EPJ SERIES INDIRECT WATER HEATERS – Installation and Service Manual

6

Pre-Installation Section 2

2.1 RECEIVING

INSPECT SHIPMENT FOR POSSIBLE DAMAGE. All goods are carefully manufactured, inspected,

checked and packed by experienced workers. The manufacturer's responsibility ceases upon delivery of

goods to the carrier in good condition. Any claims for damage and/or shortage in shipment or non-delivery

must be filed immediately against the carrier by the consignee.

Use care when receiving and unpacking the tank. Dropping the tank may cause damage and prevent safe

and proper operation.

2.2 INSTALLATION CODES AND REQUIREMENTS

All applicable national, provincial/state, and local codes, laws, regulations, and ordinances must be

followed. They expand on and take precedence over any recommendations in this booklet. Authorities

having jurisdiction shall be consulted before installations are made.

If an external electrical source is utilized, the indirect water heater must be electrically grounded and

installed in accordance with local codes or, in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70 (current edition) and/or the Canadian Electrical Code, CSA C22.1 Part 1 (current edition).

If there is any conflict in the above requirements, the more stringent requirement applies.

The installation and service must also conform to the additional requirements in this manual. If there is any

conflict with a requirement in this manual and a code requirement, the code requirement must be followed.

2.3 LOCATION

DANGER - Risk of Explosion: Do not use or store gasoline or other flammable fuels or chemicals

which have flammable vapors near the tank. The vapors may be ignited by the heat or electronic

components of the tank.

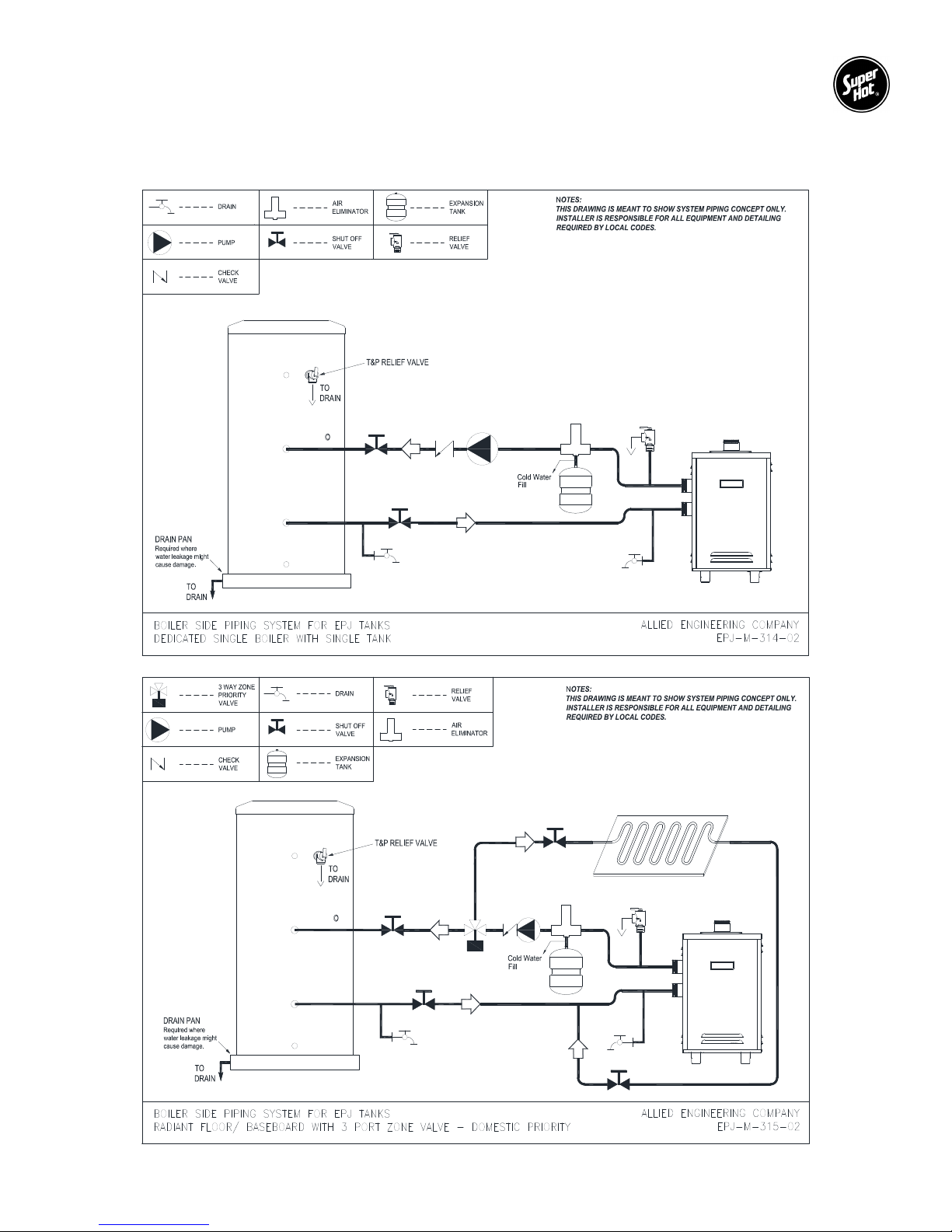

WARNING: The indirect water heater should be located in an area where water leakage of the

tank or its connections will not result in damage to the area adjacent to the appliance or to lower

floors of the structure. When such locations cannot be avoided, a suitable drain pan must be

installed under the appliance and the drain pan must be connected to a drain of adequate capacity.

Failure to comply with the above could result in severe personal injury, death or substantial property

damage.

WARNING: Failure to support and stabilize the water heater could result in severe personal injury,

death or substantial property damage. Do not lean items against the water heater. Avoid

unnecessary contact with the water heater.

This tank is designed for vertical installation. Install the tank on an area that is stable, flat, level and

capable of supporting the weight of the tank when filled with water.

This tank should not be placed where freezing might occur and is not to be installed outdoors.

Although minimal clearance is required for this tank, ensure that there is sufficient room around the

tank to access all of the fittings easily. We recommend a service clearance of 24 inches around

the piping connections.

This tank must be installed such that any electronic components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and service.

Avoid heat loss and friction loss by locating the tank as close to the boiler as possible. Further heat

loss should be avoided by insulating the pipe.

For the fastest delivery of hot water, locate the water heater in a position central to the points of

use.