2-3 Air hose

Clean the hose with a blast of compressed air before connecting the hose to air tool. This will prevent

both moisture and dust within the hose from entering the tool and causing possible rust or malfunction.

To compensate for unusually long hose (over 25 ft), the line pressure should be increased accordingly.

2-4 Inserted tools

Use only the socket or adapter which are in good condition for use. The intended socket and adapter for

this air tool could are started as "Square Drive" on the specification list.

2-5 The approved eye protector, ear-muff, mouth-muffle, and gloves shall be worn when operate this

tool.

2-6 The working place shall be ventilative.

2-7 Release the on-off device in the case of energy supply failure.

3.Operation Method

3.1 On-off device

The on-off device is on the inner or outer contour of the grip. It is a "hold-to-run" type. This tool stops

rotation within few sec, after releasing the lever. For the sake of safety, place it on a level plate or on

hanger after it completely stops.

3.2 Torque Ad uster

You can ad ust the torque by rotating the knob which indicated by 1 to 6. "1" indicates the smallest

torque output and "6" indicts the largest torque output.

3.3 Rotating Direction

One shall make sure the direction of rotation before actuate this tool. The "F" indicts foreword and the "R"

indicts reverse. Forward is defined as clockwise direction seen from the operator's position.

4. Maintenance

4-1 Lubrication

Before connecting the hose, apply 4 or 5 drops of #60 spindle oil at the air inlet. Use of a thicker oil can

lead to reduced performance or malfunction. If a thicker oil is used by accident, wash it away

immediately. Also, every 3 or 4 hours of operation, oiling is necessary.

4-2 Storage

Avoid storing the tool in a location sub ect to high humidity. If the tool is left as it is used, the residual

moisture inside the tool can cause rust. Before storing and after operation, oil the tool at the air inlet with

spindle oil and run it for short time.

4-3 Disposal

If the tool is too seriously damaged to be used any more, drop it in a resource recycling can. Never drop

it into fire.

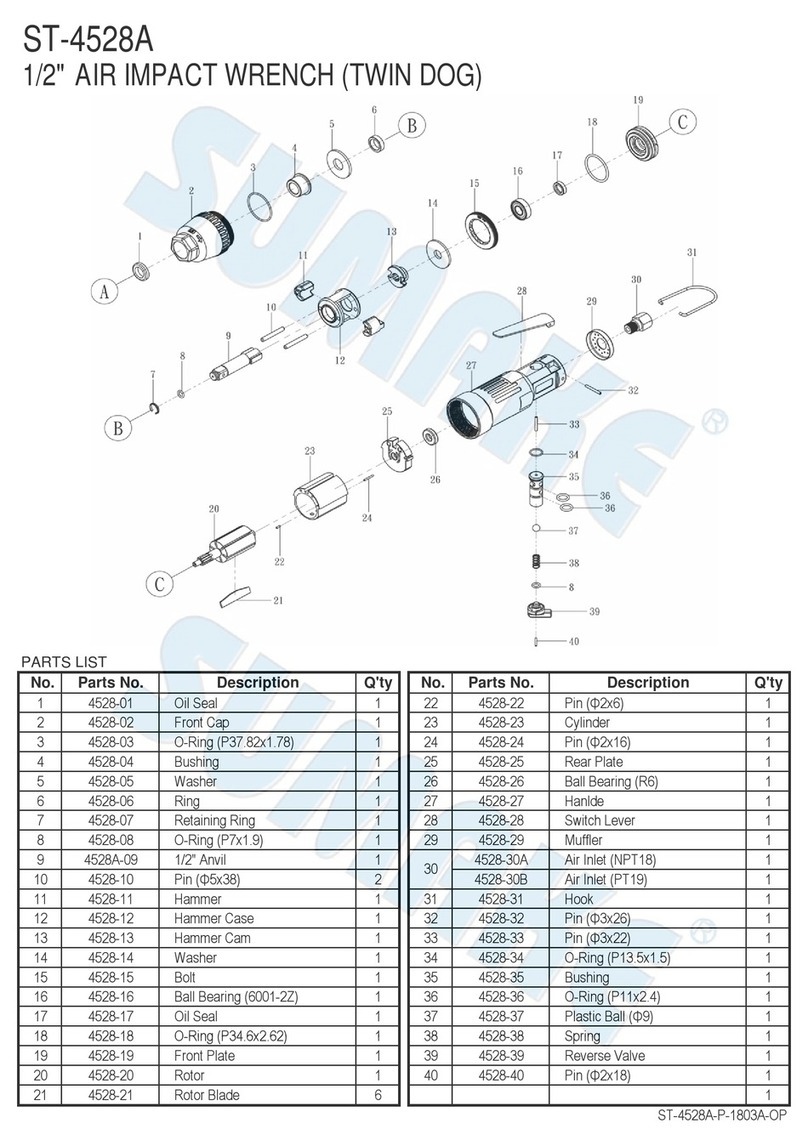

4-4 Ordering service Parts

For further operational and handling information or of replacement of parts and components, contact the

sale agent from whom you purchased the tool or the service division of our company.

* In ordering parts and components, give each part number, name and quantity.

4 / 6