3

Document Purpose

To instruct competent persons on how to safely install UniQ eHW Heat Batteries. Competent

persons are those suitably qualified to carry out plumbing and electrical work and have

successfully completed product training by Sunamp Ltd or an authorised training partner.

Contents

1Safety Instructions........................................................................................................4

1.1 Intended Use .........................................................................................................................4

1.2 Pre-installation Safety Advice..............................................................................................4

1.3 Mechanical Safety.................................................................................................................4

1.4 Electrical Safety.....................................................................................................................5

1.5 Water Safety ..........................................................................................................................5

1.6 User Competence, Qualification, and Approval ................................................................6

1.7 Compliance with Safety Laws and Regulations................................................................. 6

1.8 Post-Installation Safety .........................................................................................................7

1.9 Repair and Relocation .......................................................................................................... 7

2UniQ eHW Heat Battery Overview................................................................................8

2.1 Introduction............................................................................................................................ 8

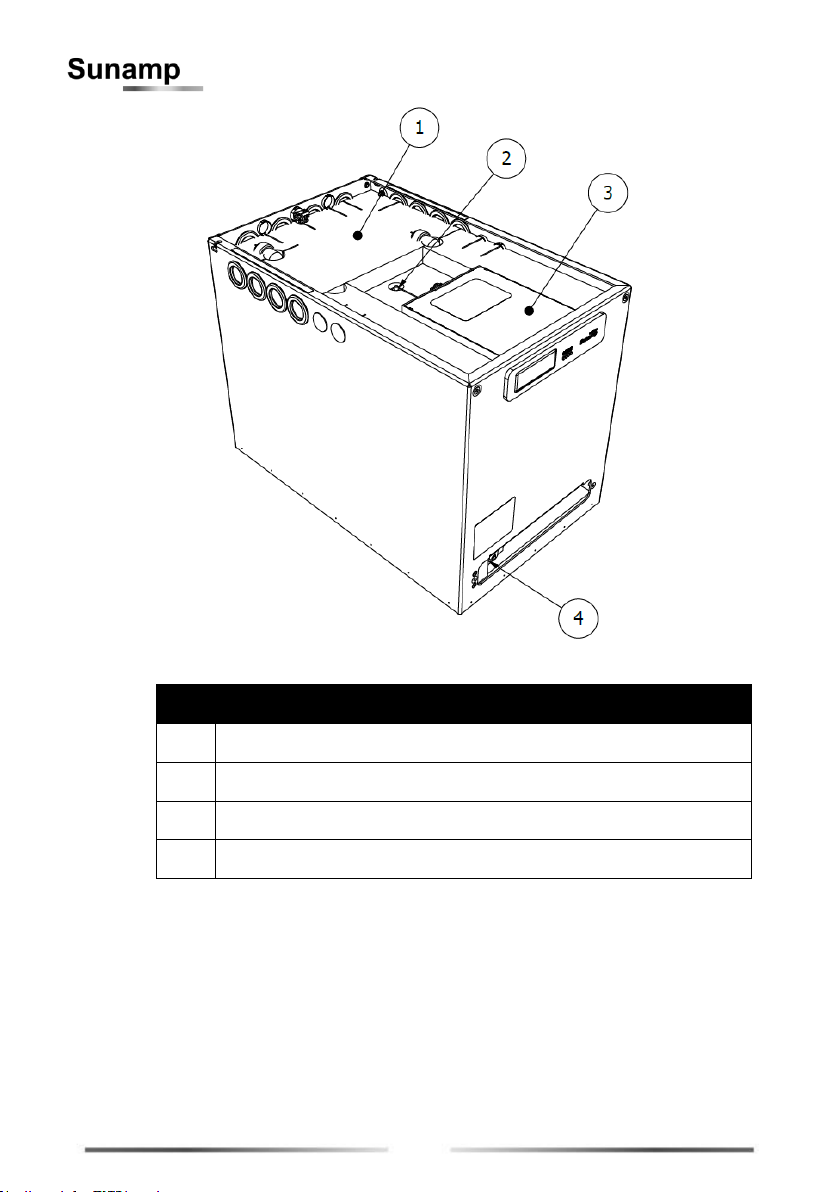

2.2 Product Overview .................................................................................................................9

2.3 Product Identification..........................................................................................................11

2.4 Accessories and Parts........................................................................................................12

2.5 Technical Specifications ....................................................................................................13

2.6 Pressure Loss Characteristics...........................................................................................16

3Installation...................................................................................................................17

3.1 Installation Process.............................................................................................................17

3.2 Water Supply Requirements..............................................................................................20

3.3 Location and Space Requirements...................................................................................21

3.4 Hydraulic Requirements.....................................................................................................23

3.5 Temperature and Insulation Requirements......................................................................23

3.6 Electrical and Wiring Requirements..................................................................................24

3.7 Wiring Option 1 –24h Grid Supply Without Time-Switch..............................................27

3.8 Wiring Option 2 –On-/Off-Peak Tariff with External Time-Switch.................................30

4Commissioning ...........................................................................................................33

4.1 Preparation ..........................................................................................................................33

4.2 Process.................................................................................................................................33

5Operation ....................................................................................................................35

5.1 Switch On/Off ......................................................................................................................35

5.2 LED Indicators and Status..................................................................................................35

5.3 Troubleshooting ..................................................................................................................36

6Maintenance................................................................................................................38

6.1 Removal of Lids...................................................................................................................38

6.2 Cleaning ...............................................................................................................................38

6.3 Warranty...............................................................................................................................39

7Recycling and Disposal ..............................................................................................39