Stromberg-Carlson 450 Dimension Guide

ENGINEERING

DATA

STROMBERG-CARLSON

NO.

450

RADIO

RECEIVERS

STROMBERG-CARLSON

TELEPHONE

MANUFACTURING

COMPANY

ROCHESTER,

NEW

YORK

P-30876

Issue

1

Printed

in

U.

S.

A.

IDENTIFICATION

TABLE

Model

Input

Power

Frequency

Chassis

Cabinet

Speaker

450-M

.

50-60

Cycles

30162

30164

27504

450-MB

.

25-60

Cycles

30163

30164

27504

SPECIFICATIONS

Type

of

Circuit.

.

Tuning

Ranges...

Number

of

Tubes

Type

of

Tubes...

Voltage

Rating...

Power

Frequency

Rating.

Input

Power

Rating.

Intermediate

Frequency.

Speaker

Voice

Coil

Impedance

at

400

Cycles

Speaker

Field

Coil

Resistance.

.Superheterodyne

with

Electric

Tuning

A—.53

to

1.7

Me.;

B—2.3

to

7.5

Me.;

C—7.5

to

23

Me.

.

Eleven

.6K7,

R.

F.

Amplifier

6A8,

Modulator

6J5,

Oscillator

6K7,

I.

F.

Amplifier

6H6,

Demodulator

6SQ7,

Audio

Amplifier

6SQ7,

Audio

Inverter

6F6G,

Output

(2)

5Z3,

Rectifier

6AF6G,

Tuning

Indicator

.105

to

125

Volts

-Standard

50-60

Cycles,

also

available

25-60

Cycles

.120

Watts

.455

Kilocycles

.Approximately

1.5

Ohms

.505

Ohms

General

FEATURES

This

is

an

eleven

tube,

three

gang,

three

band,

high

fidelity

receiver,

designed

for

operation

with

the

Stromberg-Carlson

senior

Acoustical

Labyrinth

and

Carpinchoe

Speaker.

The

chassis

is

of

the

fortified

type

with

bails

provided

for

ease

in

handling

and

servicing.

Auto¬

matic

tuning

is

accomplished

by

means

of

a

motor

drive

controlled

by

a

commutator

and

brush

assembly,

and

the

dial

is

of

the

slide

rule

type,

edge-lighted

for

clear

visibility

without

glare.

Separate

treble

and

bass

controls

are

provided

to

make

possible

accurate

adjustment

of

the

tone,

and

the

chassis

is

designed

to

be

easily

converted

for

use

with

remote

control

or

phonograph.

This

chassis

is

designed

to

provide

the

maximum

in

sensitivity

and

selectivity

and

excellent

tone

quality

for

the

discriminating

customer.

It

should

also

be

relatively

free

from

the

“birdies,

tweets

and

whistles”

and

interference

of

the

type

found

in

some

smaller

sets.

Special

Circuits

A

tuning

indicator

having

two

apertures,

one

for

strong

signals

and

one

for

weak

signals,

is

used

with

this

chassis.

One

aperture

will

close

with

a

signal

of

approximately

100,000

microvolts,

and

the

other

will

not

close

even

with

a

two

volt

signal.

Iron

core

coils

are

used

in

the

IF

and

RF

circuits

to

provide

greater

stability

and,

in

addition,

a

thermal

drift

compensator

is

included

in

the

circuit.

The

high

frequency

end

of

each

band

is

spread

out

by

means

of

special

capacitor

plates,

to

pro¬

vide

greater

ease

in

tuning

and

automatic

low

level

bass

compensation

is

provided.

The

audio

system

employs

a

special

inverter

push-pull

circuit

designed

to

provide

excellent

fidelity

and

the

chassis

is

thoroughly

shielded

throughout

with

an

electro-statically

shielded

power

transformer.

Automatic

Tuning

Twelve

push

buttons

are

provided.

From

right

to

left

their

operation

is

as

follows:

1

Manual

Control

2

Remote

Control

3-10

Pre-set

Stations

(8)

11

Phonograph

12

Off

Switch

1

Pushing

any

button

(except

the

Off

button)

turns

the

set

on

and

tuning

is

accomplished

by

means

of

an

electric

motor

driving

the

regular

variable

capacitor

to

a

pre-set

point.

Setup

is

very

easily

accomplished

by

means

of

a

switch

which

causes

the

pilot

light

to

go

out

when

the

brush

is

properly

located.

Remote

Control

Remote

selection

of

stations

may

be

accomplished

by

simply

plugging

the

remote

control

box

into

the

socket

provided

on

the

back

of

the

chassis

and

a

motor

to

control

the

volume

can

be

readily

attached

to

the

volume

control

shaft.

The

identifying

number

of

the

package

containing

the

remote

control

box,

motor

and

all

neces¬

sary

parts

is

30387

for

50-60

cycles

and

30391

for

25

cycles.

Phonograph

Operation

A

socket

is

provided

on

the

back

of

the

chassis

into

which

a

record

player

may

be

plugged,

and

a

switch

is

provided

on

the

front

of

the

chassis

for

switching

from

“Radio”

to

“Phonograph”.

Television

Switching

to

“Phonograph”

also

makes

the

audio

amplifier

and

loud

speaker

available

for

use

with

television

receivers

designed

for

this

type

of

sound

reproduction.

ACCESSORIES

Antenna

For

best

results

use

a

Stromberg-Carlson

Antenna.

These

Antennas

are

supplied

in

kits

con¬

taining

all

the

necessary

parts

for

mounting

and

installation

and

are

designed

especially

for

use

with

all

Stromberg-Carlson

receivers.

Playing

Records

To

obtain

the

best

quality

of

phonograph

reproduction

a

Stromberg-Carlson

record

player

is

recommended.

They

are

designed

for

use

with

this

receiver,

and

all

that

is

necessary

is

to

con¬

nect

the

record

player

to

the

single

prong

socket

provided

in

the

chassis

and

proceed

to

operate.

The

volume

and

tone

may

be

controlled

with

the

controls

at

the

receiver,

or

(if

such

is

pro¬

vided)

the

volume

control

on

the

record

player

may

be

used.

A

low

impedance

pick-up

may

also

be

used,

but

a

matching

transformer

must

be

placed

be¬

tween

the

phonograph

pick-up

and

the

chassis.

Remote

Control

Stromberg-Carlson

has

prepared

a

“Remote

Tuning

Control

Unit”

which

may

be

easily

installed

on

these

receivers.

This

Unit

enables

the

user

to

select

any

one

of

the

eight

favorite

stations

which

have

been

previously

set

up

on

the

electric

tuning

system

at

a

distance

from

the

receiver

up

to

the

length

of

the

attached

cable.

A

motor

and

two

push

buttons

are

also

included

for

controlling

the

volume.

These

units

complete

with

accessories

and

installation

instructions

are

available

in

package

assemblies

P.

30387

for

use

with

50-60

cycle

receivers

and

P.

30391

for

use

with

25

cycle

receivers.

Headset

Attachment

Headphones

can

be

very

simply

attached

to

this

receiver.

Ask

for

Pc.

No.

28303

Headset

Package

Assembly,

which

comes

complete

with

headphones

and

installation

instructions.

Care

of

Cabinet

The

finish

of

Stromberg-Carlson

Cabinets

should

be

protected

by

using

Stromberg-Carlson

Cabinet

Polish

regularly.

It

is

available

in

pint

cans,

designated

as

Pc.

No.

28601.

Nicks

and

scratches

of

most

kinds

can

be

repaired

quickly

and

easily

by

proper

use

of

the

Pc.

No.

26962

Touch-Up

Kit.

Complete

instructions

are

provided

with

each

kit.

Tools

Stromberg-Carlson

can

supply

all

the

tools

required

for

working

on

these

sets.

For

example:

SD-29

Phillips

Head

Screwdriver

No.

24608

Aligning

Tool

Also

pliers,

cutters,

screwdrivers,

etc.

2

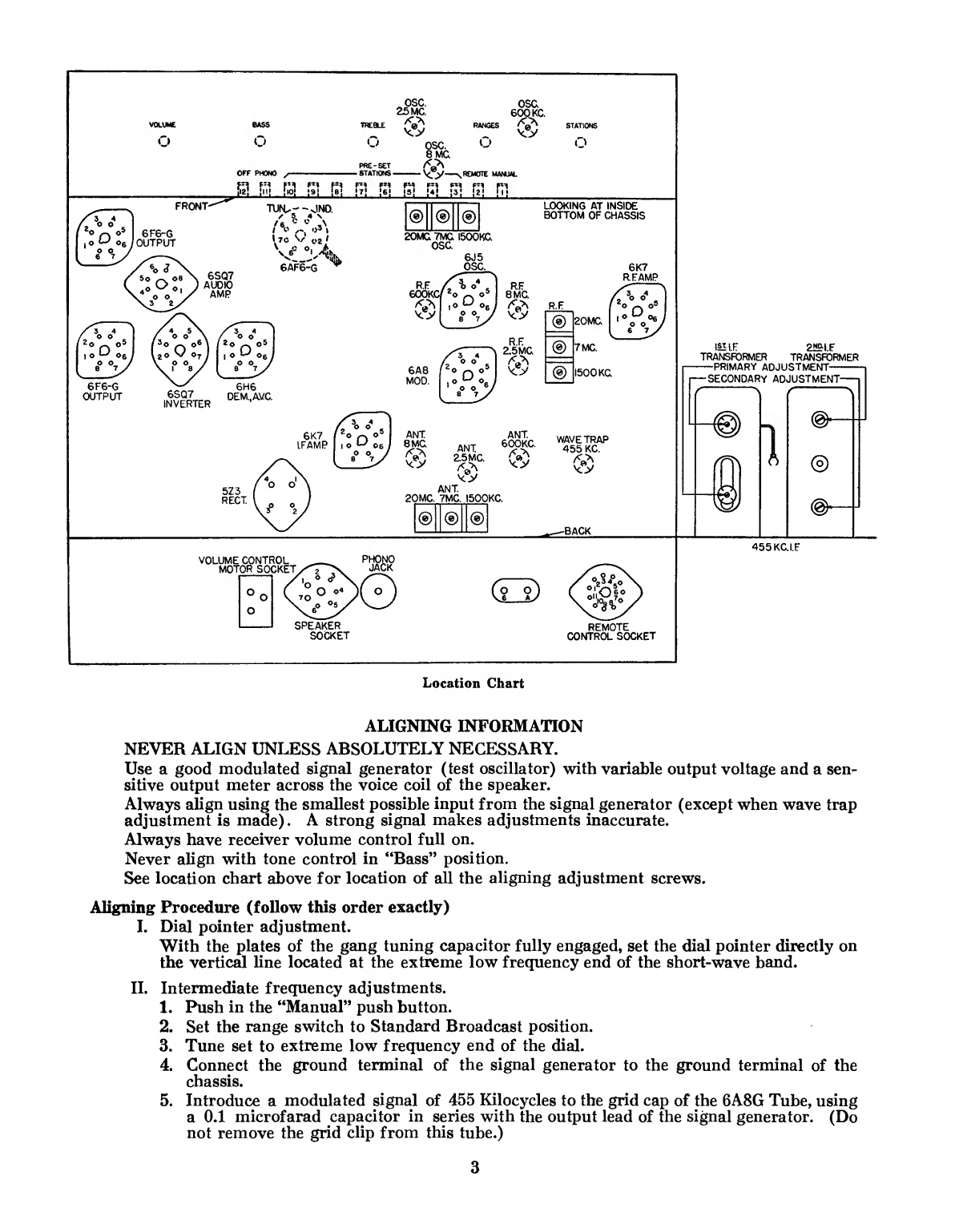

ALIGNING

INFORMATION

NEVER

ALIGN

UNLESS

ABSOLUTELY

NECESSARY.

Use

a

good

modulated

signal

generator

(test

oscillator)

with

variable

output

voltage

and

a

sen¬

sitive

output

meter

across

the

voice

coil

of

the

speaker.

Always

align

using

the

smallest

possible

input

from

the

signal

generator

(except

when

wave

trap

adjustment

is

made).

A

strong

signal

makes

adjustments

inaccurate.

Always

have

receiver

volume

control

full

on.

Never

align

with

tone

control

in

“Bass”

position.

See

location

chart

above

for

location

of

all

the

aligning

adjustment

screws.

Alig

n

in

g

Procedure

(follow

this

order

exactly)

I.

D

ial

pointer

adjustment.

With

the

plates

of

the

gang

tuning

capacitor

fully

engaged,

set

the

dial

pointer

directly

on

the

vertical

line

located

at

the

extreme

low

frequency

end

of

the

short-wave

band.

II.

Intermediate

frequency

adjustments.

1.

Push

in

the

“Manual”

push

button.

2.

Set

the

range

switch

to

Standard

Broadcast

position.

3.

Tune

set

to

extreme

low

frequency

end

of

the

dial.

4.

Connect

the

ground

terminal

of

the

signal

generator

to

the

ground

terminal

of

the

chassis.

5.

Introduce

a

modulated

signal

of

455

Kilocycles

to

the

grid

cap

of

the

6A8G

Tube,

using

a

0.1

microfarad

capacitor

in

series

with

the

output

lead

of

the

signal

generator.

(Do

not

remove

the

grid

clip

from

this

tube.)

3

6.

A

d

just

the

L

F.

Aligners

for

maximum

output

in

the

following

order:

A.

Secondary

of

second

I.

F.

transformer.

B.

Primary

of

second

L

F.

transformer.

C.

Secondary

of

first

I.

F.

transformer.

D.

Primary

of

first

I.

F.

transformer.

IIL

Radio

frequency

adjustments.

Short

Wave

Range

(C

Band)

1.

Replace

the

0.1

microfarad

capacitor

in

series

with

the

output

lead

of

the

signal

gen¬

erator

with

a

400

ohm

carbon

type

resistor,

and

connect

it

to

the

antenna

terminal

of

the

chassis.

2.

Set

the

range

switch

to

the

short-wave

range

position

(C

Band).

3.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

8

megacycles.

4.

Adjust

the

8

megacycle

oscillator

R.

F.

and

antenna

iron

cores

for

maximum

signal.

5.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

20

megacycles.

6.

Adjust

the

20

megacycle

oscillator

R.

F.

and

antenna

aligning

capacitors

for

maximum

signal.

7.

Repeat

operations

three

and

four.

8.

Repeat

operations

five

and

six.

Medium

Wave

Range

(B

Band)

1.

Leave

the

receiver

connected

in

the

same

manner

as

when

adjusting

the

Short-Wave

Range

(GBand).

2.

Set

the

range

switch

to

the

medium

wave

range

position

(B

Band).

3.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

2.5

megacycles.

4.

Adjust

the

2.5

megacycle

oscillator,

R.F.

and

antenna

iron

cores

for

maximum

signal.

5.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

7.0

megacycles.

6.

Adjust

the

7

megacycle

oscillator,

R.

F.

and

antenna

aligning

capacitors

for

maximum

signal.

7.

Repeat

operation

three

and

four.

8.

Repeat

operation

five

and

six.

Standard

Broadcast

Range

(A

Band)

1.

Replace

the

400

ohm

carbon

type

resistor

in

series

with

the

output

lead

from

the

signal

generator

with

a

200

micro-microfarad

capacitor.

2.

Set

the

range

switch

to

the

Standard

Broadcast

Range

(A

Band).

3.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

600

Kc.

4.

Adjust

the

600

Kc.

oscillator

R.

F.

and

antenna

iron

cores

for

maximum

signal.

5.

Set

the

signal

generator

frequency

and

the

receiver

tuning

dial

to

1500

Kc.

6.

Adjust

the

1500

Kc.

oscillator

R.

F.

and

antenna

aligning

capacitors

for

maximum

signal.

7.

Repeat

operation

three

and

four.

8.

Repeat

operation

five

and

six.

IV.

Wave

Trap

Adjustment.

(Leave

the

receiver

connected

in

the

same

manner

as

when

adjusting

the

Standard

Broad¬

cast

Range

(“A”

Band)

).

1.

Tune

set

to

1000

Kc.

2.

Set

the

signal

generator

frequency

to

455

Kc.

and

introduce

a

fairly

strong

modulated

signal

to

the

receiver.

3.

Adjust

the

wave

trap

aligner

for

minimum

signal.

ADJUSTING

DIAL

LAMP

The

dial

on

this

receiver

is

edge

lighted,

and

for

proper

illumination

it

is

very

important

that

the

dial

light

be

adjusted

so

that

the

filament

is

exactly

opposite

the

edge

of

the

glass.

To

make

this

adjustment

simply

slide

the

pilot

light

socket

back

and

forth

on

its

mounting

bracket

until

maximum

illumination

is

obtained.

4

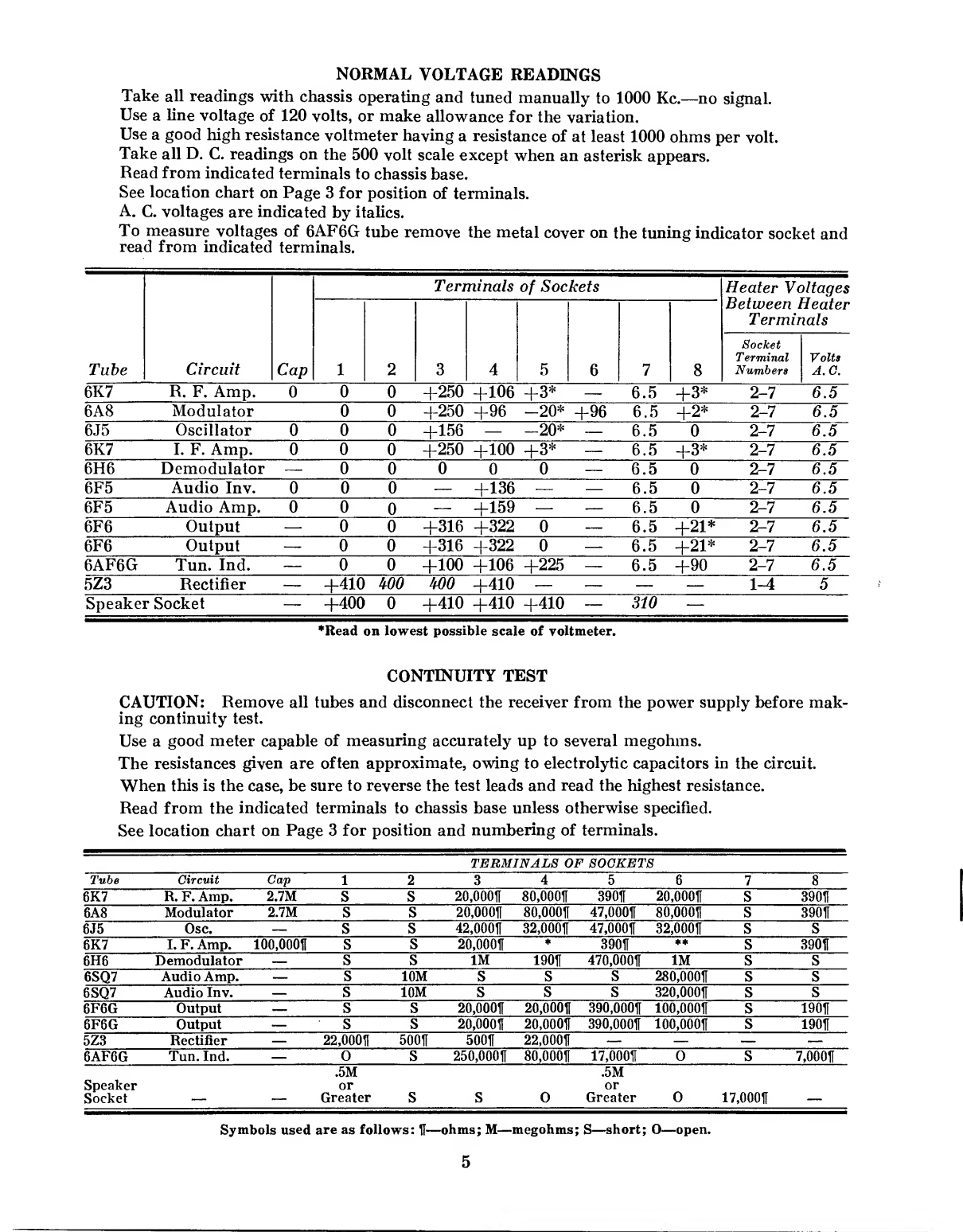

NORMAL

VOLTAGE

READINGS

Take

all

readings

with

chassis

operating

and

tuned

manually

to

1000

Kc.—no

signal.

Use

a

line

voltage

of

120

volts,

or

make

allowance

for

the

variation.

Use

a

good

high

resistance

voltmeter

having

a

resistance

of

at

least

1000

ohms

per

volt.

Take

all

D.

C.

readings

on

the

500

volt

scale

except

when

an

asterisk

appears.

Read

from

indicated

terminals

to

chassis

base.

See

location

chart

on

Page

3

for

position

of

terminals.

A.

C.

voltages

are

indicated

by

italics.

To

measure

voltages

of

6AF6G

tube

remove

the

metal

cover

on

the

tuning

indicator

socket

and

read

from

indicated

terminals.

Tube

Circuit

Terminals

of

Sockets

Heater

Voltages

1

2

6

1

8

aetween

Ter

mir

Socket

Terminal

Numbers

heater

mis

Volts

A.C.

6K7

R.

F.

Amp.

MiM

0

+250

+106

+3*

—

6.5

+3*

2-7

6.5

6A8

Modulator

0

0

+250

+96

—20*

+96

6.5

+2*

2-7

6.5

6J5

Oscillator

0

0

0

+156

—

-20*

—

6.5

0

2-7

6.5

6K7

I.

F.

Amp.

0

0

0

+250

+100

+3*

—

6.5

+3*

2-7

6.5

6H6

Demodulator

—

0

0

0

0

0

—

6.5

0

2-7

6.5

6F5

Audio

Inv.

0

0

0

—

+136

—

—

6.5

0

2-7

6.5

6F5

Audio

Amp.

0

0

0

—

+159

—

—

6.5

0

2-7

6.5

Output

—

0

0

+316

+322

0

—

6.5

+21*

2-7

6.5

2

I

3

QH

Output

—

0

0

+316

+322

0

—

6.5

+21*

■

*5911

6.5

6AF6G

Tun.

Ind.

—

0

0

+100

+106

+225

—

6.5

+90

6.5

5Z3

Rectifier

—

+410

m

m

+410

—

—

—

—

1-4

5

Speaker

Socket

—

+400

0

+410

+410

+410

—

310

—

*Read

on

lowest

possible

scale

of

voltmeter.

CONTINUITY

TEST

CAUTION:

Remove

all

tubes

and

disconnect

the

receiver

from

the

power

supply

before

mak¬

ing

continuity

test.

Use

a

good

meter

capable

of

measuring

accurately

up

to

several

megohms.

The

resistances

given

are

often

approximate,

owing

to

electrolytic

capacitors

in

the

circuit.

When

this

is

the

case,

be

sure

to

reverse

the

test

leads

and

read

the

highest

resistance.

Read

from

the

indicated

terminals

to

chassis

base

unless

otherwise

specified.

See

location

chart

on

Page

3

for

position

and

numbering

of

terminals.

TERMINALS

OF

SOCKETS

Tube

Circuit

Cap

1

2

3

4

5

6

7

8

R.

F.

Amp.

2.7M

s

S

20,000ft

80,000ft

390ft

20,000ft

s

390ft

6A8

Modulator

2.7M

s

S

20,000ft

80,000ft

47,000ft

80,000ft

s

390H

Osc.

—

s

S

42,000ft

32,000ft

47,000ft

32,000ft

s

s

fflsmm

I.

F.

Amp.

100,000ft

s

S

♦

**

s

390ft

Demodulator

—

s

S

1M

190H

470,000ft

1M

s

S

6SQ7

Audio

Amp.

—

s

10M

S

s

S

280,000ft

s

s

6SQ7

Audio

Inv.

—

s

10M

S

s

s

320,000ft

s

s

6F6G

Output

—

s

S

20,000ft

20,000ft

390,000ft

100,000ft

s

19011

6F6G

Output

—

s

s

20,000ft

20,000ft

390,000ft

100,000ft

s

190H

5Z3

Rectifier

—

22,000ft

500ft

500ft

22,000ft

—

—

—

—

6AF6G

Tun.

Ind.

—

0

s

250,000ft

80,000ft

17,000ft

0

s

7,000ft

Speaker

Socket

,5M

or

Greater

s

s

0

.5M

or

Greater

0

17,000ft

Symbols

used

are

as

follows:

ft—ohms;

M—megohms;

S—short;

O—open.

5

*

Push

“Phono”

button

in—“open”.

Push

“Manual”

button

in—100,000

ohms.

**

Push

“Phono”

button

in—“open”.

Push

“Manual”

button

in—32,000

ohms.

Other

tests

not

shown

on

chart

Test

from

phono

jack

on

back

of

chassis

base;

Push

“Phono”

button

in—1

megohm.

Push

“Manual”

button

in—“open”.

Antenna

terminal

to

chassis

base—70

ohms.

Ground

terminal

to

chassis

base—“short”.

Test

between

terminals

of

A.

C.

plug;

Push

“Off”

button

in—“open”.

Push

“Manual”

button

in—3

ohms.

Terminals

of

A.

G.

plug

to

chassis

base—“open”.

R.

F.

coil

tests

measured

directly

across

R.

F.

coil

terminals

with

range

switch

set

in

standard

position

(A

Band).

LI—1

ohm,

L2—3

ohms,

L3—.2

ohm,

L4—.2

ohm,

L5—.2

ohm,

L6—“short”,

L7—70

ohms,

L8—“short”,

L9—1

ohm,

L10—.2

ohm,

Lll—.3

ohm,

L12—.5

ohm,

L13—.1

ohm,

L14—

.5

ohm,

L15—4

ohms,

L16—.2

ohm,

L17—.3

ohm,

L18—.2

ohm,

L19—.2

ohm.

INSTRUCTIONS

FOR

SETTING

UP

PUSH

BUTTONS

IMPORTANT:

The

stations

selected

should

be

the

local

or

favorite

stations

which

give

good

reception

at

all

times.

Set

up

stations

in

the

daytime

to

avoid

unnecessary

interference.

Allow

the

set

to

run

for

about

twenty

minutes

before

setting

up

stations.

Always

use

the

tuning

indicator

unit

when

setting

up

stations

in

order

to

determine

when

the

station

is

exactly

in

tune.

1.

Put

the

call

letters

of

the

selected

stations

in

place

above

the

push

buttons.

The

stations

should

be

arranged

according

to

frequency

with

the

highest

frequency

at

the

right

and

the

lowest

frequency

at

the

left,

just

as

on

the

dial.

(The

call

letters

will

be

found

inside

the

envelope

stapled

inside

or

underneath

the

cabinet).

2.

Set

the

“Treble”

control

in

normal

position.

3.

Turn

the

set-up

switch

(located

on

the

base

just

back

of

the

brush

and

commutator

assem¬

bly)

to

the

set-up

position.

(The

slot

in

the

screw

should

point

toward

“set-up”).

4.

Push

the

button

of

the

highest

frequency

station

to

be

set

up

(button

No.

3)

and

then

tune

in

that

station

manually.

Be

sure

the

station

is

exactly

“in

tune”

by

tuning

carefully

and

watching

the

cathode

ray

indicator.

5.

Slide

the

brush

to

which

the

blue

wire

is

connected

until

it

is

over

the

slot

in

the

commu¬

tator.

Then

adjust

it

very

carefully

until

the

pilot

light

goes

out.

This

indicates

exact

ad¬

justment.

6.

Repeat

operations

4

and

5

for

each

station.

Work

from

right

to

left

or

from

the

higher

to

the

lower

frequencies

in

accordance

with

the

table

below:

Push

Button

No.

Purpose

Color

of

wire

on

brush

1

2

3

4

5

6

7

8

9

10

11

12

Manual

Remote

Highest

frequency

station

Next

lower

frequency

station

Next

lower

frequency

station

Next

lower

frequency

station

Next

lower

frequency

station

Next

lower

frequency

station

Next

lower

frequency

station

Lowest

frequency

station

Phonograph

Off

Blue

Orange

Green

Brown

Slate

Red

Black

Blue

White

f

See

diagram

on

last

page.

7.

Turn

the

set-up

switch

back

to

the

“Operate”

position.

8.

Check

the

operation

of

all

the

push

buttons

to

be

sure

that

each

has

been

accurately

set

up.

If

it

is

necessary

to

readjust

any

of

the

buttons,

follow

the

procedure

given

above.

6

£*UBL

6A

8

MQO

.

-fi&Llf.

6H6

PEMAV.fi

ASfll

AUP1Q.AML

7

i

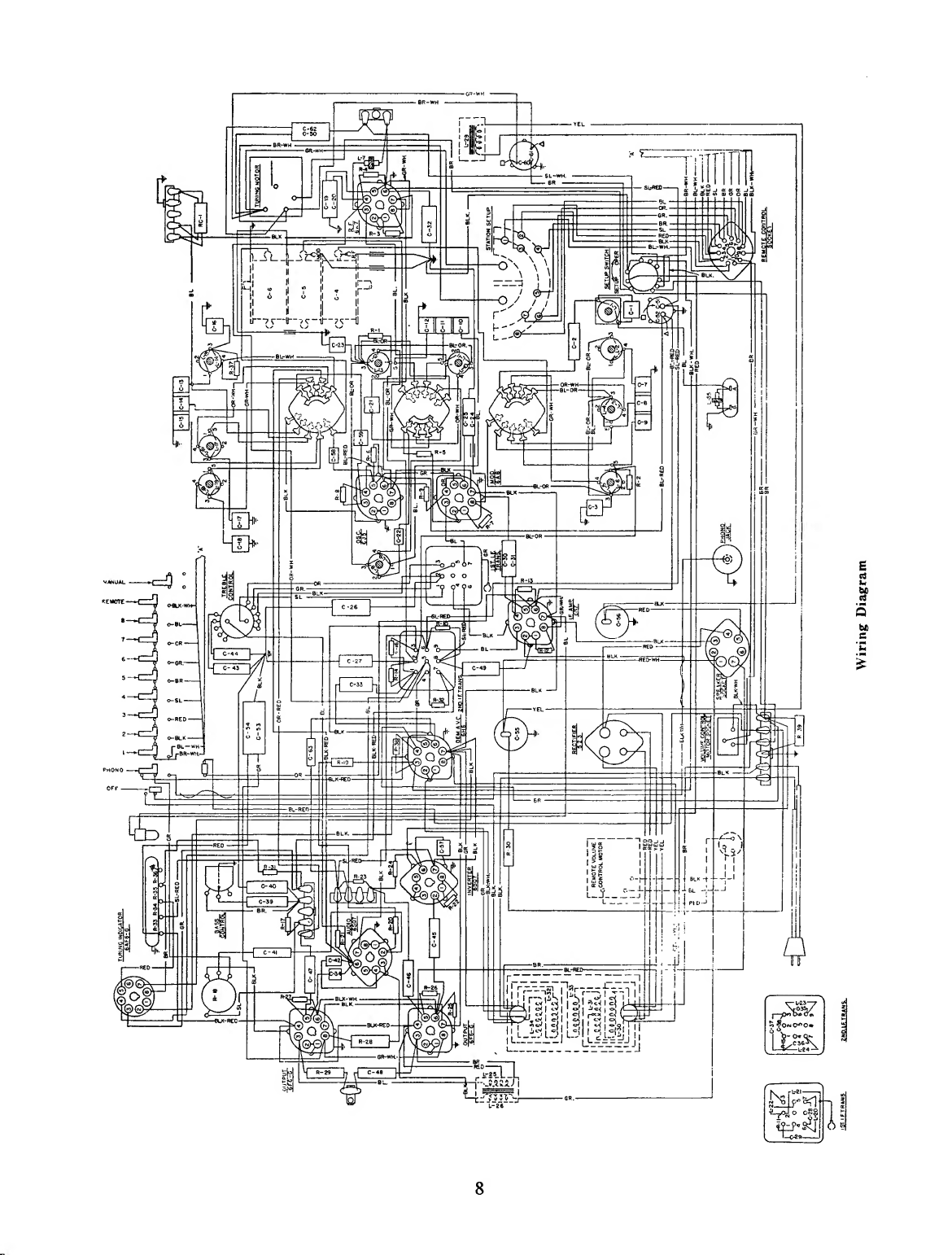

Schematic

Circuit

Wiring

Diagram

REPLACEMENT

PARTS

Use

genuine

Stromberg-Carlson

parts.

It

will

be

to

your

advantage.

They

are

made

for

use

in

Stromberg-Carlson

receivers.

The

specifications

are

correct

and

the

same

high

quality

material

and

workmanship

is

used

as

in

the

whole

radio

receiver.

Don’t

ruin

a

good

receiver

with

an

inferior

part.

Capacitors

Piece

Number

Circuit

Designation

24559

C-22,42,

57

24994

C-32,49,26

25149

C-33,43,27

25150

C-39

....

25487

C-34,59

26778

C-21

....

27108

C-18,

20,24,

25,

26,

27,

30,

31

27305

C-58

....

27646

C-44,48

28594

C-40

....

30116

C-23

....

30251

C-17

....

30252

C-18

...

30322

C-2,

41,

45,

46,

47,

63

27143

C-10,11,12

30253

C7,

8,

9,13,14,15

27336

C-55

....

27622

C-56

....

30231

C-51,52

30232

C-53,54

30282

C-4,5,6

30539

C-60,61

Part

100

mmf.

.05

mf.

.01

mf.

.02

mf.

.001

mf.

.005

mf.

2—.05

mfs.

50

mmf.

....

.02

mf.

....

.015

mf.

.003

mf.

.

.

..

.001

mf.

.002

mf.

....

.005

mf.

Aligning

Capacitor

Aligning

Capacitor

1—16

mf.

500

V

(Electrolytic)

1—16

mf.

500

V

(Electrolytic)

1—15

mf.

350

V

(Electrolytic)

1—15

mf.

300

V

(Electrolytic)

1—8

mf.

350

V

(Electrolytic)

1—

20

mf.

35

V

(Electrolytic)

Tuning

Capacitor

(3

gang)

2—

20

mfs.

Electrolytic

120

V

A.C.

Coils,

Transformers

and

Speaker

30143

L-5,6

...

Antenna

Coil

C

Band

.

30144

L-16,17

Oscillator

Coil

B

Band

30145

L-18,19

Oscillator

Coil

C

Band

30146

L-12,13

R.

F.

Coil

C

Band

30147

L-3,

4,10,11

Antenna

and

R.

F.

Coil

B

Band

30148

L-8,9

...

R.

F.

Coil

A

Band

30149

L-2,3

...

Antenna

Coil

A

Band

.

30150

L-14,15,

C-16

Oscillator

Coil

A

Band

30233

L-29

....

Choke

Assembly

30332

L-7,

35

R.

F.

Choke

....

30238

L-l,

C-l

.

.

.

Wave

Trap

....

30229

L-30

to

L-34

inc.

Power

Transformer

50/60

Cycles

30230

L-30

to

L-34

inc.

Power

Transformer

25/60

Cycles

30242

L-20,

21,

22,

C-28,29

1st

I.

F.

Transformer

.

30245

L-23,

24,

C-35,

36

2nd

I.

F.

Transformer

30247

L-25,

26

Output

Transformer

.

27504

Speaker

26250

.

Controls

and

Knobs

Cone

for

Speaker

27313

Fidelity

and

Tone

Control

.

30236

Range

Switch

30249

R-18

.

.

.

.

Volume

Control

30279

Switch

Assembly

P.

B.

Key

30250

Bass

Switch

....

30327

Set-up

Switch

....

27800

Small

Plain

Knob

27801

Knob

with

Arrow

27628

Felt

Washer

for

Knobs

9

REPLACEMENT

PARTS—Continued

Piece

Number

Circuit

Designation

Part

Resistors

26325

R-37

.

220

Ohms—Type

E

26328

R-3,

7,12

.

390

Ohms—Type

E

26333

R-5,10

1000

Ohms—Type

E

26345

R-8

.

10,000

Ohms—Type

E

26350

R-17

.

27,000

Ohms—Type

E

26353

R-6,9

47,000

Ohms—Type

E

26355

R-4

.

68,000

Ohms—Type

E

26356

R-13

.

82,000

Ohms—Type

E

26357

R-l,

2,

25

.

.1

Megohm—Type

E

.

26359

R-23,

24

.15

Megohm—Type

E

.

26362

R-21,

26,

27,

32

.27

Megohm—TypeE

.

26364

R-16

.

.39

Megohm—Type

E

.

26367

R-31

.

.68

Megohm—Type

E

.

26369

R-19,38

1

Megohm—Type

E

26373

R-14

.

2.2

Megohm—Type

E

.

26381

R-20,22

10

Megohm—Type

E

.

26775

R-29

.

20,000

Ohms—Type

F

26776

R-30

.

12,000

Ohms—Type

F

28956

R-28

.

200

Ohms

IRC

....

30235

R-33,

34,

35,

36

Voltage

Divider

30605

R-39

.

Miscellaneous

Parts

170

Ohm—Type

F

26122

Antenna

and

Ground

Terminal

Strip

26287

Pilot

Lamp

....

26678

3-Prong

Socket

...

29786

Pilot

Lamp

Socket

Assembly

30151

8-Prong

Socket

....

30152

7-Prong

Socket

....

30153

4-Prong

Socket

.

30223

11-Prong

Socket

28652

Power

Supply

Cord

29162

Spring

29628

Spring

for

Drive

Cord

30065

Dial.

30169

Station

Call

Letters

30172

Dial

Escutcheon

30176

Electric

Tuning

Escutcheon

30341

Screw

for

Mtg.

Dial

Escutcheon

.

30345

Screw

for

Mtg.

Electric

Tuning

Escutcheon

30224

Phono.

Plug

....

30225

Phono.

Guard

....

30226

Phono.

Jack

....

30256

Shaft

for

Motor

Drive

(Vol.

Control)

30262

Motor

for

Dial

Drive

.

30265

Pulley

.....

30934

Set

Screws

for

Pulley

Assembly

.

30276

Dial

Pointer

....

30286

Commutator

Assembly

30295

Brush

Holder

....

30385

Brush

(Inside

Slot)

30297

Brush

(Outside

Slot)

30261

Tuning

Indicator

Cable

30299

Cable

(Plug

to

Push

Buttons)

30292

RC-1

.

Compensator

Unit

30275

Tools

and

Accessories

Bronze

Drive

Cord

Assembly

SD-29

Phillips

No.

1

Screwdriver

.

24608

Aligning

Tool

....

28601

Cabinet

Polish

(Pt.

Can)

26962

Furniture

Touch-Up

Kit

28303

Headphone

Package

Assembly

10

Showing

Adjustable

Station

Brushes

and

Set

Up

Switch.

This manual suits for next models

2

Table of contents

Other Stromberg-Carlson Receiver manuals