Contact Superabrasive:

5

SAFETY PRECAUTIONS

RECOMMENDED USE

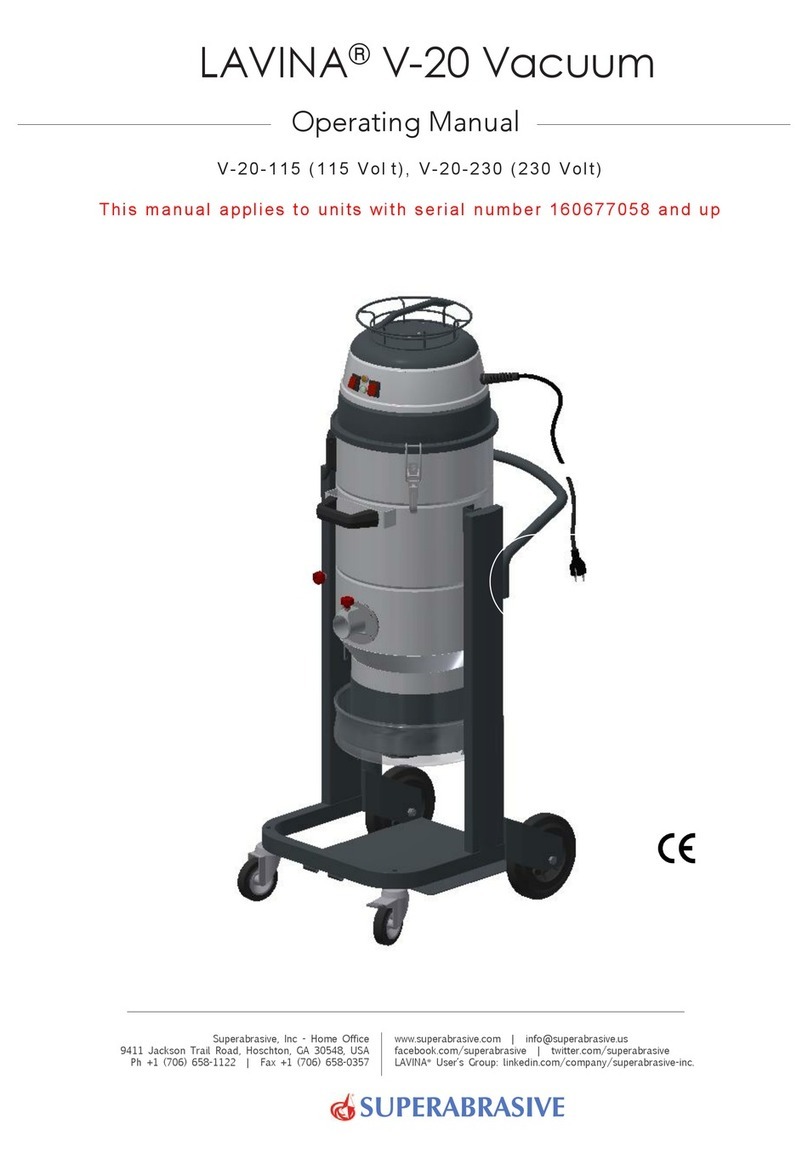

The LAVINA® V-20 Vacuum is designed and manufactured for

use with concrete, terrazzo and natural stone oors. It is recom-

mended for use with LAVINA® machines. This vacuum is rated

for dry use only, and with a machine of appropriate size. For more

information, please contact Superabrasive.

PROHIBITED USE

The vacuum MUST NOT be used:

• For applications different from those stated in this manual

• For non-suitable materials (asbestos or other toxic materials)

• In environments which (1) Possess the risk of explosion, (2

Possess high concentration of powders or oil substances

in the air, (3) Possess the risk of re, (4) Feature inclem-

ent conditions, (5) Possess electromagnetic radiation

• The vacuum should be not connected to electrical power

when performing maintenance-related tasks

PREPARATION FOR WORK

Ensure that:

• You have closed the work area, so that no person unfamiliar

with operating the vacuum can enter the area

• The vacuum is not missing parts

• The vacuum is in an upright, working position

• All protection devices are working properly

• The electrical cable is free to move and follow the vacuum

easily. In order to keep the electrical cable from being

damaged, no vehicle should enter the area where electrical

cables are present.

ARREST FUNCTIONS

Functions for arresting of the machine include following:

• Button to stop the motor

SAFE USE

The LAVINA® V20 is designed to eliminate all potential risks as-

sociated with its use. However, accidents may occur if unskilled or

uninstructed workers fail to heed the list of potential risks below:

• Position Risks due to operator’s incorrect working position

• Tangling Risks due to wearing inappropriate working clothes

• Training Risks due to lack of operational training

NOTE: Machine operators should follow the instructions in the

manual at all times.

RESIDUAL RISKS

During normal operating and maintenance cycles, the operator is

exposed to some residual risks, which cannot be eliminated due

to the nature of machine operation.

BEFORE YOU BEGIN

• The working area must be clear from any debris or objects.

• A rst-time operator must always read the manual and heed

all safety instructions.

• All electric connections and cables must be inspected for

potential damage.

• Ground wire system of the power supply must be also

inspected.

• Perform general daily inspections of the vacuum and inspect

the vacuum before each use for any sign of damage.

• Inspect all safety devices.

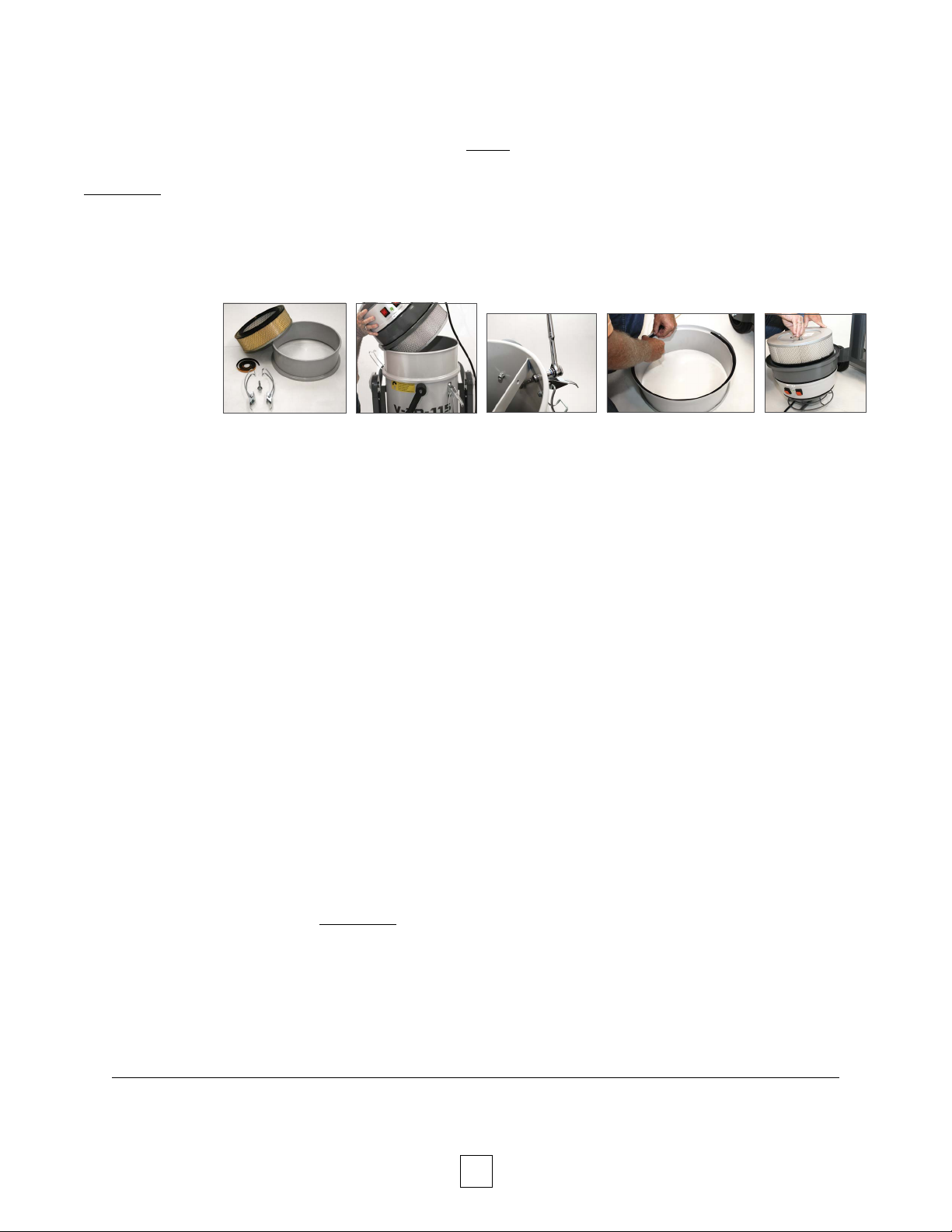

• The vacuum/lters must be clean and the hose should be

connected.

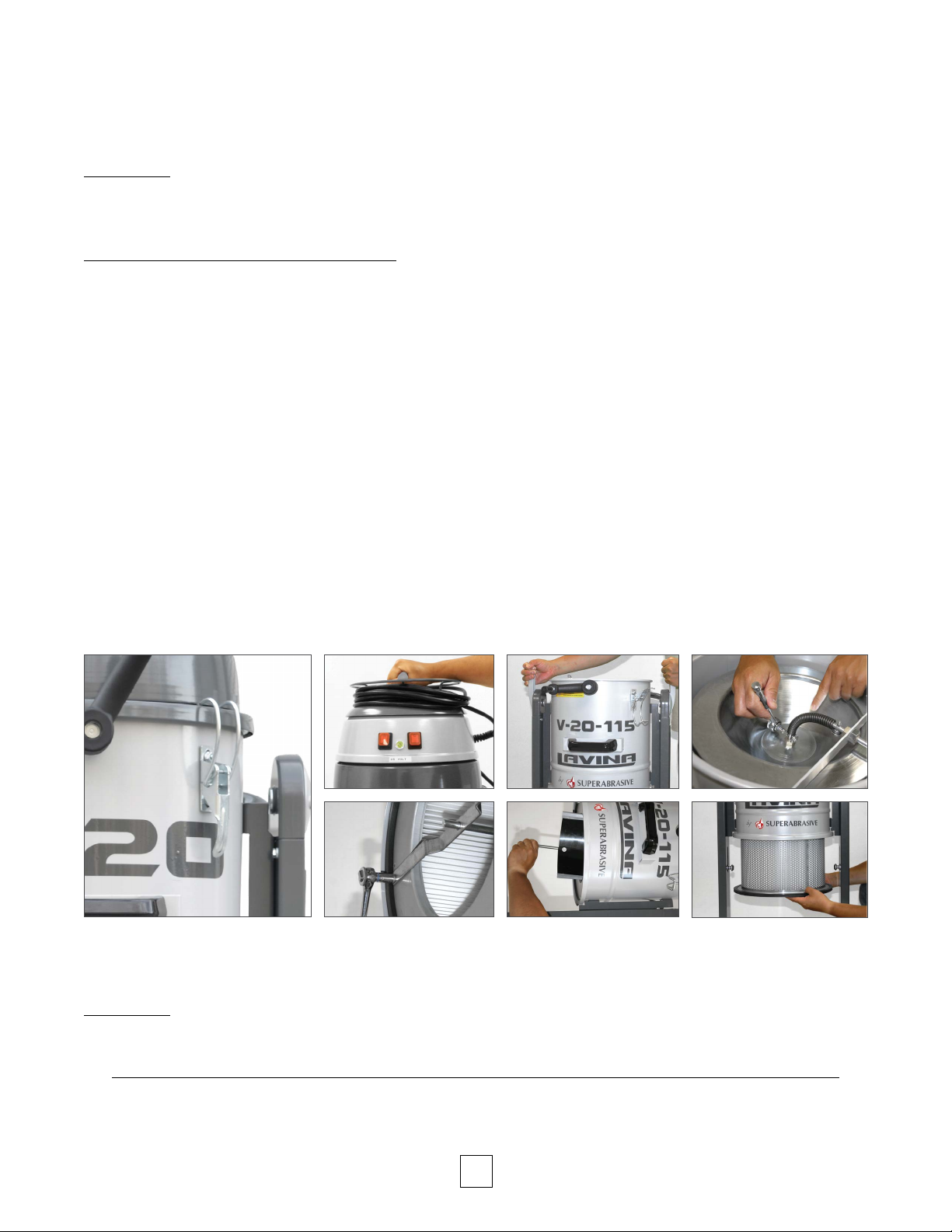

OPERATING THE VACUUM

When operating the LAVINA® V20, be sure that no one else is

within close proximity to the vacuum. Never leave the vacuum

unattended while working. The electrical cable and hose must

move freely, be damage-free, and should never run beneath the

vacuum or machine. Check the oor prior to beginning any work,

and ensure that it’s not too uneven, which can cause damage to

the vacuum.

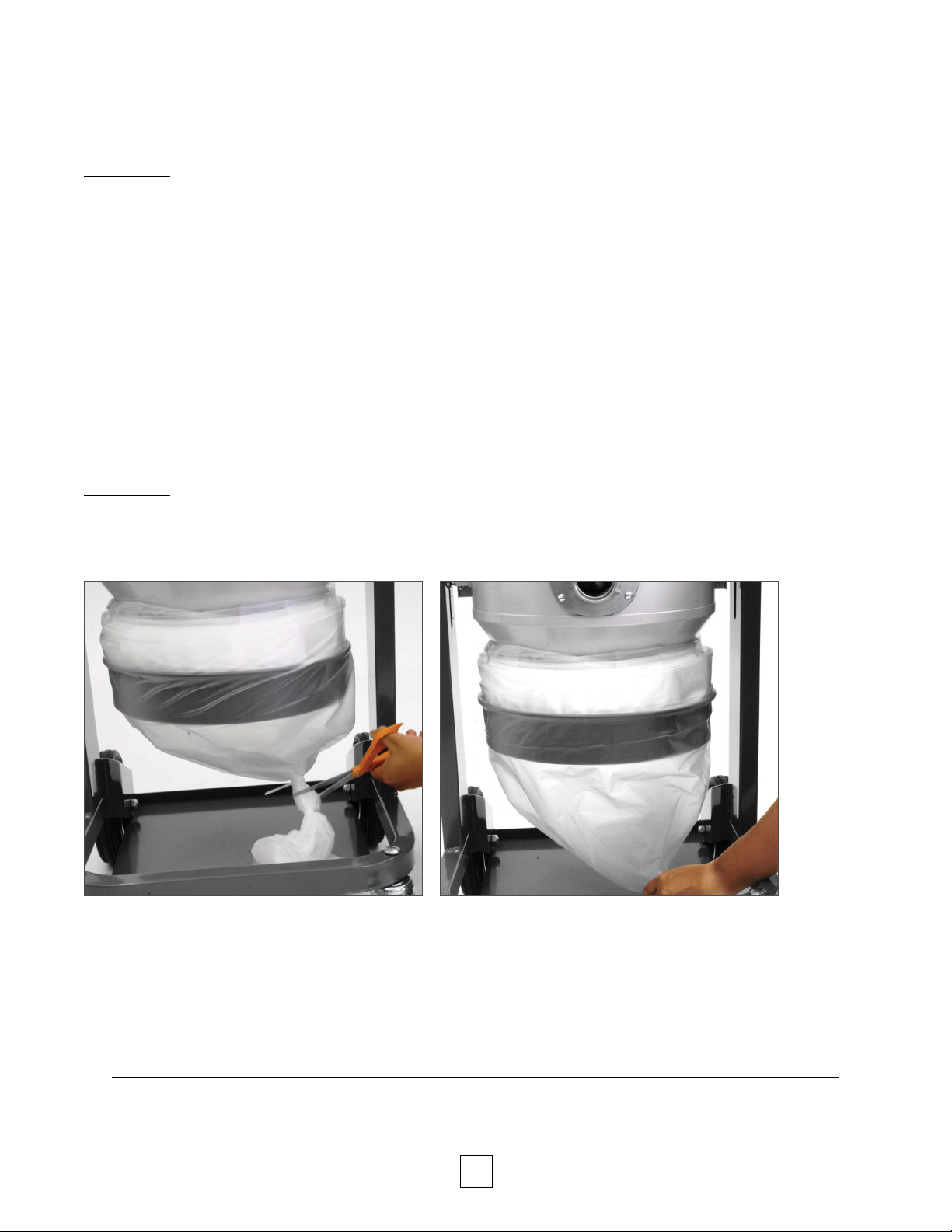

AFTER WORK IS COMPLETED

When work is complete, clean the vacuum and its surroundings

sufciently, empty all dust / debris, unplug the vacuum and wind

up the electrical cable, secure the hose, and store the vacuum in a

safe and secure place.

THE WORK AREA

Ensure that the area is free of unauthorized people or vehicles,

secure all cables and hoses, and always check the oor for debris.

PERSONAL PROTECTIVE EQUIPMENT

(PPE)

When operating the machine, always wear safety shoes, ear

protectors, safety gloves (especially when changing tools), and

suitable clothing. All persons within the immediate working area

must wear safety glasses with side shields.

OPERATOR

The operator must be aware of the vacuum’s work environment,

be properly trained prior to operating the equipment, and fully

understand this manual. Only one operator may work with the

machine at a single time The operator must understand and

interpret all the drawings and designs in manual, understand all

sanitation and safety regulations pertaining to its operation, have

oor grinding experience, know how to perform in an emergency

situation, and have an adequate technical knowledge and prepa-

ration.