664Y4500 • D

ENFRRU PL DE IT ES NL

INtroDuCtIoN

DESCRIPTION OF THE TECHNICAL

SPECIFICATIONS

The is a hot water generator linked to a condensing boiler

meeting the requirements of “” standards in force in Belgium. The

boiler is certified in compliance with “” standards as a room sealed

appliance: , but it can also be

connected as an open appliance in category B23 or as an appliance operating

at positive pressure from the category.

The boiler is enclosed in a steel casing, which has been degreased,

had a phosphate treatment process and then stove enameled at 220 °C.

The inside of this casing is lined with a layer of thermal and acoustic insulation,

which minimizes losses.

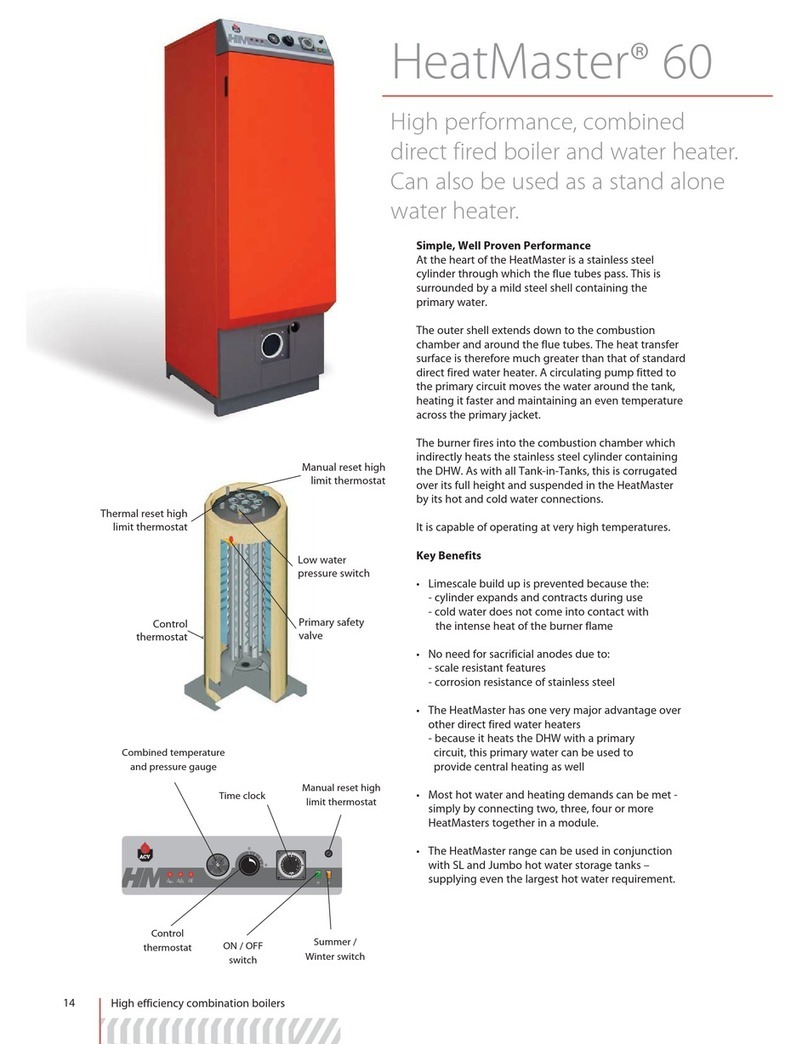

The core of the features a new stainless steel heat exchanger

which is a result of exhaustive research and intensive laboratory tests.

This reflects almost 90 years of experience in the use of stainless steel for

heating and hot water generation systems. The specific geometry of the

exchanger has been calculated in order to obtain a very large Reynolds number

through all of its routes. The thus achieves an exceptional

output remaining stable throughout the boiler’s lifespan, given that it does

not produce any oxidation on the exchanger, which is manufactured entirely

of quality stainless steel.

ACV uses its BG 2000-M burner for the : this is a modulating air/

gas premix burner providing safe and quiet operation while limiting emissions

(NOx and CO) to an incredibly low level. Although the ACV BG 2000-M burner

is very modern, it uses proven technology and is manufactured using standard

spare parts that are easily available on the market.

The is fitted with an “” regulator controlled

by a microprocessor, which handles the safety functions (ignition, flame

monitoring, temperature limitation, etc,) and the temperature control of the

boiler. The also features a weather dependent regulator. Simply connect

the outdoor temperature sensor, available as an option.

However, this regulator can also operate with a standard (on/off) room

thermostat. The temperature of the system is then dependent on the outside

conditions with compensation for the indoor temperature.

Two rotating buttons placed on the control panel are accessible to the

user, enabling adjustment of the temperature of the heating and domestic

hot water. By entering a specific maintenance code into the unit, qualified

installers may access certain parameters, in order to adapt the boiler to specific

requirements. In principle, these are factory preset for all normal applications.

HOT WATER GENERATION

In addition to its exceptional capacities for hot water production,

the Tank-in-Tank system by ACV offers the following advantages:

the corrugations allow

the tank to expand and contract during the heating cycle and thereby to

prevent the build-up of limescale deposits.

the tank is fully immersed in the primary circuit and the domestic

water is permanently maintained at a uniform temperature of greater

than 60°C.

thanks to its

stainless steel design.

This also enables you to choose between two sanitary

function methods.

: (factory preset) the boiler cuts the heating circuit

each time the domestic circuit requires it.

: (only with a radiator heating circuit) the boiler

functions for heating and domestic hot water at the same time.

FROST PROTECTION

The boiler is equipped with integrated frost protection: as soon as the outlet

temperature [NTC1 probe] goes below 7 °C, the circulator becomes active.

As soon as the outlet temperature is lower than 3 °C, the burner starts upuntil

the outlet temperature exceeds 10 °C and the circulator continues to run for

approximately 10 minutes.

If an outdoor temperature probe is connected, the circulator is activated when

the outside temperature drops below the preset threshold.