Theme Plus Issue 2.1 28/06/01 Page 1 of 12

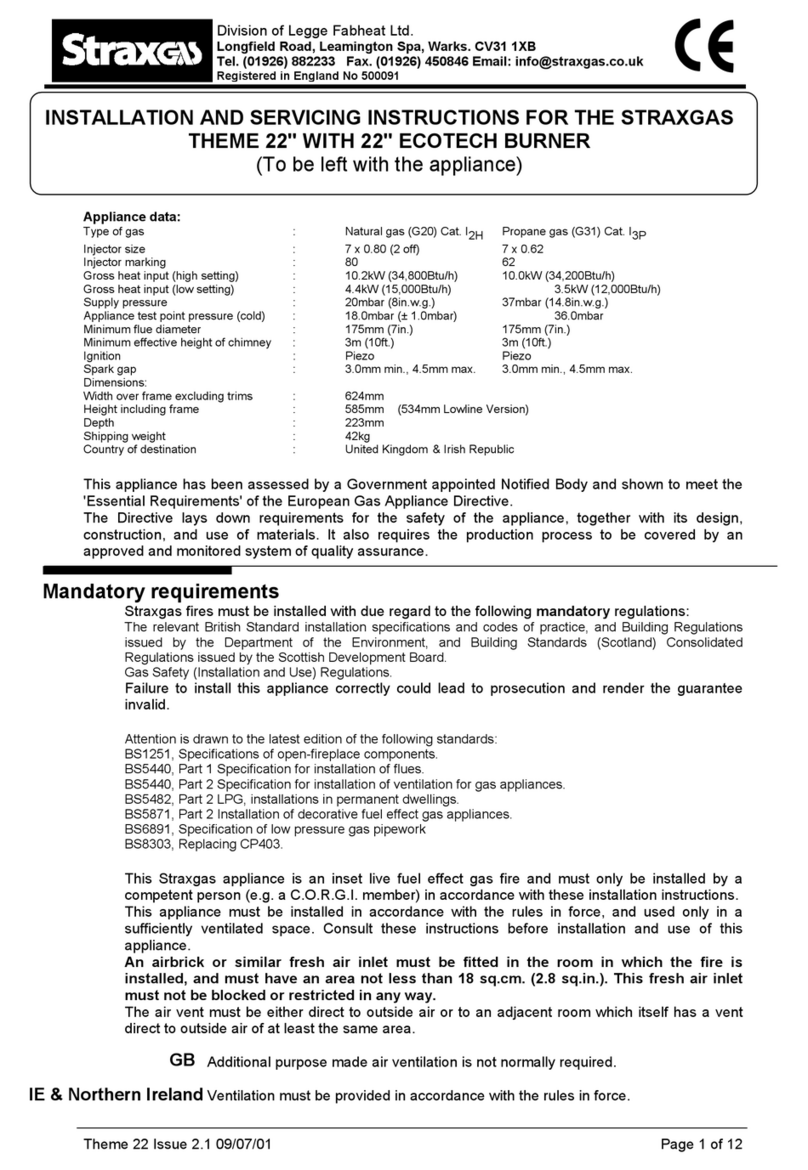

Appliance data:

Type of gas : Natural gas (G20) Cat. I2H Propane gas (G31) Cat. I3P

Injector size : 7 x 0.80 multihole 7 x 0.53 multihole

Injector marking : 80 53

Gross heat input (high setting) : 6.9kW (23,500Btu/h) 6.9kW (23,500Btu/h)

Gross heat input (low setting) : 4.4kW (15,000Btu/h) 3.5kW (12,000Btu/h)

Supply pressure : 20mbar (8in.w.g.) 37mbar (14.8in.w.g.)

Appliance test point pressure (cold) : 19.0mbar (± 1.0mbar) 36.5mbar

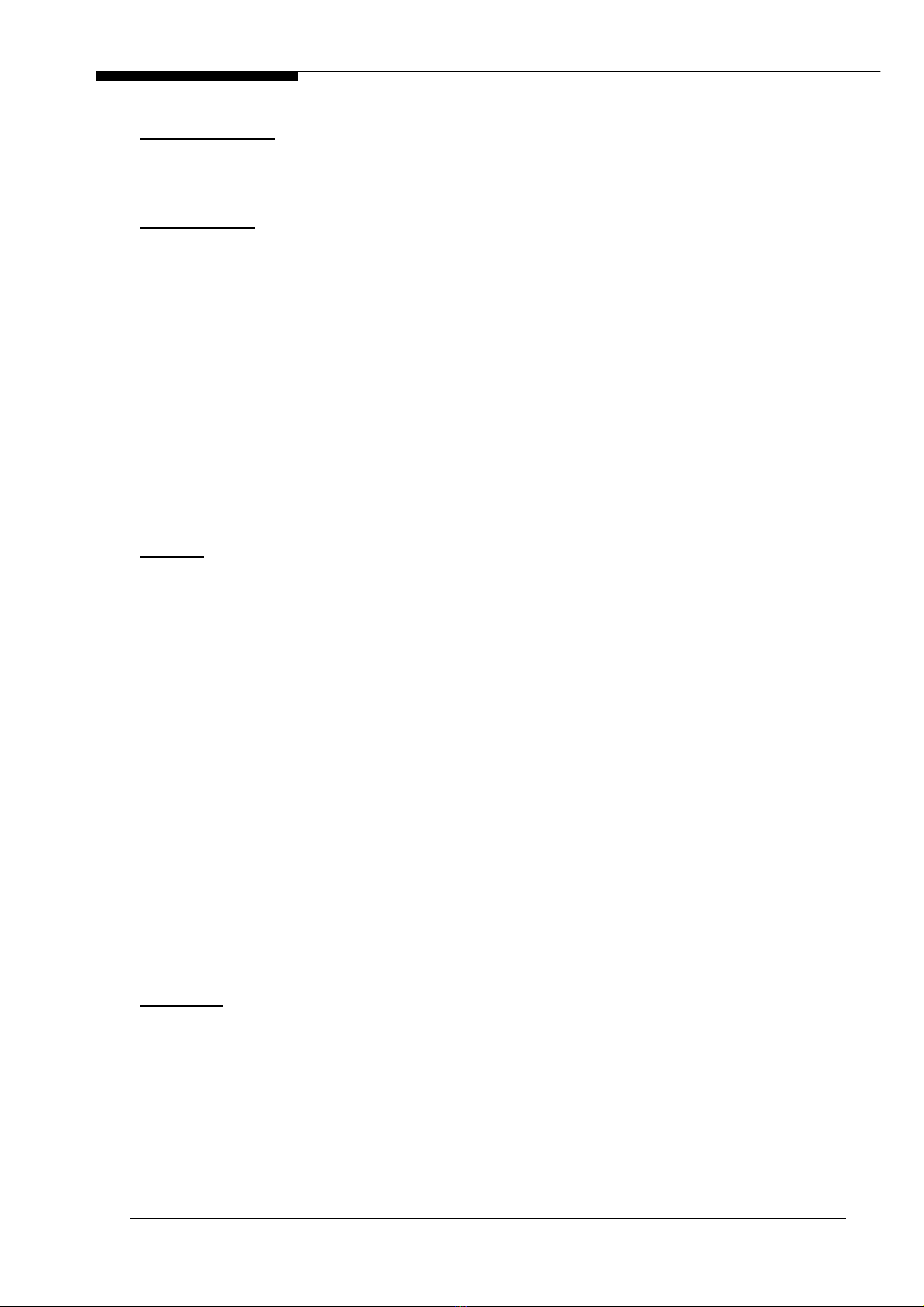

Type of flue : Class 1 (7in. dia.), Class 2 (5in. dia.) or precast block flue

Minimum effective height of chimney : 3m (10ft.) 3m (10ft.)

Ignition : Piezo Piezo

Spark gap : 3.0mm min., 4.5mm max. 3.0mm min., 4.5mm max.

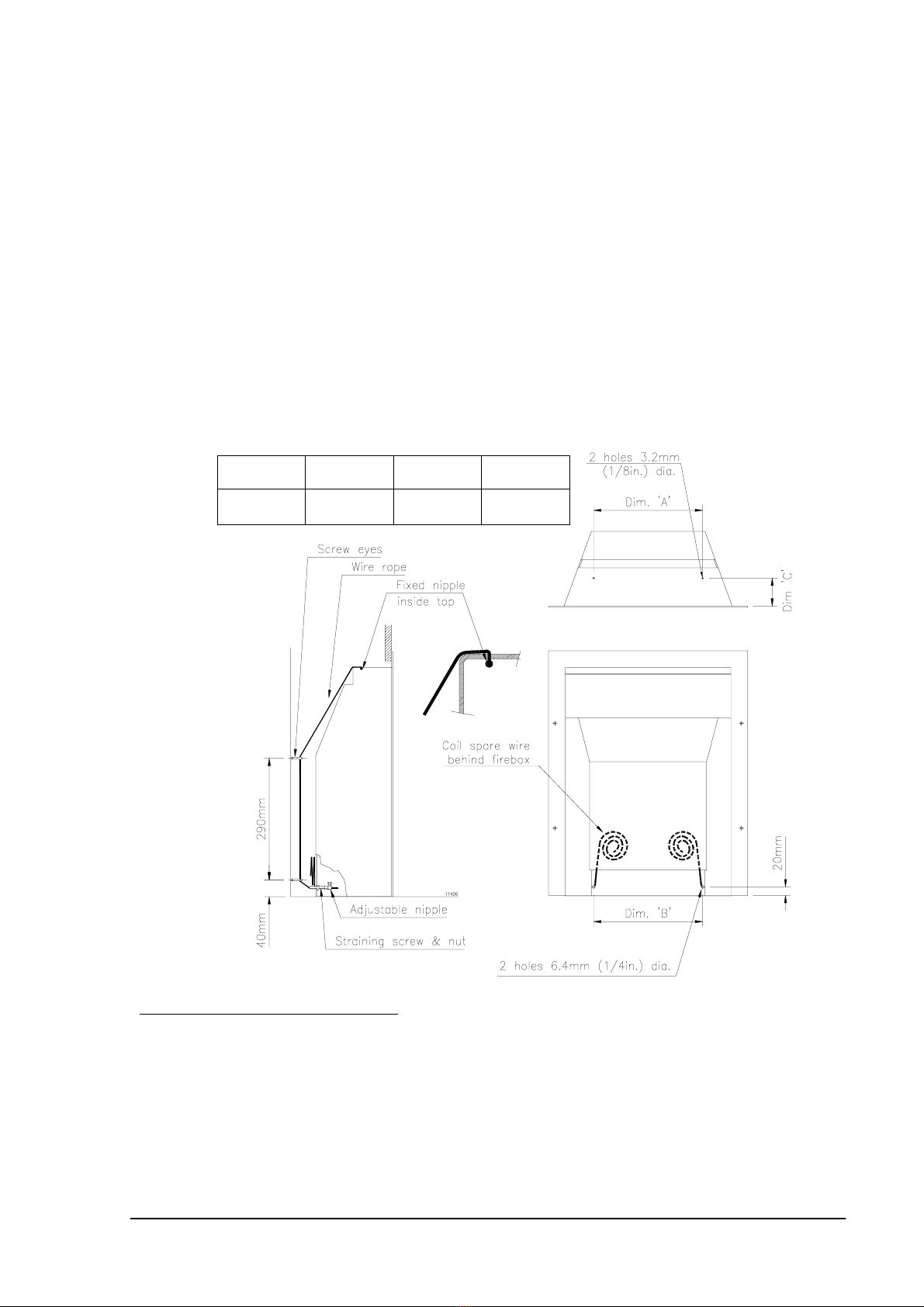

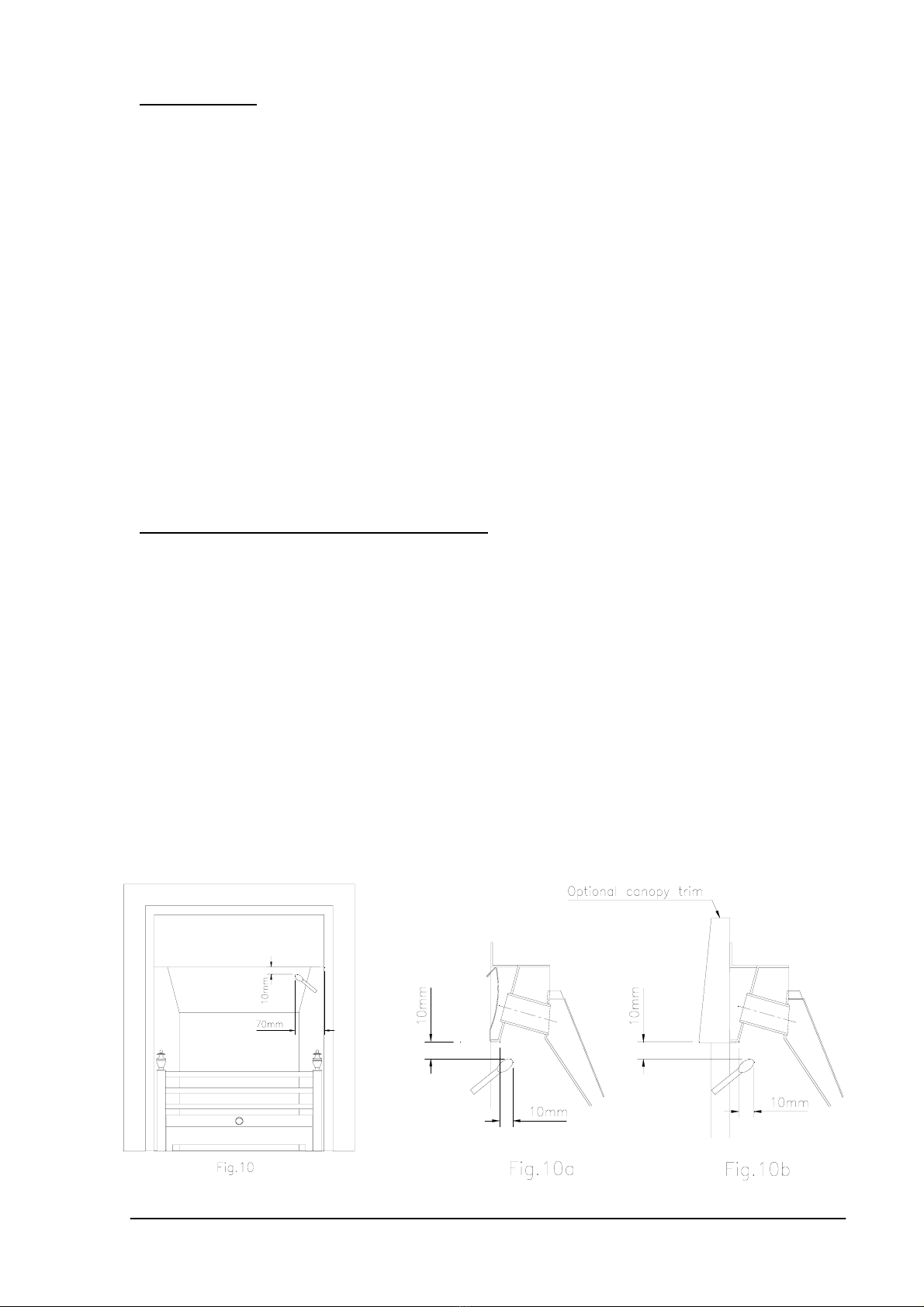

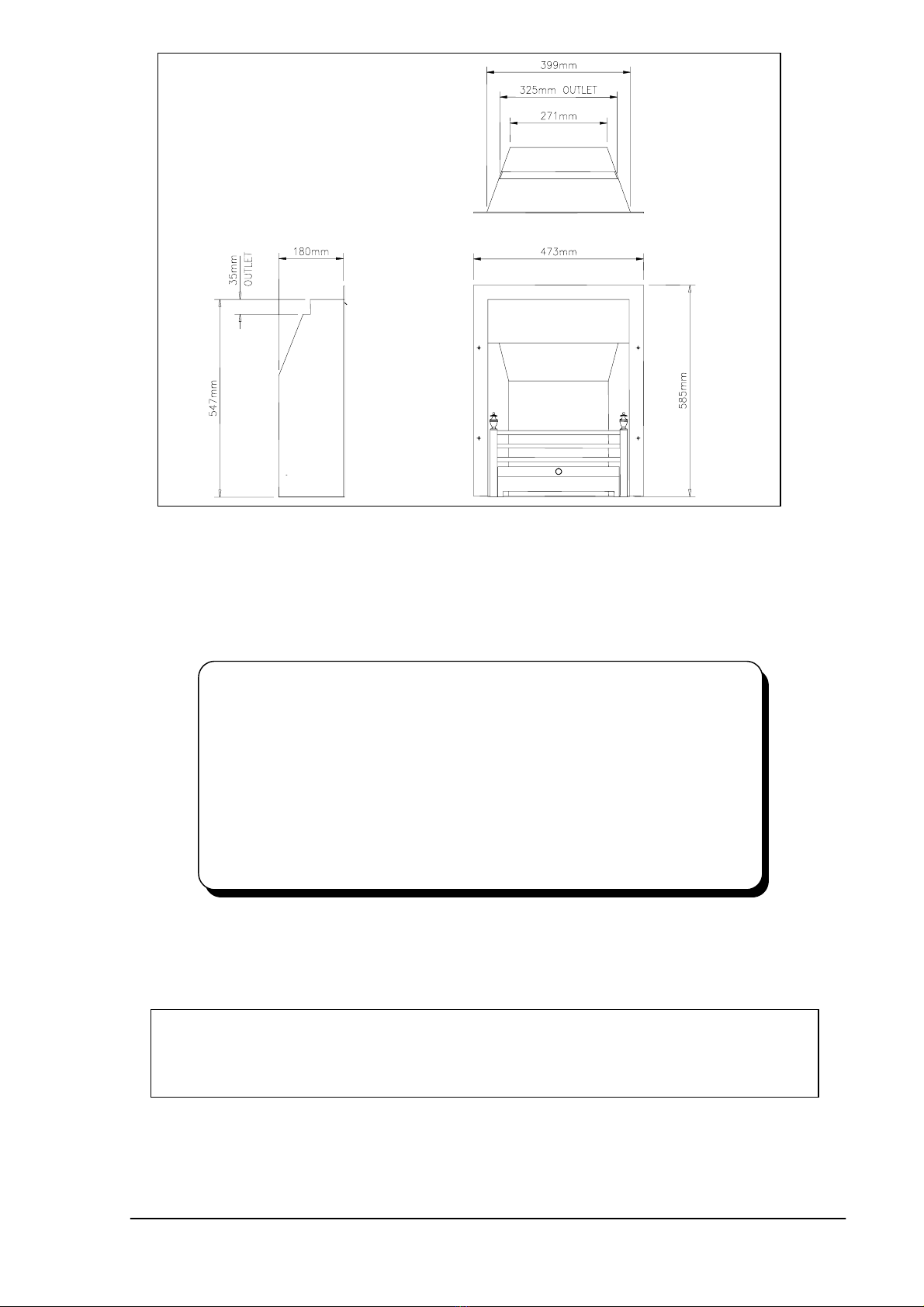

Dimensions:

Width over frame excluding trims : 473mm

Height including frame : 585mm (534mm Lowline Version)

Depth : 180mm

Shipping weight : 36kg

Country of destination : United Kingdom and The Republic of Ireland

NOTE: The Natural Gas and Propane Gas versions of this appliance are different models and

cannot be converted from one gas to another.

This appliance has been assessed by a Government appointed Notified Body and shown to meet the

'Essential Requirements' of the European Gas Appliance Directive.

The Directive lays down requirements for the safety of the appliance, together with its design,

construction, and use of materials. It also requires the production process to be covered by an

approved and monitored system of quality assurance.

Mandatory requirements

Straxgas fires must be installed with due regard to the following mandatory regulations:

The relevant British Standard installation specifications and codes of practice, and Building Regulations

issued by the Department of the Environment, and Building Standards (Scotland) Consolidated

Regulations issued by the Scottish Development Board.

Gas Safety (Installation and Use) Regulations.

Failure to install this appliance correctly could lead to prosecution and render the guarantee

invalid.

Attention is drawn to the latest edition of the following standards:

BS1251, Specifications of open-fireplace components.

BS5440, Part 1, Specification for installation of flues.

BS5440, Part 2, Specification for installation of ventilation for gas appliances.

BS5482, Part 2, LPG, installations in permanent dwellings.

BS5871, Part 2, Installation of decorative fuel effect gas appliances.

BS6891, Specification of low pressure gas pipework

BS8303, Replacing CP403.

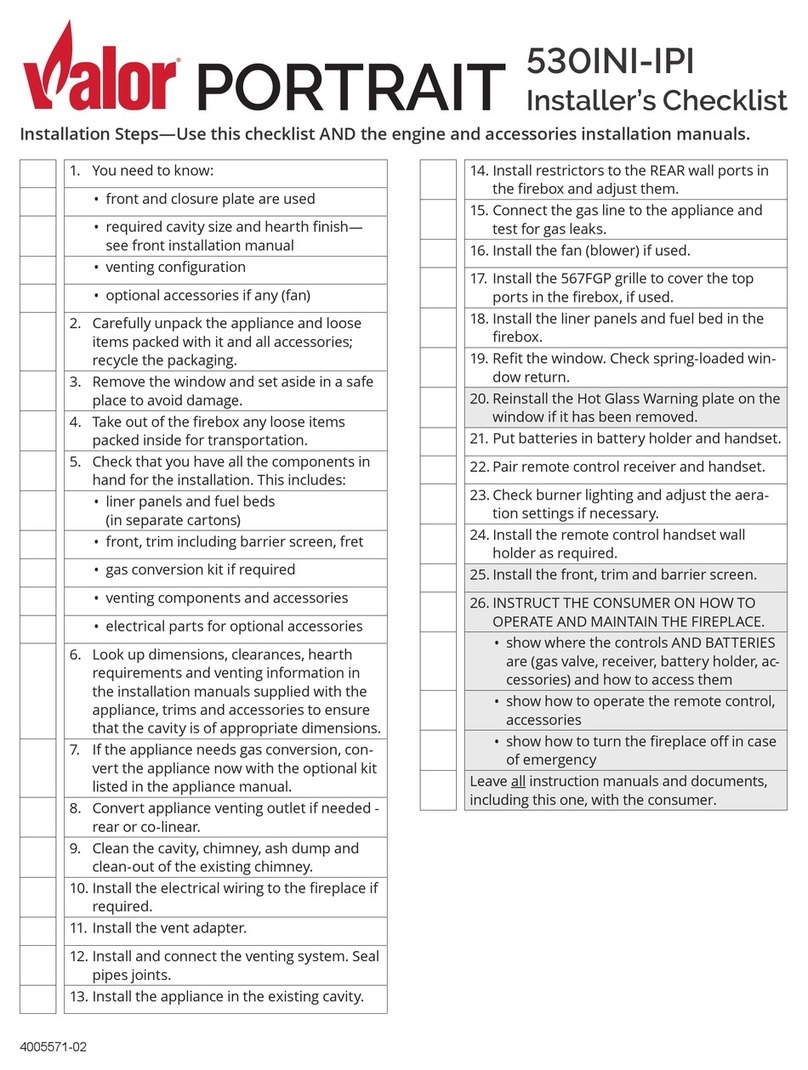

This Straxgas appliance is an inset live fuel effect gas fire and must only be installed by a

competent person (e.g. a C.O.R.G.I. member) in accordance with these installation

instructions. This appliance must be installed in accordance with the rules in force, and used

only in a sufficiently ventilated space. Consult these instructions before installation and use of

this appliance.

Additional purpose made air ventilation is not normally required.

Ventilation must be provided in accordance with the rules in force.

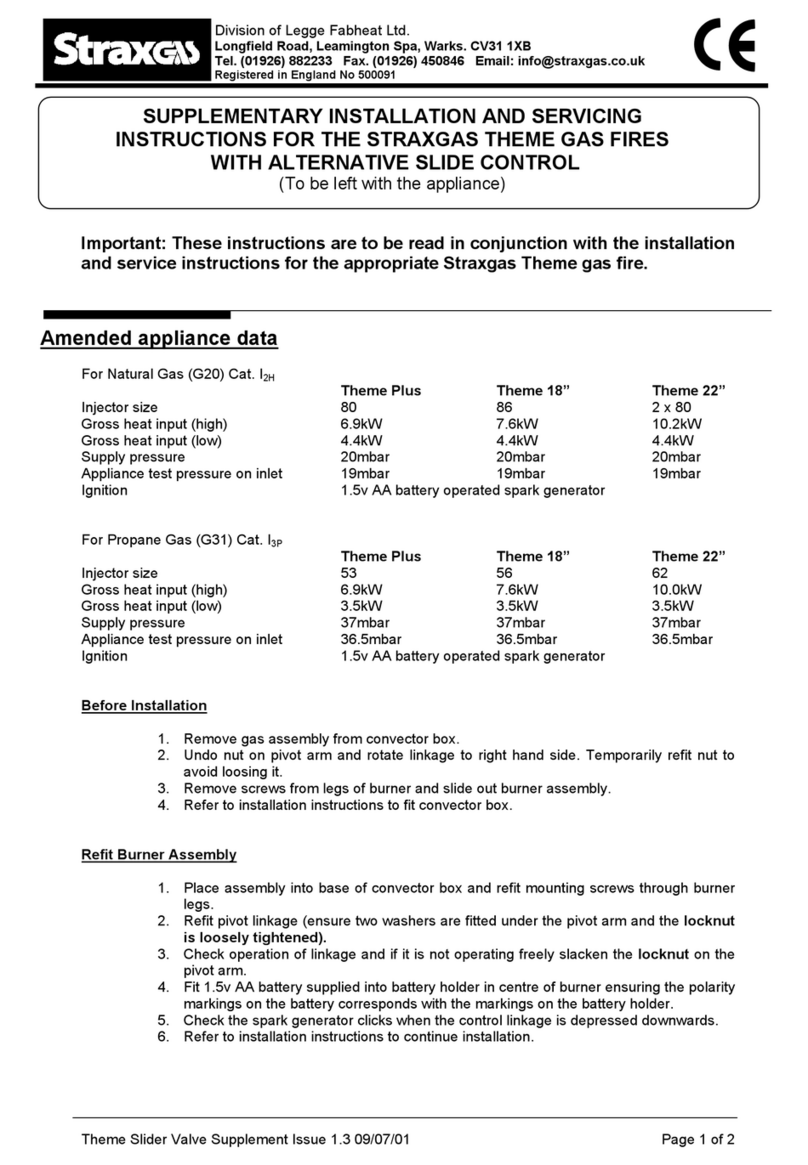

INSTALLATION AND SERVICING INSTRUCTIONS FOR THE STRAXGAS

THEME PLUS WITH 16" ECOTECH BURNER

(To be left with the appliance)

Division of Legge Fabheat Ltd.

Longfield Road, Leamington Spa, Warks. CV31 1XB

Re

istered in En

land No 500091

IE & Northern Ireland

GB