Strong Entertainment Lighting SEL10 Installation and operation manual

SEL10

Lamphead & Base Assembly

Operator’s Manual & Parts List

for Equipment Type MLS210

Rev. July 2001

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street • Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

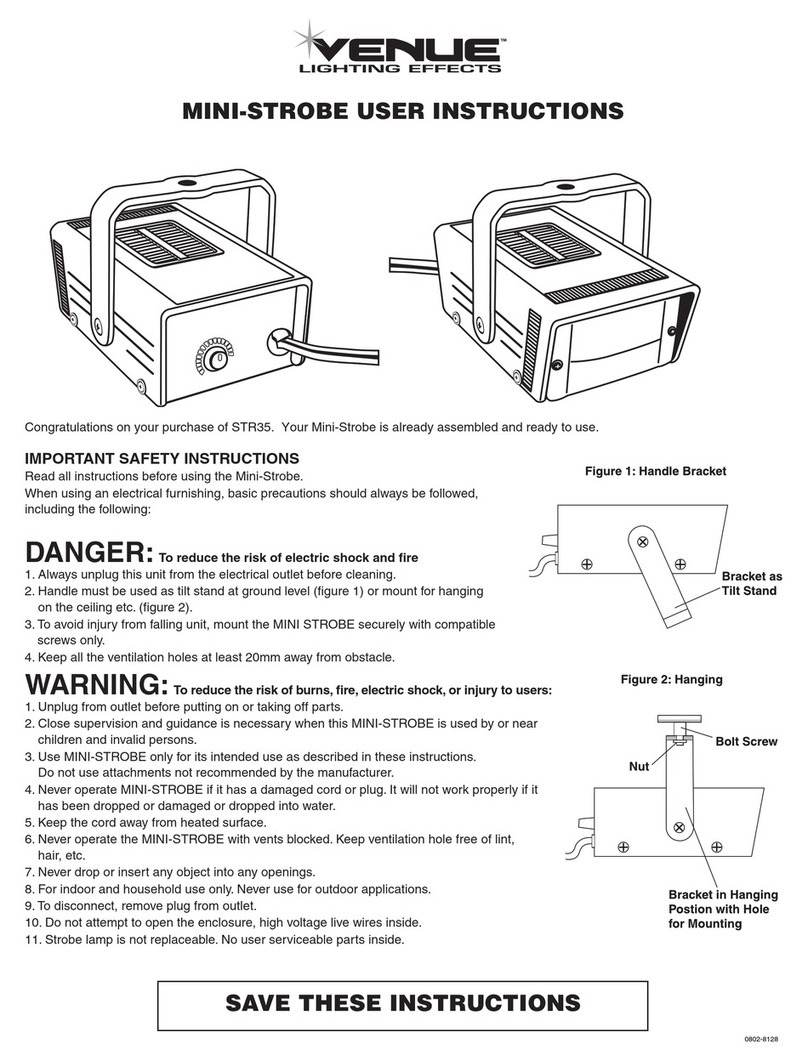

Lamphead Housing

Front Cowl Assembly This Knob used for

TRANSPORT ONLY.

Clamping Knob,

Projection Angle

Remove upper Knob after

transporting SEL10. Establish

Projection Angle and secure tilt

angle using lower Clamping

Knob only.

Locking Mechanism,

Horizontal Pan

Cover Plate,

Control Panel

Yoke Assembly

Base & Power

Supply Housing

SEL10 LAMPHEAD & BASE ASSEMBLY

Secured for Transport

Tie-Down Bracket

(1 of 4)

Cowl Clamp

(1 of 4)

Handle

(1 of 4)

Transport Support

Mechanism

Do Not Obstruct

Ventilation Openings

Yoke Retaining Screw

(1 of 2)

PREFACE

The SEL10 is a 10,000 watt xenon searchlight mounted on a rotating yoke. The angle and direction

of light projection are independently adjustable on a 360° horizontal arc and through 90° of vertical tilt,

and locks in the desired position. The base assembly is a weathertight enclosure containing the xenon

power supplies. The unit is mounted on a trailer and powered by a diesel engine-generator unit.

Continuous high output performance is assured by means of a coated, 30 inch precision electro-

formed, parabolic nickel reflector. The reflector is carefully positioned at the factory and requires no

operator adjustment. The light source is a 10,000 watt xenon bulb which can operate in any position

(vertical to horizontal) and maintains a constant color temperature of 5600° Kelvin. A squirrelcage blower

is mounted in the lamphead to provide continuous forced-air cooling while the bulb is in operation. The

bulb is warranted for 500 hours. It is recommended to replace the bulb upon expiration of the warranty.

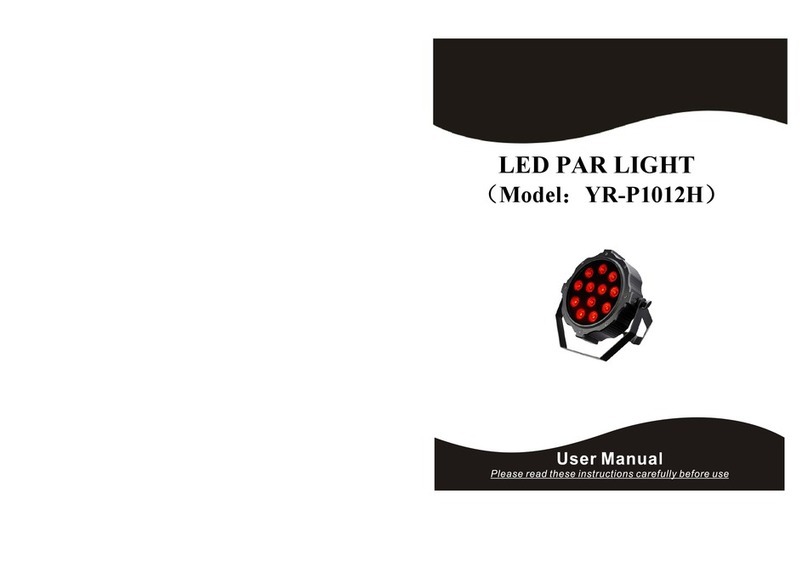

Operator controls mounted to the instrument panel include a SYSTEM ON/OFF switch and a STRIKE

(“emergency ignite”) switch to bypass the autostrike circuit. A FOCUS switch controls an AC motor inside

the lamphead which moves the bulb inside the reflector to adjust focus. An hour meter, located adja-

cent to the switches, records the elapsed time of xenon bulb operation. A volt meter and ammeter

monitor xenon bulb operation.

Direct current for the xenon bulb is derived from two high reactance xenon power supplies mounted

in the base of the unit. All models are designed for 50/60 Hertz operation, and are available in varying AC

input types, depending upon the confuguration of the main power transformer. Check the Equipment

Data Plate to determine the exact AC requirement prior to installation.

Coarse and fine taps are easily set to regulate the DC current to the xenon lamphead. Some models

of these power supplies have the capability of overdriving the xenon bulb; carefully check the power require-

ments specified by the bulb manufacturer and do not exceed the maximum current stated.

The two power supplies, wired in parallel, produce the high open circuit ( “no load”) voltage

required for bulb ignition, and, after ignition, the filtered low voltage current to sustain operation. The

bridge rectifiers utilize silicon diodes as the power conversion elements. The diodes are mounted to

oversize heat sinks to disperse the heat generated by normal operatrion. Internally wired squirrelcage

blowers provide additional forced-air cooling of each power supply. Thermal switches act as safety

interlocks to shut down the power supplies and protect the rectifier diodes in case temperatures reach

excessive levels.

INSTALLATION

Check all equipment Data Plates and make certain that the generator unit conforms to the

input requirements of the main transformers of the xenon power supplies. Refer to the instructions fur-

nished separately for generator start-up procedures. Set generator output to 208/230 V.AC, 60 Hz. All

output connections to the xenon power supplies and lampheads are factory prewired.

Remove the (2) end panels from the base assembly to gain access to the tap terminal boards of

the xenon power supplies. Remove the upper clamping knob (“TRANSPORT ONLY”) from the projection

angle locking arm. Loosen the (2) set screws securing the yoke position and fold the hinged plate of the

transport support mechanism down. Loosen the projection angle clamping knob and lower the lamphead

to a horizontal position. Retighten the clamping knob to secure the lamphead. Release the (4) cowl

clamps and remove the front cowl assembly.

1

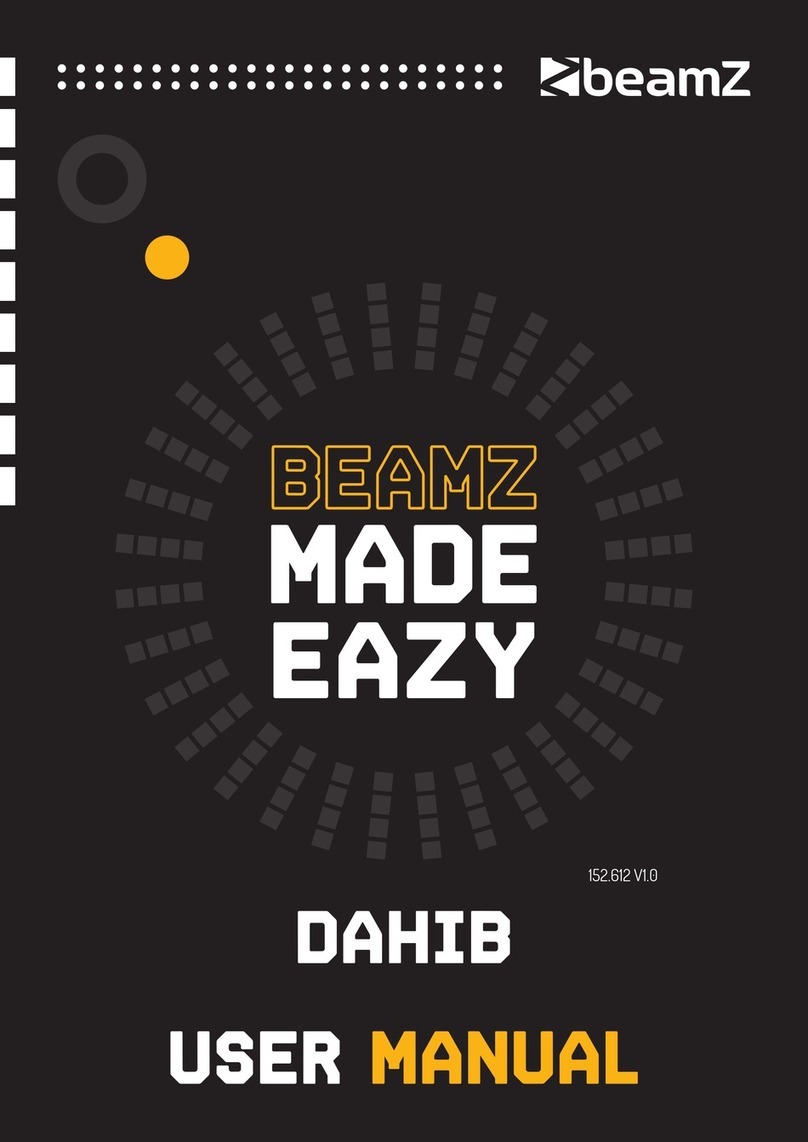

OPERATOR’S CONTROL PANEL

Indicator Lights,

Phase Detection

Circuit Breaker,

Auxilliary Power Toggle Switch,

POWER ON-OFF

Elapsed Time Meter

(HOURS)

Pushbutton Switch,

IGNITE (AutoStrike

Bypass)

Toggle Switch,

FOCUS IN-OUT

2

Volt Meter

Ammeter

Test Points,

DC Voltage

INSTRUCTIONS FOR REMOVING AND INSTALLING A TYPE “XT”

XENON BULB IN A SEL10 FIXTURE

NOTE

FAMILIARIZE YOURSELF WITH THE LOCATION AND IDENTIFICATION

OF THE COMPONENTS OF THIS SYSTEM AND ALSO THE NORMAL

OPERATION OF THE SYSTEM BEFORE ATTEMPTING ANY ADJUSTMENT

OR SERVICE.

NOTE

COMPLETELY READ THROUGH AND HAVE A GOOD UNDERSTANDING OF THE

PROCEDURES BEFORE ATTEMPTING TO SERVICE THIS SYSTEM. FAILURE TO

DO SO MAY RESULT IN FATAL INJURY OR EQUIPMENT DAMAGE.

NOTE

THE LAMPHEAD SHOULD BE LOCKED IN THE HORIZONTAL POSITION

DURING ANY SERVICE PROCEDURES.

WARNING

DISCONNECT POWER SOURCE BEFORE SERVICING THIS EQUIPMENT.

WARNING

A PROTECTIVE JACKET, FULL FACE SHIELD, AND PROTECTIVE GLOVES MUST

BE WORN AT ALL TIMES WHEN THE LAMPHEAD IS OPENED WITH A BULB

INSTALLED, OR WHEN HANDLING THE XENON BULBS. SERIOUS INJURY MAY

OCCUR IF PROPER SAFETY PRECAUTIONS ARE NOT OBSERVED.

READ ALL ENCLOSED INSTRUCTIONS AND INFORMATION SHEETS BEFORE

HANDLING THE BULB.

WARNING

NEVER OPERATE A FIXTURE WITH AN EXPOSED BULB! THERE IS AN EXTREME

DANGER OF SEVERE BURNS TO EXPOSED SKIN AND EYES FROM THE

ULTRAVIOLET LIGHT EMITTED FROM THE EXPOSED BULB. DAMAGE CAN

OCCUR IN AS LITTLE AS 30 SECONDS OF EXPOSURE. THERE IS ALSO

AN ADDITIONAL DANGER FROM FLYING QUARTZ IF AN

EXPOSED BULB EXPLODES!

EQUIPMENT REQUIRED

1.PROTECTIVESAFETYEQUIPMENTKIT

2. 7/16" END WRENCH OR SOCKET

3. ALLEN WRENCH 5/32"

3

ASSEMBLY PROCEDURE

WARNING

DO NOT REMOVE THE PROTECTIVE COVER FROM THE BULB UNTIL INSTRUCTED TO DO SO!

WARNING

DO EXERT ANY FORCE ON THE QUARTZ PORTION OF THE BULB AT ANY TIME!

NOTE

IF THE FRONT BULB HOLDER HAS NOT BEEN DISASSEMBLED, SEE THE LAST STEPS IN THE

APPROPRIATE DISASSEMBLY INSTRUCTIONS.

1. UNTIE THE CORD ON THE ANODE (+) END OF THE PROTECTIVE COVER. DO NOT REMOVE THE

COVER AT THIS TIME!

2. FASTEN FRONT BULB HOLDER TO THE BULB BY PLACING THE ANODE END (LARGE ELECTRODE)

OF THE BULB IN THE BULB HOLDER AND ALIGNING THE STUD ON THE END OF THE BULB

FERRULE WITH THE CHANNEL IN THE NOSE OF THE BULB HOLDER BODY. SLIDE THE BULB

COMPLETELY DOWN THE CHANNEL AS FAR AS IT WILL GO.

DISASSEMBLY PROCEDURE

PRIOR TO BULB INSTALLATION:

1. RELEASE THE (4) FASTENERS LOCATED AT THE SMALL SIDES OF THE COWL. PULL FORWARD

TO REMOVE THE COWL ASSEMBLY.

2. REMOVE THE (2) BRASS BOLTS CONNECTING THE SHORT LEADS TO THE FRONT BULB HOLDER

USING A 7/16" WRENCH.

3. REMOVE THE CENTER MOUNTING SCREW, WASHER, AND SPRING FROM THE SPIDER (SEE

FIGURE 4, ITEMS 2, 3, 4) USING A 5/32" ALLEN WRENCH WHILE SUPPORTING THE FRONT BULB

HOLDER SO THAT IT DOES NOT FALL WHEN THE SCREW IS REMOVED.

4. REMOVE THE BULB HOLDER FROM THE FIXTURE.

5. TO DISASSEMBLE THE FRONT BULB HOLDER, REMOVE THE (2) CLAMP RETAINING SCREWS

LOCATED ON THE SIDE OF THE LAMP SWIVEL HUB USING A 5/32" ALLEN WRENCH, AND REMOVE

THE CLAMP.

4

WARNING

DO NOT APPLY ANY PRESSURE ON THE BULB WHILE REASSEMBLING THE FRONT BULB HOLDER!

3. REPLACE THE CLAMP AND REINSTALL THE (2) CLAMP RETAINING SCREWS LOCATED ON THE

SIDE OF THE BULB SWIVEL HUB USING A 5/32" ALLEN WRENCH.

4. INSTALL THE BULB INTO THE FIXTURE BY CAREFULLY INSERTING THE CATHODE (-) END OF THE

BULB THROUGH THE OPENING IN THE REFLECTOR. DO NOT STRIKE THE SURFACE OF THE

REFLECTOR.

5. INSERT THE END OF THE BULB FERRULE INTO THE OPENING IN THE BULB LAMP HOLDER

RECEIVER BLOCK AND ALIGN THE THREADS BY TURNING THE BULB COUNTERCLOCKWISE

UNTIL THE BULB THREADS DROP INTO THE RECEIVER THREADS.

CAUTION

DO NOT OVERTIGHTEN THE BULB IN THE RECEIVER BLOCK AS THIS MAY CAUSE

THE BULB TO “FREEZE” IN THE RECEIVER BLOCK, MAKING IT DIFFICULT TO REMOVE.

TIGHTEN THE BULB JUST ENOUGH TO APPLY SPRING PRESSURE TO THE THREADS

BUT NOT SO MUCH AS TO BOTTOM OUT THE LAMP FERRULE COMPLETELY

AGAINST THE RECEIVER BLOCK.

6. GENTLY ROTATE THE BULB CLOCKWISE UNTIL RESISTANCE IS FELT.

7. AT THIS POINT, THE BULB SHOULD BE IN CONTACT WITH THE SPRING PLUNGER ASSEMBLIES.

GENTLY TURN THE BULB AN ADDITIONAL 1/16 - 1/8 OF A TURN TO LOAD THE THREADS WITH

THE SPRING PLUNGERS.

8. SECURE THE FRONT BULB HOLDER TO THE SPIDER WITH THE SHOULDER BOLT, SPRING, AND

WASHER THAT WAS REMOVED DURING DISASSEMBLY.

9. CONNECT THE (2) SHORT LEADS FROM THE SPIDER TO THE FRONT BULB HOLDER USING THE

TWO BRASS BOLTS AND WASHERS THAT WERE REMOVED DURING DISASSEMBLY.

NOTE

ANY TYPE OF ALCOHOL IS SUITABLE FOR CLEANING THE BULB EXCEPT FOR

ALCOHOL THAT HAS BEEN DENATURED USING PETROLEUM PRODUCTS SINCE

THE DENATURING AGENT WILL LEAVE A RESIDUE ON THE QUARTZ ENVELOPE.

10. REMOVE THE PROTECTIVE COVER FROM THE BULB AND CLEAN THE QUARTZ PORTION OF THE

BULB COMPLETELY WITH ALCOHOL.

11. THE INSTALLATION IS NOW COMPLETE. REPLACE THE FRONT COWL AND TEST THE BULB.

12. LOG THE HOUR METER READING AT INSTALLATION.

13. PERFORM THE OUTPUT POWER ADJUSTMENT PROCEDURES. THE 10000W-XT BULB IS

DESIGNED FOR OPERATION WITHIN THE FOLLOWING RANGE:

165-210 AMPERES

50-54 VOLTS DC

NOTE: OPERATION BELOW 165 AMPERES WILL NOT PROLONG BULB LIFE, BUT RATHER WILL

DEGRADE BULB IGNTION BY DAMAGING THE CATHODE TIP.

14. PERFORM THE FOCUS AND X-Y PROCEDURES.

5

DISASSEMBLY PROCEDURE

IF THERE IS A LAMP IS INSTALLED IN THE FIXTURE:

1. RELEASE THE (4) FASTENERS LOCATED AT THE SMALL SIDES OF THE COWL. PULL FORWARD

TO REMOVE THE COWLING.

CAUTION

DO NOT PLACE ANY FORCE ON THE LAMP WHILE REPLACING THE PROTECTIVE WRAPPER!

2. WRAP THE BULB SECURELY IN THE PROTECTIVE WRAPPER THAT THE BULB WAS ORIGINALLY

SHIPPED WITH.

3. REMOVE THE (2) BRASS BOLTS CONNECTING THE SHORT LEADS TO THE FRONT BULB HOLDER

USING A 7/16" WRENCH.

4. REMOVE THE CENTER MOUNTING SCREW, WASHER, AND SPRING (SEE FIGURE 4, ITEMS 2, 3, 4)

FROM THE SPIDER USING A 5/32" ALLEN WRENCH WHILE SUPPORTING THE FRONT BULB

HOLDER SO THAT THE BULB DOES NOT DROP WHEN THE MOUNTING SCREW IS REMOVED.

WARNING

DO NOT EXERT EXCESSIVE FORCE ON THE BULB WHILE UNSCREWING IT FROM

THE REAR BULB HOLDER! THE BULB SHOULD RELEASE FROM THE REAR BULB

HOLDER WITH A VERY LIGHT COUNTERCLOCKWISE ROTATION. IF THIS DOES

NOT HAPPEN, SEE THE PROCEDURE FOR REMOVING A “FROZEN” BULB.

5. REMOVE THE BULB BY LIGHTLY PUSHING BACK ON THE BULB TO MOVE THE REAR BULB

HOLDER TO ITS REAR MOST POSITION WHILE LIGHTLY TURNING THE BULB IN A COUNTER-

CLOCKWISE ROTATION. THE BULB WILL RELEASE FROM THE REAR BULB HOLDER IN

APPROXIMATELY 1½ COMPLETE TURNS.

6. REMOVE THE BULB WITH THE FRONT BULB HOLDER ATTACHED FROM THE FIXTURE. PLACE IT

ON A STABLE WORKING SURFACE FOR THE REMOVAL OF THE FRONT BULB HOLDER.

7. TO REMOVE THE FRONT BULB HOLDER FROM THE BULB, REMOVE THE (2) CLAMP RETAINING

SCREWS LOCATED ON THE SIDE OF THE BULB SWIVEL HUB USING A 5/32" ALLEN WRENCH AND

REMOVE THE CLAMP.

8. REMOVE THE BULB HOLDER FROM THE BULB AND PLACE THE BULB INTO ITS SHIPPING

CONTAINER FOR SAFEKEEPING. RESECURE THE PROTECTIVE WRAPPER IF NECESSARY.

REMOVING A “FROZEN” BULB

1. REPLACE THE FRONT BULB HOLDER RETAINING BOLT TO SUPPORT THE FRONT OF THE BULB

WHILE FREEING THE BULB FROM THE REAR BULB HOLDER.

DO EXERT ANY FORCE ON THE QUARTZ PORTIONS OF THE BULB

WHILE ATTEMPTING TO FREE IT FROM THE REAR LAMP HOLDER!

2. REACH THROUGH THE OPENING IN THE REAR OF THE REFLECTOR AND GRASP THE BULB’S

END CAP (THE REAR METAL FERRULE). WHILE LIGHTLY PUSHING THE BULB BACK INTO THE

RECEIVER BLOCK, TURN THE BULB IN A COUNTERCLOCKWISE DIRECTION UNTIL THE BULB

BEGINS TO ROTATE FREELY.

6

REMOVING A “FROZEN” BULB (CONTINUED)

3. ONCE THE BULB IS FREE, DO NOT YET REMOVE IT FROM THE REAR LAMP HOLDER.

4. RETURN TO STEP 5 OF THE PRECEDING SECTION.

OUTPUT POWER ADJUSTMENT PROCEDURES

NOTE

FAMILIARIZE YOURSELF WITH THE LOCATION AND IDENTIFICATION OF THE

COMPONENTS OF THIS SYSTEM AND ALSO THE NORMAL OPERATION

OF THE SYSTEM BEFORE ATTEMPTING ANY ADJUSTMENT OR SERVICE.

NOTE

COMPLETELY READ THROUGH AND HAVE A GOOD UNDERSTANDING OF

THE PROCEDURES BEFORE ATTEMPTING TO SERVICE THIS SYSTEM.

FAILURE TO DO SO MAY RESULT IN FATAL INJURY OR EQUIPMENT DAMAGE.

WARNING

DISCONNECT POWER SOURCE BEFORE SERVICING THIS EQUIPMENT.

EQUIPMENT REQUIRED

1. SCREWDRIVER, Flat Blade, Large

2. SCREWDRIVER, #2 Phillips

ADJUSTMENT INSTRUCTIONS

1. Remove lower access covers from the ends of the base enclosure by removing the (6) screws

along the sides of each panel with a Phillips screwdriver.

2. Note the location and settings of the power supply adjustment taps.

7

ADJUSTMENT INSTRUCTIONS (continued)

3. Ignite the xenon bulb and check the current. Allow (30) seconds for the current to stabilize and

provide an accurate reading. A new 10000W-XT bulb should be first operated at the nominal current

level of 180-185 amperes. If the current is not within the desired range, extinguish the bulb. It will be

necessary to increase or decrease the DC output.

4. Fine adjustment of the DC current is made to the NUMBERED taps found on the upper three terminal

blocks (TB4, TB5, TB6). Fine taps are numbered 1-2-3-4, with “1” providing the lowest output, increasing

to “4,” yielding the highest output. A “fine” tap adjustment raises or lowers the current approximately four

amperes. The three fine tap terminal blocks are interconnected by means of a three-lead jumper wire

assembly attached to like-numbered terminals.

•To increase the DC output, move the jumper wire assembly to tap the next (3) higher numbered termi-

nals, for example, move from terminals “2” to terminals “3.” ALL TAPS MUST BE ON THE SAME NUMBERED

POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too low when terminals “4” are intercon-

nected, see the following instructions for adjusting “coarse” taps.

•To decrease the DC output, move the jumper wire assembly to tap the next (3) lower numbered

terminals, for example, move from terminals “3” to terminals “2.” ALL TAPS MUST BE ON THE SAME

NUMBERED POSITION (1-1-1, 2-2-2, 3-3-3, or 4-4-4). If the DC output is still too high when terminals “1” are

interconnected, see the following instructions for adjusting “coarse” taps.

5. Coarse adjustment of the DC current is made to the LETTERED taps found on the lower three terminal blocks

(TB1, TB2, TB3). Coarse taps are lettered W-X-Y-Z, with “W” providing the lowest output, increasing to “Z” at

the highest output. The coarse tap terminals connect to contactor terminals T1, T2, and T3. The (3) contactor

leads must connect to the same lettered step (W-W-W, etc.). A “coarse” tap adjustment raises or lowers the

current approximately twelve amperes.

•To increase the coarse DC output, move each of the contactor leads to tap the next higher lettered

terminals, for example, move from terminals “W” to terminals “X.” ALL TAPS MUST BE ON THE SAME

LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap jumper on 1-1-1. Ignite the lamp,

check the output, and increase the fine tap setting as required.

•To decrease the coarse DC output, move each of the contactor leads to tap the next lower lettered

terminals, for example, move from terminals “Y” to terminals “X.” ALL TAPS MUST BE ON THE SAME

LETTERED POSITION (W-W-W, X-X-X, Y-Y-Y, or Z-Z-Z). Place the fine tap jumper on 1-1-1. Ignite the lamp,

check the output, and increase the fine tap setting as required.

NOTE: Balance power supply output; set power supplies at or near the same output setting, i.e.:

Power Supply “A” X-X-X, 4-4-4 (or as required)

Power Supply “B” Y-Y-Y, 1-1-1 (or as required)

6. Check the voltmeter and read the arc voltage. The voltage should read between 50 and 54 volts

DC. If the actual measured voltage is not in this range, consult your bulb supplier immediately.

7. Inspect tap connections to verify that the terminal is clamping the copper conductor, not the

insulation. Make certain all terminal clamping screws are tight.

8. Whenever making a coarse adjustment, again check the output current and make certain the cur-

rent is within the desired range. A fine tap re-adjustment is frequently required after changing coarse

taps.

9. After prolonged operation, the light output of the xenon bulb will decrease. This is a normal factor of

bulb aging, and can be compensated by raising the DC output of the xenon power supplies. If the

bulb was first operated at “nominal” current, the power supply output can gradually be increased

to, but not in excess of, the maximum current specified by the bulb manufacturer (210 A.). Increase

the current as instructed above. Decrease the power supply output to its former “nominal” current

level (180 A.) upon the installation of a new replacement bulb.

8

FOCUS AND X-Y ADJUSTMENT INSTRUCTIONS

FOR SYSTEMS w/ ELECTRIC FOCUS

NOTE

FAMILIARIZE YOURSELF WITH THE LOCATION AND IDENTIFICATION OF THE

COMPONENTS OF THIS SYSTEM AND ALSO THE NORMAL OPERATION OF THE

SYSTEM BEFORE ATTEMPTING ANY ADJUSTMENT OR SERVICE.

NOTE

COMPLETELY READ THROUGH AND HAVE A GOOD UNDERSTANDING OF THE

PROCEDURES BEFORE ATTEMPTING TO SERVICE THIS SYSTEM. FAILURE TO DO

SO MAY RESULT IN FATAL INJURY OR EQUIPMENT DAMAGE.

EQUIPMENT REQUIRED

1. ALLEN WRENCH 5/32"

2. #5 WELDERS GLASSES OR VERY DARK SUNGLASSES

WARNING

THE SEL10 SYSTEMS PROJECT A VERY INTENSE BEAM OF FULL-SPECTRUM LIGHT.

THE USE OF DARK GLASSES WHILE ADJUSTING THE BEAM PARAMETERS ON A

LIGHT-COLORED REFLECTIVE SURFACE AT A CLOSE DISTANCE IS MANDATORY.

WARNING

NEVER LOOK DIRECTLY INTO A LIGHTED FIXTURE'S LIGHT SOURCE.

ADJUSTMENT INSTRUCTIONS

1. Loosen the positioning fasteners and point the lamphead toward a wall, ceiling, or other flat

surface at least 10 feet away.

2. Locate the focus switch located on the control panel on the back of the lamphead housing.

3. Remove the front cowl and locate the X & Y adjustment holes located on the lower small sides of

the fixture at the ends of the front spider arms.

WARNING

SEL10 SYSTEMS PROJECT A VERY INTENSE BEAM OF FULL-SPECTRUM LIGHT.

CAUTION MUST BE TAKEN WHEN POINTING THE BEAM AT AN OBJECT AT A

DISTANCE OF LESS THAN 100 FEET WITH THE FOCUS SET FOR A CONVERGING

BEAM. COMBUSTIBLE OBJECTS AND OBJECTS WITH A DARK COLOR MAY UNEXPECTEDLY

IGNITE IF CARE IS NOT TAKEN IN THE FOCUSING AND POSITIONING OF THE BEAM.

4. Energize the fixture and ignite the lamp. A new xenon bulb should be drawing 180-185 amperes.

5. Adjust the focus by moving the focus switch up or down to produce a diverging beam pattern

with 2 or 3 clearly defined rings of light with or without an off-center “hot” spot.

6. Adjust the X & Y adjustment screws using a 5/32" allen wrench to move the inner rings of light to

create concentric rings with the “hot” spot at the center of the light field. Turning the adjustment

screw clockwise will move the rings toward that adjustment axis and turning the screw

counterclockwise will move the rings away from that adjustment axis.

9

XENON BULB MAINTENANCE

Allow the blowers to operate for at least (15) minutes after extinguishing the arc. This measure is

required by the bulb manufacturer to comply with bulb warranty conditions.

In order to insure maximum bulb life, the following procedures should be followed every 75-100 hours of

operation.

BULB ROTATION

If the fixture is used in a position other than pointed within 15% of vertical, the bulb should be rotated

1/3 of a turn to insure even deposition of the vaporized tungsten generated by the arc inside the bulb.

ADJUSTMENTPROCEDURES

1. Refer to the instructions for removal and installation of the bulb, noting all warnings.

2. Follow the disassembly procedure for a fixture with the bulb installed steps 1 thru 5.

3. When rotating the bulb for removal, continue LIGHTLY pressing rearward on the bulb. The threads

of the bulb will ride out of their current leads and drop into the next set of threads in the receiver

block. When this happens, you will feel the bulb drop down into the receiver block.

4. Immediately stop turning the bulb and reverse direction to screw the bulb in at the new

orientation.

5. Complete reinstalling the bulb per the bulb installation procedure.

POWER LEVEL ADJUSTMENT

Check the output power level of the system and readjust as necessary. A temporary current increase,

not exceeding 210 amperes, may enhance bulb ignition at its new position following rotation. After

ten to twelve hours of operation at the increased current, the arc will re-establish, and current may be

returned to the previous level.

Output may be increased to maintain light output as the bulb ages, but output must remain below

210 amperes. SEE POWER ADJUSTMENT PROCEDURES preceding.

FOCUS AND X-Y ADJUSTMENT INSTRUCTIONS (continued)

7. Readjust the focus switch to set the desired beam spread.

8. Replace the front cowl; reposition the lamphead and resecure the position locking fasteners.

10

TRANSPORTING THE SEL 10

It is recommended to remove the xenon bulbs before moving the SEL10. While there is little explosion

danger in moving the units with properly cooled bulbs and all lamphead covers in place, the bulb

manufacturer may not honor warranty claims on bulbs broken during transport. Under no

circumstances should the units be moved until the bulbs have cooled to ambient temperatures.

See the illustration facing Page 1 for the recommended method of securing the SEL10 for transport.

Raise the lamphead to the full vertical position and replace the upper clamping knob as shown.

Rotate the lamphead to align the yoke with the transport support mechanism and raise the hinged

plate. Secure the yoke in position using the (2) headless set screws. Tie-down brackets mounted to the

upright members of the yoke provide additional points to secure the lamphead if desired.

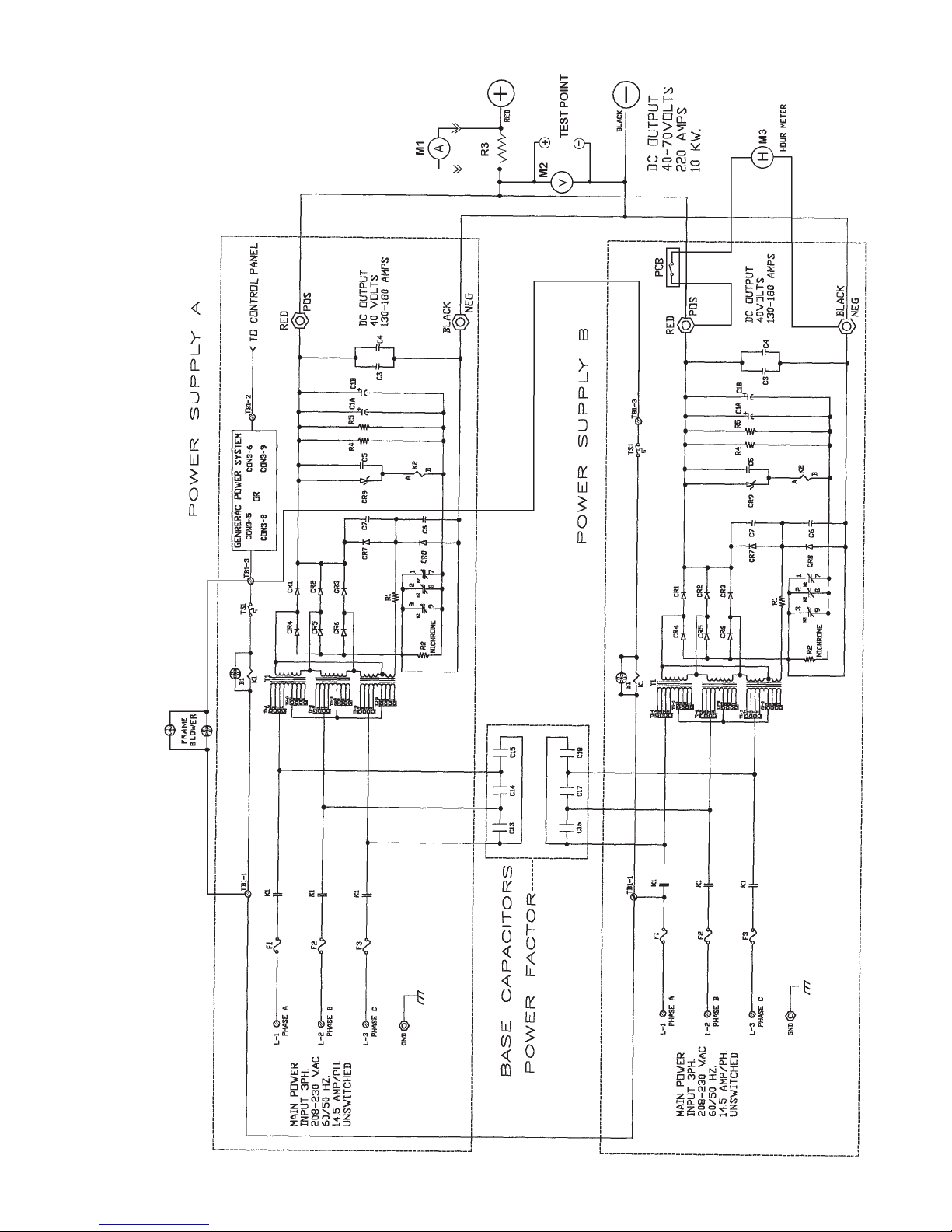

WIRING DIAGRAM

1 of 3

11

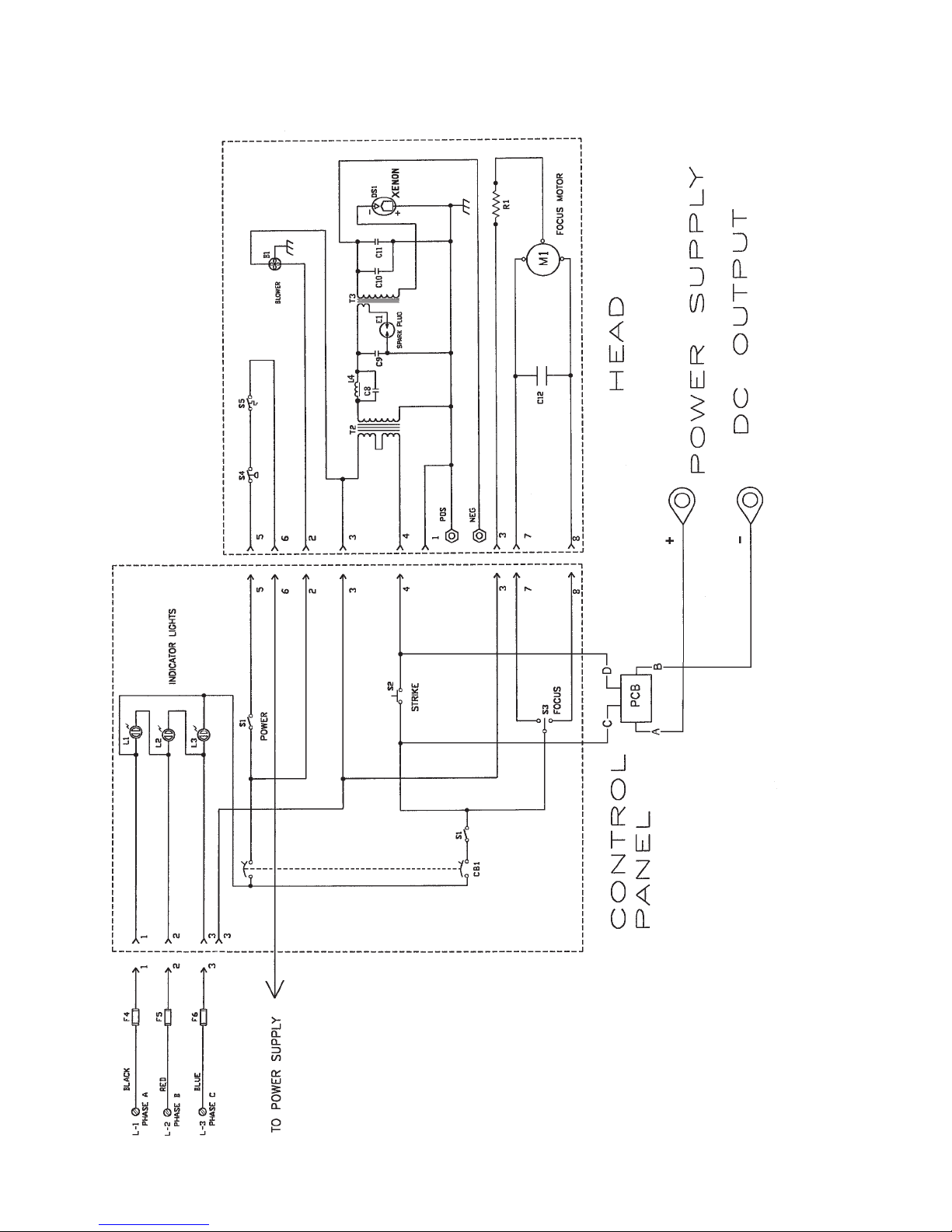

WIRING DIAGRAM

2 of 3

12

PARTS LIST, CONTROL PANEL and POWER SUPPLIES A & B (Diagram 1 of 2)

Ref.

Desig. Part No. Description

B1 81-33026 Blower

C1A,B 61-08027 Capacitor, 5400 µf, 200 V.

C3,4 81-08005 Capacitor, .33 µf

C5 81-08029 Capacitor,.01 µf, 600 V.

C6,7 81-08025 Capacitor, .005 µf, 800 V.

C13-18 31-08134 Capacitor, 4 µf, 370 V.AC

CR1-3 81-47004 Forward Diode, Rectifier; 100 A. 300 V.

CR4-6 81-47001 Reverse Diode, Rectifier; 100 A. 300 V.

CR7,8 81-47006 Boost Diode, 3 A. 600 V.

CR9 81-17002 Zener Diode, 36 V. 5 W. (1N5365B)

F1-3 31-21038 Fuse, 30 A. 250 V.

K1 81-14001 Contactor

K2 81-45016 Relay, 120 V.AC Coil

M1 31-32006 Ammeter, 0-300 A.DC

M2 31-32007 Volt Meter, 0-100 V.DC

- 31-98160 Test Point Socket, Black

- 31-98162 Test Point Socket, Red

M3 31-32004 Elapsed Time Meter*

PCB 32-70140 Printed Circuit Board, Current Detector for M3

R1 81-46026 Resistor, 100 Ohm, 100 W.

R2 92-70026 Nichrome Resistor

R3 81538000 Shunt, 300 A. 50 mV.

R4,5 81-46006 Bleeder Resistor, 2500 Ohm, 10 W.

T1 91-64011 Power Transformer

TS1 81-61010 Thermal Switch, Open at 210° F. (100° C.)

* Elapsed Time Meter may connect to either Power Supply A or B

PARTS LIST, CONTROL PANEL and LAMPHEAD (Diagram 2 of 2)

Ref.

Desig. Part No. Description

B1 32-70228 Squirrelcage Blower, 230 V.AC, 50/60 Hz.

C8 31-08009 Capacitor, .0047 µf

C9 31-08012 Capacitor, 2400 pf, 20 kV.

C10 79127000 Capacitor, .01 µf, 500 V.

C11 31-08011 Capacitor, .47 µf

C12 31-08134 Capacitor, 4 µf, 370 V.AC

CB1 32-61015 Circuit Breaker

DS1 31-30244 Xenon Bulb, 10 kW Type “XT”

E1 31-61009 Spark Plug (Air Gap)

F4-6 21-21002 Fuse, Type 3AG, 5 A.

L1-3 32-30076 Indicator Light, Amber (3 req’d.)

L4 31-71042 Choke, 16 AWG Magnet Wire

M1 32-70328 Bulb Focus Motor, 115 V.AC, 50/60 Hz. (with R1)

R1 11-46110 Resistor, 100 Ohm, 50 W. (incl. with M1)

PCB 32-00009 Igniter Printed Circuit Board Assembly (see Diagram 3 of 3)

S1 31-61048 Switch

S2 31-61011 Pushbutton Switch

S3 31-61049 Switch

S4 31-61078 Pressure Switch

S5 31-61134 Thermal Switch, Open at 325° F. (163° C.)

T2 31-64004 Transformer, High Voltage

T3 32-50230 Transformer, RF

13

14

WIRING DIAGRAM

3 of 3

Igniter Printed Circuit Board Assembly

Ref.

Desig. Part No. Description

C201 88263 Capacitor, .05 µf, 600 WVDC

C202 79127 Capacitor, .01 µf, 600 WVDC

C203 39156 Capacitor, 15 µf, 30/35 WVDC

C204 88249 Capacitor, .1 µf, 600 WVDC

CR201 85112 Diode, 2.5 A. 1000 PRV

CR202 85112 Diode, 2.5 A. 1000 PRV

CR203 85112 Diode, 2.5 A. 1000 PRV

K201 39154 Relay, P&B R10-E1-W2S800

- 39160 Relay Socket

- 39161 Relay Hold-Down Spring

Ref.

Desig. Part No. Description

R201 39157 Resistor, 1k Ohm, 12 Watt

R202 39158 Resistor, 100k Ohm, ½ Watt

R203 39159 Resistor, 200k Ohm, ½ Watt

U201 72185 Timer IC, Motorola MC11455P1

- 39164 IC Socket, (6) Pin

VR201 39211 Zener Diode, 1N5377A

VR202 39162 Zener Diode, 1N4742

- 39145 PC Board (less Components)

* 32-00009 PCB Assembly, Complete

POWER SUPPLY MAINTENANCE

VERY LITTLE MAINTENANCE is required to keep this power supply in good operating condition. Like

most lighting equipment, cleaning is the most important element.

WARNING

Turn off ALL primary AC power before making any

adjustments or performing service procedures. Allow several

minutes for the capacitors to drain stored energy.

Allow the power supply to cool to ambient temperature.

1. Remove all accumulated dust and dirt from the rectifier. Vacuum the heat sinks. Make

certain all air inlets and outlets are unobstructed.

2. Check all electrical connections for tightness. Clean, retighten, or replace any discolored

connections or terminals.

3. Apply a drop or two of SAE 20-weight oil to the squirrelcage blower motor bearings. It is neces-

sary to dismount the blowers from the chassis plate to access the oil holes.

POWER SUPPLY TROUBLESHOOTING

WARNING: Exercise extreme caution when

taking voltage measurements in a power

“ON” condition. Allow the capacitors (2)

minutes to discharge.

POWER LINE PROBLEMS

PRIMARY POWER (AC source) problems are most commonly (a) complete loss of AC power, or (b)

phase loss, in which one phase loses power.

a ) Check line safety switch (“ON”). Check fuses or breakers insupply line. Using an AC voltmeter,

measure input power at contactor terminals L1, L2, L3.

b ) When power is lost on one phase, the current ripple will increase and trip the AC line circuit

breaker (where supplied). To detect a lost phase, measure the AC voltage phase-to-phase at

contactor input terminals L1, L2, and L3.

PROBLEMS of this nature, once detected, are generally corrected at the power connection, or in the

generator unit.

BOOST CIRCUIT PROBLEMS

The boost circuit generates the high open circuit (“no load”) DC voltage which, in conjunction with the igniter

pulse, will ignite the xenon bulb. The open circuit voltage should measure at least 110 V.DC.

A tertiary winding on the main transformer (T1) supplies the source for the Boost Circuit. Three wires derive

from the T1 transformer; two are single conductors, and the third is a soldered pair. The Boost Circuit should

be connected only to the (2) single conductors. Filter capacitors C1A & C1B store energy and also contribute

to bulb ignition.

CONTROL CIRCUITRY

The main power transformer is energized by contactor K1, which is pulled by manual actuation of the

lamphead “ON” switch. All lamphouse interlock switches (air pressure & thermal overload) must also be closed

to complete the contactor circuit.

15

CONTROL CIRCUITRY (continued)

Any interruption of the control circuit will disable K1 and open the AC circuit to the rectifier. In addition to the

above lamphead interlock switches, thermal switch TS1, mounted to the rectifier heat sink, will open and

disable K1 if the temperature at the heat sinks exceeds 190° F. (88° C.). The TS1 switch will automatically re-

set when temperatures fall to safe levels.

POWER CONVERSION PROBLEMS

Rectification (AC to DC) is performed by bridge diodes CR1 - CR6. CR1, CR2, and CR3 are forward diodes,

and CR4, CR5, and CR6 are reverse diodes. The two types are not interchangeable.

An open diode will cause a pronounced flicker in the light output. Two or more open diodes will disable bulb

ignition. A shorted diode will trip the circuit breaker protecting the AC input line. See the following DIODE

TESTING & REPLACEMENT section.

Banked can capacitors C1A & C1B filter the rectified DC output. C1A and C1B capacitors also store energy to

contribute to the open circuit ignition discharge. A shorted capacitor can trip the AC circuit breaker.

Relay K2, in the presence of high DC open circuit voltage, will pull and place Resistor R2 in series with Capaci-

tors C1 and C2. This resistor limits the inrush surge and prolongs the discharge of C1A & C1B to promote bulb

ignition. If K2 relay fails, ignition may become erratic, and R2 may remain in circuit. With R2 in circuit, ripple

will increase to a level noticeable in light output, but not necessarily enough to trip the AC line circuit breaker.

DIODE TESTING & REPLACEMENT

1. Disconnect the diode from its circuit. Inspect for discoloration, oxidation, or loose crimp at lead junction.

2. A “shorted” diode will show low resistance in both directions. An “open” diode will have infinite

resistance in both directions. An Ohmmeter test is required.

3. a) Analog VOM: Select R x 1 Ohm scale. With meter leads connected in one direction, the

reading should be zero (or nearly so); reversing the meter leads should show very high resis-

tance. If the diode does not exhibit these characteristics, replace it. NOTE DIODE TYPE: forward

or reverse.

b) Digital VOM: Select “Diode Test.” With meter leads connected in one direction, the reading

should be “OL” (overload); reversing the meter leads should display approximately .4 volt. If the

diode does not exhibit these characteristics, replace it. NOTE DIODE TYPE: forward or reverse.

4. Carefully clean the area of the heat sink in which the diode mounts. Apply heat sink compound

(Radio Shack #276-1373 or equivalent) using a wood or plastic spatula or stick. A thin layer is

adequate.

WARNING

HEAT SINK COMPOUND IS HIGHLY CAUSTIC.

Do not apply with fingers; keep away from

eyes. Carefully follow ALL the instructions

printed on the package.

5. Install the new diode and tighten securely for maximum mechanical contact and electrical con-

duction. Clean and firmly secure the lead terminal to the buss.

16

POWER SUPPLY TROUBLESHOOTING

Contactor does not energize (no audible “click”).

1. Line safety switch open. Turn “ON.”

2. Circuit breaker or fuse in AC line open. Check AC source.

3. Faulty contactor coil or loose connection at coil terminals. Repair or replace.

Contactor pulls but lamphead igniter does not fire.

1. Faulty contactor contacts. With coil energized, check for continuity across the contacts from the

“L” side to the “T” side; repair or replace if defective.

2. Insufficient DC output. See INSTALLATION section; increase taps as required.

3. Faulty igniter.

4. Low open circuit voltage (less than 110 V.DC).

a) Check ceramic resistor R1; should be in circuit and measure 100 Ohms.

b) Check boost diodes CR7 and CR8. See preceding DIODE TESTING section.

c) Check filter capacitors C1A and C1B. Replace if defective.

5. Defective igniter printed circuit board assembly. Press STRIKE switch to override; do not hold STRIKE

switch longer thatn one second to prevent damage to high voltage transformer.

Bulb requires multiple ignition pulses to light.

1. Insufficient DC output. See INSTALLATION section; set taps as required.

2. Faulty K2 relay. Replace if defective.

3. Faulty or expired xenon bulb. Check for darkened envelope, worn electrodes; replace if re-

quired.

4. One or more faulty bridge diodes. See preceding DIODE TESTING section.

Bulb goes out during operation.

1. Excessive heat at rectifier heat sinks; thermal switch TS1 opening. Check for free air flow, blower(s)

operating at full speed. Check for loose connection.

2. Open lamphead thermal interlock switch.

3. Defective bulb. Check for scorched electrodes or discolored envelope.

Excessive flicker in light output.

1. Improper tap setting. All taps must be on same numbered or lettered step.

2. Faulty bridge diode. See preceding DIODE TESTING section.

3. Faulty xenon bulb. Check for cracked or sagging electrode(s).

4. Open filter capacitor C1A or C1B. Replace if defective.

Bridge diodes (CR1-6) fail repeatedly.

1. Insufficient air flow; defective blower. Clean, repair, or replace as required.

2. Incorrect replacement diode. Use only the specified rated diode(s).

17

LAMPHEAD MAINTENANCE

The SEL10 lamphead requires very little maintenance to keep it in good working order. Cleanli-

ness is the most important element.

The reflector should be cleaned periodically with a soft, clean, lint free cloth to remove any

dust from the reflecting surface. If excessively soiled, use of a mild commercial glass cleaner (Windex®

or equivalent) is acceptable; USE NO ABRASIVE CLEANERS.

The xenon bulb should be checked occasionally for the presence of foreign material on the

envelope. Any dirt or other foreign material should be removed promptly. Use only alcohol and a

clean cloth to clean the bulb; rinse with distilled water and dry carefully. DO NOT touch the bulb with

bare fingers, and observe all safety procedures when working around the bulb.

The inside of the lamphead and the impeller blades of the blower should be cleaned periodi-

cally, depending on the dust conditions at each installation. Although the blower motor may have oil

ports, the bearings are factory sealed and require no lubrication.

Check all electrical connections periodically for tightness, especially the DC leads at the xenon

bulb and igniter.

Follow the instructions on Page 10 regarding periodic bulb rotation. After rotating a bulb,

increase current to the maximum allowable level, and operate the bulb at this level for 10 to 12 hours.

This period will re-excite the thorium in the cathode tip and allow the new arc pattern to establish.

After the 10 or 12 hours, return the current setting to its previous level.

Always allow the lamphead blower to operate for at least ten minutes after extinguishing the

bulb. Failure to do so will shorten bulb life.

LAMPHEAD TROUBLE CHART

ALLOW THE LAMPHEAD to cool, with all blowers operating, for at least (20) minutes before opening.

Normal Operation:

The lamphead blower will start when the generator first supplies power to the SEL10. When the

control panel SYSTEM switch S1 is in the “ON” position, the power supply blowers will start, and the AC

circuit to the xenon power supply will energize the circuitry necessary to supply DC voltage to the

igniter and bulb.

The DC open circuit (“no load”) voltage will be detected by the igniter printed circuit board,

which in turn will close the circuit to the igniter. There will be an audible high voltage arc ping at the

spark gap in the igniter and at the xenon bulb. The bulb should ignite immediately after one or two of

these high voltage pulses, and the lamp current will adjust to the sustaining level set at the xenon

power supply. The STRIKE switch may be pressed to override a defective igniter PC board.

A reed switch mounted to a printed circuit board tie-wrapped to a DC output cable in the

xenon power supply will detect current flow and complete a circuit to the elapsed time meter. The

elapsed time meter will record the unit’s hours of operation.

Troubleshooting:

If the xenon bulb does not ignite, observe the following operational sequences for assistance in

locating and isolating the trouble area.

When the three phase indicator lights are “ON,” the AC circuit in the power supply is trouble

free up to the terminal block (L1, L2, L3) in the power supply. Check the 230 V.AC control circuit at the

blower leads at terminals #2 and #3.

18

Table of contents