Document No SM-412 Issue B 12.02.03 9

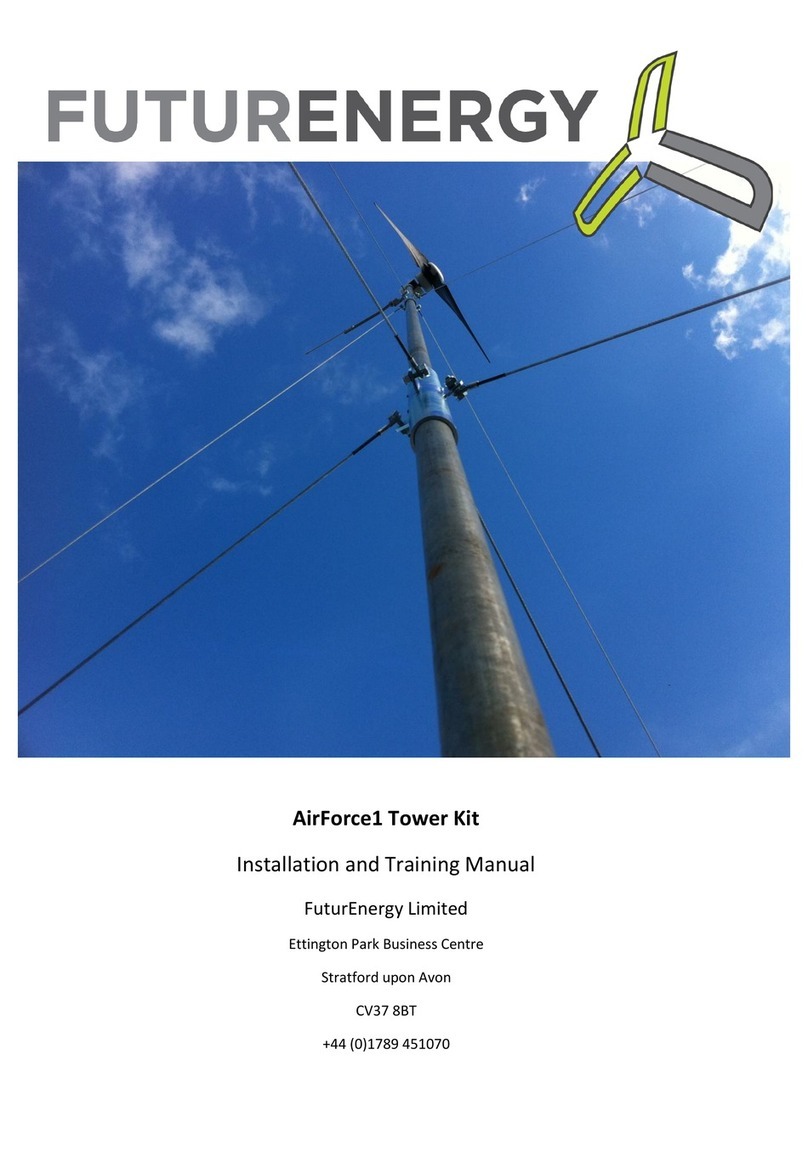

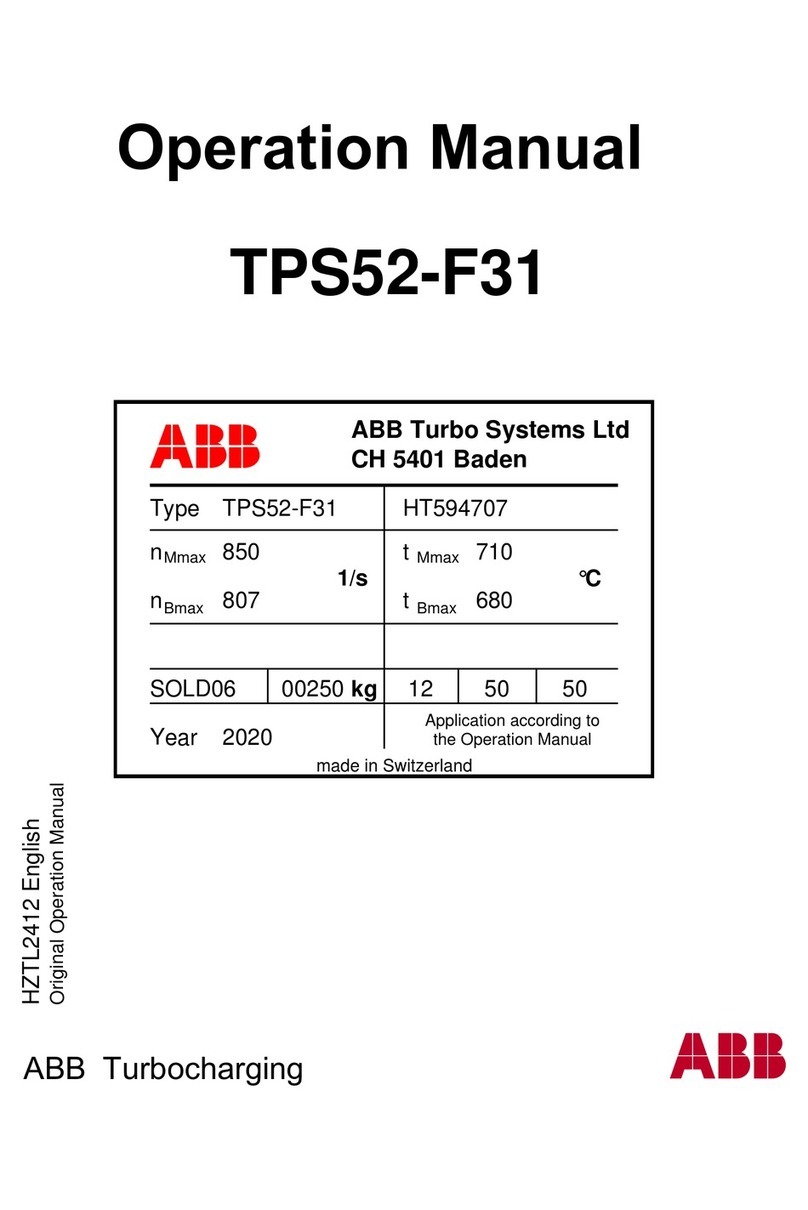

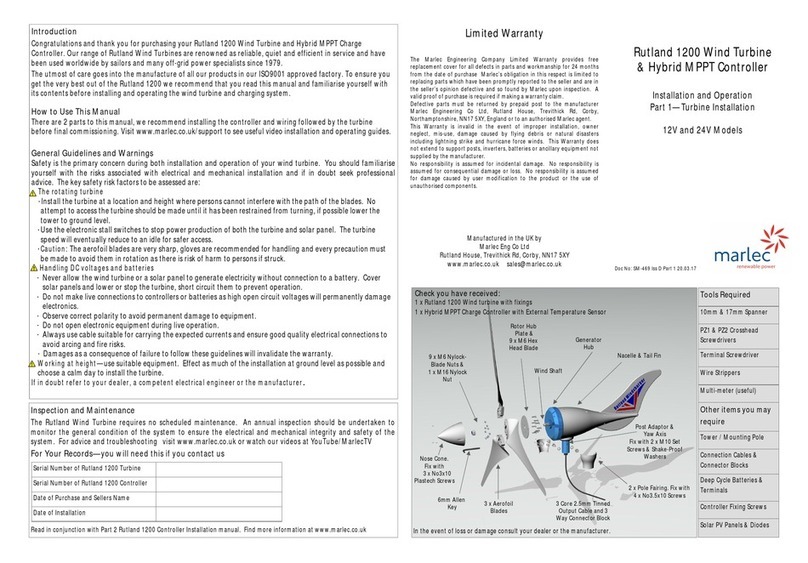

ASSEMBLY

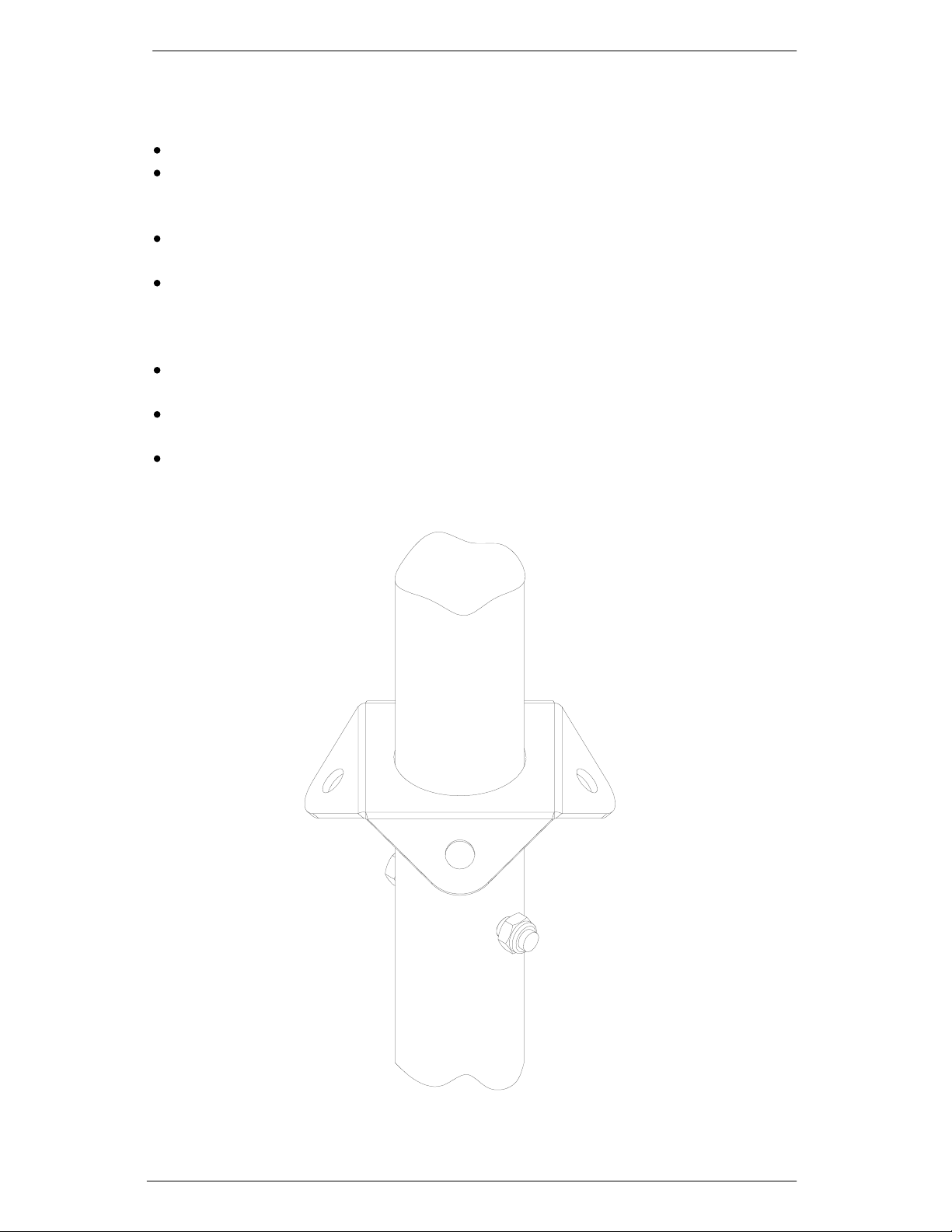

Place the Tower Base over the four threads protruding from the concrete foundation,

ensuring the pivot is orientated correctly. Fit the Nuts & washers & securely tighten.

Lay the tower tube in position on the ground with it’s bottom end in the tower base &

insert the M10 x 70 bolt, secure with the washer & nut ensuring the tube is free to

pivot.

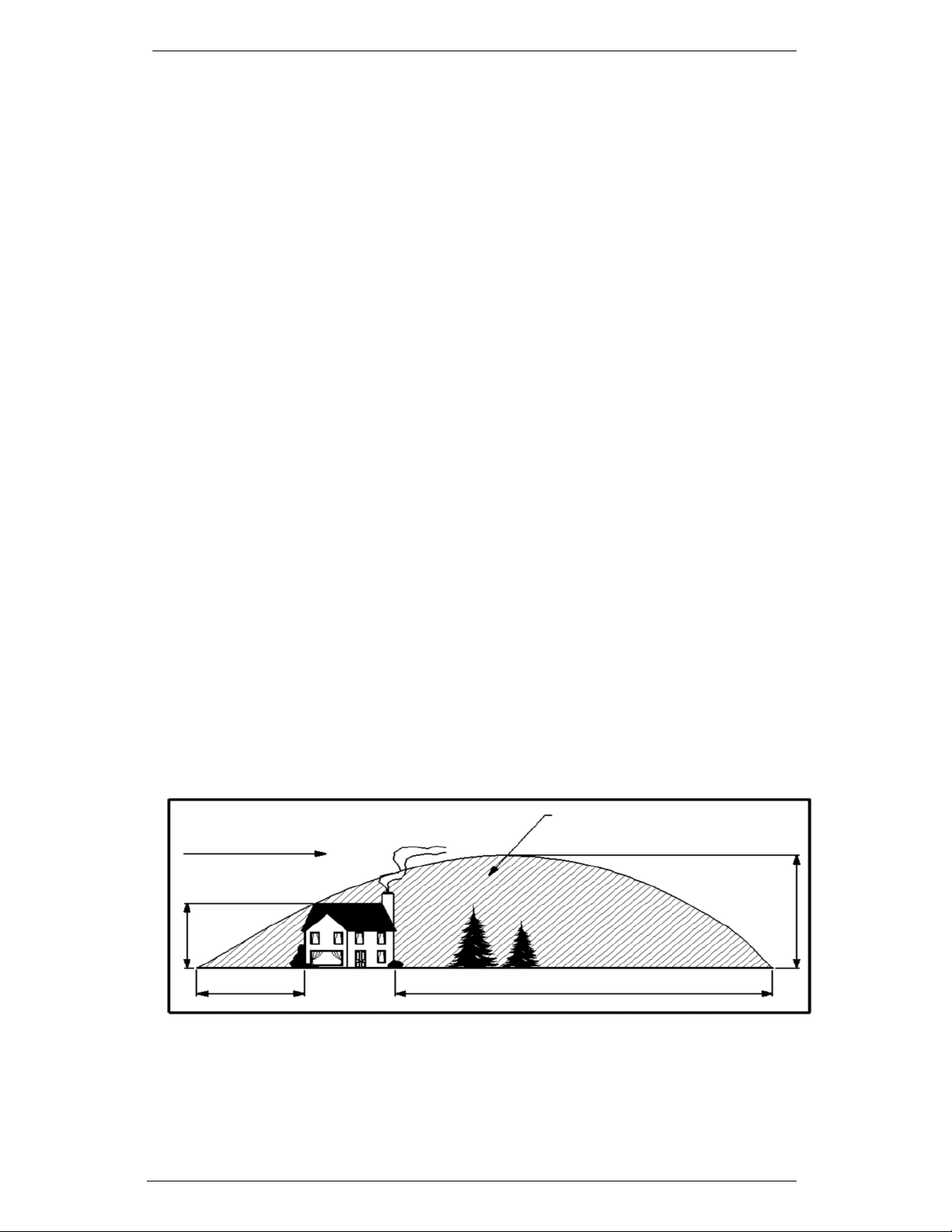

Attach the guys to the guy plates with the shackles through the looped ends of the

guys, the 6.5m guys are fitted towards the top of the tube, the 4.5m guys towards the

bottom.

Fit the remaining 4 shackles to the guy ground anchors. Place the hooked ends of 2 of

the rigging screws through the shackles on the side anchor points. Open the rigging

screws to approx ¾ their maximum length.

Take the 2 upper side guys & pass the free ends through the looped ends of the

rigging screws & around the thimbles pulling the cables to remove the slack, secure in

position using 3 rope grips on each guy. Repeat the procedure with the fore & aft guys

by laying them alongside the side guys to achieve the same length.

Note: If the ground is uneven or not level, the guy lengths may differ.

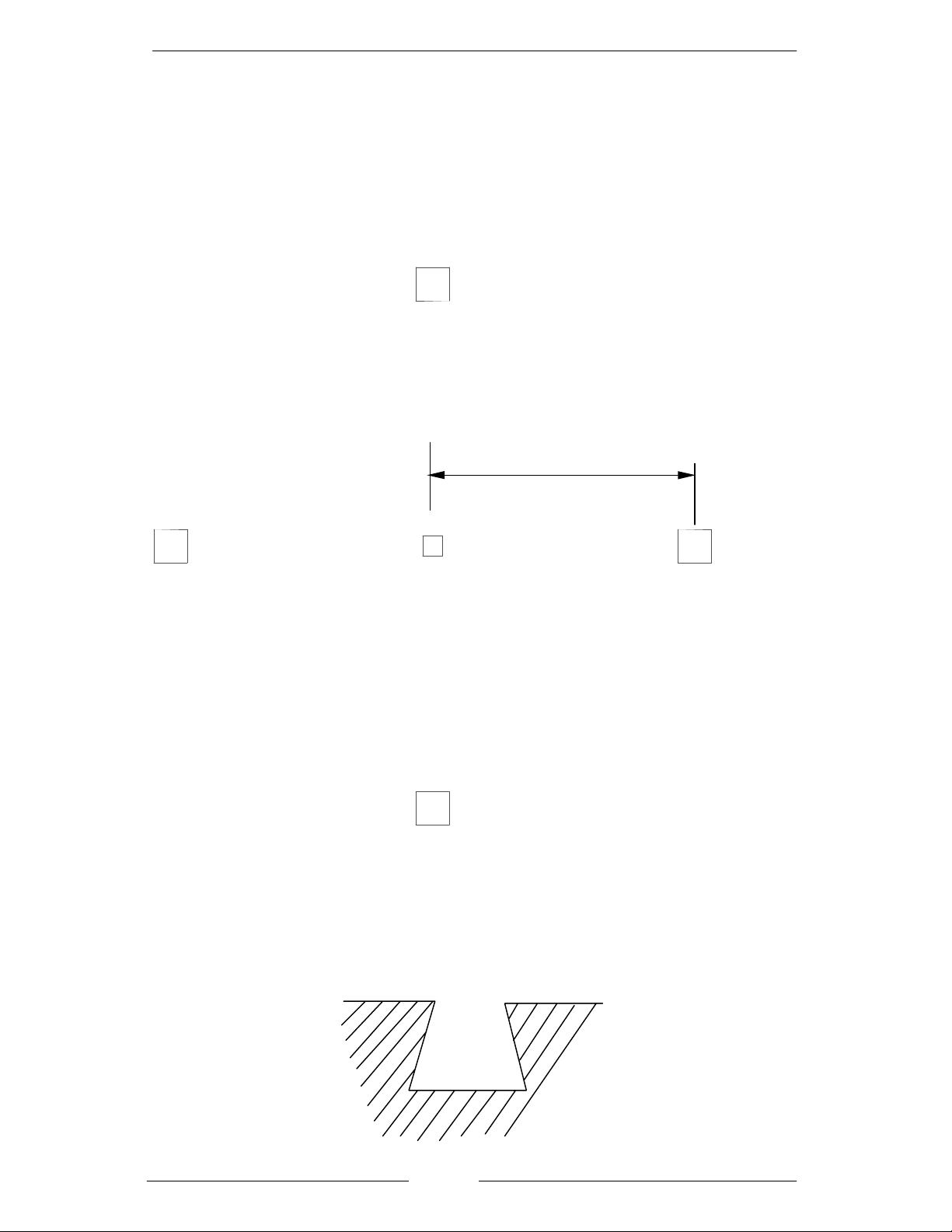

The first rope grip must be placed immediately against the thimble. The grips must be

placed so that they are separated by a minimum distance of 30mm. The ‘U’ bolt must

always be placed on the tail end of the rope ie non load bearing end.

Hook the rigging screw into the shackle on the anchor point for the rear guy, ie the

anchor point covered by the tower.

Fig 7