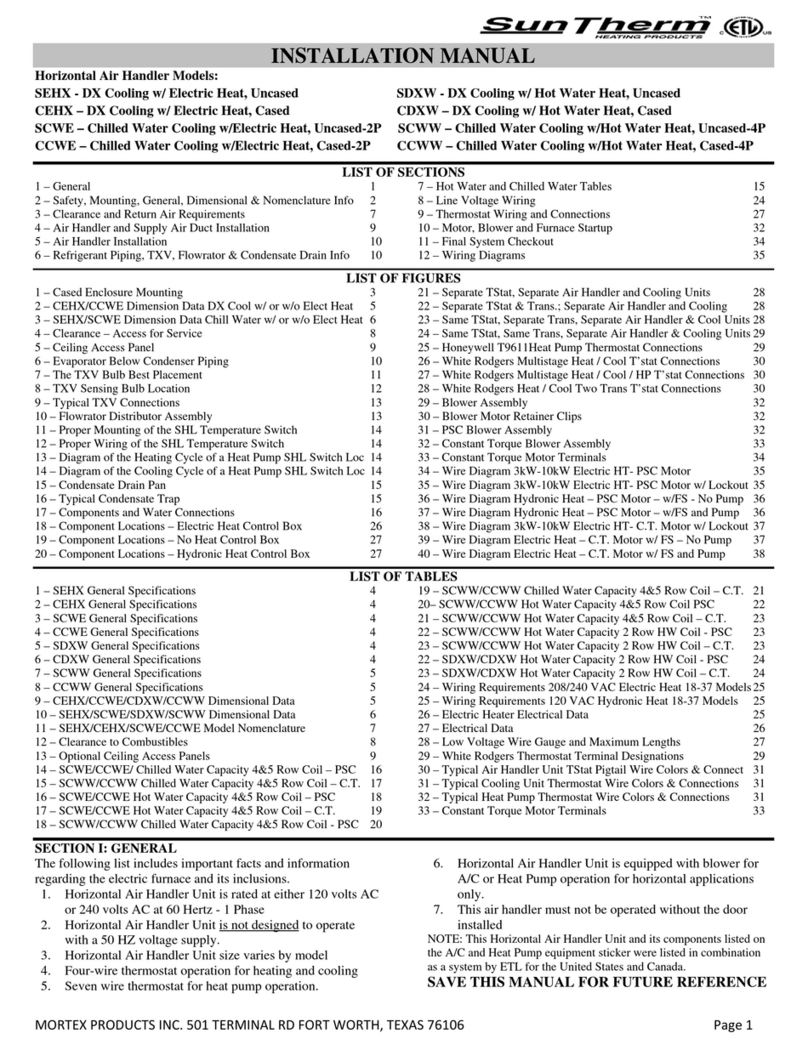

MORTEXPRODUCTSINCFORTWORTH,TX76106Page10

10. Check the blower wheel for dust and debris. Use the

brush and the vacuum cleaner to remove any dust or

debris from the wheel. Be careful not the move or

accidentally remove the blower wheel balance weight

located on the wheel blade. If it is moved or removed it

will cause the blower wheel to vibrate. If the wheel is

vibrating, you must replace it.

11. Check the blower motor for dust and debris. Be sure to

clean the openings on the motor housing as these

openings are used to cool the motor. If the dust, dirt or

debris has not been removed from these openings it will

cause the motor to run hotter than normal and will shorten

the life of the motor.

12. Check and clean with the brush and vacuum cleaner any

dust in the supply and return ducts as far as you can reach.

If these ducts look like they have an excessive amount of

dust, dirt or debris you should recommend to the home

owner or user to call a professional to properly clean the

duct system.

13. Check and clean any dust, dirt, or debris from all of the

controls and all of the surfaces in the control box. If dust

or dirt is left on the components they will operate at a

much hotter temperature causing premature component

failure.

14. Reinstall the blower assembly and secure the assembly to

the casing by using the screws that was removed in step 5.

15. Reinstall the lower access door on the front of the

evaporator coil compartment.

16. Reinstall the upper access door on the air handler.

17. Follow the instructions exactly as shown in Startup and

Shutdown Section in this manual to properly startup this

appliance.

SECTION III: AIR HANDLER CONTROLS

Electric Heat Models

This section discusses the air handler controls and how they

operate. Refer to Figure 9 for component locations.

1. The Limit Controls – Each electric heater element has a

limit control directly in front of it to sense overheating of

the element and open if the temperature gets above the set

point of the limit control.

2. The Heater Relays – The electric heater relays simply

turn the heater elements on and off. The relays are

controlled by the thermostat. On a call for heat 24 VAC is

sent to the relay(s) 24 VAC coil energizing the relay.

When the call for heat has been satisfied the 24 VAC is

removed from the relays 24 VAC coil de-energizing the

relay(s).

3. Cooling Time Delay Relay (TDR) – The cooling

sequencer relay is used only on models with a PSC motor.

When the thermostat calls for cooling or the fan switch on

the thermostat is moved from the “AUTO” to the “ON”

position, 24 VAC is placed on the “G” terminal from the

thermostat to the 24 VAC coil on the sequencer relay. The

relay controls the blower on time delay and is not

adjustable. The sequencer setting is approximately 30 - 45

seconds on and 1 – 20 off.

4. Circuit breakers – The circuit breakers are designed as

over-current protection for the air handler internal

electrical components. Field wiring must be protected by

field supplied circuit breakers or fuses sized to protect the

wire connected to the air handler circuit breakers.

5. Transformer – The transformer is used to step down

voltage from 240 VAC to 24 VAC. The transformer

provides the required 24 VAC for the system control

circuit.

6. Blower Motor Isolation Relay - This relay is used to

load the TDR when using a PSC or X-13 motor or for

isolation between the high and low speeds of a motor. The

wiring has been designed so that the normally closed

contacts are used for heating and the normally open

contacts are used for cooling. The relay coil is energized

after the thermostat has a call from the “G” terminal

starting the time delay cycle on the sequencer relay. Once

the time delay relay has reached the delay setting the relay

contacts close energizing the isolation relay coil. The

normally closed contacts on the isolation relay open and

the normally open contacts close, energizing the motor on

the selected cooling speed.

ECM Motor Isolation Relay - This relay is not used on the

ECM motor which has programmable heating and cooling

blower time delays along with climate profile time delays. See

climate profile section for more information.

Hydronic Heat Models

This section discusses the air handler controls and how they

operate. Refer to Figure 10 for component locations.

1. Transformer – The transformer is used to step down

voltage from 240 VAC to 24 VAC. The transformer

provides the required 24 VAC for the system control

circuit.

2. Pump Relay – This relay is not used on all hydronic

models. This relay is a single pole single throw relay that

energizes the water pump on a call for heat. The 24 VAC

coil is connected to the thermostat “W” terminal. The coil

is energized on a call for heat closing the normally open

terminals sending 120 VAC thru the relay contacts to the

water pump motor. Once the call for heat has been

satisfied, the 24 VAC is removed from the thermostat

“W” terminal de-energizing the relay coil and opening the

contacts to the water pump motor.

3. PSC Blower Motor Isolation Relay - This relay is a

single pole double throw relay. Is required for isolation

between the high and low speeds of a motor. The wiring

has been designed so that the normally closed contacts are

used for heating and the normally open contacts are used

for cooling. The relay coil is energized after the

thermostat has a call from the “G” terminal. The normally

closed contacts on the isolation relay open and the

normally open contacts close, energizing the motor on the

selected cooling speed.

4. ECM Motor Isolation Relay - This relay is not used on

the ECM motor has programmable heating and cooling

blower time delays along with climate profile time delays.

See climate profile section for more information.

SECTION IV: SEQUENCE OF OPERATION

Continuous Blower – Electric Heat Models

The thermostat has a manual fan switch that can be moved to

the “On” position or it can be programmed for continuous fan