StoneAge BADGER BA-LKD-P4 User manual

BADGER FAMILY

SELF ROTARY SWIVELS

USER MANUAL

*EXCLUDES BA-H6 4” 40K MODEL

2 INCH

4 INCH

6 INCH

PL 663 REV P

(06/2020)

866-795-1586 • WWW.STONEAGETOOLS.COM

2

This manual must be used in accordance with all applicable national laws. The manual shall be

regarded as a part of the machine and shall be kept for reference until the nal dismantling of the

machine, as dened by applicable national law(s). Updated manuals can be downloaded at:

https://www.stoneagetools.com/manuals

MANUFACTURER’S INFORMATION ...........................................................3

SPECIFICATIONS FOR ALL MODELS .....................................................3

FEATURES FOR ALL MODELS ............................................................3

WARNING AND SAFETY INSTRUCTIONS .....................................................4

OPERATOR TRAINING, RISK ASSESSMENT, PPE ........................................4

PRE-RUN SAFETY CHECK ................................................................5

2” BADGER ....................................................................................6

MODEL AND HEAD INFORMATION .......................................................6

BACKOUT PREVENTION ..................................................................7

OPERATION AND TROUBLESHOOTING ..................................................8

HEAD REPLACEMENT INFORMATION ....................................................9

ASSEMBLY AND PARTS...................................................................11

4” BADGER ....................................................................................12

MODEL AND HEAD INFORMATION .......................................................12

BACKOUT PREVENTION ..................................................................13

OPERATION AND TROUBLESHOOTING ..................................................14

TOOL SERVICE AND VISCOUS FLUID INFORMATION ....................................15

DISASSEMBLY ............................................................................16

ASSEMBLY ................................................................................18

PART NUMBERS AND SERVICE KITS.....................................................20

6” BADGER ....................................................................................21

MODEL AND HEAD INFORMATION .......................................................21

BACKOUT PREVENTION ..................................................................22

OPERATION AND TROUBLESHOOTING ..................................................23

SPEED CONTROL ADJUSTMENT .........................................................24

TOOL SERVICE AND VISCOUS FLUID INFORMATION ....................................25

DISASSEMBLY ............................................................................26

ASSEMBLY ................................................................................28

PART NUMBERS AND SERVICE KITS.....................................................30

TERMS AND CONDITIONS AND WARRANTY ...........................................32

TABLE OF CONTENTS

866-795-1586 • WWW.STONEAGETOOLS.COM 3

StoneAge Inc.

466 S. Skylane Drive

Durango, CO 81303, USA

Phone: 970-259-2869

Toll Free: 866-795-1586

www.stoneagetools.com

StoneAge NL

Reedijk 7Q

3274 KE Heinenoord

Netherlands

(+31) (0) 85 902 73 70

Badger Model Specifications

Tool

Size

Tool Model

Number Pressure Range Flow Range

Inlet

Connection Weight Rotation Speed

Max Water

Temperature

2”

BA-LKD-P4

BA-LKD-BSPP4

8–15k psi

552–1034 bar

7-16 gpm

26–61 LPM

1/4 NPT

or

1/4 BSPP

0.45 lb

0.20 kg High Speed 250 ºF

120 ºC

BA-LKD-MP6R

BA-LKD-MP9L

BA-LKD-MP9R

15–22k psi

1034–1500bar

9.5 -18.5 gpm

36–70 LPM

3/8 MP

or

9/16 MP

0.45 lb

0.20 kg High Speed 250 ºF

120 ºC

4”

BAE-P6 5–15k psi

345 –1035 bar

12–35 gpm

45-132 LPM 3/8 NPT 3.0 lbs

1.4 kg

20-100 rpm (Slow Fluid)

75-250 rpm (Fast Fluid)

250 ºF

120 ºC

BAE-BSPP6

BAE-MP9L

BAE-MP9R

BAE-M24

5–22k psi

345–1500bar

12–34 gpm

45–130 LPM

3/8 BSPP

9/16 MP

M24

3.0 lbs

1.4 kg

20–100 rpm (Slow Fluid)

75–250 rpm (Fast Fluid)

250 ºF

120 ºC

BA-H6

(Not included in

this manual)

44k psi

3000 bar

4.5–12 gpm

17– 45.5 LPM

3/8 HP

Female

4.0 lbs

1.8 kg 100–400 rpm 250 ºF

120 ºC

6”

BA-MP9

BA-M24

12–22k psi

840 –1500 bar

14–43 gpm

53–163 LPM

9/16 MP

or

M24

8.0 lbs

3.6 kg

50–300 rpm

(Adjustable)

250 ºF

120 ºC

BA-P8 2–15k psi

140–1000 bar

15–55 gpm

57–208 LPM 1/2 NPT 8.0 lbs

3.6 kg

50–300 rpm

(Adjustable)

250 ºF

120 ºC

Badger Model Features

2”

• The only self-rotary tool on the market that can navigate 2 in. (50 mm) lines with bends and comes with head

locking technology for increased safety

• Head options allow the tool to be optimized for a variety of pump pressures and ows - unplug, polish, or

run longer lines based on jetting

• Optional fairing available to streamline tool during retrieval

4”

• Different jetting congurations allow for more or less pull and forward hitting power

• Navigates elbows as small as 4 in. (102 mm) at up to 22k psi (1500 bar)

• Self-rotary, speed controlled head provides complete internal coverage with optimum jet delivery

• Two speeds to choose from to maximize cleaning by choosing slower speeds for hard to clean or plugged

lines, and faster speeds for polishing easy to clean lines with a single tool

• Multiple jetting options optimize the tool for a variety of pumps pressures and ows - unplug, polish, or run

longer lines based on jetting

• Designed to easily pair with the AutoBox ABX-500 or ABX-PRO hose tractors for hands-free line cleaning.

6”

• Features adjustable speed control for ne-tuning to specic requirements

• Different jetting congurations allow for more or less pull and forward hitting power and optimize the tool for

a variety of pumps pressures and ows.

• Navigates elbows as small as 6 in. (152 mm)

• Speed controlled rotary tools provide complete internal coverage with optimum jet delivery

• Maximize cleaning by choosing slower speeds for hard to clean or plugged lines, and faster speeds for

polishing easy to clean lines with a single tool

• Centralizer options for larger line sizes available

• Designed to easily pair with the AutoBox ABX-500 or ABX-PRO hose tractors for hands-free line cleaning.

MANUFACTURER’S INFORMATION

866-795-1586 • WWW.STONEAGETOOLS.COM

4

PERSONAL PROTECTIVE EQUIPMENT

REQUIREMENTS

Use of Personal Protective Equipment (PPE) is

dependent on the working pressure of water and

the cleaning application. Managers, Supervisors,

and Operators MUST carry out a job specic risk

assessment to dene the exact requirements for

PPE. See Protective Equipment for Personnel

(Section 6) of WJTA-IMCA’s Recommended

Practices For The Use Of High-pressure

Waterjetting Equipment for additional information.

Hygiene - Operators are advised to wash

thoroughly after all waterjetting operations to

remove any waterblast residue which may contain

traces of harmful substances.

First aid provision - users MUST be provided with

suitable rst aid facilities at the operation site.

PPE may include:

• Eye protection: Full face visor

• Foot protection: Kevlar® brand or steel toe

capped, waterproof, non-slip safety boots

• Hand protection: Waterproof gloves

• Ear protection: Ear protection for a minimum

of 85 dBA

• Head protection: Hard hat that accepts a full

face visor and ear protection

• Body protection: Multi-layer waterproof

clothing approved for waterjetting

• Hose protection: Hose shroud

• Respiratory protection: May be required;

refer to job specic risk assessment

StoneAge has designed and manufactured this

equipment considering all hazards associated

with its operation. StoneAge assessed these risks

and incorporated safety features in the design.

StoneAge WILL NOT accept responsibility for the

results of misuse.

IT IS THE RESPONSIBILITY OF THE INSTALLER/

OPERATOR to conduct a job specic risk

assessment prior to use. Job specic risk

assessment MUST be repeated for each different

set up, material, and location.

The risk assessment MUST conform to the Health

and Safety at Work Act 1974 and other relevant

Health and Safety legislation.

The risk assessment MUST consider potential

material or substance hazards including:

• Aerosols

• Biological and microbiological (viral or

bacterial) agents

• Combustible materials

• Dusts

• Explosion

• Fibers

• Flammable substances

• Fluids

• Fumes

• Gases

• Mists

• Oxidizing Agents

OPERATOR TRAINING

Managers, Supervisors, and Operators MUST be

trained in Health and Safety Awareness of High-

pressure Water Jetting and hold a copy the Water

Jetting Association (WJA) Code of Practice, or

equivalent (see www.waterjetting.org.uk).

Operators MUST be trained to identify and

understand all applicable standards for the

equipment supplied. Operators should be trained

in manual handling techniques to prevent bodily

injury.

Operators MUST read, understand, and follow the

Operational and Training Requirements (Section

7.0) of WJTA-IMCA’s Recommended Practices For

The Use Of High-pressure Waterjetting Equipment,

or equivalent.

Operators MUST read, understand and follow

the Warnings, Safety Information, Assembly,

Installation, Connection, Operation, Transport,

Handling, Storage, and Maintenance Instructions

detailed in this manual.

WARNING AND SAFETY INSTRUCTIONS

866-795-1586 • WWW.STONEAGETOOLS.COM 5

WARNING

Operations with this equipment can be potentially

hazardous. Caution MUST be exercised prior

to and during equipment and water jet tool use.

Please read and follow all of these instructions,

in addition to the guidelines in the WJTA

Recommended Practices handbook, available

online at www.wjta.org. Deviating from safety

instructions and recommended practices can lead

to severe injury and/or death.

• Do not exceed the maximum operating

pressure specied for any component in a

system.

• The immediate work area MUST be marked

off to keep out untrained persons.

• Inspect the equipment for visible signs

of deterioration, damage, and improper

assembly. Do not operate if damaged, until

repaired.

• Make sure all threaded connections are tight

and free of leaks.

• Users of all Badger Tools

MUST be

trained and/or experienced in the use and

application of high-pressure technology

and cleaning, as well as all associated

safety measures, according to the WJTA

Recommended Practices for the use of

High-pressure Waterjetting Equipment.

• Install mechanical stops, stingers and back

out preventers as appropriate when doing any

tube, line or vessel cleaning.

• Always de-energize the system before

servicing or replacing any parts. Failure to do

so can result in severe injury and/or death.

PRE-RUN SAFETY CHECK

Refer to WJTA-IMCA’s, Recommended Practices

For The Use Of High-pressure Waterjetting

Equipment and/or The Water Jetting Association’s,

WJA Code of Practice for additional safety

information.

• Complete a job specic risk assessment and

act on the resulting actions.

• Adhere to all site specic safety procedures.

• Ensure the waterblasting zone is properly

barricaded and that warning signs are posted.

• Ensure the workplace is free of unnecessary

objects (e.g. loose parts, hoses, tools).

• Ensure all Operators are using the correct

Personal Protective Equipment (PPE).

• Check that the air hoses are properly

connected and tight.

• Check all hoses and accessories for damage

prior to use. Do not use damaged items. Only

high quality hoses intended for waterblast

applications should be used as high-pressure

hoses.

• Check all high-pressure threaded connections

for tightness.

• Operate the high-pressure water at full

pressure and use the Pneumatic Foot Pedal

Dump Control to verify that the dump valve is

working properly.

• Ensure that Operators never connect,

disconnect, or tighten hoses, adapters, or

accessories with the high-pressure water

pump unit running.

• Ensure no personnel are in the hydroblasting

zone.

WARNING AND SAFETY INSTRUCTIONS

866-795-1586 • WWW.STONEAGETOOLS.COM

6

2” BADGER MODEL AND HEAD INFORMATION

2” BADGER MODELS

The BA-LKD-P4 / BA-LKD-BSPP4 / BA-LKD-MP6R / BA-LKD-MP9L /

BA-LKD-MP9R are self-rotating swivels designed for cleaning 2” to 4”

tubes and lines with bends and long radius elbows, such as U-Tubes

and process lines.

The P4 and BSPP4 tools can be used at operating pressures up to

15,000 psi (1035 bar) and have either a 1/4”NPT or 1/4”BSPP female

pipe thread inlet.

The MP6R, MP9L and MP9R tools at up to 22,000 psi (1500 bar). The

MP6R tool has a 3/8” female right-hand medium pressure inlet. The

MP9L tool has a 9/16” female left-hand medium pressure inlet and

the MP9R has a 9/16” female right-hand medium pressure inlet.

The tools do not use any bearings, seals, or lubricating uid.

Rotation is powered by the jet thrust.

If a standard 1/4” NPT or BSPP hose end is used, they can pass

through elbows in 3” and larger lines. If using the tool in 2” line a

special shorter hose end is required to allow tool to travel through

elbows. Contact StoneAge for more information on the hose

requirements.

An OPTIONAL BA 530 Fairing Assembly is available for all 2” Badger

models when using hose sizes up to 6mm. The fairing is designed to

be attached to the back of the 2” Badger to help prevent the rear edge

of the tool from getting caught on obstructions during withdrawal from

tubes or lines. BA 530 Fairing

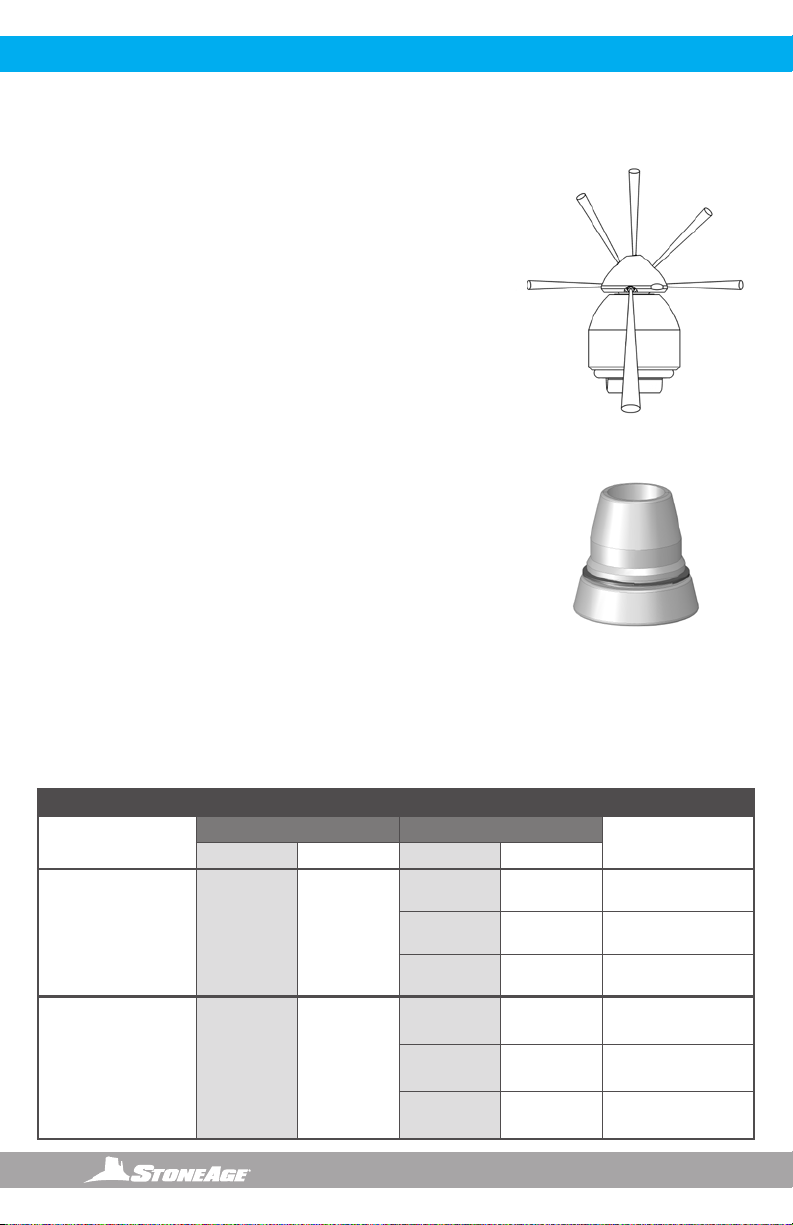

7 Ports:

1 @ 15º

1 @ 30º

1 @ 45º

2 @ 90º

2 @ 132º

15º

30º 45º

90º90º

2 x 132º

Port Locations

2” BADGER BACKOUT PREVENTION

2” BADGER HEAD CHART

MODEL / INLET

CONNECTIONS

PRESSURE RANGE FLOW RANGE BA 546-LKD-X

HEAD

psi bar gpm lpm

BA-LKD-P4

1/4 NPT

BA-LKD-BSPP4

1/4 BSPP

8-15K 552-1034

11-16 42-61 A

9-12.5 34-47 B

7-9.5 26-36 C

BA-LKD-MP6R

3/8 MP RIGHT

BA-LKD-MP9L

9/16 MP LEFT

BA-LKD-MP9R

9/16 MPRIGHT

15-22K 1034-1500

16-18.5 61-70 A

12.5-14.5 47-55 B

9.5-11 36-42 C

DETERMINING HEAD TYPE:

Three different universal head options can meet different pressure and ow congurations. The drilled

heads eliminate the need for replacing jet inserts. Operators can swap the drilled heads quickly to meet

the unique demands of each job. Specication assistance is available through one of our StoneAge

customer service reps at 1-866-795-1586. Or on line at www.stoneagetools.com

The chart below is calculated with hose pressure loss from 50 feet of 6 mm or ¼” ex lance.

866-795-1586 • WWW.STONEAGETOOLS.COM 7

DANGER

If the 2” BADGER is being used in lines larger than 4 inch diameter, a rigid stinger should be installed

between the tool inlet and the hose end; otherwise the tool can turn around and come back toward the

operator, causing serious injury or death.

Operations with this equipment can be potentially hazardous. Caution must be exercised prior to and

during machine and water jet tool use. Please read and follow all of these instructions, in addition to the

guidelines in the WJTA Recommended Practices handbook, available online at www.wjta.org.

Deviating from safety instructions and recommended practices can lead to severe injury and/or death.

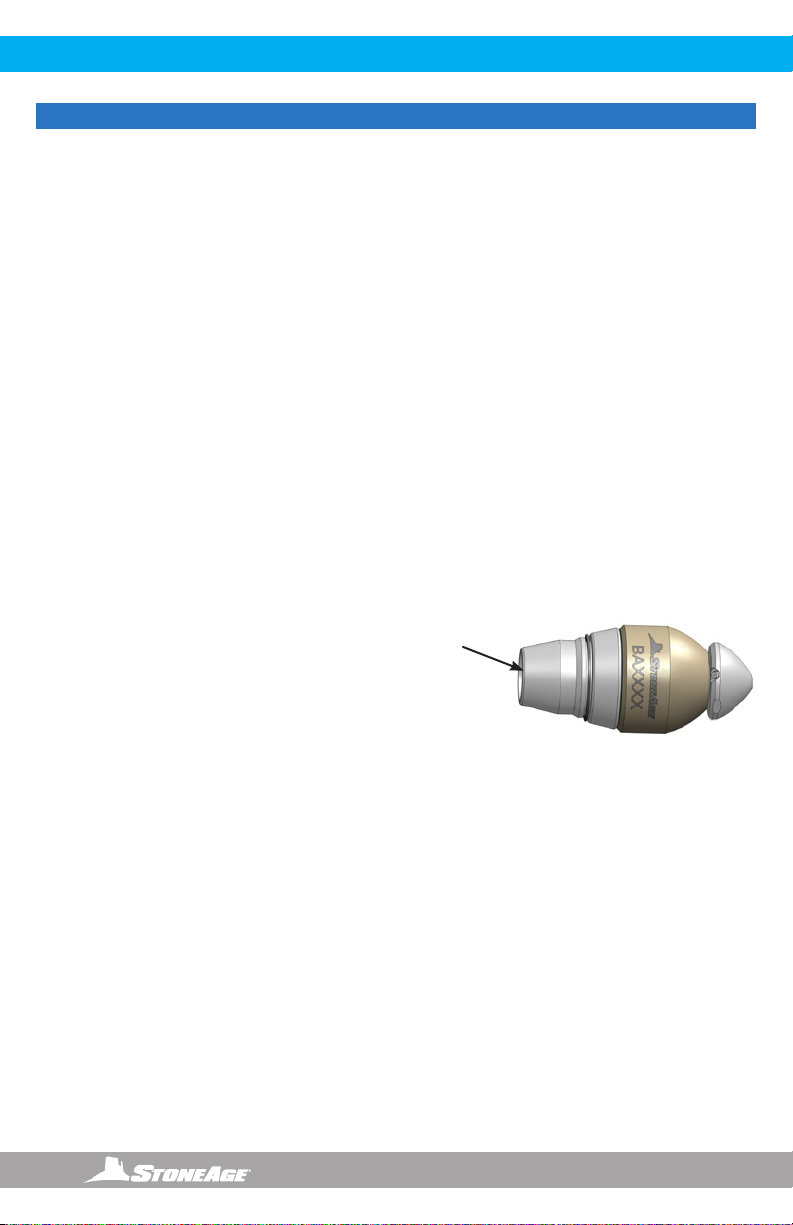

2” BADGER BACKOUT PREVENTION

WARNING

Because of the short length of the Badger, the tool can turn around in large lines and come back at the

operator at a high rate of speed. If cleaning larger lines, a rigid “stinger” should be used between the

hose and the tool. It is recommended that the rigid length of the tool including hose end is 1-1/2 times

the inside diameter of the line being cleaned (see below).

Make sure there is an operator controlled dump in the system, operated by the person closest to the

cleaning job. The StoneAge ABX-500 and ABX-PRO Hose Tractors can be used to achieve safe and

consistent feed rates for line cleaning.

Follow all operating instructions in this manual.

1-1/2 times

line ID

Rigid

Stinger

IMPROPER USE:

Badger will turn around in

large diameter line

VERY DANGEROUS!

PROPER USE:

Badger with rigid “stinger”

to prevent turnaround, still

able to pass through elbows.

866-795-1586 • WWW.STONEAGETOOLS.COM

8

2” BADGER OPERATION AND TROUBLESHOOTING

OPERATION

1. Make sure the operator has a controlled

dump in the system and it is operated by

the person closest to the job. Test the dump

prior to beginning the job.

2. Flush out the high pressure hoses before

connecting the Badger to eliminate debris.

3. Attach tool to the end of the hose. Use

Parker Thread Mate and Teon tape on all

pipe thread connections (P4, BSPP4); use

anti-seize on all straight thread connections

(MP6R, MP9L, MP9R) to the swivel inlet.

4. The 2” Badger has a large O-Ring (WV 008)

around the inlet. This O-Ring helps prevent

the tool from getting caught on the rear

edge when pulling the tool back out of the

line. An optional Fairing Assembly (BA 530)

will also help prevent snagging during tool

removal.

5. It is recommended that the hose be marked

a few feet from the end with a piece of tape

so the operator knows when to stop on the

way back out.

6. Position the tool in the line opening.

7. Close the dump and slowly bring the pump

up to pressure the rst time to make sure

no nozzles are plugged and the jet thrust is

correct. The Badger should begin to slowly

rotate.

8. Once operating pressure is reached, feed

the tool into the line to begin the cleaning

job.

9. Allow the jets time to do their work by

feeding the hose out at a controlled rate.

10. 2” BADGER ONLY- After the Badger is

removed from the hose, blow out water with

compressed air and spray a light oil such as

WD-40 into the tool.

TROUBLESHOOTING

HEAD WILL NOT ROTATE:

• First, make sure the head (BA 546-LKD) is still

tightened into the shaft (BA 501-LK). A safety

feature built into the shaft stops the tool from

rotating if the head comes loose.

• If the head isn’t loose, try spraying a light oil

such as WD-40 into the tool and rotate head

by hand until it turns freely again.

• Make sure that the jets in the head are not

plugged.

• If the tool still does not rotate after trying the

steps above, it may need to be disassembled

and cleaned on the inside. Follow the

instructions in the “2” Badger Tool Service

Information” section of this manual.

BA 530

Fairing

NOTICE

The most important item in maintaining the Badger tool is ushing high pressure hoses before use. This

keeps debris from entering the tool and preventing a loss in rotation.

866-795-1586 • WWW.STONEAGETOOLS.COM 9

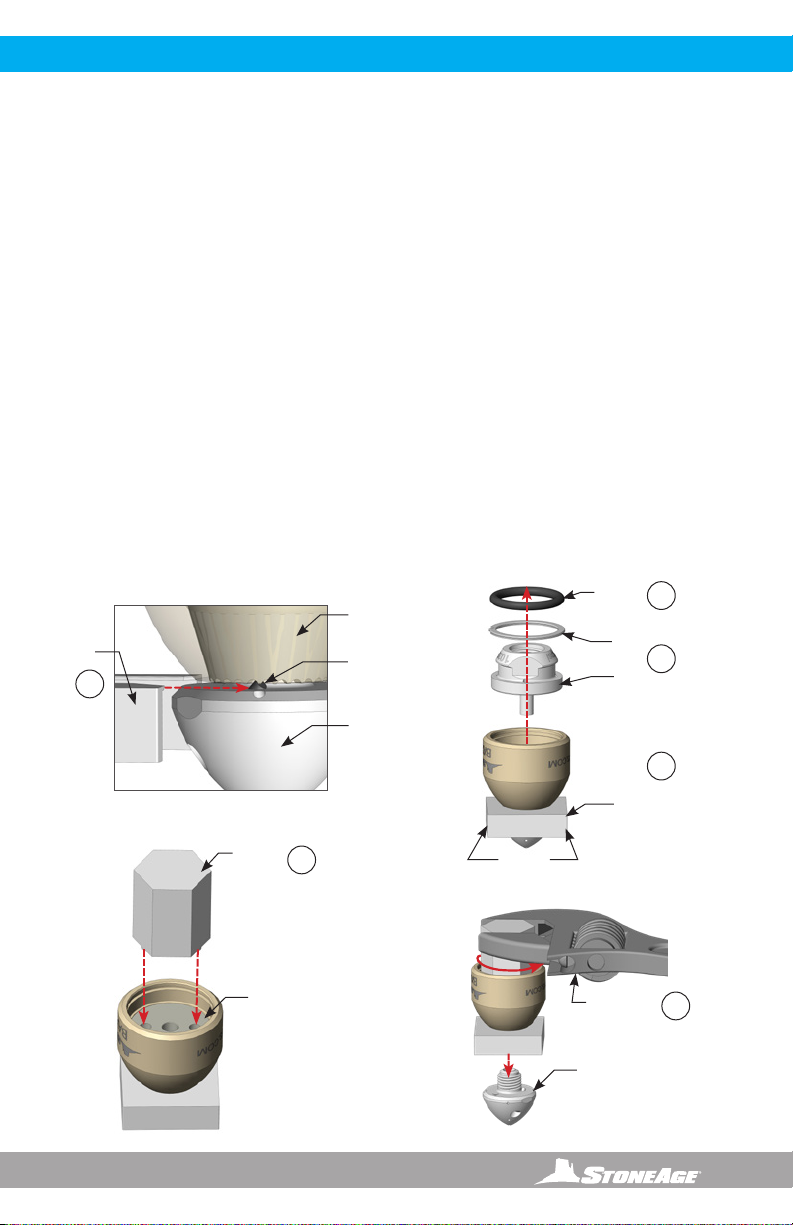

2” BADGER HEAD REPLACEMENT INFORMATION

TO REPLACE THE HEAD:

DISASSEMBLY:

1. Slide the BA 182 Head Removal Tool

between the Head and the Shaft to release

the Head Locking Pin. There is only one

direction that will release the Pin. See the

gure below.

2. Leave the Badger in the BA 182 Removal

Tool and clamp the removal tool into a vise.

3. Using a small pick, remove the O-Ring.

4. Using a small at head screw driver, pry the

Retaining Ring off the Inlet Nut, and pull the

Inlet nut out the Shaft.

5. Insert the two pins on the WV 181 Spanner

Wrench into the two bores in the Shaft.

6. Rotate the Spanner Wrench

Counterclockwise with an adjustable end

wrench to remove the Head from the Shaft.

BA 612-LK TOOL KIT INCLUDES:

• BA 182 Head Removal Tool

• BA 185 Red Loctite® 262

• WV 010 Retaining Rings (2)

• WV 181 Spanner Wrench

Loctite®is a registered trademark

of Henkel AG & Co. KGaA.

RECOMMENDED GENERAL TOOLS:

(Not included in the BA-612-LK Kit)

• Bench Vise (recommended)

• Adjustable End Wrench

• 7/8” socket wrench

• Clean lint free rags or blue shop towels

Product training and proper tools are required to service this tool. If you are uncomfortable performing

the service, bring the nozzle to your authorized dealer. Please go to the link below for more information

and service videos for the 2 inch Badger.

https://www.stoneagetools.com/2inch-badger

BA 182

Head

Removal

Tool Head

Locking

Pin

Head

Shaft

1

WV 181

Spanner

Wrench

Shaft

5

Adjustable

End Wrench

Head

6

BA 182

Head

Removal

Tool

O-Ring

Retaining

Ring

Inlet

Nut

Clamp

in Vise

3

4

2

866-795-1586 • WWW.STONEAGETOOLS.COM

10

2” BADGER TOOL SERVICE INFORMATION

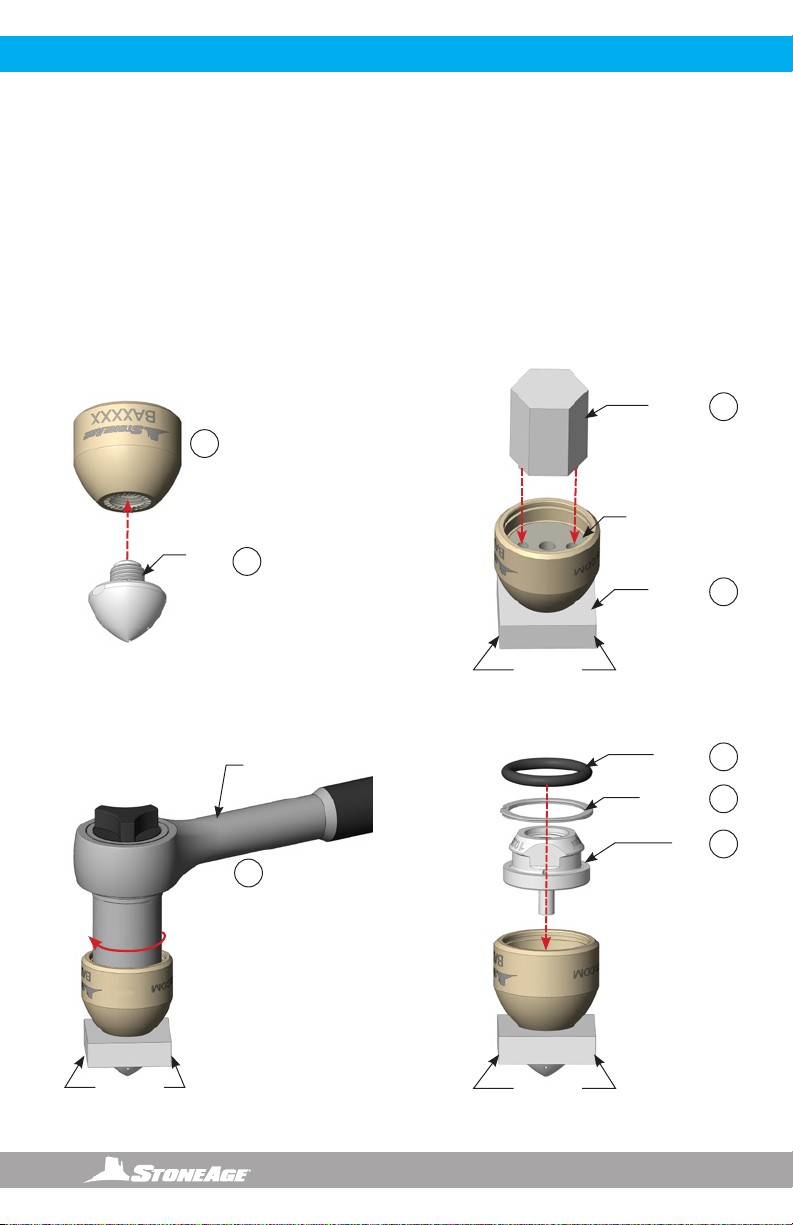

ASSEMBLY:

1. Apply 2-4 drops of BA 185 Red Loctite®262

around the circumference of the threads on

the Replacement Head prior to screwing it

into the Shaft.

2. Care must be taken NOT to allow Red

Loctite®into the internal shaft bore below

the female threads or onto the tapered

external surface of the shaft.

3. Slip the Removal Tool between the Head and

the Body and clamp it into a vise.

4. Insert the WV 181 Spanner Wrench into the

Shaft.

5. Using a 7/8” socket wrench, torque to 100

in-lbs

6. Install the Inlet Nut into the Shaft.

7. Always replace the Retaining Ring with a

new one during each reassembly.

8. Finally, install the O-Ring.

BA 182

Head

Removal Tool

4

3

WV 181

Spanner

Wrench

Shaft

Clamp

in Vise

O-Ring

Retaining

Ring

Inlet

Nut

8

7

6

Clamp

in Vise

Red

Loctite®

2

1

5

Clamp

in Vise

7/8” Torque

Wrench

866-795-1586 • WWW.STONEAGETOOLS.COM 11

2” BADGER ASSEMBLY AND PARTS

BA 546-LKD-A

or

BA 546-LKD-B

or

BA546-LKD-C

Head

NEVER REMOVE

SET SCREW

FROM HEAD

BA 501-LK

Shaft

BA 503

Body

WV 008

O-Ring

WV 010

Retaining Ring

BA 002-P4 (15k)

or

BA 002-BSPP4 (15K)

or

BA 502-MP6R (22K)

or

BA 502-MP9L (22K)

or

BA 502-MP9R (22K)

Inlet Nut

GP 200-BSPP4

Copper Seal Ring .250

REQUIRED FOR BSPP

INLETS ONLY

*Optional

BA 530 Fairing

Accessories

866-795-1586 • WWW.STONEAGETOOLS.COM

12

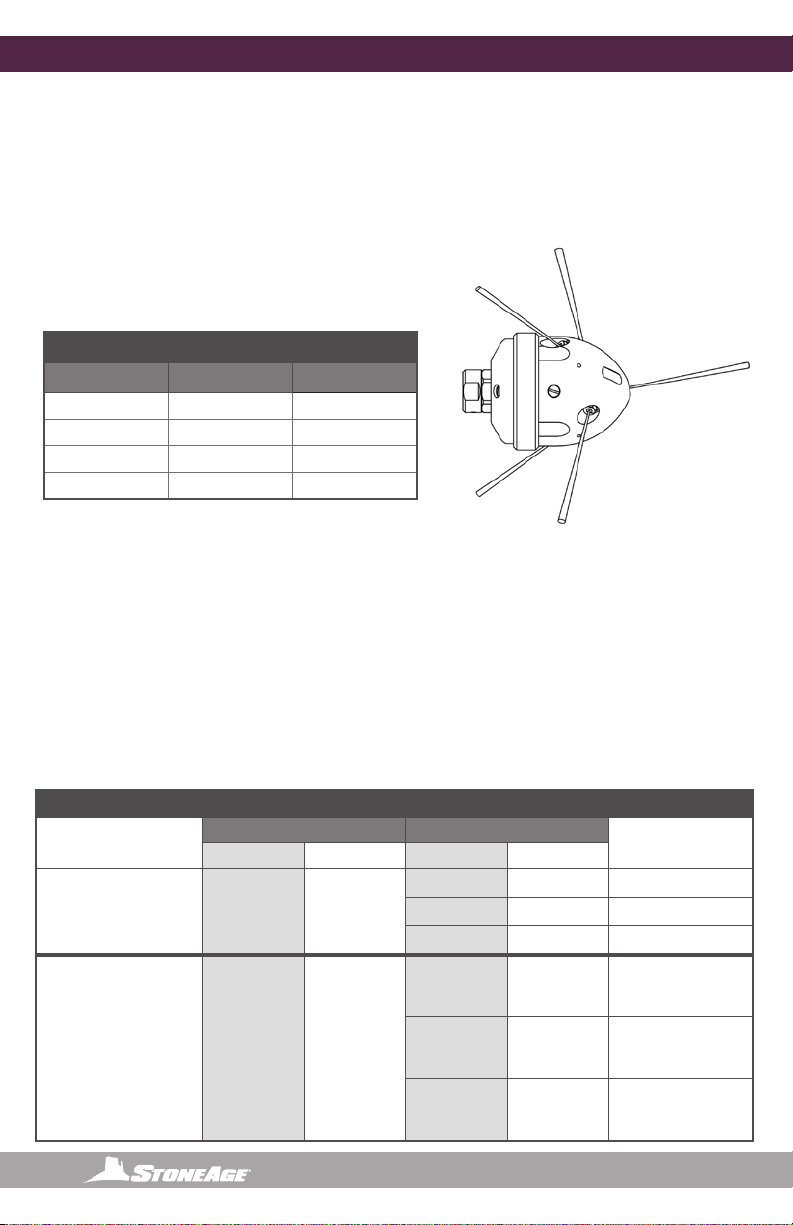

4” BADGER MODEL DESCRIPTION

The Badger™ Rotary Waterblast Nozzle was designed for waterblast cleaning of lines with as small as 4

inch with elbows. The tool has an outside diameter of 2.8”. A thin uid is used for rotation speeds of 75

to 250 rpm. The uid in the swivel can be changed to provide either fast or slow rotation. The Badger™

heads have ve 1/8 NPT ports; See diagram and chart below.

4” BADGER TOOL MODEL AND HEAD INFORMATION

4” BADGER

5 Ports:

1 @ 10º

2 @ 100º

2 @ 135º

10˚

135˚

135˚

100˚

100˚

NOZZLES AND PLUGS

The 4” Badger can be jetted in different congurations

depending on the application. The table below shows

commonly used nozzle/plug congurations for the 4”

Badger tool.

4” BADGER NOZZLE AND PLUG CHART

10º PORT 100º PORTS 135º PORTS

1 x Nozzle 2 x Nozzle 2 x Nozzle

1 x Plug 2 x Nozzle 2 x Nozzle

1 x Nozzle 2 x Plug 2 x Nozzle

1 x Plug 2 x Plug 2 x Nozzle

Nozzles are Part Number: AP2-XXX

Plugs are Part Number: GP 025-P2SS

HEAD OFFSET OPTIONS

Engraved on each head is R12, R18 or R22; this number is the offset of the head that makes it rotate.

The approximate ow range for each head offset is given in the table; pump operating pressure, hose

size and hose length, and actual ow rate will precisely determine the correct head offset and nozzle

sizes to match operating conditions. Refer to the StoneAge Jetting App Calculator to aid in proper

head selection. If the resulting pressure and ow is below the correct range for a head offset the tool

may not rotate; if it is more than the allowable the tool may rotate too fast and quickly wear out the

seals and bearings

4” BADGER HEAD OFFSET CHART

MODEL / INLET

CONNECTION

PRESSURE RANGE FLOW RANGE

HEAD

psi bar gpm lpm

BAE-P6

3/8 NPT FEMALE 5000-15K 345-1035

12-16 45-60 BAE 040-R22

16-23 60-87 BAE 040-R18

23-35 87-132 BAE 040-R12

BAE-BSPP6

3/8 BSPP FEMALE

BAE-MP9R

9/16 FEMALE

BAE-MP9L

9/16 FEMALE

BAE-M24 X 1.5

24mm MALE

5000-22K 345-1500

12-16 45-60 BAE 040-R22

16-22 60-83 BAE 040-R18

22-34 83-130 BAE 040-R12

Once you have conrmed the required jetting conguration, use the StoneAge Jetting App to determine

nozzle sizes: Jetting.stoneagetools.com

866-795-1586 • WWW.STONEAGETOOLS.COM 13

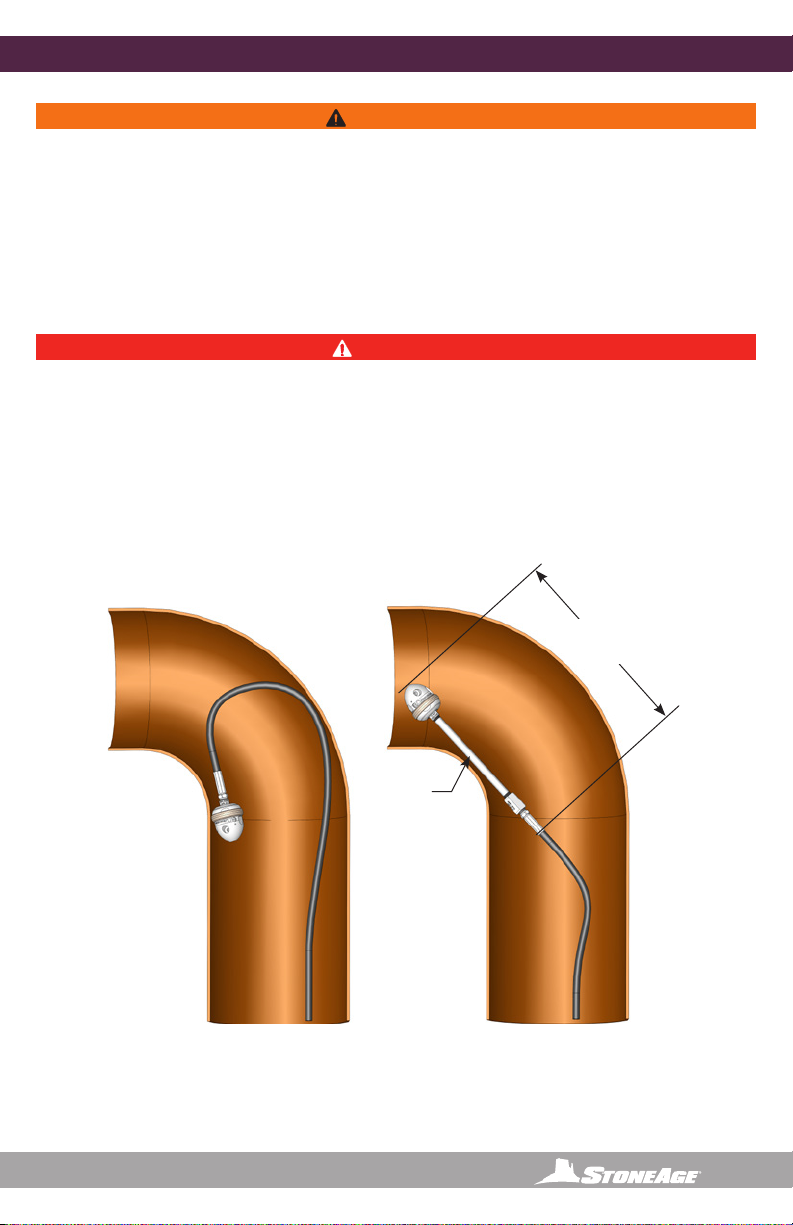

4” BADGER BACKOUT PREVENTION

IMPROPER USE:

Badger will turn around in

large diameter line

VERY DANGEROUS!

PROPER USE:

Badger with rigid “stinger”

to prevent turnaround, still

able to pass through elbows.

Rigid

Stinger

1-1/2 times

line ID

WARNING

Because of the short length of the Badger, the tool can turn around in large lines and come back at the

operator at a high rate of speed. If cleaning larger lines, a rigid “stinger” should be used between the

hose and the tool. It is recommended that the rigid length of the tool including hose end is 1-1/2 times

the inside diameter of the line being cleaned (see below).

Make sure there is an operator controlled dump in the system, operated by the person closest to the

cleaning job.

Follow all operating instructions in this manual.

DANGER

If the 4” BADGER is being used in larger diameter lines, a rigid stinger should be installed between the

tool inlet and the hose end; otherwise the tool can turn around and come back toward the operator,

causing serious injury or death.

Operations with this equipment can be potentially hazardous. Caution must be exercised prior to and

during machine and water jet tool use. Please read and follow all of these instructions, in addition to the

guidelines in the WJTA Recommended Practices handbook, available online at www.wjta.org.

Deviating from safety instructions and recommended practices can lead to severe injury and/or death.

866-795-1586 • WWW.STONEAGETOOLS.COM

14

4” BADGER OPERATION AND TROUBLESHOOTING

OPERATION:

NOTICE

The two most important items in maintaining the

Badger tools;

- Keep debris from entering the tool and pre-

venting it from rotating by ushing high pressure

hoses before use.

- Keep the 4” and 6” models full of viscous uid

to maintain control and rotation speed. When the

viscous uid is lost or contaminated, the rotation

speed of the tool will increase, which reduce the

life of the high pressure seal and bearing.

1. Make sure the operator has a controlled

dump in the system and it is operated by

the person closest to the job. Test the dump

prior to beginning the job.

2. Flush out the high pressure hoses before

connecting the Badger™ to eliminate debris.

3. Attach tool to the end of the hose.

4. It is recommended that the hose be marked a

few feet from the end with a piece of tape so

the operator knows when to stop on the way

back out.

5. Position the tool in the pipe opening.

6. Close the dump and slowly bring the pump

up to pressure the rst time to make sure

no nozzles are plugged and the jet thrust is

correct. The Badger should begin to slowly

rotate.

7. Once operating pressure is reached, feed the

tool into the pipe to begin the cleaning job.

8. Allow the jets time to do their work by

feeding the hose out at a controlled rate.

9. When the work is complete and the tool is

disconnected from the hose, blow out all

water to prolong the life of the tool.

10. A small amount of 3-IN-ONE or equivalent

lubricant can be blown into the tool as well.

TROUBLE SHOOTING:

HIGH-PRESSURE WATER SEAL LEAK:

• The high pressure seal may leak initially at

lower pressures, but should pop closed as

pressure is increased. A continuous leak

at operating pressure from the weep holes

indicates the need to replace the HP Seal and

Seat. HP Seals wearing out too quickly can

be an indication that the shaft bore is worn,

the HP Seat is installed upside-down, or the

tool is over spinning. Over spinning is caused

by low or contaminated viscous uid, water

in the uid chamber (replace shaft seals), or

too much jet torque. Relling the viscous uid

every 80-100 hours of operation is important

for proper speed control. Only use StoneAge

recommended viscous uid.

TOOL SPINS TOO FAST:

• A signicant increase in rotation speed means

that the speed control mechanism in the tool

has lost functionality. This can be a result

of viscous uid loss or uid contamination.

Operation of the tool in this state can

cause damage to other components and

accelerated wear of the high pressure seal. If

this occurs, the rst step is to ush the tool

with new viscous uid as shown below.

TOOL WILL NOT ROTATE:

• Check the nozzles for plugging or wear

(nozzles have to be removed to check for

obstructions), Check that the nozzle sizes

are correct for the desired ow and that the

desired ow matches the head ow range.

Check that the nozzle sizes are installed in

a balanced conguration. If the tool feels

rough when manually rotating the head, this

indicates internal damage. Replace bearings,

shaft seals, viscous uid, and check the Inner

and Outer Discs for atness. These discs

can be deformed if tool is reassembled

when discs are not properly aligned with the

internal ats inside the head.

WEEP

HOLES

866-795-1586 • WWW.STONEAGETOOLS.COM 15

4” BADGER TOOL SERVICE INFORMATION

TOOL SERVICE

Product training and proper tools are required to service this tool. If you are uncomfortable performing the

service, bring the nozzle to your authorized dealer. Please go to the link below for more information and

service videos for the 4 inch Badger.

https://www.stoneagetools.com/4inch-badger

The use of a bench vice and an arbor press is highly helpful. Take care throughout the entire procedure

to keep the internals clean and free from grit, lint, and contamination. Failure to do so could result in

premature tool failure after service.

LIST OF TOOLS:

• Bench Vise (recommended)

• Arbor Press (recommended)

• 18” adjustable wrench (such as Crescent®C718

Automatic Adjustable Pipe Wrench)

• 13/16” open end wrench or small adjustable

Crescent®Wrench

• Medium size at-head screw driver

• Pick

• BAE 612 Tool Kit for 4” Badger Includes;

BAE 181 Wrench

BA 105 Seal Press Tool

LIST OF MATERIALS:

• Clean lint free rags or shop towels

• Anti-Seize - Swagelok®Blue Goop®

StoneAge PN (GP 043 Blue Goop)

• Grease - Chevron Multifak®EP1

StoneAge PN (GP 049)

• Isopropyl Alcohol or Denatured Alcohol

Blue Goop®is a registered trademark of Swagelok®

Company

Multifak®is a registered trademark of Chevron®

Corporation.

VISCOUS FLUID FLUSH INSTRUCTIONS

1. Remove both Port Plugs in the Head

(BAE 040-RXX) (see below).

2. Fill the Syringe with viscous uid by

removing the end near the handle,

pulling out the plunger, and pouring the

Viscous Fluid (BJ 048-F) in to ll the

Syringe Body. With plunger re-installed,

purge air out of Syringe hose.

3. Thread the syringe end into a port in the

Head. Hold the tool sideways, so the

bleed port is on top and the injection

port is on the bottom. Squeeze fresh

Viscous Fluid in until clean Viscous

Fluid comes out the bleed port. Keep

ushing new uid until air bubbles stop

coming out of the bleed port.

4. Install a Port Plug into the bleed side

rst. Remove the Syringe and install

the Port Plug back into the Injection

side port.

BJ 026

Port Plug

(Bleed)

BJ 026

Port Plug

(Injection)

BAE 040-RXX

Head

BC 410

Syringe

REMOVE

TO FILL

Viscous Fluid Flush

866-795-1586 • WWW.STONEAGETOOLS.COM

16

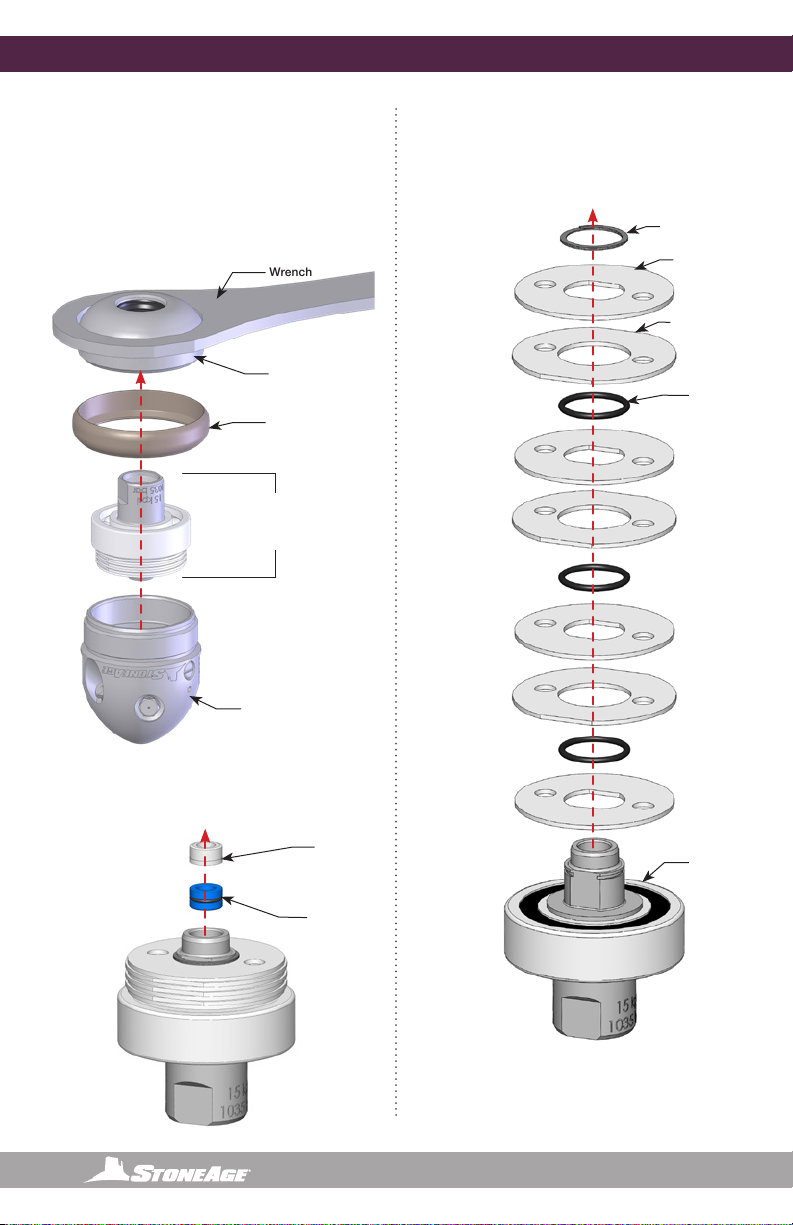

4” BADGER DISASSEMBLY

Figure 2: For Step 4

BAE 017

Retaining Ring

BAE 015

Inner Disc (4)

BAE 016

Outer Disc (3)

BAE 010

O-Ring (3)

Figure 3: For Step 5-6

4. Use a small pick to remove the Carbide Seat

and H.P. Seal from the bore of the Shaft.

BAE 181

Wrench

Shaft /Bearing

Assembly

RJ 011-C

Carbide

Seat

RJ 012-TO

H.P. Seal

5. Use a small screw driver or pick to remove

the Retaining Ring from the shaft.

6. Pull the Discs and O-Rings off of the Shaft.

DISASSEMBLY

1. Use an adjustable end or BAE 181 wrench

on the ats of the Nut and remove it from the

Head.

2. Slip off the Wear Ring.

3. Lift the Shaft Assembly out of the head.

Figure 1: For Steps 1-3

BAE 030

Wear Ring

BAE 002

Nut

BAE 040-Rxx

Head

Shaft, Bearing,

Carbide, HP Seal,

and

Disc Stack

866-795-1586 • WWW.STONEAGETOOLS.COM 17

BA 006

Shaft Seal

BAE 008

O-Ring

BRLM 109

Bearing

BAE 001-Px

Shaft

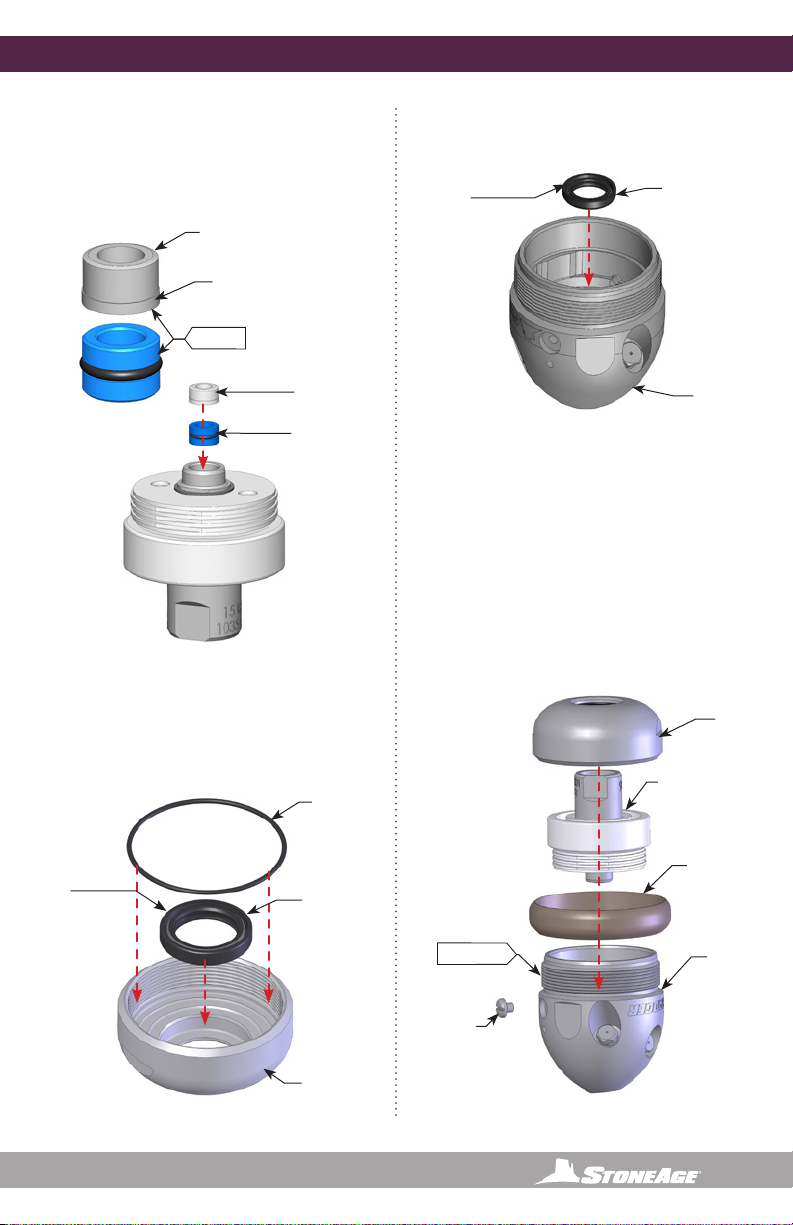

4” BADGER DISASSEMBLY

Figure 4: For Step 7

Figure 5: For Step 8

7. Use an arbor press to press the Bearing off

of the Shaft. Be sure the bearing is set at on

the press before applying pressure. Pressing

the shaft out of the bearing at an angle could

cause damage to the bearing.

9. Remove both Port Plugs from the Head.

10. Use a at head screwdriver to remove the

Shaft Seal and inspect for damage.

Figure 6: For Steps 9-10

8. Use a small pick to remove the O-Ring and

the Shaft Seal and inspect both for damage.

BA 007

Shaft Seal

BAE 002

Nut

BJ 026

Port Plug

BAE 040-Rxx

Head

INSPECT

INSPECT

NOTICE

Before reassembly of the tool

Wash all parts in solvent and blow dry

and

Inspect wear items, (High Pressure Seal

Assembly, O-Rings, and Port Screw.)

See the “Maintenance Kits” section of this

manual for a complete list of Service, Overhaul,

and, Tool kits.

866-795-1586 • WWW.STONEAGETOOLS.COM

18

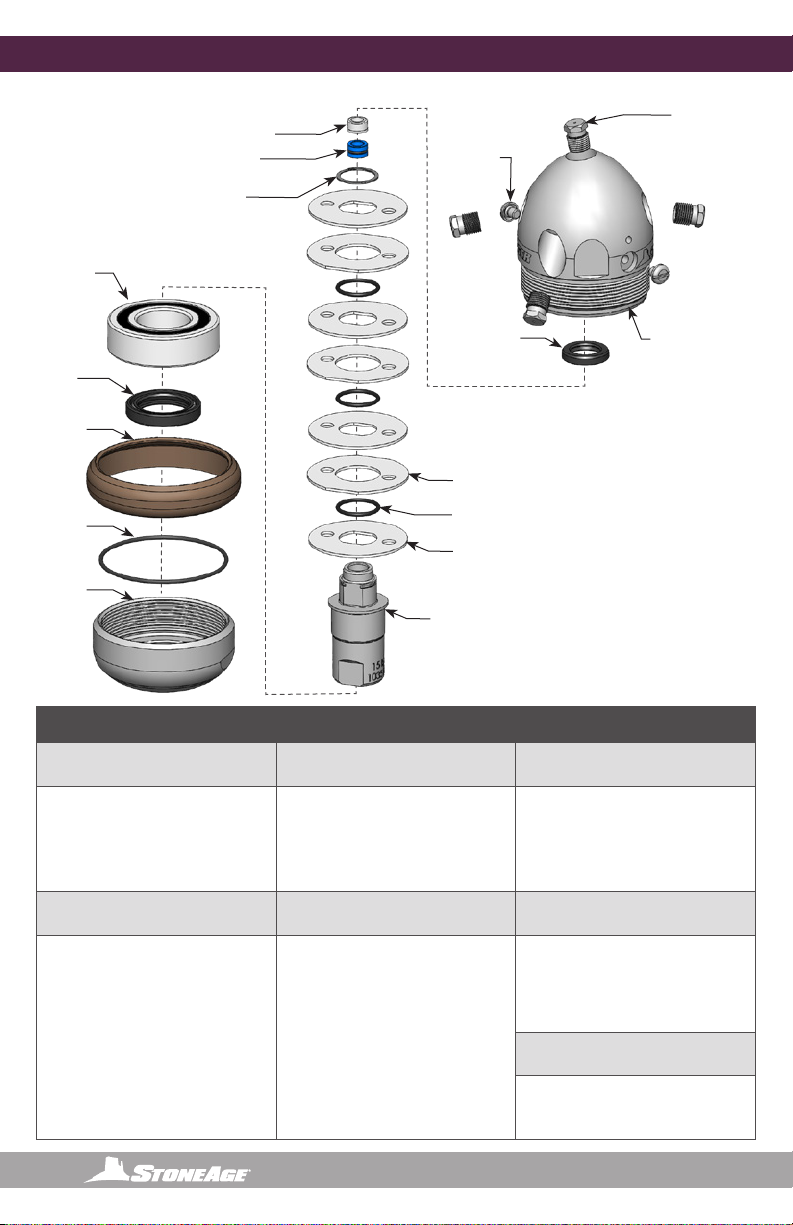

4” BADGER ASSEMBLY

ASSEMBLY

1. Grease the open side of the Bearing.

2. Note the orientation of the Bearing before

pressing it onto the Shaft. The greased side

should be down. Use an arbor press to

press the Bearing onto the Shaft. Be sure

the bearing is set at on the press before

applying pressure. Pressing the shaft into the

bearing at an angle could cause damage to

the bearing.

3. Align the internal ats of an Inner Disc with

the ats of the Shaft and place over the Shaft.

4. Place an O-Ring on top of this Disc.

5. Place an Outer Disc on after the O-Ring. The

external ats of the Outer Discs should be

aligned with the ats inside the head.

6. Repeat these steps until there are three Outer

Discs and four Inner Discs on the Shaft.

7. Push down on top disc and install the

Retaining Ring in the groove around the

Shaft.

BAE 001-xx

Shaft

Figure 7: For Steps 1-2

BRLM 109

Bearing

BAE 017

Retaining Ring

BAE 015

Inner Disc (4)

BAE 016

Outer Disc (3)

BAE 010

O-Ring (3)

The Outer

Disc ats

will align

with the

ats inside

the head

Align Inner

Disc ats to

Shaft ats

GREASE

Figure 8: For Steps 3-7

GREASE

ANTI-SEIZE

= Chevron Multifak®EP1 Tan

= Swagelock®Blue Goop or Equal

866-795-1586 • WWW.STONEAGETOOLS.COM 19

4” BADGER ASSEMBLY

8. Apply grease to the H.P. Seal and install into

the bore of the Shaft.

9. Apply grease to the Flat Face of the Seat and

place into the bore of the Shaft, on top of H.P.

Seal, as shown.

Figure 10: For Steps 10-11

BA 007

Shaft Seal

BA 006

Shaft Seal

BAE 002

Nut

Figure 9: For Steps 8-9

RJ 011-C

Seat

RJ 012-TO

H.P. Seal

Chamfered

Face

Flat

Face

Figure 12: For Steps 13-15

BAE 008

O-Ring

Figure 11: For Step 12

10. Install the Shaft Seal into the center of the Nut

with the lip spring side up.

11. Install the O-Ring in the groove in the bottom

of the Nut.

BAE 002

Nut

BAE 030

Wear Ring

Shaft/Bearing

Assembly

BJ 026

Port Plug

12. Install the Shaft Seal into the Head with the

lip spring side up.

13. Align the ats on the Outer Discs with the

ats inside the Head; slide shaft assembly

into the Head.

14. Apply anti-seize to threads on Head; install

the Wear Ring onto the Head; thread the Nut

onto the Head and tighten to 50 ft-lb.

15. Follow the “Lubricant Replacement

Instructions” Section before installing the

Port Plugs back into the head.

BAE 040-Rxx

Head

Lip Spring

Side

GREASE

ANTI-SEIZE

Lip Spring

Side Up

BAE 040-Rxx

Head

866-795-1586 • WWW.STONEAGETOOLS.COM

20

4” BADGER PART NUMBERS AND SERVICE KITS

4” BADGER KITS AND KIT CONTENTS

BAE 600-F

SERVICE KIT (FAST)

BAE 600-S

SERVICE KIT (SLOW)

BAE 602

H.P. SEAL KIT

1 BC 410 Syringe Assembly

1 BJ 048-F Visc Fluid, Fast, 6oz

1 BJ 062-S Anti-seize, 2g

1 RJ 011-C Carbide Seat

1 RJ 012-TO H.P. Seal and O-Ring

1 PL 663 BADGER Family Manual

1 BC 410 Syringe Assembly

1 BJ 048-S Visc Fluid, Slow, 6oz

1 BJ 062-S Anti-seize, 2g

1 RJ 011-C Carbide Seat

1 RJ 012-TO H.P. Seal and O-Ring

1 PL 663 BADGER Family Manual

1 RJ 011-C Carbide Seat

1 RJ 012-TO H.P. Seal

and O-Ring

BAE 610-F

OVERHAUL KIT (FAST)

BAE 610-S

OVERHAUL KIT (SLOW)

BAE 604

DISC KIT

1 BA 006 Seal

1 BA 007 Seal

1 BAE 008 O-Ring

3 BAE 010 O-Ring

1 BAE 017 External Retaining Ring

1 BJ 026 Port Plug

1 BJ 048-F Visc Fluid, Fast, 6oz

1 BJ 062-S Antiseize, 2g

1 BRLM 109 Bearing, Single Sided

1 PL 663 BADGER Family Manual

1 RJ 011-C Carbide Seat

1 RJ 012-TO H.P. Seal and O-Ring

1 BA 006 Seal

1 BA 007 Seal

1 BAE 008 O-Ring

3 BAE 010 O-Ring

1 BAE 017 External Retaining Ring

1 BJ 026 Port Plug

1 BJ 048-S Visc Fluid, Slow, 6oz

1 BJ 062-S Antiseize, 2g

1 BRLM 109 Bearing, Single Sided

1 PL 663 BADGER Family Manual

1 RJ 011-C Carbide Seat

1 RJ 012-TO H.P. Seal and O-Ring

3 BAE 010 O-Ring

4 BAE 015 Inner Disc

3 BAE 016 Outer Disc

1 BAE 017 External Retaining Ring

1 PL 663 BADGER Family Manual

BAE 612

TOOL KIT

1 BAE 181 Wrench

1 BA 105 Seal Press Tool

BRLM 109

Bearing

BA 007

Shaft Seal

BAE 030

Wear Ring

BAE 002

Nut

BAE 008

O-Ring

BAE 001-xx

Shaft

BAE 017

Retaining Ring

BAE 015

Inner Disc (4)

BAE 016

Outer Disc (3)

BAE 010

O-Ring (3)

RJ 011-C

Carbide Seat

RJ 012-TO

H.P. Seal

AP2-XXX

Nozzles (5)

BA 006

Shaft Seal

BJ 026

Port Plug (2)

BAE 040-Rxx

Head

This manual suits for next models

13

Table of contents

Other StoneAge Pipe Cleaner manuals