Keystone Garage

Assembly Manual

© Suncast Corporation

revised 10/25/06

Please read through the entire manual before starting!

Note: It is very important that you have a solid, level site for the garden building. If the structure

is being used as a garage for automobiles or other heavy items, the unit must be assembled on

a concrete pad.

When using tools and ladders always follow manufacturer’s recommended safety guidelines!

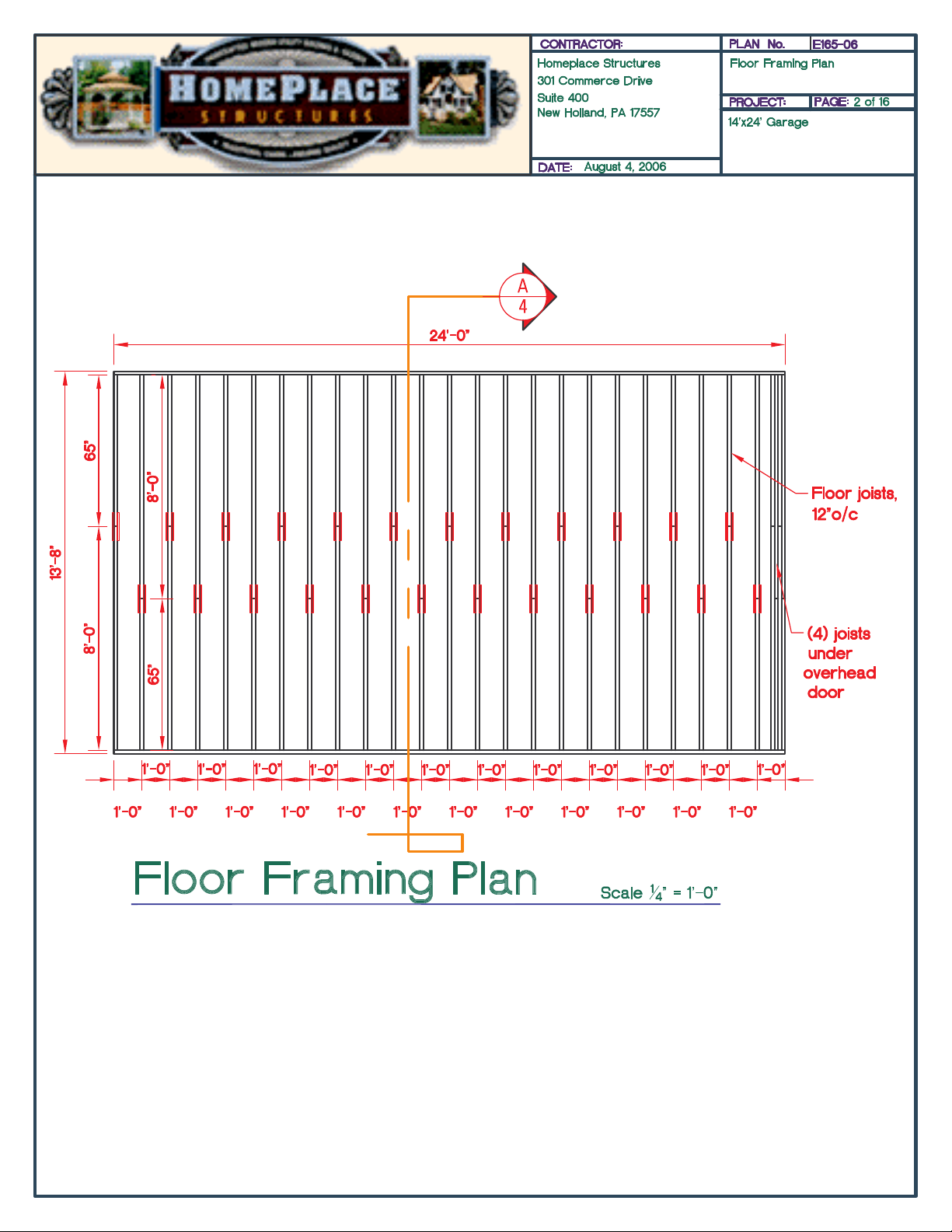

For proper layout for floor, walls, and roof, please refer to the drawings included throughout

this manual and the set of engineered drawings included at end of manual. The pictures shown

in this manual may depict a different layout, if discrepancies occur always refer to drawings.

Tools Needed:

Level

Screw Gun

Hammer

Tape Measure

Skill Saw

Square

Chalk Line

Pencil

5/16” Drill Bit

Tin Snips

Caulking Gun

Other Items Needed:

Approximately 8 gallons of paint

Approximately 20 Bundles of shingles

Heavy duty Silicone Caulk/Sealer

When your kit arrives, it should look like this.

Inspect the package for any damage that

may have occurred during shipping - dented

corners, punctured plastic, etc. If the pack-

age is damaged, alert HomePlace Structures

immediately - 717.354.2333

14x24 Garage