20

M-750H

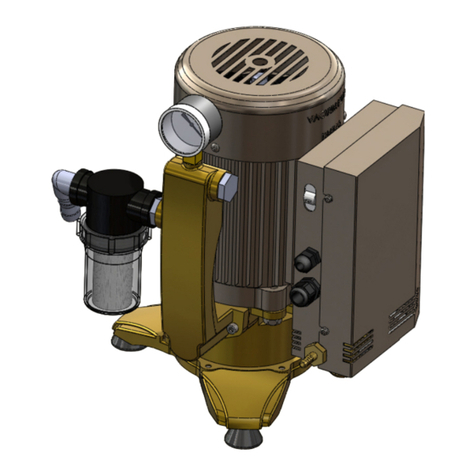

Description, Care and Maintenance

Hydraulic Powered Centrifugal Pump

Care and maintenance of the hydraulic motor and pump are covered in this manual and/or the

manufacturer operator’s manuals supplied and should be read and understood. We suggest the following

daily checks be carried out prior to using the system. Check the fluid level in YOUR hydraulic reservoir is

sufficient. Check the hydraulic filtering system is working properly. Check the pump seal grease cup is full

(see grease cup instructions Fig.5). Check that any water intake valve(s) are open and the reservoir tank has

sufficient liquid to supply the centrifugal pump.

The pump is mounted directly to a bearing block and the hydraulic motor, so there is no “drive

coupler” to check or maintain. The bearings in the bearing block are factory greased to provide constant

lubrication. The pump is the primary component that will see the most wear due to the nature of the

material it is handling therefore it will require regular checks, adjustments and maintenance.

There is a section of this manual dedicated to the pump itself and should be read and understood

which will help should any problems or concerns arise in the field.

The pump should never be allowed to start or run dry, as this WILL damage the internal pump seal (grease

seal) and render the unit inoperable until the seal is fixed.

To prime the pump or check to visually see if the pump is primed, slowly undo the plug on top of the

pump beside the discharge elbow (see Fig.4) and stop after about 3 turns. If the pump is primed, fluid & air

will escape from around the plug threads. This indicates that the pump housing is full, and the plug can be

tightened back up. If no fluid is escaping from around the threads, completely remove the plug.

Fluid or water can be poured into this opening to fill the pump cavity, and a visual of the fluid level inside

the pump can be made. The level should be approximately to the top of the pump housing.

Another way to prime the pump is to have the tank FULL of fluid, and standing off to the side of the

hopper, rotate the hopper valve SLOWLY to the open position. As the valve is opened, you will hear air

escaping followed by fluid, into the hopper itself. Close the valve as the fluid enters the hopper. This means

the fluid in the tank has filled the pump cavity of the pump and flowed from the outlet of the pump to the

remaining piping on the unit.

CAUTION

IMPROPER INSTALLATION OF THE

MECHANICAL or GREASE SEAL

will result in leakage and possible

damage to the seal. All maintenance,

operating and repair of this unit, must be

done per the instructions in the operators

manual for safety and reliability.

Fig.3

DANGER

IN AN EMERGENCY

rotate the flow control valve

lev er tothe STOP position

to halt the pump, and fluid fl ow.

DANGER

NEVER ATTEMPT REPAIRS

OR DISASSEMBLY

without shuttingoff the hydraulic

power source (customer supplied)

Serious personal inj ury will result.

CAUTION

BEFORE STARTING THE HYDRAULIC MOTOR,

BE SURE THE PUMP IS PRIMED!

Check the pumpbyslowly&carefully

opening the plug located on the top

of the centrifugal pump discharge elbow.

A visual inspection canbe made if the fluid

escapes around the plug as it is loosened.

Remove the plug to v iewinside fluid level.

The centrifugal pumpseal WILL be

damaged if allowed to cavitate or run dry.