StripIR 4185 User manual

Dear Customer,

Thank you for purchasing the Model 4185 StripIR™. We believe it is the finest system of

its type and are confident you will think so too.

For technical assistance, training, replacement parts and assemblies, or any other

problems or questions, contact our Field Service specialists. They will do everything they

can to help you or will put you in touch with someone who can.

This instruction manual has been carefully prepared to ensure you get all the capabilities

out of your system we designed and built into it. To tell us how we can make the system,

our support of it, or this manual even more useful, we invite you to call our product

manager with your suggestions and recommendations.

Additional copies of this manual are available at reasonable cost from our Customer

Service Department.

Once again, let us welcome you to the growing family of Research, Inc. customers. We

look forward to working with you in the future.

Sincerely,

Terry Nigon

President

Research, Inc.

1

Instruction Manual

Infrared Strip Heater

7128 Shady Oak Road

•

Eden Prairie, MN 55344

(952) 949-9009 Fax (952) 949-9559

www.researchinc.com

Model 4185 StripIR

Publication No. 106991-001 Rev. 1

June 2005

Another quality product from:

1

Contents

Section 1

Introduction

Features and Benefits………………………………………………… 1-2

Heater Description……………………………………………………. 1-2

Product Sizes…….……………………………………………………. 1-3

Lamps………...…..……………………………………………………. 1-3

Power Controller………….…………………………………………… 1-4

Section 2

Safety

General………………………………………………………………… 2-1

Infrared Radiation…………………………………………………….. 2-1

High Temperatures…………………………………………………… 2-1

Electrical Safety………………………………………………………. 2-1

Fire Safety……………………………………………………………... 2-2

Section 3

Assembly

Required Tools…………………………………………………………. 3-1

Reflector and Lamp Installation ……………………………………… 3-1

Exploded View.…………………………………………………………. 3-1

Section 4

Installation

Unpack and Check for Damage……………………………………... 4-1

Required Tools………….……………………………………………… 4-1

Mechanical Installation...………………………………………..……. 4-1

Heater Dimensions …….……………………………………………… 4-2

Wiring Power to Heater……………………………………………….. 4-3

Section 5

Maintenance

General………………………………..………………………………… 5-1

Lamp and Reflector Surface Maintenance………………………….. 5-1

Lamp Replacement…………………………………………………….. 5-1

Section 5

Product Information

Specifications….……………………..………………………………… 6-1

Ordering Information……………………….………………………….. 5-1

Accessories/Replacement Parts…….……………………………….. 5-1

Section 1

Introduction

The Model 4185 StripIR infrared heater is a lamp and formed reflector heating system

that provides even heat distribution across a 1.7” wide strip. The Model 4185 heater uses

T-3, halogen lamps backed by a ceramic reflector to provide heat and offer the users

benefits of a high density heating solution.

The Model 4185 StripIR infrared heaters are designed for use in any application that

requires a clean, responsive, non-contact heat source. Some typical applications for the

heater are listed below:

•Curing epoxy

•Curing rubber coating on steel

•Drying and Curing Paint

•Drying and Curing adhesive

•Forming plastic

•Heating acrylic

•Laminating

•Preheating

•Reglossing

•Shrink Insulation

•Thermoforming

•Weld Stress Relief

1-1

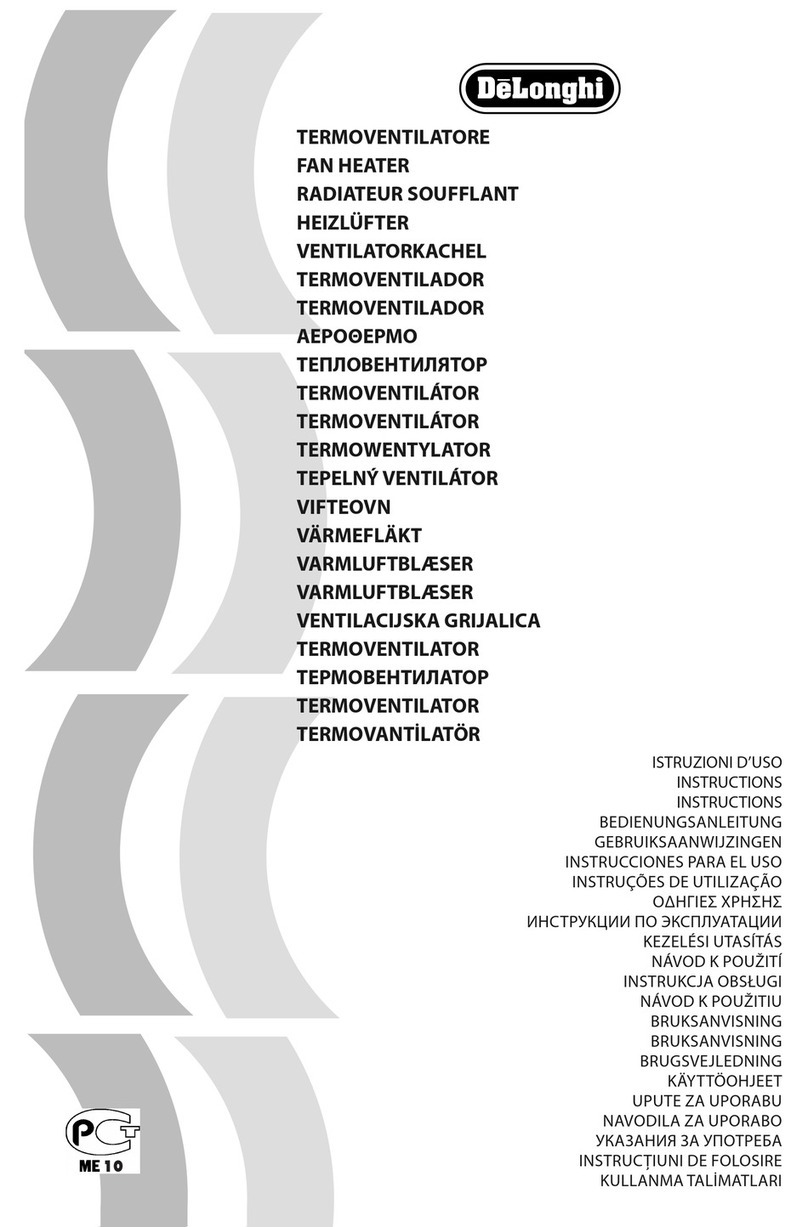

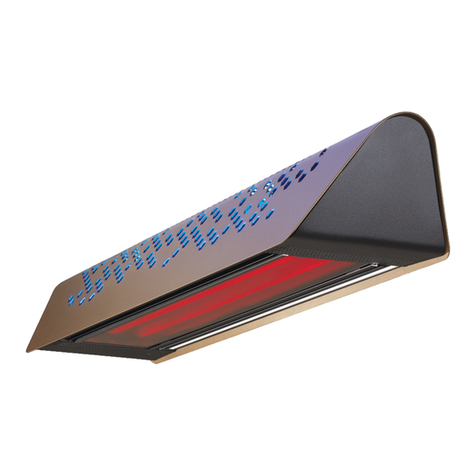

Figure 1-1: Model 4185 StripIR

Heater.

The lamps of these heaters heat up and cool down instantly in response to power

rcent of full operating temperature within three seconds of a cold

nergy dissipates to ten percent five seconds after the power supply is

focuses only on the desired area without heating the rest of the

ruction of these heaters, combined with air-cooling, allows them to

ith product being heated. eating

nsistent process outputs.

pplications. This

eater Module

aracteristics of the ceramic reflector surfaces in the Model

eramic Reflector

rovides heat by re-emitting medium wave and short-wave energy.

ounting

he Model 4185 has six 10-32 NF threaded holes for mounting purposes.

roduct Temperatures

temperature depends upon a number of conditions: the ability

erate as much as 100 watts per linear inch (3.9 watts per mm).

1-2

EATURES AND

EATER ION

F•

BENEFITS

control signals.

•They reach 90 pe

start.

•The radiant e

disconnected.

•Localized heat

product.

•The const

withstand continuous high temperature operation.

•Non-contact heat source does not come in contact w

•The infrared energy emitted from these heaters can be adjusted to match the h

requirements of a variety of applications.

•Repeatable results can be achieved for co

•Integrated power controllers to control the operation of the heater.

•The ceramic reflector in the heater module is self-cleaning in most a

feature provides both high efficiency and low maintenance cost.

H

Hhe absorption/emission ch

DESCRIPT

T

4185 heater module maintain a high surface temperature. The reflector material also

serves as a re-emitter of medium wave (3 to 4 microns) infrared energy. This can be

beneficial in many processes depending on the absorptive properties of the material

being heated.

C

he ceramic reflector p

T

M

he back of t

T

P

he maximum work-pieceT

of the work-piece to absorb radiant energy, the amount of heat loss, and the applied

voltage to the heater emitter. For continuous heating processes, the maximum work-

piece temperature should be less than 1300°F (704°C).

eat Flux DensitiesH

he Model 4185 can genT

Dissipated power for the heaters varies with heated length and is listed in Specifications.

Heat flux density is a product of the lamp type, applied voltage, and distance between the

lamp and the target surface.

Product Sizes

A strip 1.7 inches in width and length from 5 to 38 inches (43 by 965 mm) can be heated

with a single Model 4185. Mounting two or more heaters side-by-side can create different

heated areas. For example, Figure 3 shows eight heaters installed cylindrically to provide

high heat concentration on work-piece objects. Heating efficiency is highest on objects 1

inch or larger. Figure 4 shows three heaters installed to provide heat to a moving web of

material. Additional heaters could be used in similar applications requiring greater heat

flux density.

Figure 1-2: Cylindrical Heating

Figure 1-3: Web Drying

Lamps

The Model 4185 utilizes high intensity, short wave tungsten lamps. The tungsten emitter

in the lamps has an operating temperature of up to 4000°F (2205°C) with a spectral

energy peak wavelength of 1.15 microns. Each heater requires one lamp to operate. The

Model 4185 will heat a strip that is 1.7 inch (43 mm) wide and is available in heated

lengths of 5, 10, 16, 25 and 38 inches (127, 254, 406, 635 and 965 mm). Heated lengths

should be at least 20% larger than work-piece.

1-3

Power Controller

The Model 4185 heater comes with the Research, Inc. Model 5420 SCR Power

Controller. A separate instruction manual for the Power Controller is included with the

heater.

Figure 1-4: Model 4185 with

Power Controller

1-4

Safety

The Model 4185 Strip Heater is designed for safe operation. Nevertheless, installation,

maintenance and operation of the heater can be dangerous for a careless operator or

maintenance person. For your safety and the safety of others, please read the

instructions in this INSTRUCTION MANUAL and follow these safety practices that will

help to prevent accident or injury.

CAUTION!

Parts of the heater may exceed 500°F (260°C). Contact with the lamps, reflectors, or

metal parts near the lamps may cause severe BURNS.

WARNING!

There is danger of electrical shock when servicing the heater.

CAUTION!

2-1

GENERAL

INFRARED

RADIATION

HIGH

TEMPERATURES

ELECTRICAL

SAFETY

Observe that all applicable local and national electrical codes are met and a safe

electrical ground system is installed before attempting to operate the heater. Refer

to the Section 3 for proper installation procedures.

NEVER place hands under the heating elements.

ALWAYS allow heating element to cool at least 5 minutes before touching the

lamps or adjacent parts.

Continuous exposure to high intensity infrared radiation at close proximity could be

harmful to eyes or skin. Although infrared lamps are not emitting ultra violet

electromagnetic radiation, harmful burns could still result if an operator is in close

contact with lamps being operated at high intensity.

Because of the brilliant light emitted by infrared lamps at full intensity, it is

recommended that the eyes be shielded from the glare if observing the lamps or

radiant heat chamber for an extended period of time. Use suitable shaded lenses or

dark glasses.

Section 2

WARNING!

1. Obey the same fire-safety rules you observe when you work with hot plates, high

intensity infrared heaters, propane or acetylene torches, soldering irons, and

other equipment that gets very hot.

2. Remove all solids, liquids, and gases that burn easily from the area around the

heater.

3. Know where the nearest fire extinguisher is located and how to use it.

4. Know how to put out fired from all the types of material near the Model 4185

Heater.

ALWAYS disconnect the external power lines prior to servicing the heater.

ALWAYS disconnect the power lines AND any optional interlock circuits before

installing or changing lamps.

NEVER operate the heater with the heater end covers removed.

FIRE SAFETY

2-2

Assembly

Remove the Model 4185 heater from its shipping container and associated packaging.

Check the entire unit for any potential damage due to shipping. In the unlikely event

damage has occurred, keep all shipping containers and materials and file a damage

claim with the shipping company that delivered the heater.

•Phillips Screwdriver

•Pliers

•Wire Stripper

NOTE:

The Reflectors and Lamp are shipped separately and must be installed prior to operation.

Refer to Figures 3-1 Reflector and Lamp Assembly operations.

1. Remove both Ceramic End Covers, item 1, from both End Reflector assemblies, item

4.

2. Remove End Reflector assemblies, item 4, from Heater Housing, item 2, on the end

opposite Power Cord, item 19.

3. Slide Reflectors, item 3 into Heater Housing, item 2.

4. Reassemble End Reflector, item 4.

CAUTION!

Section 3

UNPACK AND

CHECK FOR

DAMAGE

REQUIRED TOOLS

REFLECTOR

AND LAMP

INSTALLATION

Wear soft, clean, oil-free flannel or plastic gloves when handling halogen, quartz

lamps. Oils and contaminants are readily transmitted to the quartz by unprotected

hands and can cause premature lamp failure.

5. From the end of the assembly insert the Lamp, item 18, through the End Reflector

openings

6. Trim approximately 4“ off each Lamp Lead then strip.25” of insulation off each Lamp

Lead.

7. Insert Lamp Lead into Terminal Blocks, item 17, to make connections to power

wiring. Repeat at other end.

8. Reassemble End Covers, item 1.

3-1

DESCRIPTIONOVERALL LENGTHMODEL NO. 5 INCH9.504185-05 10 INCH14.504185-10 16 INCH20.504185-16 25 INCH29.504185-25 38 INCH42.504185-38

COMPONENT NO. QTY ITEM DESCRIPTION

037193-000 2 1 COVER-END 4184

037194-004 1 2 FAB-COVER 4184 20.50 LG

037195-004 2 3 REFL-4184-10

037197-000 2 4 FAB/ASSY-END REFLECTOR

037603-002 1 5 FAB-COVER SAFETY 4184-16

054979-027 2 6 SCRW-PH 4-40X1 SST PH

054979-105 8 7 SCRW-PH 10-32X1/4 SST PH

054979-123 10 8 SCRW-PH 10-32X.5 PH SS SEMS-IN

055029-002 2 9 WASHER-FLAT #4 SST

055307-017 2 10 NUT-HEX 4-40 SST

055310-017 2 11 WASHER-SPLIT,#6,SST

055455-011 4 12 WASHER-LOCK #10 INT ZI

055729-004 1 13 PLUG-BUTTON,7/8 DIA.

060512-001 1 14 STRAIN RELIEF-BUSHING

095180-006 2 15 LABEL-THERMAL/BARCODE (2X1)

098901-001 1 16 LABEL-HOT SURFACE UL IEC 5041

100571-001 2 17 TERMINAL BLOCK CERAMIC 2P 10A

103390-004 1 18 LAMP-QIH240-2000/V CER.END

106690-002 1 19 CABLE-14/3 TEFLON JACKET 200°C

***

***

***

***

*** DENOTES PART NUMBERS LISTED ARE FOR MODEL 4185-10.

CONSULT FACTORY FOR PART NUMBER CORRESPONDING TO

YOUR MODEL.

7

REF

1

2

2

1

3

2

4

2

5

1

6

2

7

8

8

10

9

2

10

2

11

2

12

4

13

1

14

1

17

2

19

1

18

1

Figure 3-1: Reflector and

Lamp Assembly

3-2

Section 4

Installation

TOOLS REQUIRED

MECHANICAL

INSTALLATION

Figure 4-1: Typical

Installation for Model 4185

Heater

•Phillips Screwdriver

NOTE:

Refer to Figures 4-1 Typical Installation.

Refer to Figure 4-2 Mounting Dimensions.

As shown in Figure 4-1, six 10-32 x 1/2 inch screws are provided on the top of the Model

4185 heater for mounting purposes. The heater can be attached directly to a suitable

frame structure or mounting brackets using these six screws. Mount the heater so that

the intended target absorbs the generated infrared energy yet not so close that the heater

touches the target. The heater should be mounted so that each end cover may easily be

removed for lamp installation.

Multiple Model 4185 heaters can be mounted side-by-side to form large heating arrays.

4-1

Figure 4-2: Mounting

Dimensions for Model 4185

Heater

38 (965)

25 (635)16 (406)10 (254)5 (127)

B Lighted

Length

Inches (mm)

42.5 (1080)29.5 (749)20.5 (521)14.5 (368)9.5 (241)

A

Overall

Length

Inches (mm)

4185-38

4185-254185-164185-104185-05

Dimension

DIMENSIONS STRIP IR 4185

4-2

WIRING POWER

TO HEATER

All electrical wiring from the Model 4185 to the Model 5420 SCR Power

Controller is included on Model 4185 units. Refer to Model 5420 SCR Power

Controller Instruction Manual for further wiring details.

4-3

Maintenance

Periodic inspection and removal of dirt and contaminants will ensure that equipment can

be operated safely.

In dirty environments or heating operations the lamps may become contaminated with

smoke, dust, fingerprints or other foreign matter. When this occurs it is recommended

that the lamp be cleaned. Doing so will extend the life of the lamp and improve the

heater’s overall performance. Use the following procedure:

WARNING!

CAUTION!

1. With a soft, dry cloth or tissue, wipe the residue from the lamps. Household strength

ammonia can be used to clean the lamps if necessary.

The ceramic reflector is a high temperature material with unlimited life and is essentially

self-cleaning.

CAUTION!

1. Remove both end covers from the Model 4185 by removing the two screws from

each end cover using the Phillips screwdriver.

2. Disconnect lamp leads from terminal blocks.

Section 5

GENERAL

LAMP AND

REFLECTOR

SURFACE

MAINTENANCE

LAMP

REPLACEMENT

Disconnect the power cable from the power source and allow the heater to cool

before continuing.

Wear soft, clean, oil-free flannel or plastic gloves when handling quartz lamps. If

skin oils come in contact with the quartz tube, the lamp will fail prematurely.

Wear soft, clean, oil-free flannel or plastic gloves when handling quartz lamps. If

skin oils come in contact with the quartz tube, the lamp will fail prematurely.

3. Grasp lamp end and pull the lamp out of heater.

4. Feed one end of the new lamp (wire first) into the lamp slot in end reflector, through

the heater, and into the lamp slot on the heater’s opposite end.

5. Connect lamp leads to terminal blocks.

6. Reinstall both end covers, insert all four end cover screws, and ‘hand tighten’ each

screw using the Phillips screwdriver.

5-1

Section 6

Product Information

Specification

4185-16-

1

600

Clear

103390-005

1.6 KW

4185-10-

1

00

0

Clear

103390-003

1.0 KW

4185-38-3800

Clear

103390-010

3.8

480

V

o

l

t

12.8

(5

.

8)

4185-38

8.4 (3.8)5.4 (2.6)3.3 (2.6)2.0 (0.91)

Weight lb (kg)

2.51.0 KW0.5 KW

Power at

Rated voltage

480 Volt240 Volt240 Volt120 Volt

Rated Voltage

103390-007097771-001

103390-001

Lamp

4185-25-2500

4185-10-

1000E

4185-05-500

Part to Order

ClearEZ eyeClear

Optical

4185-254185-164185-104185-05Specifications

MODEL SPECIFICATIONS 4185

6-1

Ordering Information

MODEL 4185

Product Description - 5 inch Strip heaters (500 watt)

4185-05-500-01-00 4185-05 with Model 5420-120 controller (includes potentiometer)

4185-05-500-02-00 4185-05 with Model 5420E-120 controller (includes potentionmeter and timer)

4185-05-500-03-00 4185-05 with Model 5420mA-120 controller (includes 4-10 mA input control)

Product Description - 10 inch Strip heaters with EZ eye lamp (1000 watt)

4185-10-1000E-01-00 4185-10 with Model 5420-120 controller (includes potentiometer)

4185-10-1000E-02-00 4185-10 with Model 5420E-120 controller (includespotentionmeter and timer)

4185-10-1000E-03-00 4185-10 with Model 5420mA-120 controller (includes 4-10 mA input control)

Product Description - 10 inch Strip heaters (1000 watt)

4185-10-1000-01-00 4185-10 with Model 5420-240 controller (includes potentiometer)

4185-10-1000-02-00 4185-10 with Model 5420E-240 controller (includes potentionmeter and timer)

4185-10-1000-03-00 4185-10 with Model 5420mA-240 controller (includes 4-10 mA input control)

Product Description - 16 inch Strip heaters (1600 watt)

4185-16-1600-01-00 4185-16 with Model 5420-240 controller (includes potentiometer)

4185-16-1600-02-00 4185-16 with Model 5420E-240 controller (includes potentionmeter and timer)

4185-16-1600-03-00 4185-16 with Model 5420mA-240 controller (includes 4-10 mA input control)

Product Description - 25 inch Strip heater with EZ Eye lamps (2500 watt)

4185-25-2500E-01-00 4185-25 with Model 5420-240 controller (includes potentiometer)

4185-25-2500E-02-00 4185-25 with Model 5420E-240 controller (includes potentionmeter and timer)

4185-25-2500E-03-00 4185-25 with Model 5420mA-240 controller (includes 4-10 mA input control)

Product Description - 25 inch Strip heaters (2500 watt)

4185-25-2500-01-00 4185-25 with Model 5420-480 controller (includes potentiometer)

4185-25-2500-02-00 4185-25 with Model 5420E-480 controller (includes potentionmeter and timer)

4184-25-2500-03-00 4185-25 with Model 5420mA-480 controller (includes 4-10 mA input control)

Product Description - 38 inch Strip heaters (3800watt)

4185-38-3800-01-00 4185-38 with Model 5420-480 controller (includes potentiometer)

4185-38-3800-02-00 4185-38 with Model 5420E-480 controller (includes potentionmeter and timer)

4185-38-3800-03-00 4185-38 with Model 5420mA-480 controller (includes 4-10 mA input control)

6-2

Accessories/Replacement Parts

6-3

Model 5420E-240 Power Controllers5420E-240 Model 5420-240 Power Controllers5420-240

480 Power Controllers

Model 5420E-480 Power Controllers5420E-480

Model 5420-480 Power Controllers5420-480

Model 5420m

240 Volt Power Controllers

A

-240 Power Controllers5420m

A

-240

Model 5420m

A

-480 Power Controllers5420m

A

-480

Model 5420m

A

-Power Controller5420m

A

-120

4185-10-1000 Heater Module4185-10-1000

4185-38-3800 Heater Module4185-38-3800 4185-25-2500 Heater Module4185-25-2500 4185-16-1600 Heater Module4185-16-1600

Model 5420-120 Power Controller5420-120

120 volt Power Controllers

38 inch len

g

th

(

6

p

er heater

)

037795-002

4184-05-500 Heater Module4185-05-500

Heater Modules

Model 5420E-120 Power Controller5420E-120

10 inch len

g

th

(

2

p

er heater

)

25 inch len

g

th

(

4

p

er heater

)

037195-002 16 inch len

g

th

(

3

p

er heater

)

037195-001

05 inch len

g

th

(

2

p

er heater

)

037195-003

16 inch, 1600 watt103390-005 25 inch 2500 watt

103390-007

Re

p

lacement Reflectors

38 inch, 3800 watt103390-010

5 inch

,

500 watt

,

103390-001

Re

p

lacement Lam

p

s

(

all lam

p

s sold in

p

airs

)

MODEL 4185

103390-003

037195-004

10 inch, 1000 watt

Accessories/Replacement Parts continued

4184/4185 Ceramic Reflectors Replacement Part Numbers

Heater Size Old Reflector Part # Length Qty. New Reflector Part # Length Qty.

5 037195-003 6.0” 1 037195-003 6.00” 1

10 037195-004 5.5” 2 037195-008 11.0” 1

16 037195-001 5.66” 3 037195-008

037195-003 11.0”

6.0” 1

1

25 037195-002 6.5” 4 037195-008

037195-007 11.0”

4.0” 2

1

38 037195-002 6.5” 6 037195-008

037195-003 11.0”

6.0” 3

1

6-4

Table of contents