Rutland 914i Windcharger Installation & Operation

Doc No:SM-137 Iss. E 11.03.19 8 Marlec Eng Co Ltd

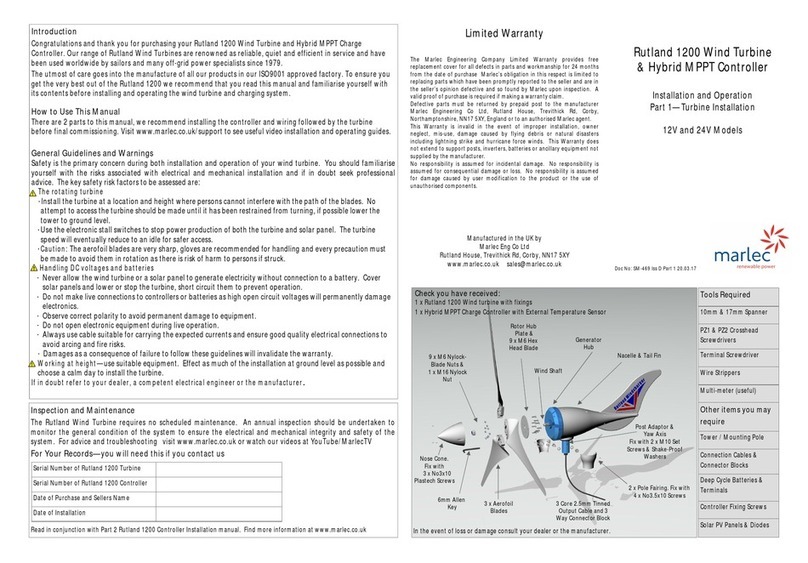

Assembly and Installation

Twelve Step Quick Start Guide

1. Choose an open site to expose the Windcharger to a clear flow of wind and avoiding

obstructions. On board mount the Windcharger at least 2.4 metres above the deck and on

land at least 4-6m high. Read the full section on Siting.

2. Choose a mounting pole with an internal diameter of 41.0mm and external diameter of

no greater than 48.5 mm for the top 0.6m minimum to (i) prevent accidental damage and

(ii) meet warranty conditions.

3. Mount a charge regulator, from the Marlec range, to a suitable vertical surface and close

to the battery. Follow instructions supplied with the charge regulator.

4. Drill the mounting pole, if required, in preparation to accept and secure the

Windcharger. See Assembly and Installation section.

5. Choose suitable two core cable to connect from the Windcharger to the regulator. Up to

20m this should be of at least 2.5mm² cross sectional area. A short section of 4mm² cross

sectional area is required to link the regulator to the battery. For other distances see the

table in Cable Specifications.

6. Position the mounting pole ( this may be done on the ground before raising the pole ) so

that the selected cable can be threaded along it.

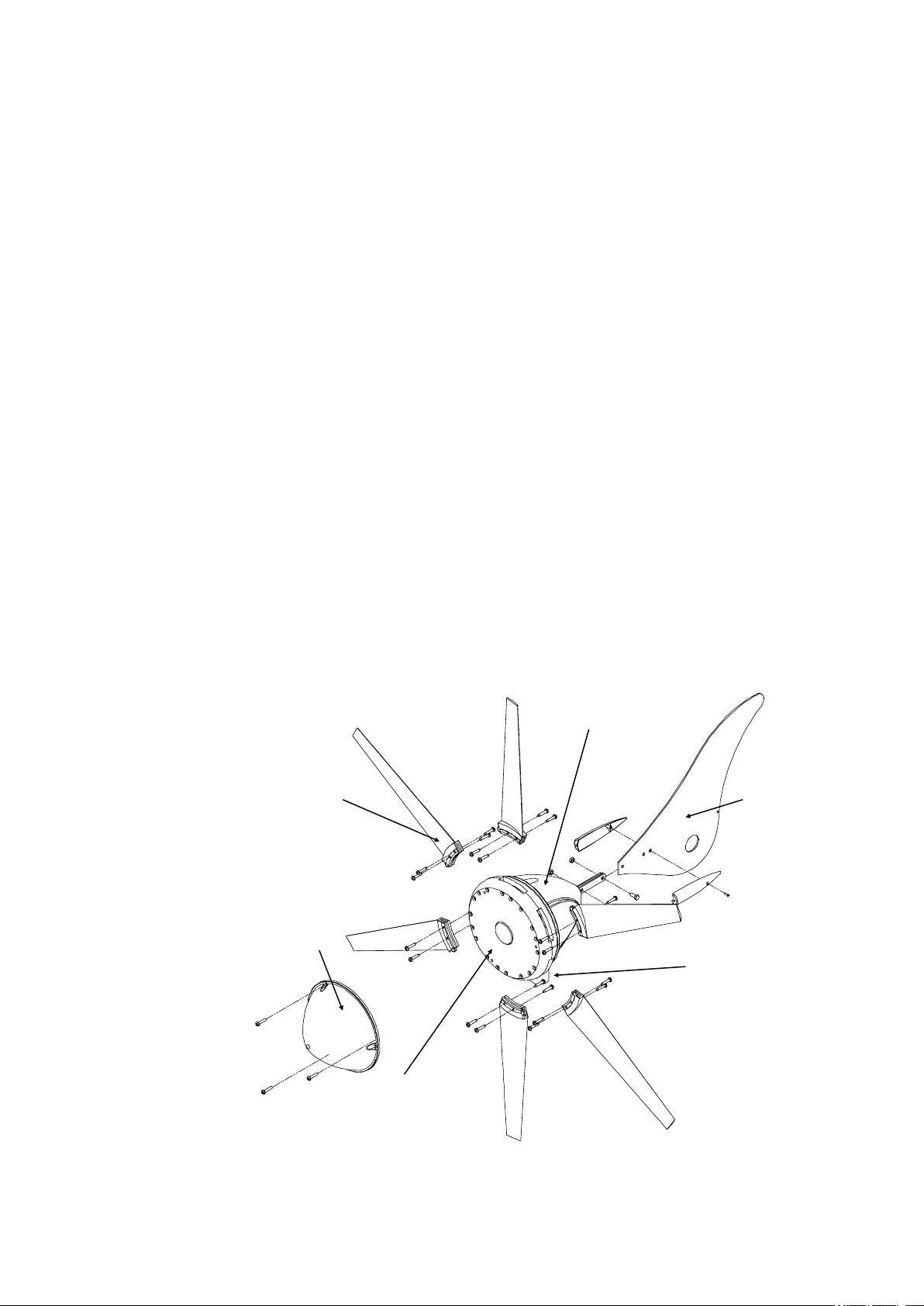

7. Fit the blades, tail and nose to the Windcharger using fasteners provided. It is

essential that 4 screws are fitted per blade.

8. Join the cable threaded through the pole to the Windcharger output cable using the

connector block provided. Wrap with insulating tape. Alternatively use a latching plug and

socket. We recommend looping back the cable and securing with a cable tie to provide

strain relief to the joint.

9. Carefully push the cables down the pole whilst sliding the post adaptor down the pole.

Line up the holes and secure in place with the hex head screws and tab washers

provided. The tab washer long part should be shaped to curve around the pole and the

short tab wrapped flat onto one hex head flat to prevent the hex head from loosening in

service. Do not allow the turbine to spin freely.

10.Locate the charge regulator close to the batteryand carefully follow ALL the regulator

guidelines and installation sequences for connecting the Windcharger through to the

battery.

11.Ensure that the battery connections are permanent as the Windcharger should NEVER

be operated without a connection to the battery.

12.Raise and secure the Windcharger. It can now be allowed to rotate. Follow the

“ Up and Running- Four Points Final Checklist” featured later. Also the

“ General Guidelines and Warnings” section expands on the above points.