Tel: +44 (0)845 652 0396 Skyrrid Farm, Pontrilas, Hereford. HR2 0BW. UK www.leturbines.com

Page 5 of 47

Safety Precautions

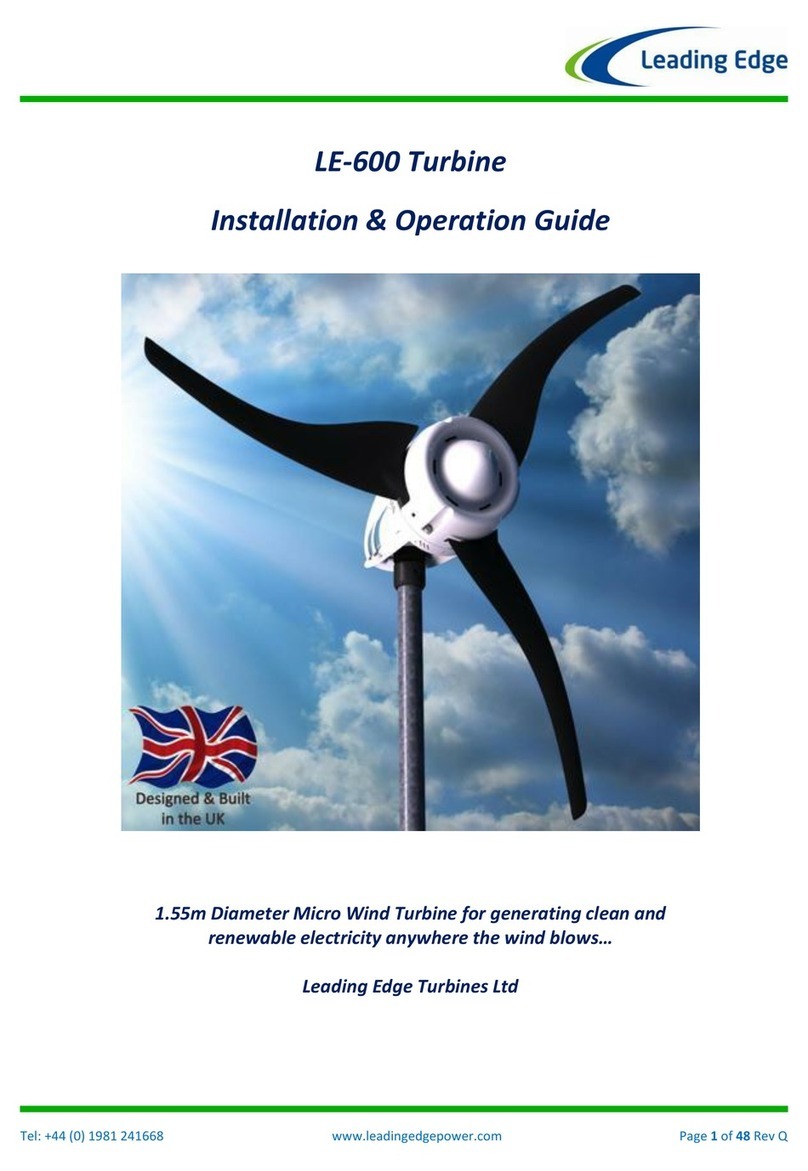

Safety must always be your primary concern during the assembly, installation and operation of your

LE-450turbine. Always be aware of the risks involved with mechanical and electrical installation

work. If in doubt about any issue regarding your turbine, please seek further assistance before

proceeding. Installation of the LE-450turbine should only be undertaken by suitably competent and

qualified personnel.

Mechanical Safety Hazards

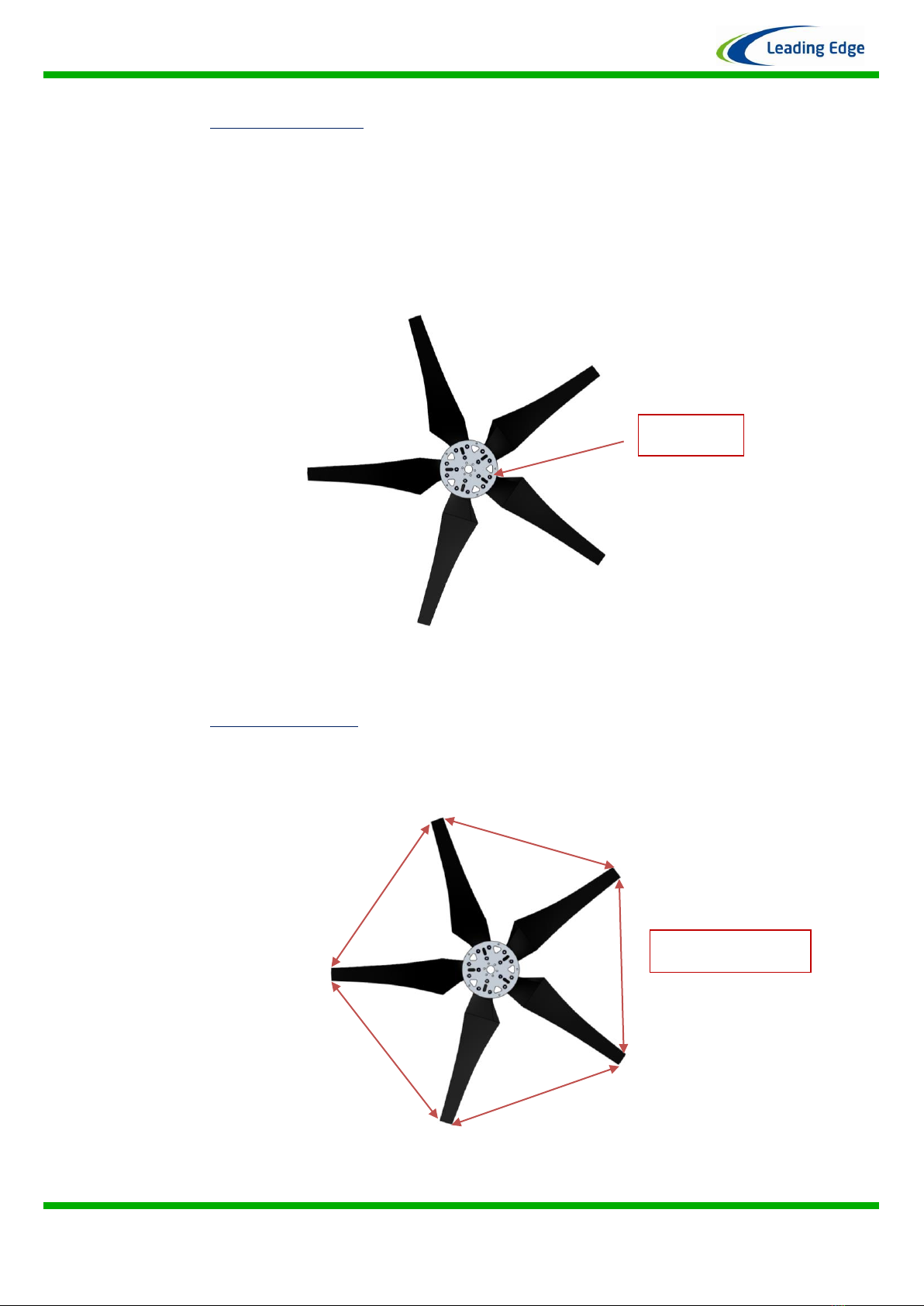

The main rotor is the most obvious and serious mechanical safety risk. When the turbine is

operating at its rated performance, the blades will be very difficult to see, due to the

speed of rotation. Never approach the turbine whilst it is operating. Always shut down the

turbine by activating the stop switch. Ensure that the turbine is installed in a suitable

position where nobody can approach or interfere with the path of the rotor blades.

Working with tools of any kind can be dangerous. Your LE-450turbine requires some basic

mechanical assembly with rudimentary hand tools. If you are in any doubt about how to

use these tools correctly, please seek advice from a suitably experienced person.

Your LE-450turbine will inevitably be installed upon a tower or other support mount. This

may mean working at height. Always ensure that all personnel in the immediate vicinity

are aware of any lifting / hoisting operations that will be occurring. Check there are no

loose components or tools likely to fall and cause injury during the lifting operation. Where

possible, all assembly work should be completed at ground level. In the case of roof mount

brackets, a suitable fitter should carry out the installation with the appropriate equipment

for working at height.

Ensure that the batteries are disconnected during the installation procedure.

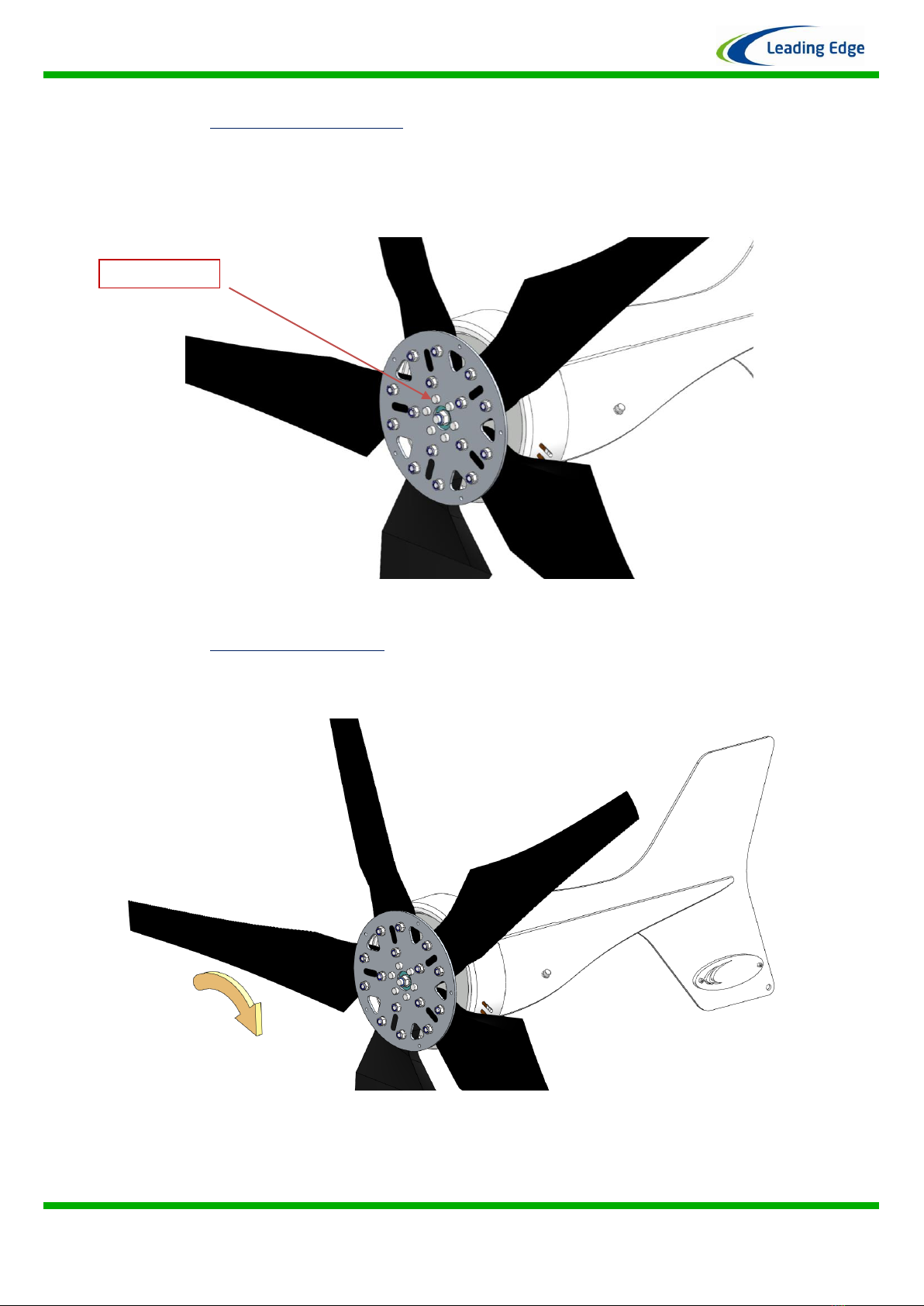

Twist the turbine output cables together (to create a short circuit) during the mechanical

installation process. This will prevent the turbine from ‘spinning up’ during the installation.

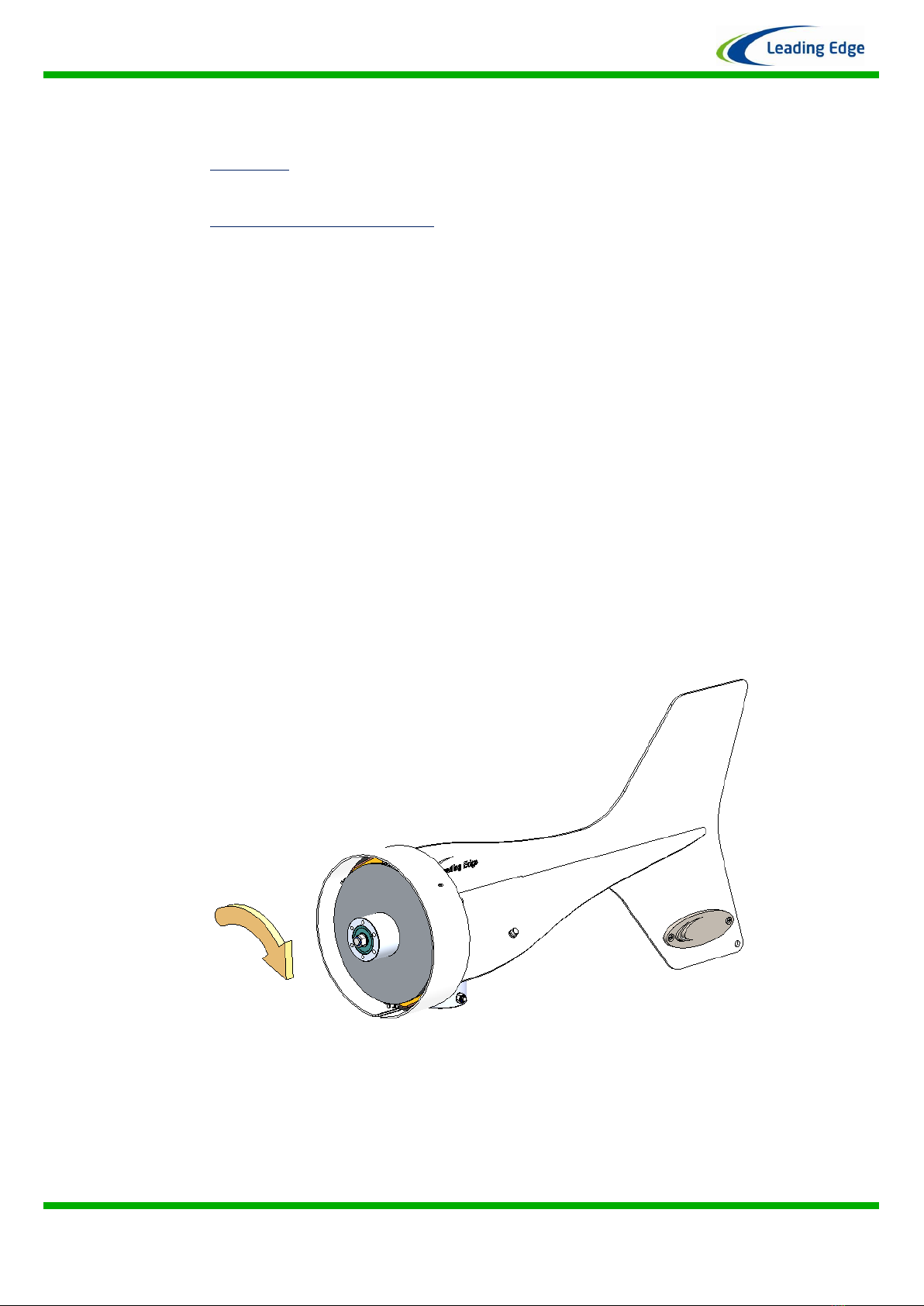

Never install the turbine upside down or in any orientation other than that depicted on the

installation instructions.

Install your turbine during a calm day.

When performing routine inspection or maintenance, always stop the turbine by activating

the stop switch.

Electrical Safety Hazards

The LE-450generates rectified DC voltage. Even at these low voltages there are inherent

risks. Caution should always be used when connecting the LE-450to the electrical system.

Be sure that you have followed the cable-sizing chart to ensure that the correct size of

transmission cable has been selected. If a cable of insufficient cross-sectional area is used,

heat may build up in the cables causing a potential fire hazard. A properly sized fuse or

circuit breaker should be used in the cables connected to the battery. This will stop the risk

of short circuit currents. Using cables of insufficient cross-sectional area may also reduce

the power transmission efficiency of the turbine.

Battery systems can deliver a serious amount of current. A short circuit in the battery

circuit can lead to hundreds of amps flowing through the battery cables. This will cause a

heat build-up and ultimately an electrical fire. Batteries can explode when shorted. Always

use insulated electrical tools when working on the battery’s electrical connections.

Batteries are very heavy. Do not attempt to move batteries by yourself. Always use manual

handling tools and an assistant.

Always keep lead-acid batteries the correct way up. Do not allow the acidic electrolyte to

spill or come into contact with your skin or face. Always follow the manufacturer’s safety

instructions when handling lead-acid batteries.

Never run the LE-450 'off-load' with the output cables not connected to anything.

Please use common sense when installing and operating your turbine!