetting.stoneagetools.com

NOZZLE AND PLUG LOCATIONS

RAPTOR TOOL CONFIGURATIONS CONTINUED

PLEASE NOTE: The following table lists head selection approximations of common jetting scenarios for Raptor

swivels:

Pressure Flow Head Type

6 X P2 PORTS 2” Ø 7 X P2 PORTS 2” Ø 6 X P4 PORTS 2.5” Ø

5k psi

350 bar

10–23 gpm

38–87 l/min RPT 043-P2-6-R30 RPT 043-P2-7-R30 RPT 044-P4-6-R30

16–38 gpm

60 –140 l/min RPT 043-P2-6-R18 RPT 043-P2-7-R18 RPT 044-P4-6-R18

25–60 gpm

95–230 l/min RPT 043-P2-6-R11 RPT 043-P2-7-R11 RPT 044-P4-6-R11

10k psi

700 bar

10–18 gpm

38–68 l/min RPT 043-P2-6-R30 RPT 043-P2-7-R30 RPT 044-P4-6-R30

15–31 gpm

57–120 l/min RPT 043-P2-6-R18 RPT 043-P2-7-R18 RPT 044-P4-6-R18

25–51 gpm

95 –190 l/min RPT 043-P2-6-R11 RPT 043-P2-7-R11 RPT 044-P4-6-R11

15k psi

1000 bar

10–17 gpm

38–64 l/min RPT 043-P2-6-R30 RPT 043-P2-7-R30 RPT 044-P4-6-R30

16–28 gpm

60 –110 l/m in RPT 043-P2-6-R18 RPT 043-P2-7-R18 RPT 044-P4-6-R18

26–47 gpm

98 –180 l/min RPT 043-P2-6-R11 RPT 043-P2-7-R11 RPT 044-P4-6-R11

22k psi

1500 bar

10–16 gpm

38–60 l/min RPT 043-P2-6-R30 RPT 043-P2-7-R30 RPT 044-P4-6-R30

17–26 gpm

64–100 l/min RPT 043-P2-6-R18 RPT 043-P2-7-R18 RPT 044-P4-6-R18

27–43 gpm

100–160 l/min RPT 043-P2-6-R11 RPT 043-P2-7-R11 RPT 044-P4-6-R11

7

866-795-1586 • WWW.STONEAGETOOLS.COM

OPERATION

OPERATION:

• Make sure there is an operator controlled dump in the system, operated by the person closest to

the cleaning job.

• Flush out the high pressure hoses before connecting Raptor to hose end or stinger to eliminate

debris.

• When cleaning a pipe, it is recommended that the hose be marked a few feet from the end with a

piece of tape so the operator knows when to stop on the way back out.

• When cleaning a pipe, a stinger is recommended; a stinger is a rigid piece of pipe or tubing used

between the end of the hose and the nozzle. It is typically 2 feet in length, and is primarily a safety

device for hand ex lancing. This is illustrated on the “Warning and Safety Instructions” page of

this manual.

• Position the Raptor in a tube or the pipe while the pressure is being set. The high pressure seal

may leak initially; it should stop when pressure is increased and rotation begins.

• Close the dump and slowly bring up to pressure the rst time, to make sure no nozzles are

plugged and that the jet thrust is correct. The swivel should begin to slowly rotate.

• Once operating pressure is reached, feed the tool into the tube or pipe to begin the cleaning job.

• When using rotating heads in plugged tubes, the Raptor must not be forced into the deposit, as

this may stop the rotation of the tool and impede the cutting ability. When the Raptor contacts

the deposit, allow it to cut away the material and advance at it’s own rate. If it stops advancing,

pull back slightly on the hose to pull the head slightly away from the deposit, in case it is being

stopped from rotating by the deposit. This also allows the angled jets to attack the deposit at

different places.

• When polishing tubes with scale, it is possible to allow the tool to pass through the tube at very

fast rates; unless the deposit is very easy to remove, this will not completely remove the scale.

• The operator needs to be trained to feed the Raptor through the tube at a rate sufcient to clean

the tube.

• Once the work is complete and the Raptor is disconnected from the hose, blow out all water to

prolong the life of the tool. A small amount of oil can be blown into the inlet nut as well.

8866-795-1586 • WWW.STONEAGETOOLS.COM

TROUBLESHOOTING

HIGH-PRESSURE WATER SEALS LEAK:

• The high pressure seal may leak initially at lower pressures, but should pop closed as pressure

is increased. A continuous leak at operating pressure from the weep holes indicates the need

to replace the HP Seal and Seat. HP Seals wearing out too quickly can be an indication that the

shaft bore is worn, the HP Seat in the seal assembly is installed upside-down, or the tool is over

spinning. Over spinning is caused by low or contaminated viscous uid, water in the uid chamber

(replace shaft seals), or too much jet torque. Relling the viscous uid every 40-80 hours of

operation is important for proper speed control. Only use StoneAge recommended viscous uid.

SEALS WEAR OUT TOO QUICKLY:

• The tool must be disassembled and inspected. The carbide seat should be checked for being

installed in the right direction, and it should not have any chips or erosion marks on it. The bore

of the shaft where the high pressure seal is located should be checked for grooving. If it is worn

larger than .508”, the shaft will need to be replaced.

HEAD WILL NOT ROTATE:

• First try rotating head by hand and see if it feels rough or gritty to turn. If it does, the tool must

be disassembled and repaired. If the head starts to rotate but as pressure is increased it slows

down and stops, it likely has bad bearings. If the tool feels okay, check to see if any nozzles are

plugged; even if a nozzle is only partially blocked it can keep the head from rotating. Nozzles must

be removed from the head to properly clean them; it does not do any good to poke the material

plugging the nozzle back into the head, as it will just replug a nozzle. If none of these are the

problem, the jets are too small or the head offset is not correct; refer to the above description

about the head offset and double check the nozzle sizes to make sure they are correct for the

expected ow rate.

HEAD SPINS TOO FAST:

• A signicant increase in rotation speed means that the speed control mechanism in the tool has

lost functionality. This can be a result of viscous uid loss or uid contamination. Operation of

the tool in this state can cause damage to other components and accelerated wear of the high

pressure seal. If this occurs, the rst step is to ush the tool with new viscous uid as shown in

the “Lubricant Replacement” instructions in this manual.

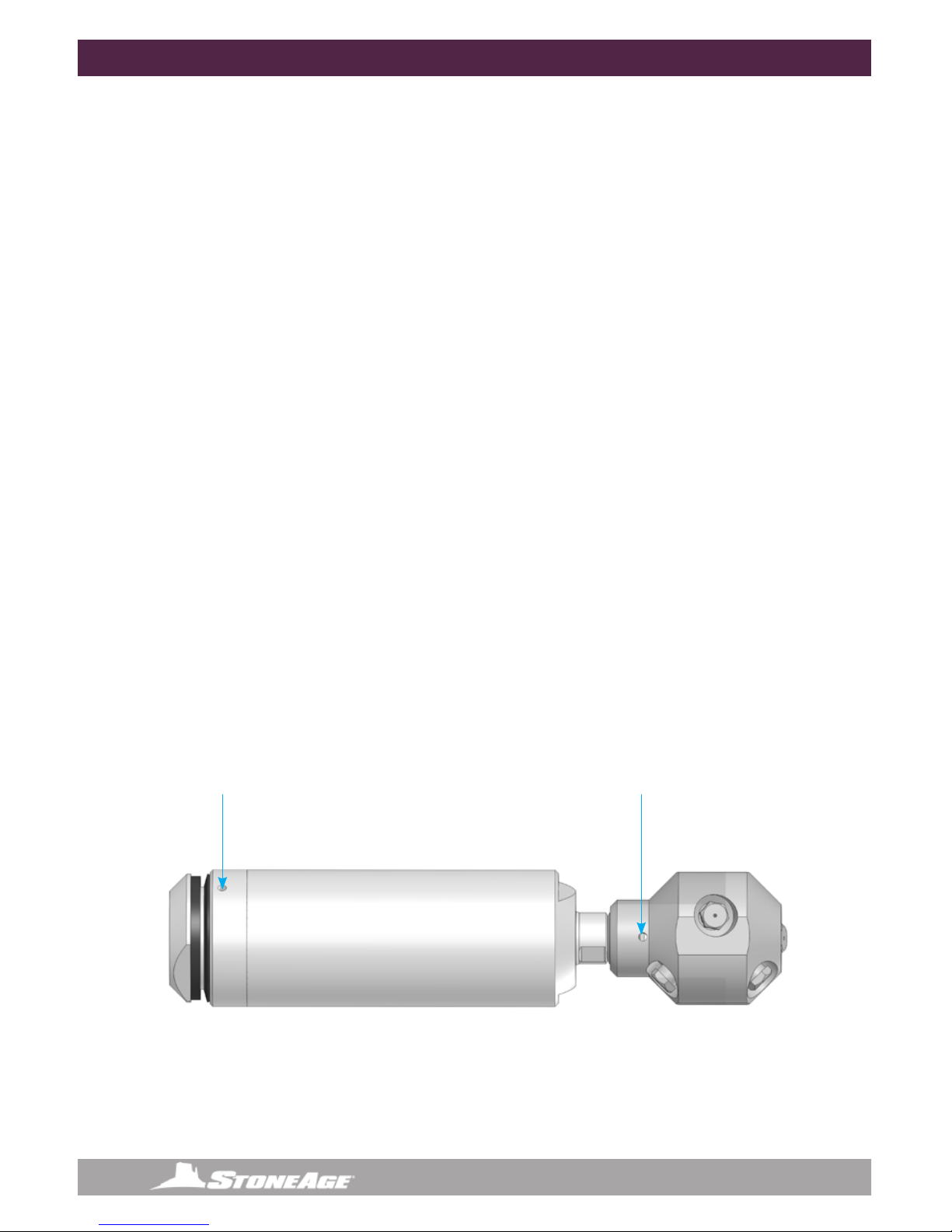

LEAKAGE FROM HERE

INDICATES WORN O-RINGS

LEAKAGE FROM HERE

INDICATES A WORN SEAL

9

866-795-1586 • WWW.STONEAGETOOLS.COM

TROUBLESHOOTING TOOL SERVICE INFORMATION

TOOL SERVICE

***Product training and proper tools are required to service this nozzle.

If you are uncomfortable performing the service, send in or bring the tool to your authorized dealer.

StoneAge provides maintenance videos for the Raptor models online.

https://www.youtube.com/watch?v=U2ABW4lcDkE

The use of a bench vice and an arbor press is recommended. Take care throughout the entire

procedure to keep the internals clean and free from grit, lint, and contamination. Failure to do so could

result in premature failure after service.

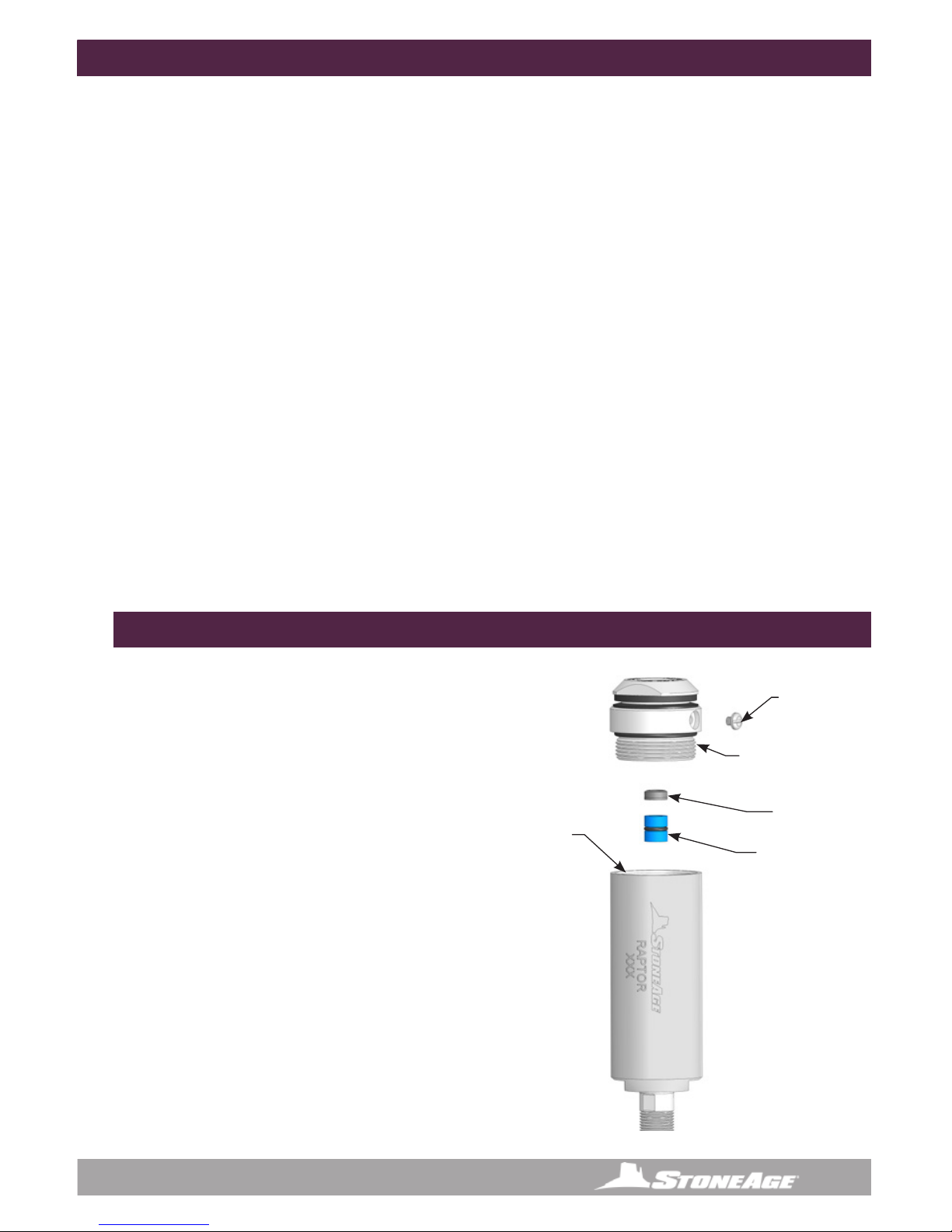

LUBRICANT FILL INSTRUCTIONS

The most important item in maintaining this swivel

is keeping the tool full of viscous uid, which

provides lubrication and speed control. The viscous

uid should be checked when the tool begins to

run faster than usual, and during high pressure seal

replacement. Clamp the ats of the Raptor body in

a vice.

1. Remove the BJ 026 Port Plug from the Inlet Nut

2. With an adjustable end wrench, remove and

retain the nut assembly. Remove and retain the

High Pressure Seal and Carbide.

3. If the uid appears contaminated, it should be

drained and replaced

4. Rell with Viscous uid to covering bearing.

5. Install the High Pressure Seal and Carbide Seat.

6. Install the Inlet Nut onto the body with an

adjustable end wrench.

7. Install the Port Plug.

LUBRICANT REPLACEMENT

BJ 026

Port Plug

Fill with

viscous uid

to cover

bearing

Figure 1: Lubricant Flush

LIST OF TOOLS:

• Bench Vice (recommended)

• Arbor Press (recommended)

• RPT 612 Kit Contains; RPT 105 Seal Press tool

• 18” Adjustable Wrench (such as Crescent®

C718 Automatic Adjustable Pipe Wrench)

• Small size at-head screw driver

• Medium size at-head screw driver

• Pick

• Ball point pen

• 9/64” Hex Wrench

• Snap Ring Pliers

LIST OF MATERIALS:

• Clean lint free rags or blue shop towels

• BJ 048-F Viscous Fluid

• BJ 048-S Viscous Fluid will help slow the

rotation of the Swivel if desired

• Anti-Seize -

StoneAge Part Number GP 043 Blue Goop

• Lithium Soap Grease –

StoneAge Part Number GP 048 Grease

• P-80®Grip-IT Lubricant

Blue Goop® is a registered trademark of the Swagelock®Corporation.

P-80®Grip-IT Lubricant is a registered trademark of the International Products Corporation.

BJ 012-TRO

H.P. Seal and

O-Ring

BJ 011-C

Carbide Seat

RPT 002-P8 or

MP9 or M24x1.5

Inlet Nut

10 866-795-1586 • WWW.STONEAGETOOLS.COM

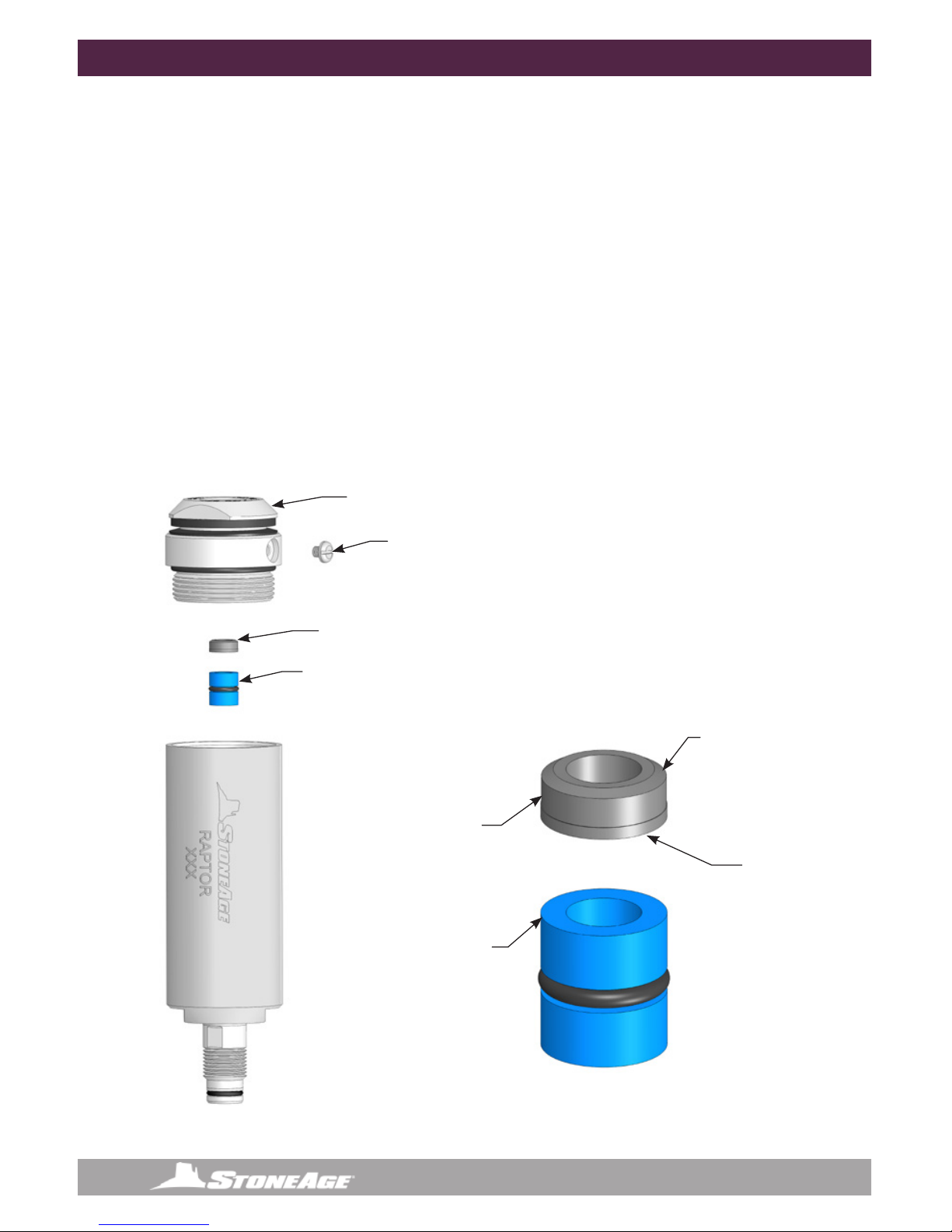

Chamfered face of

carbide seat

Flat face of

carbide seat

BJ 012-TRO

H.P. Seal and

O-Ring

BJ 012-TRO

H.P. Seal and

O-Ring

BJ 011-C

Carbide Seat

BJ 011-C

Carbide Seat

BJ 026

Port Plug

RPT 002-P8 or MP9 or

M24x1.5 Inlet Nut

Figure 2:

Figure 3: High Pressure

Seal Subassembly

HIGH PRESSURE SEAL REPLACEMENT

TO REPLACE THE HIGH PRESSURE SEAL:

1. Remove the Port Plug (BJ 026).

2. Unscrew the Inlet Nut (RPT 002-P8, MP9 or M24x1.5) from the Body.

3. Pull out the Seat (BJ 011-C) and H.P. Seal (BJ 012-TRO) from the bore of Shaft.

4. Inspect the bore of the Shaft; if it is badly grooved it should be replaced.

5. Inspect the face of the Inlet Nut where the Seat makes contact; if it is pitted or dented, it should be

faced or replaced.

6. Check the viscous uid level and condition; if the uid appears badly contaminated it should be

replaced. Otherwise add uid to cover the Bearing.

7. Apply grease to a new H.P. Seal and install into bore of Shaft. Do not push it all the way in.

8. Place a new Seat (BJ 011-C) on top of H.P. Seal; the at face of the Seat goes against the seal (see

detail). Push it in just far enough so that it will stay in the bore.

9. Apply anti-seize to threads of Inlet Nut and thread into Body; make sure the Seat stays centered in

bore of Shaft. Tighten to 50 ft-lb.

10. Install the Port Plug.

DISASSEMBLY

11

866-795-1586 • WWW.STONEAGETOOLS.COM

RPT 002-P8

or MP9

or M24x1.5

Inlet Nut

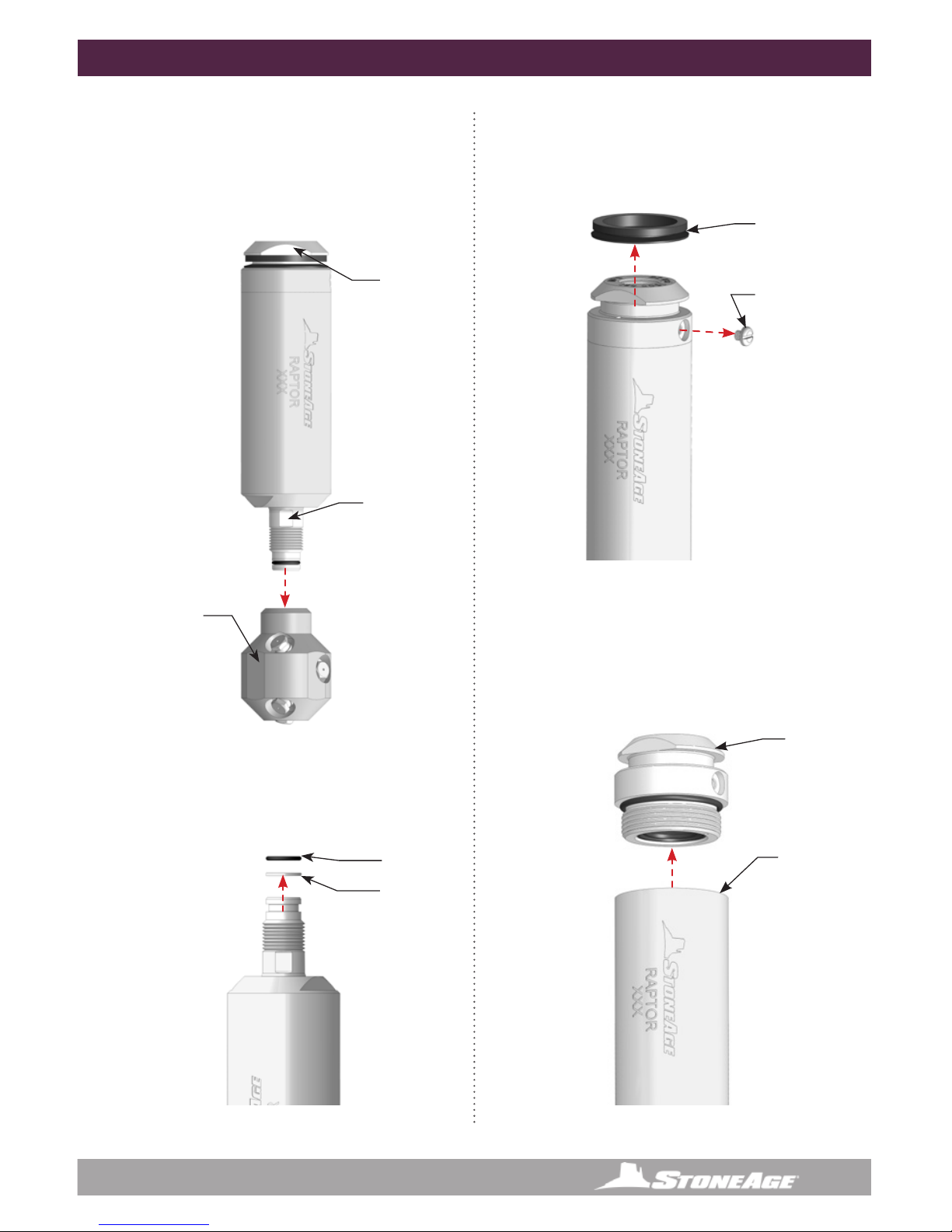

DISASSEMBLY

DISASSEMBLY

1. Locate the ats on the Head and tighten

them in a vice, so that the Inlet Nut end of

the Raptor is facing up.

2. Slide an adjustable wrench onto the Collar

ats and loosen the Head from the Body.

Figure 4: For Steps 1-2

Figure 5: For Steps 3-5 Figure 7: For Step 8

Figure 6: For Steps 6-7

Shaft Flats

Inlet Nut

Flats

Head Flats

in the vice

3. Remove the Raptor from the vice, ip it over

and using a pick, remove the MJ 016 O-Ring

from the Shaft Assembly.

4. Remove the BC 031 Backup Ring.

MJ 016

O-Ring

BC 031

Backup Ring

5. Remove the BJ 021-S Weep Seal with a pick.

6. Remove the BJ 026 Port Plug with a small

at-head screw driver.

7. With and adjustable end wrench remove the

Inlet Nut.

RPT 003

Body

BJ 026

Port Plug

BJ 021-S

Weep Seal

12 866-795-1586 • WWW.STONEAGETOOLS.COM

8. With a pick remove the Carbide Seat and

High Pressure Seal from inside of the Shaft.

Figure 8: For Step 8

Figure 9: For Steps 9-10

9. With a pick remove the remove the O-Ring

from around the Inlet Nut.

10. Gently pry the Shaft Seal out of the Inlet

Nut with a common screwdriver.

11. Slide the Shaft Assembly out of the Body.

12. Remove all the Bearings from the Shaft

DISASSEMBLY / ASSEMBLYDISASSEMBLY

RPT 008

O-Ring

RPT 010

Dual Lip Seal

RPT 003

Body

RPT 001

Shaft

CJSW 009

Bearings

CJ 009

Bearing

Figure 10: For Steps 11-12

TECH TIP: A bearing separator/puller set

and an arbor press will help with the bearing

removal from the Shaft.

BJ 012-TRO

H.P. Seal

BJ 011-C

Carbide Seat

13

866-795-1586 • WWW.STONEAGETOOLS.COM

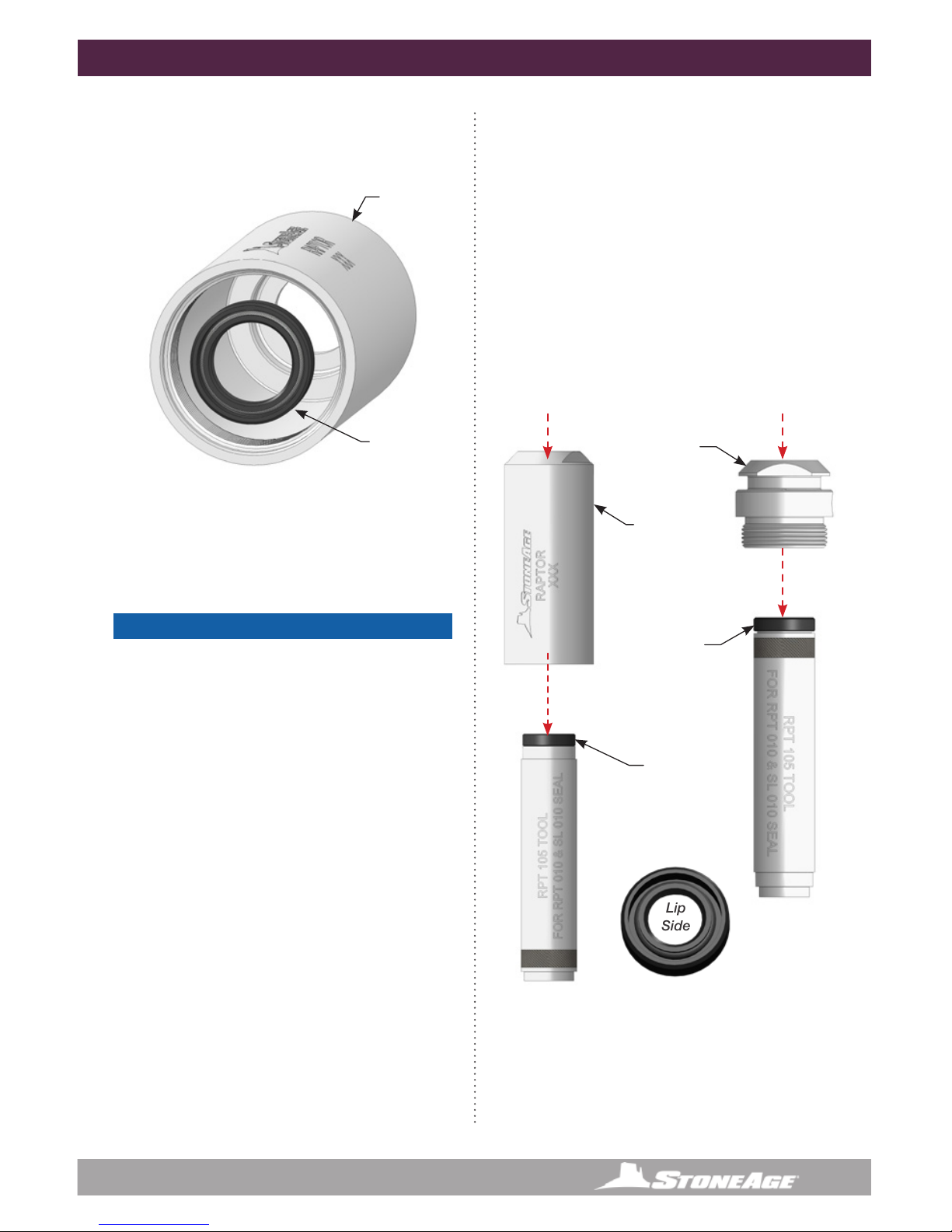

13. Remove the SL 010 Shaft Seal from the

RPT 003 Body with a pick or Snap Ring

Pliers.

Figure 11: For Steps 13

DISASSEMBLY COMPLETE

RPT 003

Body

NOTICE

Before reassembly of the tool

Wash all parts in solvent and blow dry

and

Inspect wear items, (High Pressure Seal

Assembly, O-Rings, and Port Plug.)

See the “Maintenance Kits” section of this

manual for a complete list of Service, Overhaul,

and, Tool kits.

DISASSEMBLY / ASSEMBLY

SL 010

Shaft Seal

Figure 12: For Steps 1-3

RPT 002

Inlet Nut

RPT 003

Body

PRESS PRESS

ASSEMBLY

1. Lubricate the SL 010 and RPT 010 Shaft

Seals with P-80®Grip-IT Lubricant or

equivalent.

2. Put the RPT 010 Shaft Seal on the RPT 105

tool (LIP SIDE DOWN) and using an Arbor

press, press the seal into the Body.

3. Put the SL 010 Shaft Seal on the RPT 105

tool (LIP SIDE DOWN) and using an Arbor

press, press the seal into the Body.

Lip

Side

SL 010

Shaft Seal

(Lip side DOWN)

RPT 010

Shaft Seal

(Lip side DOWN)

14 866-795-1586 • WWW.STONEAGETOOLS.COM

ASSEMBLY

4. Press clean or new bearings onto shaft in

the order shown below.

RPT 001

Shaft

Shaft

Assembly

Grease

Seal at

this end

Fill with

Viscous

uid

Turn Shaft

to remove

bubbles in

uid

RPT 003

Body

CJSW 009

Bearings

CJ 009

Bearing

Figure 13: For Step 4

Figure 14: For Steps 5-6

5. Grease the Shaft Seal in the Body

generously.

6. Slide the Shaft Assembly into the Body.

Figure 15: For Steps 7-8

Figure 16: For Steps 7-8

BJ 012-TRO

H.P. Seal

BJ 011-C

Carbide Seat

7. Grease H.P. Seal and insert into the Shaft.

Push down enough to leave 1/16” recess

for the Carbide Seat.

8. The Carbide Seat should be inserted with

the at side down and nestle onto the H.P.

Seal with the chamfer side facing up.

Chamfered

face of

carbide

seat

Flat face

of carbide

seat

9. Fill tool with BJ 048-Fast or Slow viscous

uid. Turn shaft to remove bubbles in uid

and repeat until tool is completely full of

viscous uid.

15

866-795-1586 • WWW.STONEAGETOOLS.COM

ASSEMBLY

Figure 16: For Steps 11-12 Figure 19: For Steps 14-15

Figure 17: For Step 13Figure 15: For Step 10

10. Place O-Ring at base of Inlet Nut threads.

RPT 008

O-Ring

Inlet Nut

Assembly

Anti-seize

11. Apply Anti-seize to the threads and screw

the Inlet Nut into the Body

12. Tighten down with an adjustable end

wrench to 50 ft lbs.

13. Replace the Port Plug and Weep Seal.

BJ 021-S

Weep Seal

BJ 026

Port Plug

14. Flip the Raptor in the vice and clamp

down on the Inlet Nut ats.

15. Slip the Backup O-Ring onto the Shaft rst

with the at side down and concave side

up to receive the regular O-Ring.

Concave

Side

Flat

Side

Regular

O-Ring

MJ 016

O-Ring

BC 031

Backup

Ring

16 866-795-1586 • WWW.STONEAGETOOLS.COM

ASSEMBLY

16. Grease the O-Rings

17. Apply Anti-seize to the threads and screw

the head onto the tool.

18. Place the ats on the Head in a vice and

Tighten from the Shaft ats with an ad-

justable wrench.

Figure 20: For Steps 16-18

Lithium

Soap

Grease

Anti-Seize

Head

Flats

Shaft

Flats

17

866-795-1586 • WWW.STONEAGETOOLS.COM

MAINTENANCE KITS

KITS PART NUMBER OVERVIEW

RPT 600-F or S SERVICE KIT

1 BJ 011-C Carbide Seat

1 BJ 012-TRO H.P. Seal & O-Ring

1 BJ 026 Port Plug

1 BJ 048-F Fast Viscous Fluid-6oz (-F)

1 BJ 048-S Slow Viscous Fluid-6oz (-S)

1 PL 543 Raptor User Manual

RPT 602 SEAL KIT

1 BJ 072 O-Ring

1 GO 123 O-Ring

1 RJ 011-KC Carbide Seat

1 RJ 012-KTO H.P. Seal & O-Ring

RPT 610-F or S OVERHAUL KIT

1 BJ 011-C Carbide Seat

1 BJ 012-TRO H.P. Seal & O-Ring

1 BJ 021-S Weep Seal

1 BJ 026 Port Plug

1 BJ 048-F Fast Viscous Fluid-6oz (-F)

1 BJ 048-S Slow Viscous Fluid-6oz (-S)

2 CJ 009 Bearing

1 CJSW 009 Bearing

1 MJ 016 O-Ring

1 PL 543 Raptor User Manual

1 RPT 008 O-Ring

1 RPT 010 Dual Lip Seal

1 RPT 031 Back-up O-Ring

1 SL 010 Large Seal

RPT 612 TOOL KIT

1 RPT 105 Double End Seal Press Tool

1 RPT 064 Raptor Fill Tube

1 RPT 106 Shaft Wrench

CJ 009

Bearing

BJ 011-C

Carbide Seat

BJ 012-TRO

H.P. Seal and

O-Ring

RPT 010

Seal

RPT 008

O-Ring

RPT 002

Inlet Nut

BJ 026

Port Plug

BJ 021-S

Weep Seal

SL 010

Seal

MJ 016

O-Ring

RPT 031

Back-up

O-Ring

RPT 001

Shaft

RPT 003

Body

CJSW 009

Bearings

RPT 043-XX

Head with

AP2-XXX

Nozzles (5)

OR

RPT 044-XX

Head with

AP4-XXX

Nozzles (5)

18 866-795-1586 • WWW.STONEAGETOOLS.COM

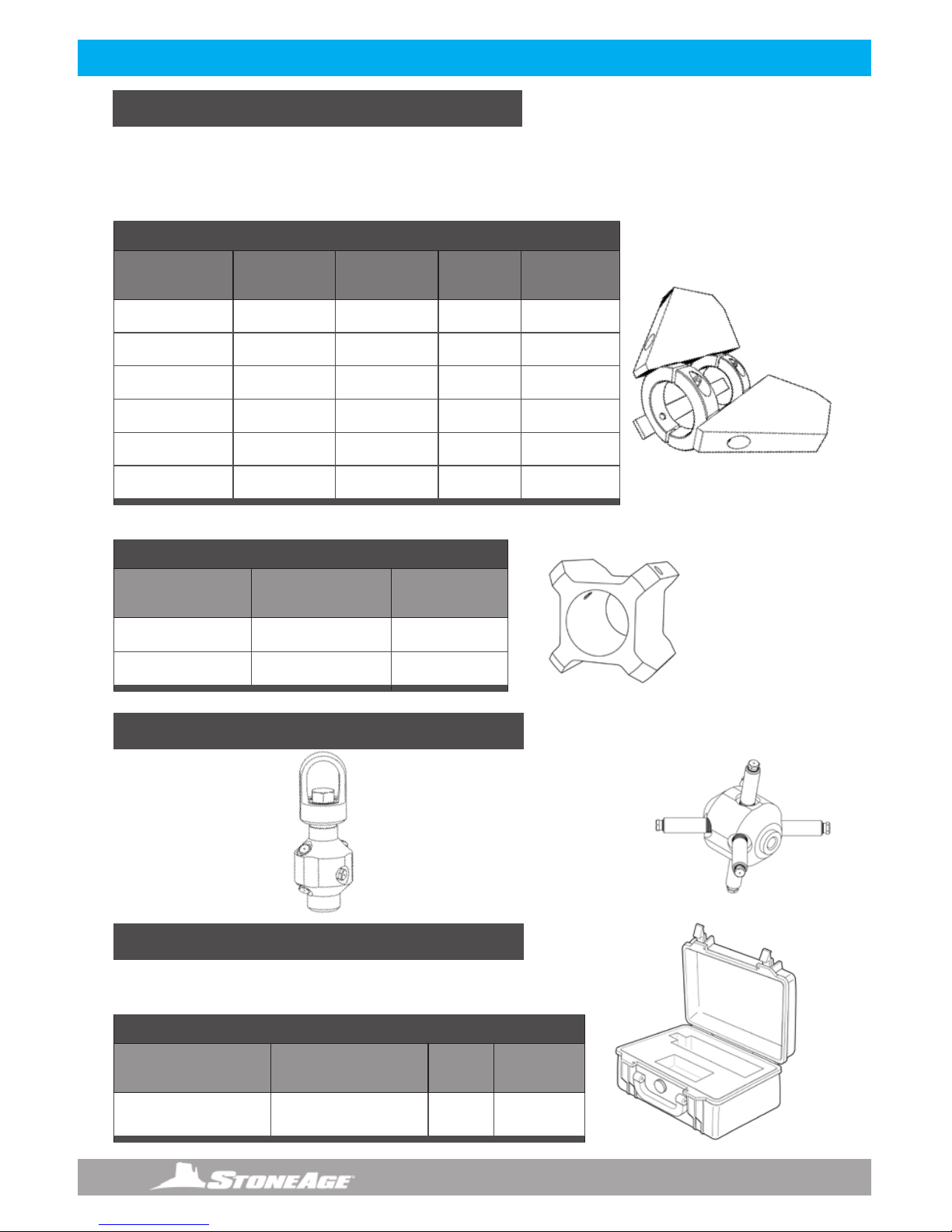

ACCESSORIES

A centralizer helps to protect the tool as it passes through the pipe and balances jet standoff distance for

more consistent cleaning. In cases where pipe size is more than 1.5 times the diameter of the tool, a central-

izer is an important safety device, preventing the tool from turning around and thrusting backwards out of the

pipe. Two types of centralizers are available for Raptor tools. See the tables below.

CENTRALIZER OPTIONS

STORAGE

HEAD ACCESSORIES

PLASTIC CENTRALIZER WITH SET SCREWS

Pipe Size Centralizer

(Complete) Weight

3 in. 76 mm RPT 075-3 0.3 lb 0.1 kg

4.5 in. 114 mm RPT 075-4.5 0.5 lb 0.2 kg

CENTRALIZER WITH SKIDS AND COLLARS

Pipe Size Centralizer

(Complete) Weight Collar* Skid**

4 in. 100 mm RPT 070-4 1.4 lb 0.6 kg RPT 070.1 RJ 070.2-4

5 in. 127 mm RPT 070-5 1.6 lb 0.7 kg RPT 070.1 RJ 070.2-5

6 in. 152 mm RPT 070-6 1.9 lb 0.9 kg RPT 070.1 RJ 070.2-6

8 in. 203 mm RPT 070-8 2.2 lb 1.0 kg RPT 070.1 RJ 070.2-8

10 in. 254 mm RPT 070-10 3.7 lb 1.7 kg RPT 070.1 RJ 070.2-10

12 in. 305 mm RPT 070-12 4.0 lb 1.8 kg RPT 070.1 RJ 070.2-12

*Set of 2 collars **Set of 3 skids with 6 screws

CARRYING CASE

Exterior Dimensions

(L x W x D)

Interior Dimensions

(L x W x D) Color Case Part

ID

11.6 x 8.3 x 3.8 in.

29.6 x 21.2 x 9.6 cm

10.5 x 6.0 x 3.2 in.

26.8 x 15.3 x 8.0 cm Black RPT 080

A PelicanTM brand protection/carrying case with custom cut

foam insert is available for Raptor tool models.

PULLING RING RPT 045

A pulling ring is

available for 6-port

Raptor heads.

EXTENSION NIPPLES

Extension nipples up to 12 inches

are available for use with 6-port P4

Raptor heads. A complete list of

Nozzles and Extensions is available

in the StoneAge Tools Waterblast

catalog and website.

19

866-795-1586 • WWW.STONEAGETOOLS.COM

ACCESSORIES ACCESSORIES

SAFETY OPTIONS

MAINTENANCE RESOURCES

Backout preventers increase operator safety by keeping the tool from backing out of the pipe. Several options are

available including xtures for small diameter pipes, pipes with various ange bolt circle diameters, and adapters

for pipes with no-ange entry.

BACKOUT PREVENTERS

Pipe Size Hose OD Backout

Preventer Description Weight

2–6 in.

51–150 mm

0.3–0.7 in.

8–18 mm BJ 305* Backout preventer for small pipes 5.6 lb

2.5 kg

4–8 in.

100–200 mm

0.3–1.5 in.

8–38 mm BJ 310 Backout preventer for small to medium pipes 7.6 l b

3.4 kg

5–17 in.

130–430 mm

0.3–1.5 in.

8–38 mm BJ 320 Backout preventer for medium to large pipes 6.3 lb

2.9 kg

15–36 in.

380–910 mm N/A BJ 325 Extension kit for BJ 320 backout preventer 8.5 lb

3.6 kg

8–36 in.

130 –910 mm N/A BJ 340 No-ange kit for BJ 320 backout preventer 17 lb

7.7 kg

*Securing device not supplied

BJ 305 BJ 310 BJ 320 BJ 320

shown with BJ 325

extension kit and BJ 340

No-ange attachment kit

KITS

Rotation

Speed Service Kit Seal Kit Overhaul Kit Tool Kit Lubricant Manual

Fast RPT 600-F RPT 602 RPT 610-F RPT 612 BJ 048-F PL 543

Slow RPT 600-S RPT 602 RPT 610-S RPT 612 BJ 048-S PL 543

Complete part breakdowns of each kit are available in the “Maintenance Kits” sections in this manual.

Kit components and tool maintenance/assembly videos are also available on our website:

WWW.STONEAGETOOLS.COM

For questions or help with a specic application, conguration or tool repairs, please contact StoneAge

Customer Service.

20 866-795-1586 • WWW.STONEAGETOOLS.COM

TERMS AND CONDITIONS AND WARRANTY INFORMATION

1. Acceptance of Terms and Conditions. Receipt

of these Terms and Conditions of Sale (“Terms and

Conditions”) shall operate as the acceptance by

StoneAge, Inc. (“Seller”) of the order submitted by

the purchaser (“Buyer”). Such acceptance is made

expressly conditional on assent by Buyer to these Terms

and Conditions. Such assent shall be deemed to have

been given unless written notice of objection to any of

these Terms and Conditions (including inconsistencies

between Buyer’s purchase order and this acceptance) is

given by Buyer to Seller promptly on receipt hereof.

Seller desires to provide Buyer with prompt and efcient

service. However, to individually negotiate the terms

of each sales contract would substantially impair

Seller’s ability to provide such service. Accordingly, the

product(s) furnished by Seller are sold only according

to the terms and conditions stated herein and with the

terms and conditions stated in any effective StoneAge

Dealer Agreement or StoneAge Reseller Agreement, if

applicable. Notwithstanding any terms and conditions

on Buyer’s order, Seller’s performance of any contract

is expressly made conditional on Buyer’s agreement

to these Terms and Conditions unless otherwise

specically agreed to in writing by Seller. In the absence

of such agreement, commencement of performance,

shipment and/or delivery shall be for Buyer’s

convenience only and shall not be deemed or construed

to be an acceptance of Buyer’s terms and conditions.

2. Payment/Prices. Unless other arrangements have

been made in writing between Seller and Buyer, payment

for the product(s) shall be made upon receipt of invoice.

The prices shown on the face hereof are those currently

in effect. Prices invoiced shall be per pricelist in effect

at the time of shipment. Prices are subject to increase

for inclusion of any and all taxes which are applicable

and which arise from the sale, delivery or use of the

product(s), and the collection of which Seller is or may

be responsible to provide to any governmental authority,

unless acceptable exemption certicates are provided

by Buyer in accordance with applicable law. Buyer

shall pay all charges for transportation and delivery

and all excise, order, occupation, use or similar taxes,

duties, levies, charges or surcharges applicable to the

product(s) being purchased, whether now in effect

or hereafter imposed by any governmental authority,

foreign or domestic.

3. Warranty. SELLER MAKES NO WARRANTIES OR

REPRESENTATIONS AS TO THE PERFORMANCE

OF ANY PRODUCT EXCEPT AS SET FORTH IN THE

STONEAGE LIMITED WARRANTY PROVIDED WITH THE

PRODUCT.

4. Delivery. Seller is not obligated to make delivery by

a specied date, but will always use its best efforts to

make delivery within the time requested. The proposed

shipment date is an estimate. Seller will notify Buyer

promptly of any material delay and will specify the

revised delivery date as soon as practicable. UNDER

NO CIRCUMSTANCES SHALL SELLER HAVE ANY

LIABILITY WHATSOEVER FOR LOSS OF USE OR

FOR ANY DIRECT OR CONSEQUENTIAL DAMAGES

RESULTING FROM DELAY REGARDLESS OF THE

REASON(S).

All product(s) will be shipped F.O.B. point of origin,

unless specically agreed otherwise, and Buyer shall

pay all shipping costs and insurance costs from that

point. Seller, in its sole discretion, will determine and

arrange the means and manner of transportation of the

product(s). Buyer shall bear all risk of loss commencing

with the shipment or distribution of the product(s) from

Seller’s warehouse. Order shortages or errors must be

reported within fteen (15) business days from receipt of

shipment to secure adjustment. No product(s) may be

returned without securing written approval from Seller.

5. Modication. These Terms and Conditions are

intended by Seller and Buyer to constitute a nal,

complete and exclusive expression of agreement

relating to the subject matter hereof and cannot be

supplemented or amended without Seller’s prior written

approval.

6. Omission. Seller’s waiver of any breach or Seller’s

failure to enforce any of these Terms and Conditions

at any time, shall not in any way affect, limit or waive

Seller’s right thereafter to enforce and compel strict

compliance with every term and condition hereof.

7. Severability. If any provision of these Terms and

Conditions is held to be invalid or unenforceable, such

invalidity or unenforceability shall not affect the validity

or enforceability of the other portions hereof.

TERMS AND CONDITIONS AND WARRANTY INFORMATION

This manual suits for next models

3

Table of contents

Other StoneAge Pipe Cleaner manuals