Product Section View

Information:

Below the page, you can check the A-A cross-section

of the SKYCLOUD system and below that B-B cross-section.

This section view includes every detail of the connection

of the parts. You can check every supporting

part against impact and leak (like water or air)

A-A

B-B

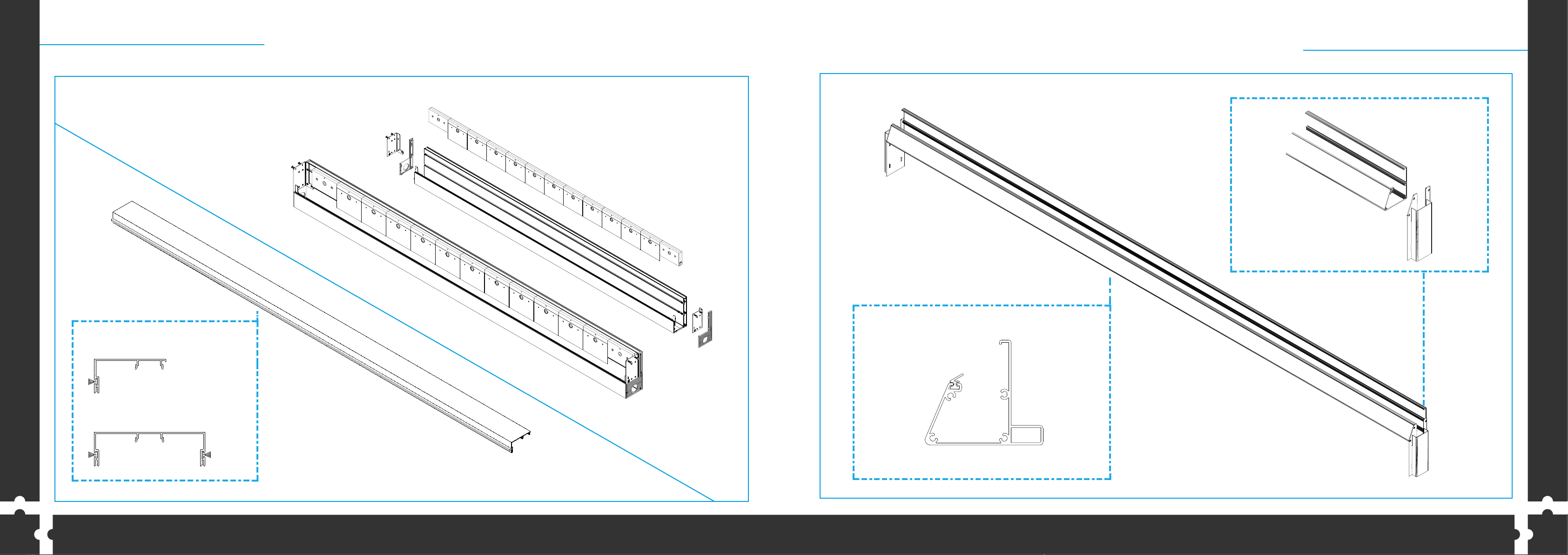

FRONT GUTTER

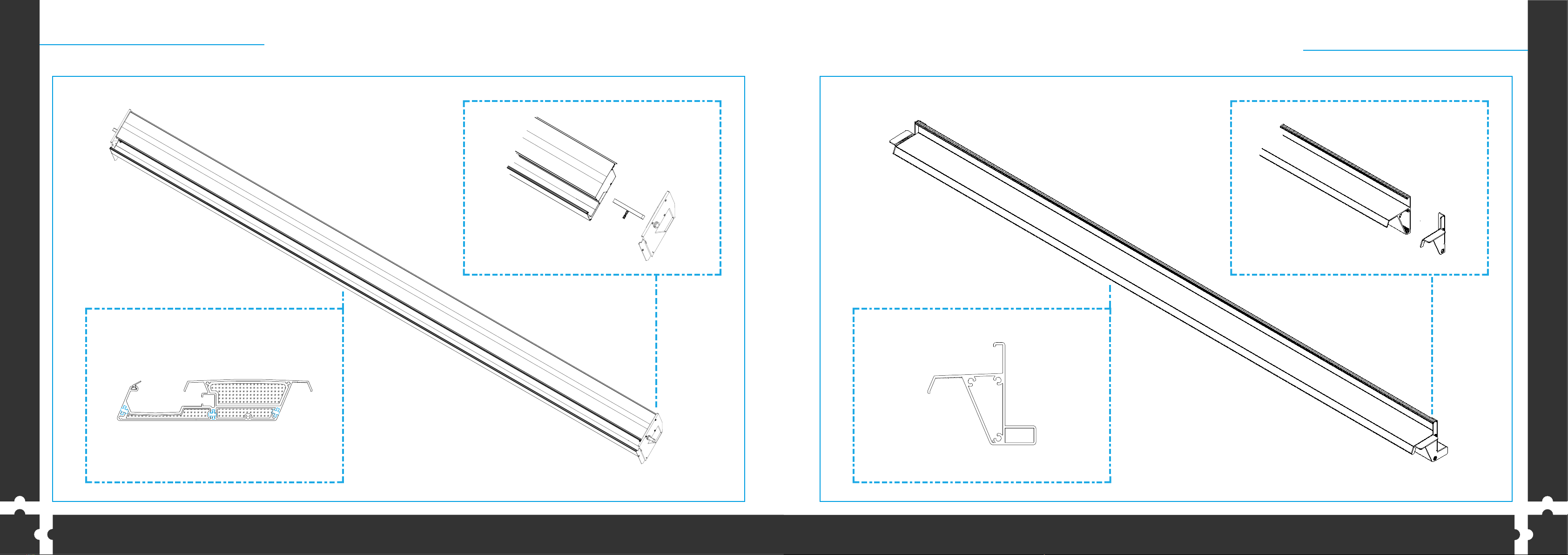

PANEL

BACK GUTTER PILLAR

RAIL PROFILES

PANEL

267

267

133 133

162 162

267

267

133 133

162 162

240

222

Eco Cloud

Active Cloud

165165

267

267

133

133

7070 Project-dependent

FRONT GUTTER

PANEL

BACK GUTTER

FRONT GUTTER

PANEL

BACK GUTTER

2

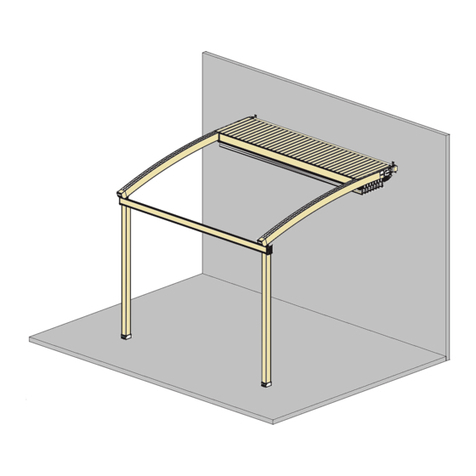

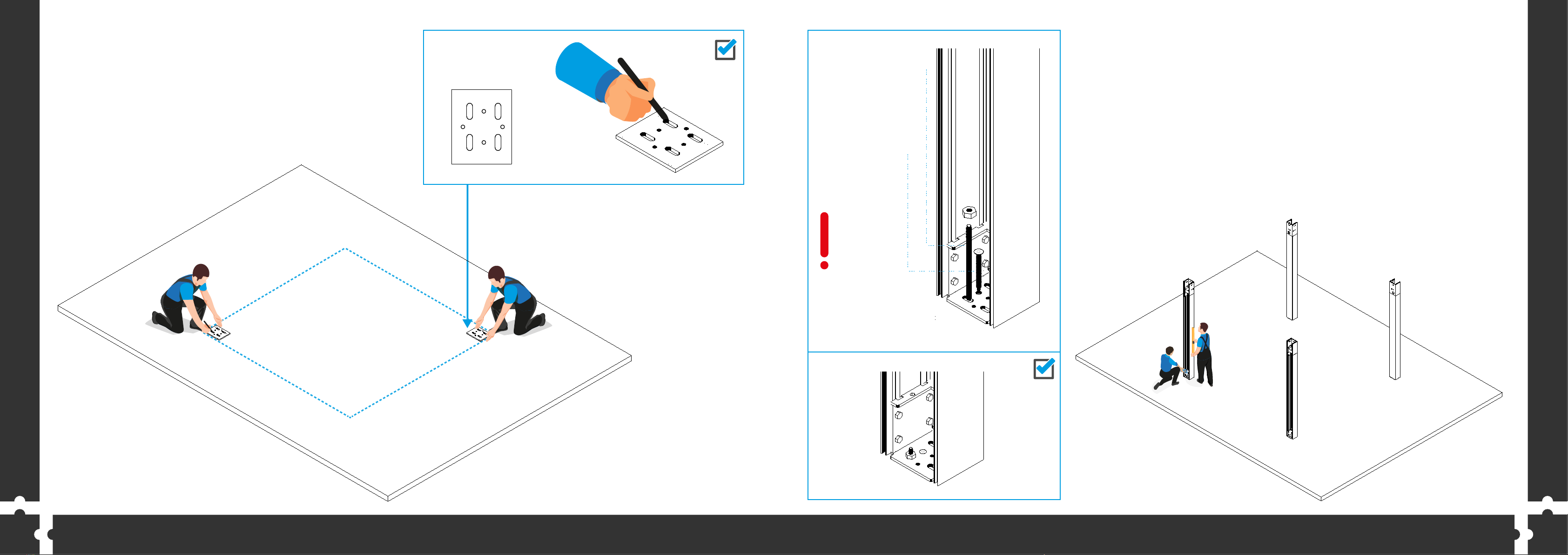

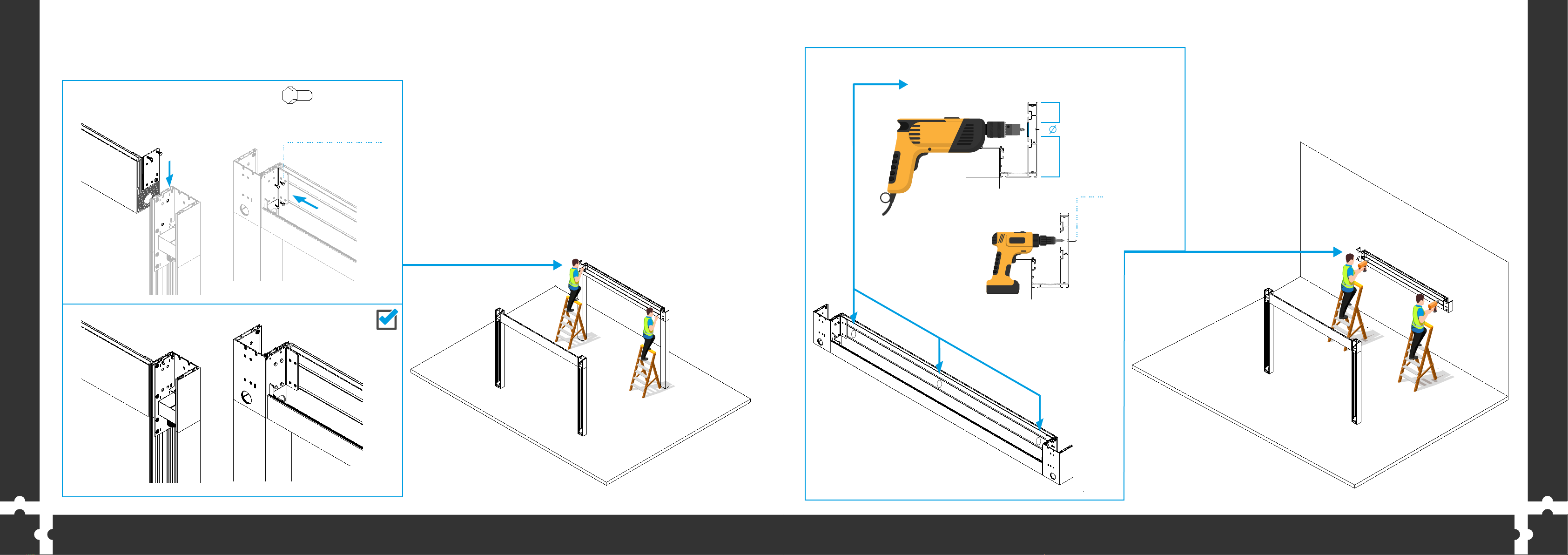

Thank you for purchasing Sunset Pergola Product.

These instructions include helpful hints and important information needed to safely assemble and properly

main- tain the Product. Please read these instructions completely before you begin and follow the steps

in the order they are presented.

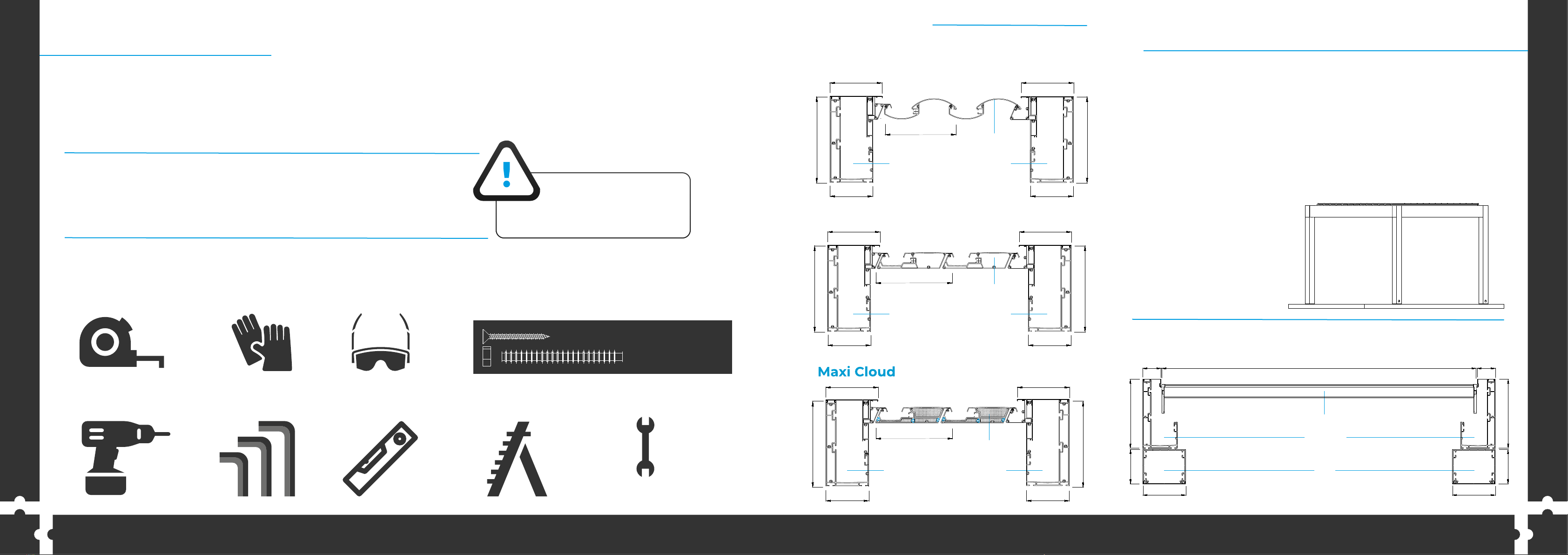

1. Make sure you have all the necessary parts.

2. Lay the parts out in separate staging areas.

3. Select a Location.

4. Prepare a Foundation. (if necessary)

5. Make sure you have the proper tools:

•Tape Measure •Work Gloves •Safety goggles

•Drill •Hex Key •Spirit Level •2 Small Step Ladders •Wrench

•Concrete Screw - Buldex

Threaded Rod & Somun

7.5 x 120 / 7.5 x 150 / 7.5 x 180

10 x 90 ( for soft grounds )

ATTENTION:

DO NOT ATTEMPT

TO ASSEMBLE ALONE!

Introduction

1

267

267

133 133

162 162

240

13 mm

3 mm

4 mm

5 mm