Foreword

Sumake is a manufacturer and exporter of air

tools since established. We have devote all our

efforts in improving quality and tools’ life. As

well as the noise and vibration of tools. Bring all

of you working efficiences, profits, and enjoy

using the tool is ourprinciple.

Features

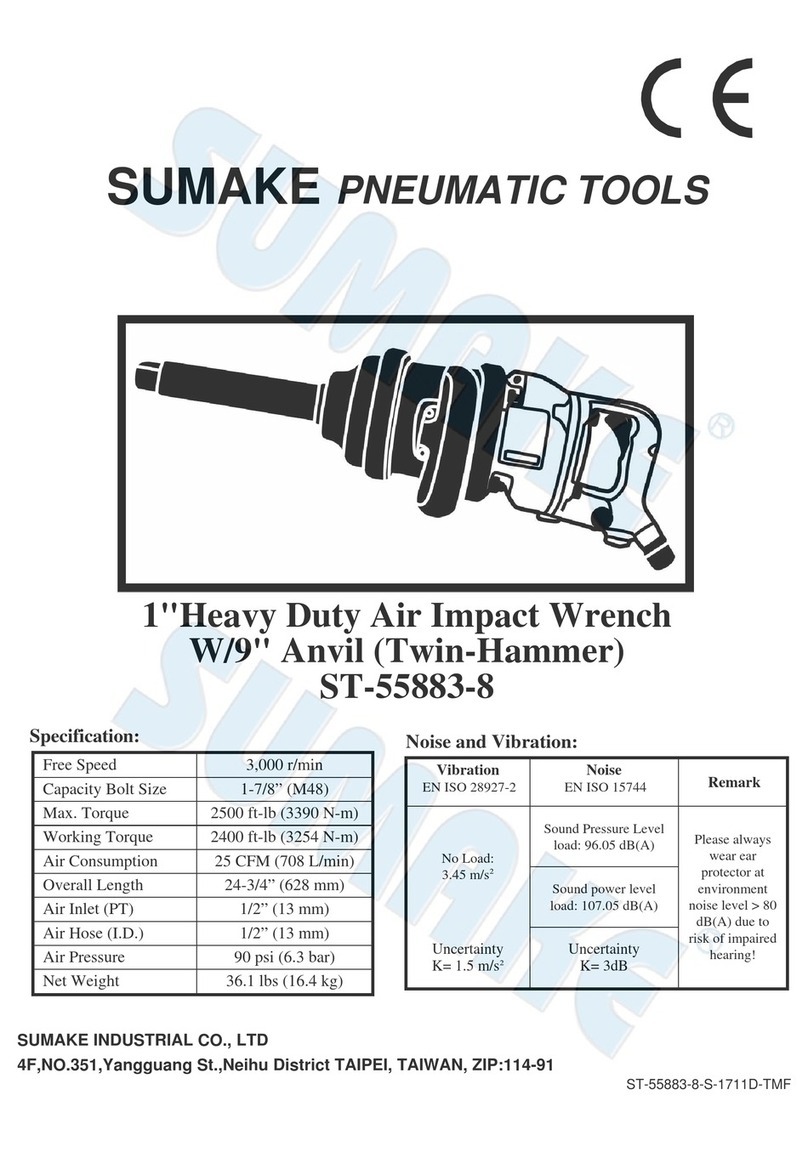

This tool with a reversible spindle driving a

hammer which periodically strikes an anvil which

includes a drive adapter for the purpose of

tightening or loosening nuts and bolts without

roducing any major torque reaction on th

ower tool.

Operator’s instruction

1. Main Applications

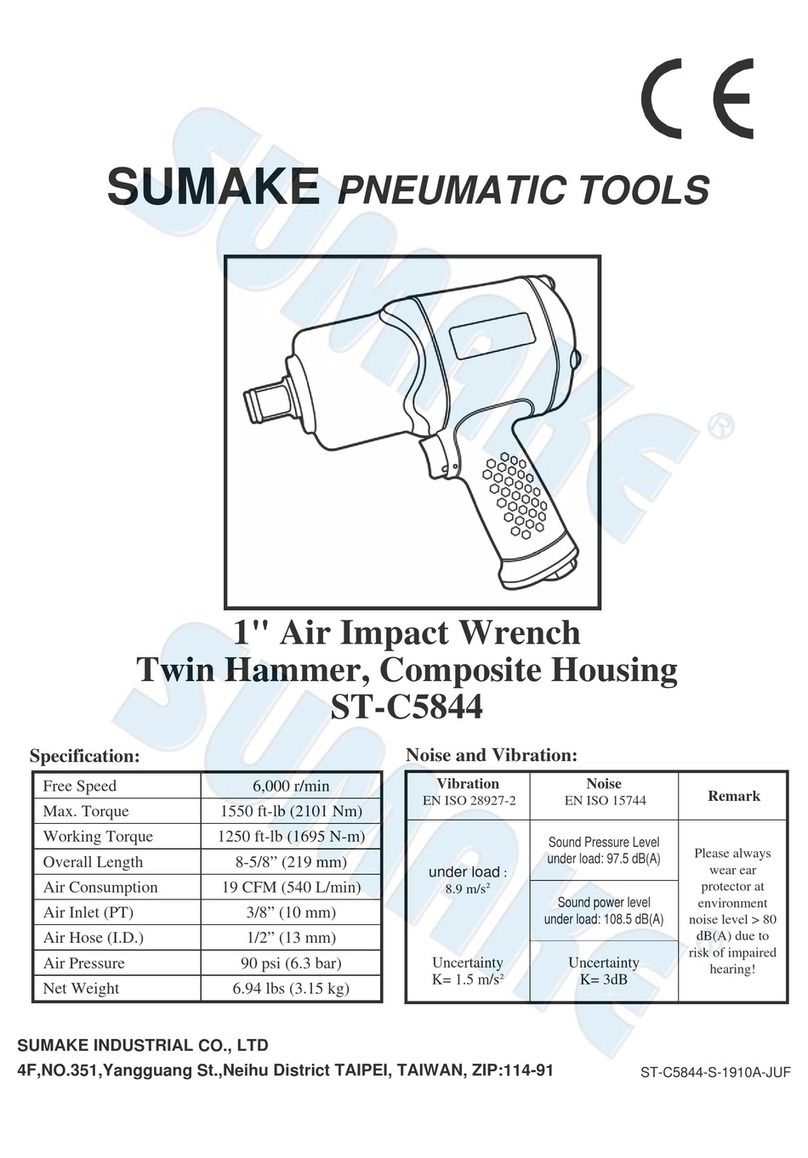

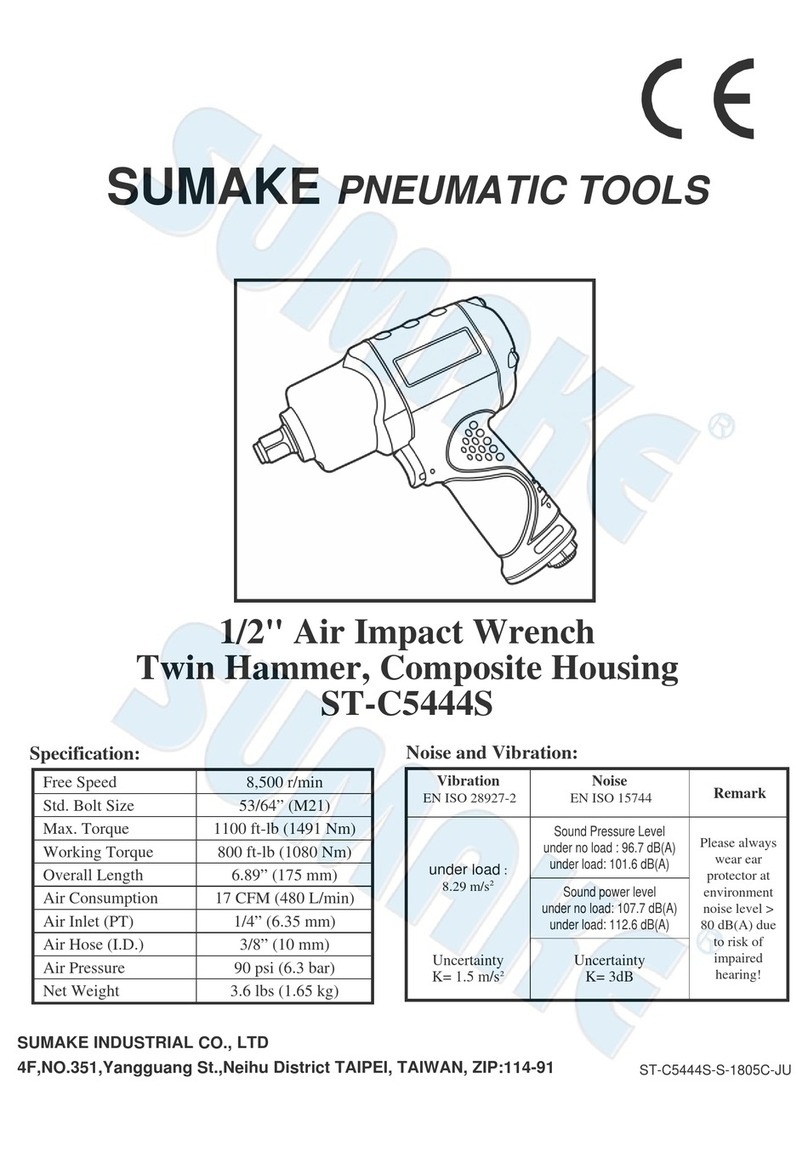

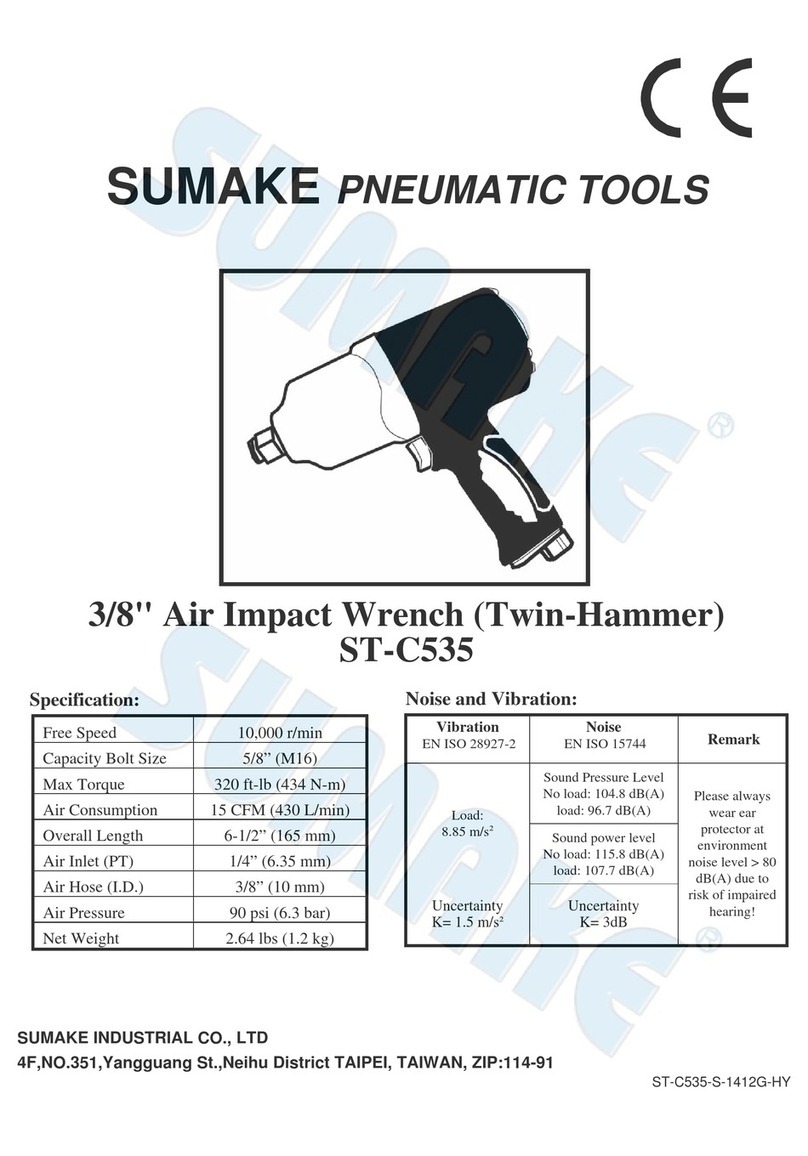

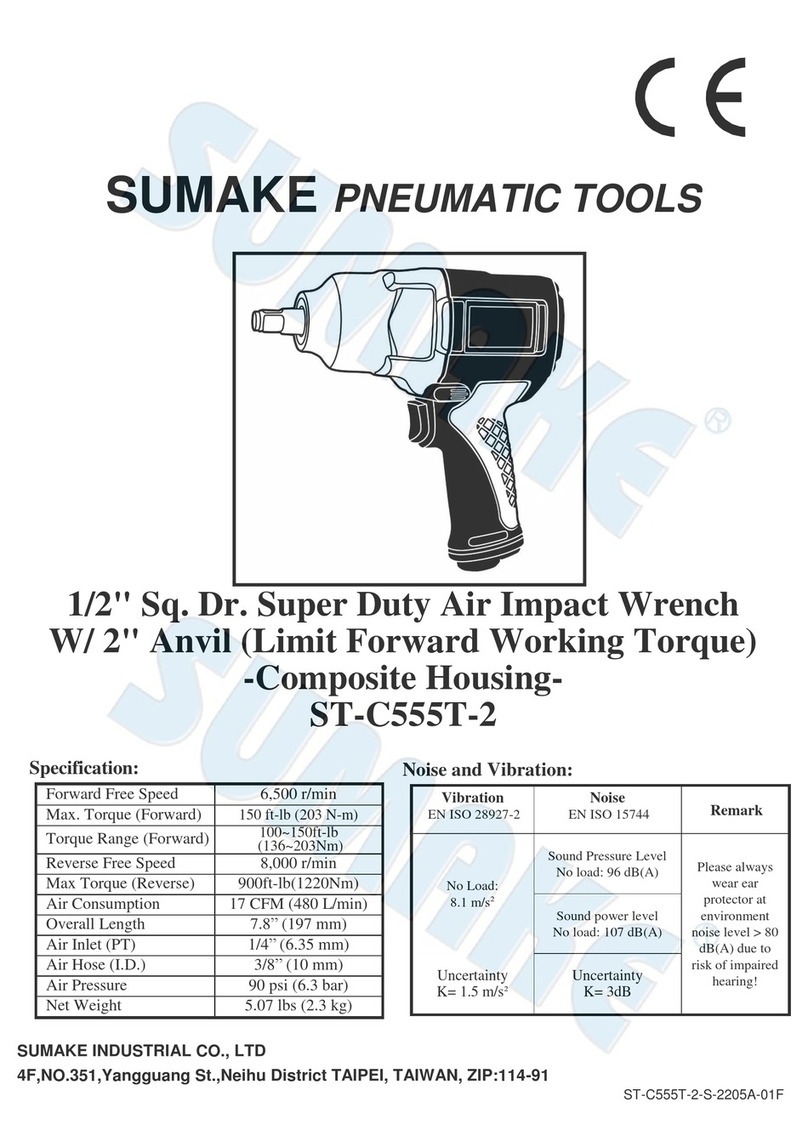

The most popular 1/2” drive impact wrench. It

combines compact size and light weight with

high torque to meet awide range of applications.

It is ideal for overall automotive service, body

shop,farm, and light truckwork.

2. Cautions for Use

2-1 Air pressure

Maximum performance is displayed at the proper

sanding speed, obtainable at a gauge pressure of

6.2 bar. Range-wise, this is an airpressure from 5

to 7 bar (70 to 100 psi)

57

2-2 Air line

Use a 3/4“air hose between the compressor and

the tool . Compressed air is cooled and its water

content separated, as soon as the air leaves the

compressor. A portion of the water content,

however, is condensed in the piping, and can

enter the tool mechanism, and may cause trouble.

So, install an air filter and on oiler between the

compressor and the tool. Use a 3 HP or large

compressor for each sander.

Tool

Nipple

Coupler Recoil

hose

Leader

hose

Oiler Regulator

Water

separation Air

supply

Drain

daily

2-3 Air hose

Clean the hose with a blast of compressed ai

efore connecting the hose to air tool. This wil

prevent both moisture and dust within the hos

from entering the tool and causing possible rus

or malfunction. To compensate for unusuall

long hose (over 25 ft), the line pressure should b

increased accordingly.

Drainage

2-4 Inserted tools

Use only the socket or adapter which are in goo

condition for use. The intended socket an

adapter for this air tool could are stated as “

Square Drive"on the specification list.

2-5 The approved eye protector, ear-muff,

mouth-muffle, and gloves shall be worn whe

operate this tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case o

energy supply failure.

3. Operation Method

3.1 On-off device

The on-off device is on the inner or outer contou

of the grip. It is a “hold-to-run"type. This too

stops rotation within few sec, after releasing th

lever. For the sake of safety, place it on a leve

plate or on hangerafter it completelystops.

3.2 Torque Adjuster

You can adjust the torque by rotating the knob

which indicated by 1 to 6. “1"indicates the

smallest torque output and “6"indicts the

largest torqueoutput.

3.3 Rotating Direction

One shall make sure the direction of rotation

before actuate this tool. The “F"indicts

foreword and the “R“indicts reverse. Forward

is defined as clockwise direction seen from the

operator`s position.

4. Maintenance

4-1 Lubrication

Before connecting the hose , apply 4 or 5 drops

of #10 spindle oil at the air inlet. Use of a thicker

oil can lead to reduced performance or

malfunction. If a thicker oil is used by accident,

wash it away immediately. Also, every 3 or 4

hours of operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location subject to

high humidity. If thetool is left as it is used , the

residual moisture inside the tool can cause rust.

Before storing and after operation, oil the tool at

the air inlet with spindle oil and run it for a short

time.

4-3 Disposal

If the tool is too seriously damaged to be used

anymore, drop it in a resource recycling can.

ever drop it into fire.

4-4 Ordering service Parts

For further operational and handling information

or for replacement of parts and components,

contact the sale agent from whom you purchased

the tool or the service division of our company.

*In ordering parts and components, give each

art number, name and quantity.

Warning

1. The power toll shall not be used in potentially

explosive atmospheres.

2. Disconnect the air hose before changing or

adjusting anyinserted tools.

3. Prevent long hair or loose clothing from

drawing in while operate this tool.

4. Keep your body in well balanced position and

always wear gloves to reduce the risk of crushing

caused bytorque between handle and workpiece.

5. Unexpected direction ofrotating could cause a

hazardous situation.

6. Slip/Trip/Fall is a major reason of serious

injury or death. Beware of excesshose left on the

walking or work surface.

7. Wearing eye/face protector could reduce the

danger to person from high speed splinters being

emitted fromthistool in thecase of inserted tool

failure or emitted from the workpiece.

8. Wearing mouth-muff couldavoid inhaling dust

or handling debris from work process that can be

harmful to your health.

9. Excessive high air pressure and too much free

rotation may speed the wear of this tool and

might cause danger situation.

ST-C544-I-1204B-YC