STS M-750LG User manual

Surface to Surface Inc. ®

Operators Manual

** M-750LG **

USE IN CONJUNCTION WITH OEM MANUALS (ENCLOSED)

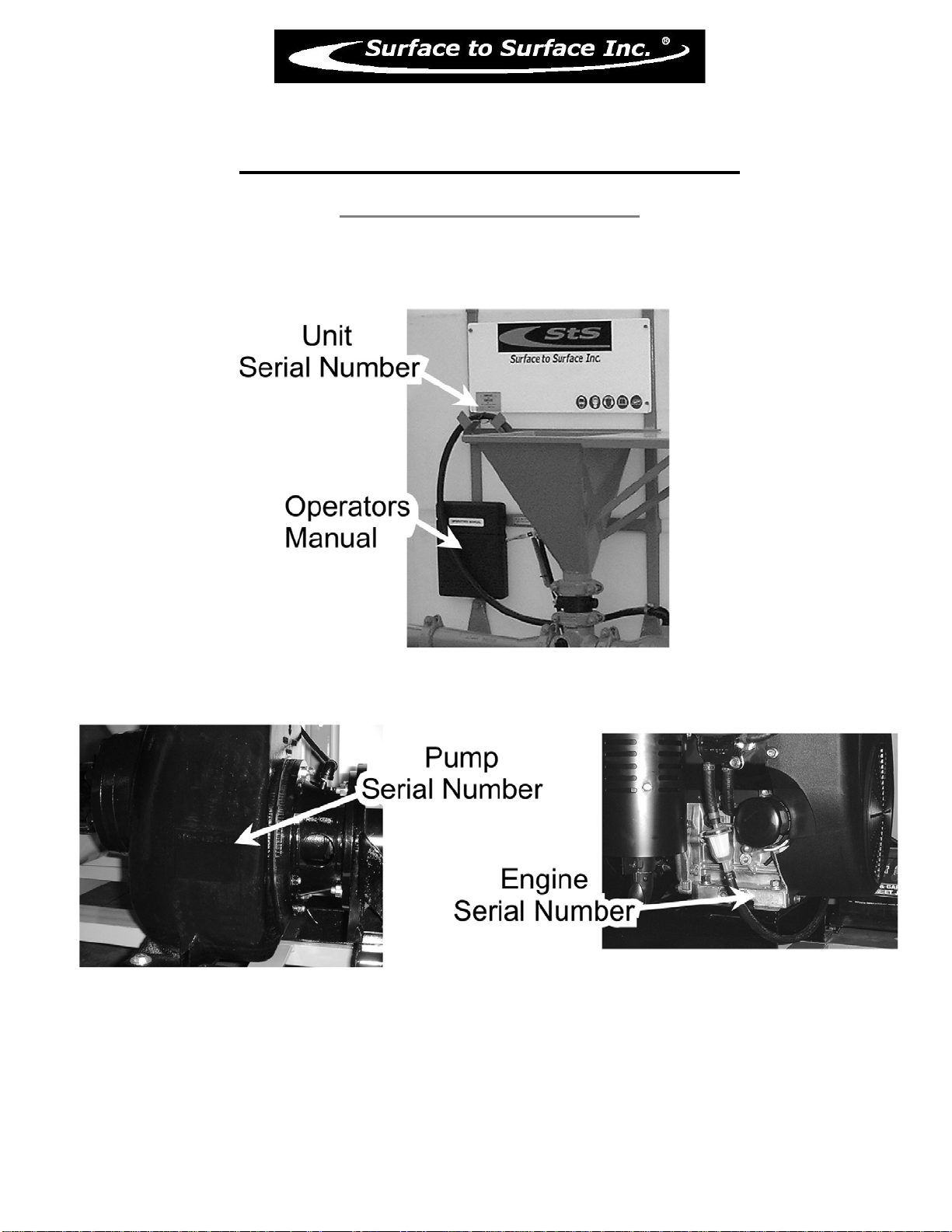

Unit Serial No. _______________

Engine

Robin Engine Serial No. ______________

Gorman-Rupp Pump

GR-84B2 – Serial No. ________________

Links relating to this Manual

www.stsmixers.com

www.robinamerica.com

www.grpumps.com

STS-046 Rev. 09/29/22 www.stsmixers.com

Dealer

2

TABLE OF

CONTENTS

PAGE

STS Inc Warranty………………………………………………………….. 5

Safety Statements………………………………………………...………… 6-9

Safety Markings……………………………………………………………. 10

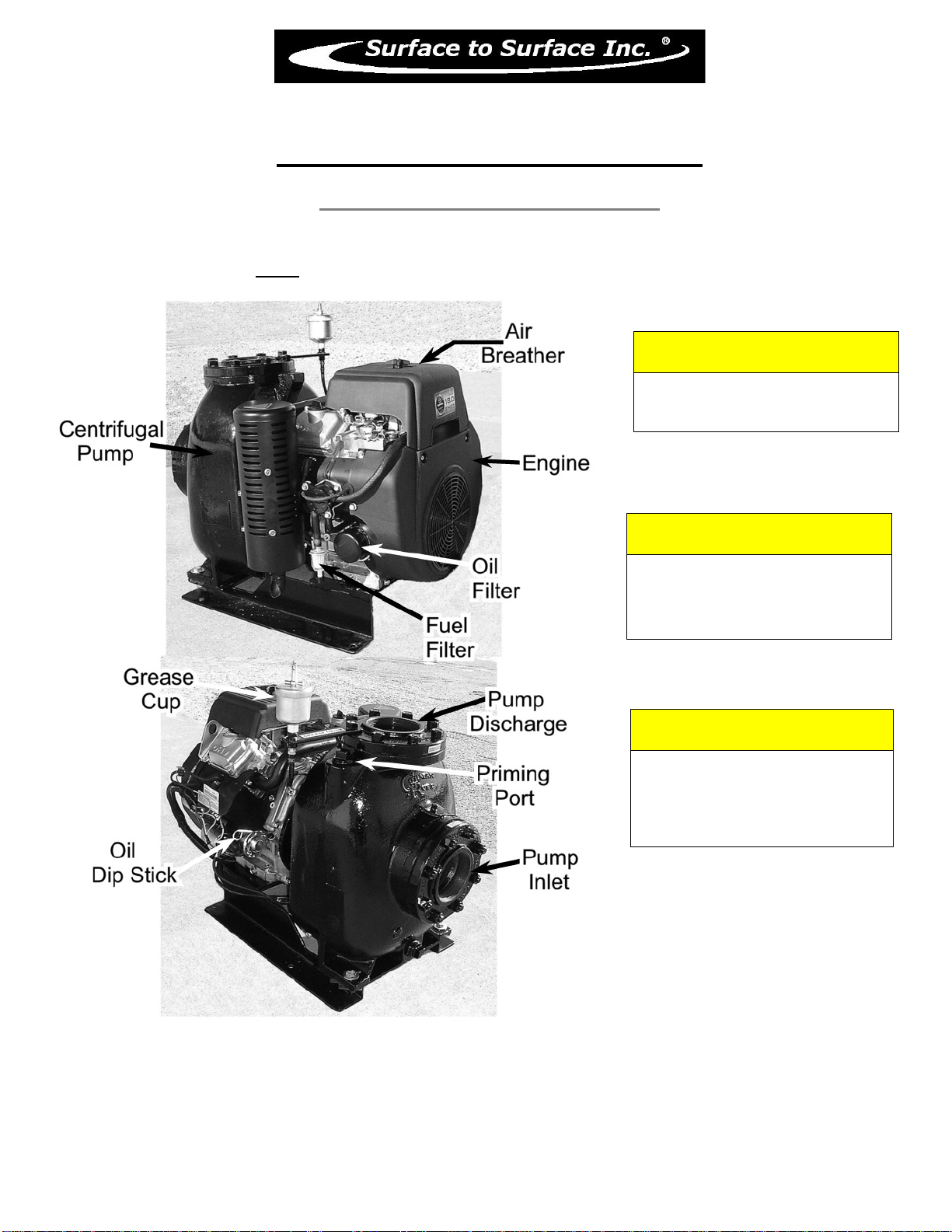

Main Working Components (Photo)……………………………………… 11

Introduction to the M-750……………….………………………………. 12

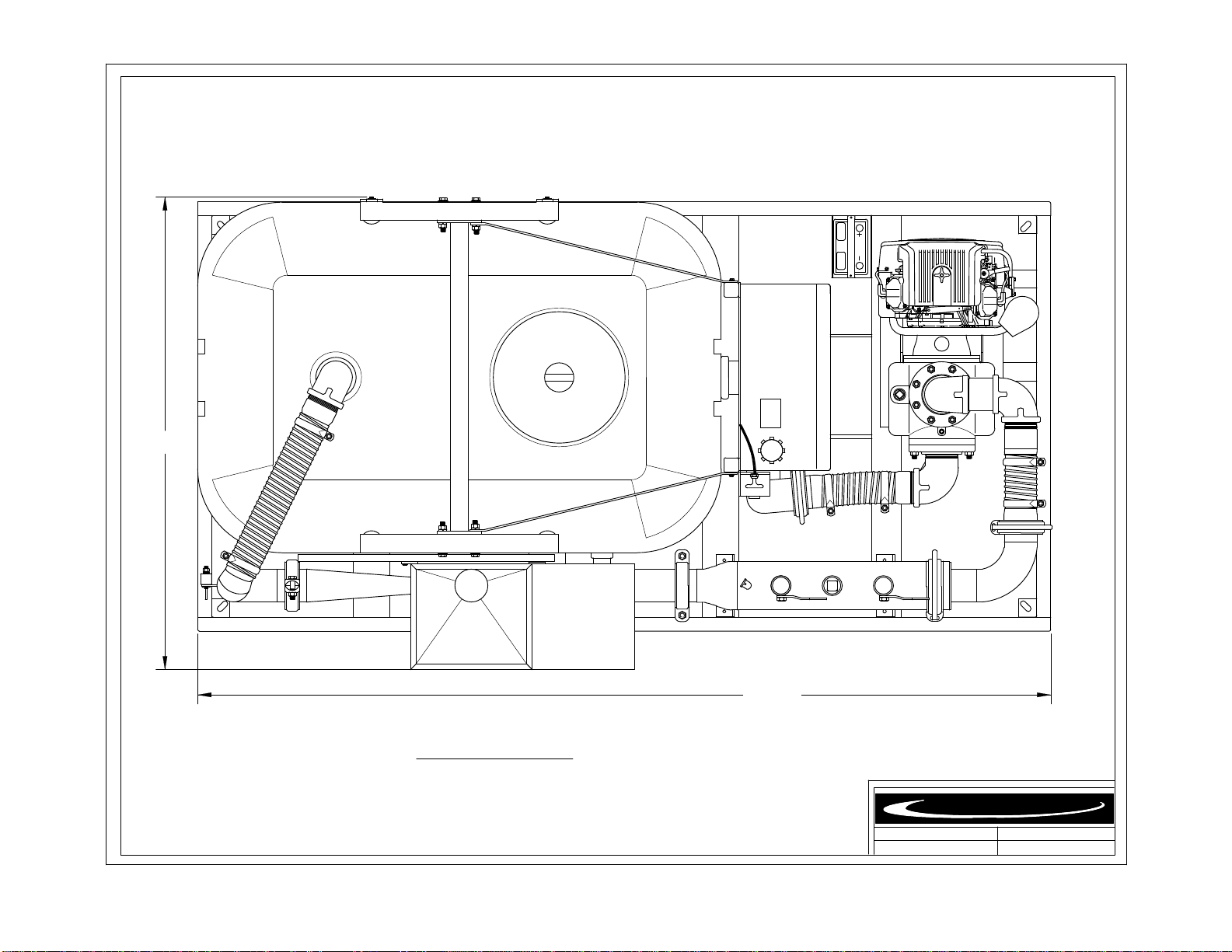

M-750LG Foot Print (top view)……………………………………………… 13

M-750LG General Data Sheet………………………………………………. 14

Identifying Your Machine & Components………………………………. 15

SECTION II (Description, Care and Maintenance)

Polyethylene Plastic Reservoir Tank…………………….…………… 17-18

Gasoline powered centrifugal pump.…….…………….……. 19-22

Filter shear system……………………………………………………. 23-24

Venturi mixing tee……………………………..………..……………. 25

Wash wand……………………………………………………...……. 26

Dry hopper with table & hopper valve…………………………..…… 27

Internal tank jet gun…………………………………...……………… 28

SECTION III (Set-up and installation of unit in Detail)

Permanent mounting of unit…………………………...…………….. 30

Portable use of unit…………………….…………………….………. 30

3

TABLE OF

CONTENTS

PAGE

SECTION IV (Operating the M-750 Unit.)

Site set-up and pre-check…………………………………………….. 32

Starting the engine and pump………………………....……………… 33

Typical mixing operation……………………….……………………. 34

Typical transfer / off-loading operation……………………………… 35

Shutdown, cleanup & storage

Warm weather…………………………………….…………. 36

Cold/ freezing weather………………………………….…… 37

Prolonged periods of storage………………………………… 38

**Optional self-loading feature……………………………...………… 39

SECTION V (Trouble shooting)

Trouble Shooting the M-750…………….…………………..……… 41-42

SECTION VI (Periodic Maintenance & Repair Information)

Maintenance Schedule…………………….….………………….…... 44

Centrifugal Trash Pump Seal Replacement………………………..… 45

Bolt torque Specifications…………………………………….……... 46

Notes…………………………………………………….…………… 47

4

TABLE OF

CONTENTS

PAGE

SECTION VII (OEM Repair Information)

GR Centrifugal Pump Owner’s Manual……………………..………… 49-60

Engine Manufacture Customer Help (web-site)………………………. 61

Gruvloc® Pipe Couplings……………………….………………..…… 62-64

SECTION VIII (Parts Manual)

M-750LG PARTS MANUAL…………………….……………….……. 66-69

5

Limited Warranty

United States and Canada

Surface to Surface Inc. or it’s subsidiary which last sold the product, warrants new products sold by it for use in the

United States and Canada to be, at the time of manufacture, free from defects in workmanship and materials. This

warranty covers for a period of Twelve (12) Months of operation from the date of delivery for initial use, whichever

comes first.

Exclusions and Additional Limitations

1. This warranty relates to the condition of the product at the time of manufacture and does not cover parts or

service as a result of:

(a) Normal wear and tear or required maintenance including, without limitation, adjustments or replacement of

components subject to wear and tear, such as belts, hoses, seals and/or packing, fuses, bulbs,

switches and ignition parts.

(b) Abuse including, without limitation, neglect, improper operation, misapplication, overloading, accident or

alterations not approved by Surface to Surface Inc.

(c) Lack of maintenance, including, without limitation, failure to inspect and maintain, improper repair, use of

“unapproved parts”, cracked engine heads and blocks unless caused by the failure of

an internally lubricated part or repair of engine valves, rings or guides.

2. The Company’s warranty does not apply to purchased components manufactured by others where separate

warranty is made by the manufacture of such components and will be applied as interpreted by

the supplier.

3. All claims under his warranty shall be submitted in writing by the distributor to the Company, which will be the

sole judge in determining the merits of the claim.

4. The company shall have the right to have all products or parts claimed to be defective returned to it and the

cost of shipping such items shall be borne by the distributor.

……………………………………………………………………………………

Warranty Registration Card

In order to help us provide complete service for our product, please complete this card and return it.

If not returned, all requests for warranty will be denied.

Print Name: …………………………………………………………………….….

Address: …………………………………………………………………………...

City: ……………………State/Province………………Zip/PC…………………...

Model No. ………………………….. Serial No. …………………………………

Date of Purchase ………………………… Dealer ………………………………..

Return to: Surface to Surface Inc.

5150 Forest Rd. RR#3

Watford, Ontario, Canada

N0M 2S0

01/14/08

6

M-750LG

SAFETY STATEMENTS

Your personal safety and the safe operation of this unit are the concern of Surface to Surface Inc, and by

reading and understanding this manual and understanding the safety statements, you will decrease the risk of

personal and equipment damage.

Safety statements are listed here and throughout this manual to draw your attention to potential hazards that

may be encountered while operating this piece of equipment. While reading this manual, you will notice that

certain safety statements will relate directly to the operation, or maintenance of that particular part of the unit and

should be followed carefully. Decals on the unit also follow the same format as the warnings in this manual, and

therefore should be kept in good repair to alert the operator and others of the potential hazard.

The engine / motor manual also contains hazard warnings which pertain to the engine / motor and should

also be followed.

This safety alert symbol appears with most safety statements.

It means attention, become alert, your safety is involved!

Please read and abide by the message that follows the safety alert symbol.

DANGER

WARNING CAUTION

CAUTION

Caution "without the safety alert symbol"

indicates an potentially hazardous

situtation that can cause damage to the,

machine, personal property and / or the

environment or cause the machine to

operate improperly.

Danger (the word "DANGER" is in white

letters with a red rectangle behind it)

indicates an imminently hazardous

situation, which, if not avoided, will

result in death or serious injury.

Danger is limited to the most extreme

situations.

Warning (the word "WARNING" is in black

letters with an orange rectangle behind it)

indicates an potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Caution (the word "CAUTION" is in black

letters with a yellow rectangle behind it)

indicates an potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

7

M-750LG

SAFETY STATEMENTS

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

DANGER

IN AN EMERGENCY

DANGER

NEVER ATTEMPT REPAIRS

OR DISASSEMBLY

without shutting off the engine / motor

and disconnecting the power source.

Serious personal injury will result.

WARNING

NEVER USE BODY PARTS,

OR FOREIGN OBJECTS

in an attempt to unplug or clean the

hopper valve or mixing tee.

Serious personal injury or

damage will result.

WARNING

Serious personal injury will result.

DO NOT REMOVE OR MODIFY

SAFETY COVERS OR GUARDS.

WARNING

while the unit is in operation.

Serious personal injury will result.

NEVER ATTEMPT TO REMOVE

OR CLEAN THE FILTER SHEAR

CAUTION

DO NOT POSITION

ANY PART OF YOUR BODY

over the hopper, valve,

or mixing tee while cleaning.

CAUTION

WHEN THE UNIT

IS IN OPERATION,

the fluid in the piping may reach

pressures up to 50 p.s.i.

When the engine is idling, the system is

still pumping fluid under pressure.

CAUTION

NEVER OPERATE THE MIXING

unit with the tank lid open.

If viewing is necessary, open

only the small inspection

vent cap in the center of the lid.

rotate the key switch to

the STOP position

to halt engine, pump, and fluid flow

8

M-750LG

SAFETY STATEMENTS continued

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

CAUTION

TRAPPED FLUID MAY BE PRESENT

and will spill out when piping, hoses,

pump or filter shear are removed.

CAUTION

AVOID ALLOWING FOREIGN MATERIAL

into the Venturi Mixing Tee thru the

Hopper, by keeping the valve closed

when not in use.

CAUTION

NEVER LEAVE LIQUID IN THE

PUMP CASING, PIPING, OR HOSES

during freezing weather conditions,

as damage will result.

Follow instruction for winterizing.

CAUTION

BEFORE STARTING THE ENGINE,

BE SURE THE PUMP IS PRIMED!

CAUTION

CAUTION

CARE MUST BE TAKEN WHEN

INSTALLING THE COUPLER GASKETS.

If the gaskets are not properly lubricated

and installed, a leak may develop.

CAUTION

BEFORE STARTING OR RESTARTING

the engine and centrifugal pump, make

sure any valves installed on the pump

suction inlet line are open, and the

fluid level in the tank is above

the suction line.

IMPROPER INSTALLATION OF THE

MECHANICAL or GREASE SEAL

will result in leakage and possible

damage to the seal. All maintenance,

operating and repair of this unit, must be

done per the instructions in the operators

manual for safety and reliability.

CAUTION

WHEN TRANSFERRING FLUID

to the drill rig, fluid pressure may

reach or exceed 50 p.s.i.

CHECK the drill rig manufacturers

specifications regarding maximum inlet

pressures allowed for their pump.

Check the pump by slowly & carefully

opening the plug located on the top

of the centrifugal pump discharge elbow.

A visual inspection can be made if the fluid

escapes around the plug as it is loosened.

Remove the plug to view inside fluid level.

The centrifugal pump seal WILL be

damaged if allowed to cavitate or run dry.

9

M-750LG

SAFETY STATEMENTS continued

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

CAUTION

CAUTION

The manufacturer should be consulted

when considering alternative uses

for this piece of equipment.

This unit was designed for the mixing

and shearing of a dry additive, into a

liquid stream.

Other uses may create unforeseen safety

issues and personal injury risk.

CAUTION

BEFORE LIFTING OR MOVING THE UNIT,

all fluid should be removed from the tank.

CAUTION

AVOID PLACING OBJECTS

on top or against the tank as damage

may result from the weight.

CAUTION

WARNING

LIFTING LUGS OR THE LIFTING POINT(S)

identified and labelled on the skid

structure must be used in order to

safely lift and transport the unit.

TO ENTER THE TANK is not recommended

Personal injury could result from

the presents of hazardous fumes,

remaining fluid or unit start-up.

REFER TO THE SAFETY

STATEMENTS IN THE

ENGINE OEM MANUAL

AND

THIS MANUAL

REGARDING THESE

OPERATIONS.

10

M-750LG

Safety Markings

Hazard and warning markings have been placed at appropriate points on the unit. International symbols

have been used, in order to ensure universal understanding of the nature of the hazard. Please comply

with all warnings and markings to ensure safe use of the equipment. These include but are not limited to:

a) Lifting points b) Flammable Liquids

c) High temperature areas d) Personal Protection recommendations

e) Personal dangers f) Equipment dangers

g) Operating instructions h) Fluid flow direction

SOME EXAMPLES FOUND ON THE EQUIPMENT

Liftin

g

Point

Personal Protection

,

Read and understand O

p

erator’s manual and Maintenance manual

Flammable Li

q

uid Hot Surface

Fluid Flow Direction

Maintenance Instructions

Liftin

g

Point

Safet

y

Instructions

KEEP LID CLOSED

W

HILE MIXING

CLEAN FILTER DAILY

11

12

M-750LG

Operators Manual

Congratulations on your acquisition of the time proven M-750 Mixing System. You have acquired the

fastest and most efficient mixing system manufactured for mixing Bentonite drilling slurry (mud). As a

manufacturer of HDD support equipment, we are well aware of the extreme conditions that HDD

equipment is exposed to on a daily basis. Surface To Surface Inc. strives to overcome these conditions,

with better design and manufacturing practices. Please feel free to call our toll free number

(1-800-567-0978) if you have any questions or concerns about your M-300D.

Thank you, for choosing the M-750 series mixer.

The M-750 mixing unit was designed to mix dry or liquid drilling products with clean

water, into a slurry. The slurry is continually circulated through the mixing cycle until it

reaches the desired consistency. The operator can then transfer the final product to a holding

reservoir or directly to the drilling equipment.

The M-750 mixing unit consists of a 750 u.s. gal. (2839 litre) polyethylene plastic tank,

gasoline or diesel powered centrifugal pump, filter/shear unit, venturi mixing tee assembly,

dry hopper with a table, tank internal jet gun and a discharge valve to pump the finished

slurry to a holding tank or the drill rig. These components are all mounted on a frame type

skid, built for lifting or solid mounting. For ease of interpretation, looking at the mixing unit

hopper straight on will be considered looking at the front of the unit. Hence the other long

side, will be the rear and the ends will be right or left end.

RECORD OF OWNERSHIP:

• Unit Serial No. __________________________________________

• Engine Serial No.________________________________________

• Pump Serial No:_________________________________________

• Tank Serial No:__________________________________________

• Date Purchased/Leased:___________________________________

• Dealer Purchased/Leased From:_____________________________

• Special Custom Features:__________________________________

13

REV.

DATE.

DWR. NUM.

116.50"

65.00"

* Due to our continuing product improvement, specifications are subject to change without notice. *

UNLEADED

GASOLINE

ONLY

Surface to Surface Inc.

DRY WEIGHT

2010 lbs.

M-750L (Gasoline )

M-750L (GR)

10 / 15 / 09

Height: 73"

14

Surface to Surface Inc.

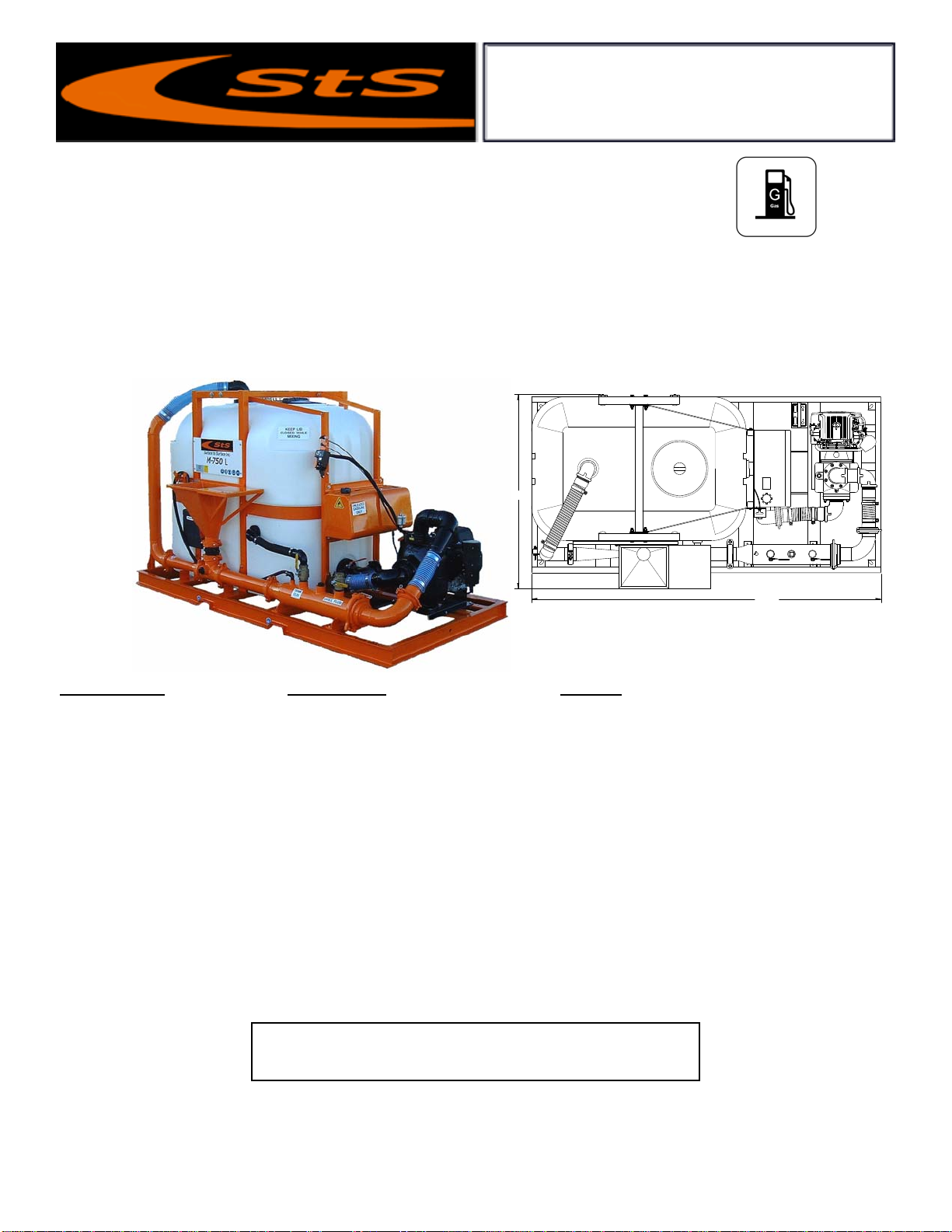

Specifications M-750L Mixer Benefits

Dimensions 65” W x 116.5” L x 75” H The long design allows for alternative

Approx. Weight 2010 Lbs placement by the contractor.

Hopper Height 39” High Waist high hopper reduces back strain.

Mixing System 4” Proprietary StS Mixing System Fast, efficient mixing time ( 8 min. mix ).

Mixing Tank 750 gal. Roto-Molded polyethylene Minimal maintenance required.

Skid Frame 5” Steel channel, welded Built for the rigors of the construction trade.

Gasoline Engine 18.0 hp air-cooled, electric start Industrial rated for long service life.

Pump 4” Cast iron centrifugal trash pump Rugged & repairable for extended service life.

Pump Drive Direct coupled engine to pump No expensive couplers or inserts to replace.

Fuel Tank 15 gal. Steel c/w sight gauge Provides a full day running on a fill up.

Pipe Couplers Bolt & Snap-groove type Provides fast cold weather draining of system.

Pressure Wand Hopper maintenance wand Removal of blockages caused by additives.

Tank Drain Bottom tank drain supplied Provides fast cold weather tank drainage.

Also available in Diesel (M-750LD) - Hydraulic (M-750LH) – Electric (M-750LE) models.

∗∗∗ All Specifications Subject to Change Without Notice ∗∗∗

Features and Benefits M-750L Mixer

The M-750L was designed and manufactured to provide an alternative footprint for special applications. The longer,

narrower footprint allows the contractor the option of mounting the unit to one side of a 96 inch platform, while allowing

a 31 inch walk way and work area in front of the mixer. Powered by an 18.0 hp Air Cooled electric start engine, driving

a 4 inch centrifugal pump making effective use of the proprietary StS mixing system, this Bentonite Mud Mixer is

capable of providing 750 gallons of full yield mud to your drill rig in less then eight (8) minutes. Added benefits to this

unit include the ability to draw water from a second tank and send mud to your drilling rig or storage tank with-out the

use of a second pump. Other power drives available

Bentonite Mud Mixer

Model M-750L

Surface to Surface Inc.

5150 Forest Road, R.R.#3, Watford, Ontario, N0M 2S0

Tel: 1-800-567-0978

Check our website for the latest products and specifications

www.stsmixers.com

01/29/10

116.50"

6

5.00"

UNLEADED

GASOLINE

ONLY

15

M-750LG

Identifying Your Machine & Components

Location of Tags and PIN Plates

16

SECTION #II

Description, Care and Maintenance

17

M-750LG

Description, Care and Maintenance

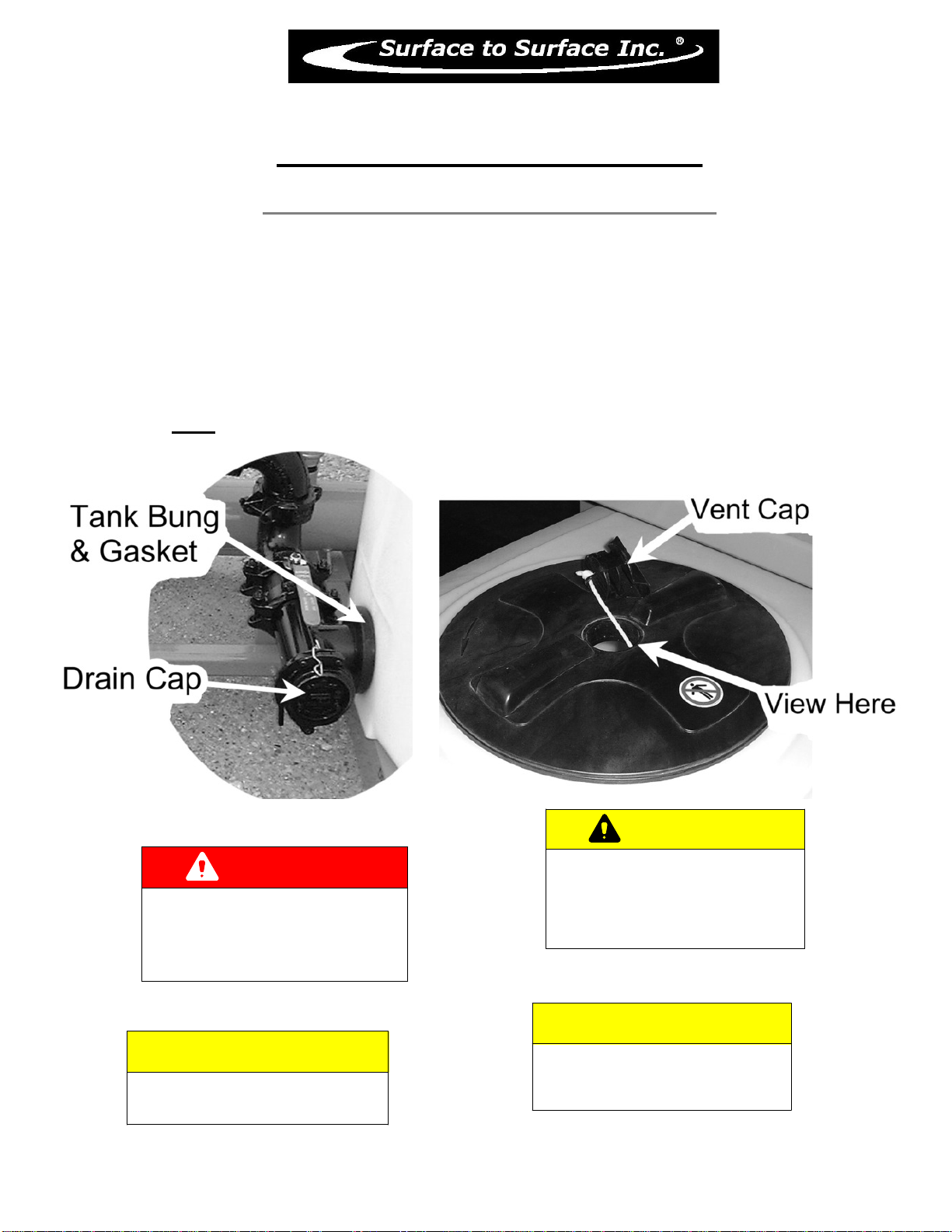

Polyethylene Plastic Reservoir Tank (750 us. gal)

Maintenance of this tank is required, but is simple. The tank should be cleaned on a regular basis by opening

the drain cap on the tank tee, located at the bottom right end of the tank (see Fig.1) and or open the

customer installed bottom tank drain (see Fig.2) and rinse the tank with clear water. Residue such as leaves,

stones, etc can be removed using a wet /dry vacuum.

All tank ports are of a threaded type bung (see Fig.1) with rubber gaskets. If a leak is noticed between

the tank and gasket, the connection can be tightened up by tightening the large nut flange in the direction of

the arrows (counter clock wise).

DANGER

NEVER ATTEMPT REPAIRS

OR DISASSEMBLY

without shutting off the engine / motor

and disconnecting the power source.

Serious personal injury will result.

CAUTION

NEVER OPERATE THE MIXING

unit with the tank lid open.

If viewing is necessary, open

only the small inspection

vent cap in the center of the lid.

CAUTION

BEFORE LIFTING OR MOVING THE UNIT,

all fluid should be removed from the tank.

CAUTION

TO ENTER THE TANK is not recommended

Personal injury could result from

the presents of hazardous fumes,

remaining fluid or unit start-up.

Fig.1

18

M-750LG

Description, Care and Maintenance

Polyethylene Plastic Reservoir Tank (750 us. gal)

INSTALLATION OF (CUSTOMER INSTALLED) TANK DRAIN

• Find a suitable location on the tank floor for the drain to be installed, taking into consideration the

placement of the unit on a trailer. LOOK under the deck for obstructions (cross-members, wiring, and axles,

ect.) Allow room for a shut off valve.

• Drill holes into floor of tank using the top (inside) portion of the drain as the template.

• Make sure the holes are free of burs and both surfaces are clean.

• Install the drain bung as per FIG 1. Note the gaskets are on the inside and outside of the tank.

• Tighten nuts as to slightly squeeze the rubber gaskets.

• Cut a hole into the deck of the trailer or truck for the piping and valve to be installed.

• Install 2” pipe nipple and valve into tank bung with a sealant on the threads. CAUTION: DO NOT OVER-

TIGHTEN!

• The nipple and valve should not extend to far from the tank without a support, as this will cause excess

stress on the threads, drain bung and the tank floor.

• Fill with water and check for leaks.

GASKETS

CUSTOMER SUPPLIED

PIPING AND VALVE

TOP

(INSIDE)

BOTTOM

(OUTSIDE)

FIG 1

TANK FLOOR

1 3/4" Ø

IN FLOOR

Fig.2

19

M-750LG

Description, Care and Maintenance

Gasoline Powered Centrifugal Pump

Care and maintenance of the engine and pump are covered in this manual and/or the manufacturer

operator’s manuals supplied and should be read and understood. We suggest the following daily checks be

carried out prior to using the system. Check the gasoline fuel tank is full. Check oil level by removing the oil

plug / dip stick, and viewing the oil level. Check the pump seal grease cup is full (see grease cup instructions

Fig.5). Check the engine air filter (due to environmental conditions). Check that the suction valve (see Fig.3)

is open and the reservoir tank has sufficient liquid to supply the centrifugal pump.

The pump is mounted directly to the engine, so there is no “drive coupler” to check or maintain. The

pump is the primary component that will see the most wear due to the nature of the material it is handling

therefore it will require regular checks, adjustments and maintenance.

There is a section of this manual dedicated to the pump itself and should be read and understood

which will help should any problems or concerns arise in the field.

The pump should never be allowed to start or run dry, as this WILL damage the internal pump seal (grease

seal) and render the unit inoperable until the seal is fixed.

To prime the pump or check to visually see if the pump is primed, slowly undo the plug on top of the

pump beside thedischarge elbow (see Fig.4) and stop after about 3 turns. If the pump is primed, fluid & air

will escape from around the plug threads. This indicates that the pump housing is full, and the plug can be

tightened back up. If no fluid is escaping from around the threads, completely remove the plug.

Fluid or water can be poured into this opening to fill the pump cavity, and a visual of the fluid level inside

the pump can be made. The level should be approximately to the top of the pump housing.

Another way to prime the pump is to have the tank FULL of fluid, and standing off to the side of the

hopper, rotate the hopper valve SLOWLY to the open position. As the valve is opened, you will hear air

escaping followed by fluid, into the hopper itself. Close the valve as the fluid enters the hopper. This means

the fluid in the tank has filled the pump cavity of the pump and flowed from the outlet of the pump to the

remaining piping on the unit.

DANGER

NEVER ATTEMPT REPAIRS

OR DISASSEMBLY

without shutting off the engine / motor

and disconnecting the power source.

Serious personal injury will result.

CAUTION

IMPROPER INSTALLATION OF THE

MECHANICAL or GREASE SEAL

will result in leakage and possible

damage to the seal. All maintenance,

operating and repair of this unit, must be

done per the instructions in the operators

manual for safety and reliability.

Fig.3

CAUTION

BEFORE STARTING THE ENGINE,

BE SURE THE PUMP IS PRIMED!

Check the pump by slowly & carefully

opening the plug located on the top

of the centrifugal pump discharge elbow.

A visual inspection can be made if the fluid

escapes around the plug as it is loosened.

Remove the plug to view inside fluid level.

The centrifugal pump seal WILL be

damaged if allowed to cavitate or run dry.

DANGER

IN AN EMERGENCY

rotate the key switch to

the STOP position

to halt engine, pump, and fluid flow

20

M-750LG

Description, Care and Maintenance

Gasoline Powered Centrifugal Pump

CAUTION

NEVER LEAVE LIQUID IN THE

PUMP CASING, PIPING, OR HOSES

during freezing weather conditions,

as damage will result.

Follow instruction for winterizing.

CAUTION

BEFORE STARTING OR RESTARTING

the engine and centrifugal pump, make

sure any valves installed on the pump

suction inlet line are open, and the

fluid level in the tank is above

the suction line.

CAUTION

TRAPPED FLUID MAY BE PRESENT

and will spill out when piping, hoses,

pump or filter shear are removed.

Fig.4

This manual suits for next models

1

Table of contents

Other STS Music Mixer manuals