RFX

DOC#:024091

Superior Innovations Reservation

All of the information and data in this Operator’s Manual was up to date at the time the

Operator’s Manual was sent to print. Superior Innovations research and development is

continually working on product development and improvements. Therefore, we reserve

the right to modify the design, appearance and features of the product without prior

notice. The most current version of manuals can be found at:

www.superiorinnovationsinc.com/manuals

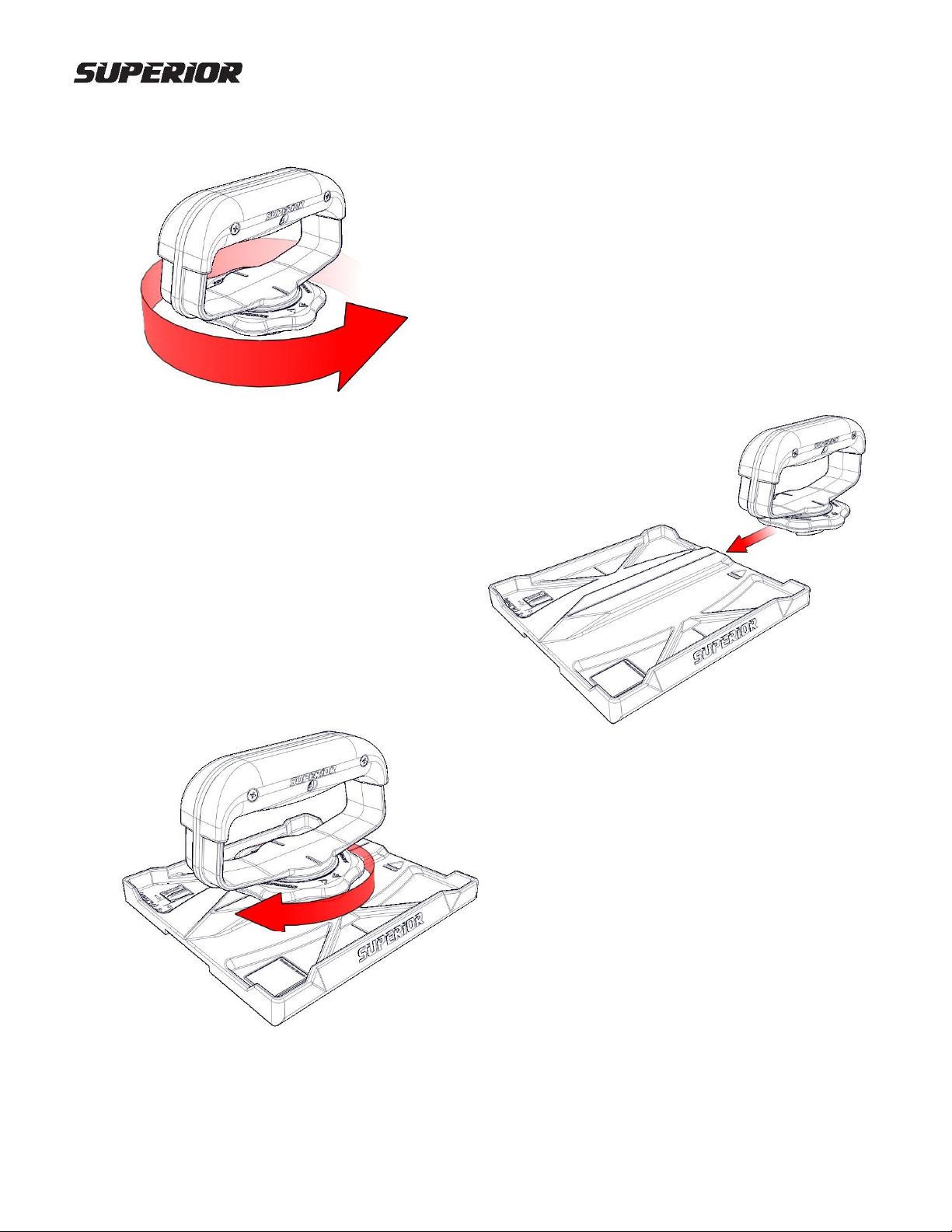

Transportation and Storage

Secure the equipment during transportation to avoid transport damage and accidents.

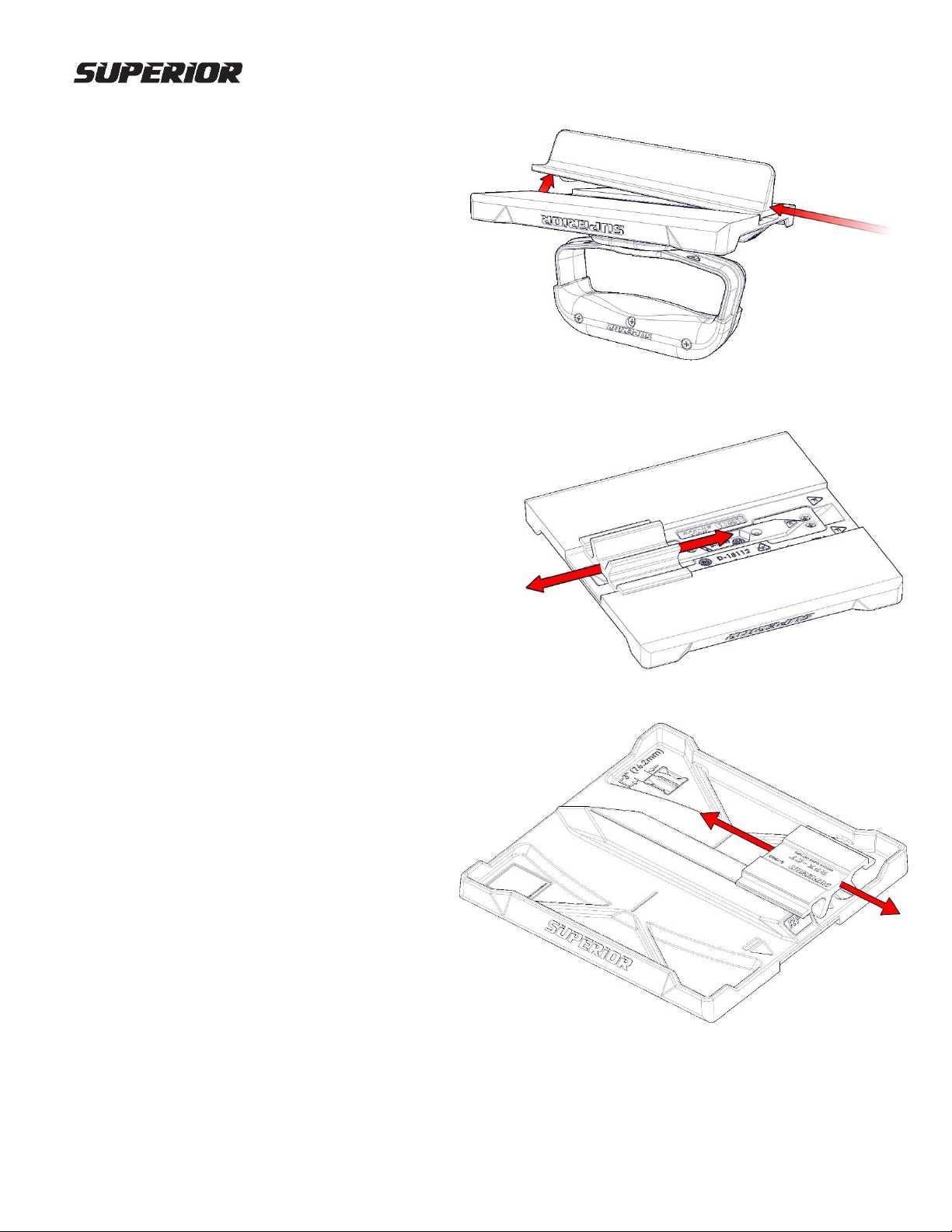

After work is completed, remove the RFX™ fin from the RFX™-HG and thoroughly wipe

down before the concrete has time to setup. DO NOT USE A PRESSURE WASHER!

Pressure washing can remove important safety decals, could remove the handles rubber

coating or force water and debris into sealed chambers.

Personal Protective Equipment (PPE)

You must use approved personal protective equipment (PPE) whenever working.

Personal protective equipment cannot eliminate injury, but it will reduce the degree of

injury if an accident does happen. Ask your dealer for help in choosing the right

protective equipment.

Common Sense

It is not possible to cover every conceivable situation in this document. Exercise care and

use common sense if you get into a situation where you feel unsafe. Stop and seek

expert advice by contacting Superior Innovations, Inc., a service dealer or an experienced

user. Do not attempt any task that you are unsure of.

Work Area Safety

Observe your surroundings to ensure nothing can affect your control of the tools.

Observe your surroundings to ensure there is no risk of people or animals that can come

into contact with the tools while in operation.

Do not use tools in bad weather, such as heavy rain, strong winds, intense cold, or heavy

fog. Working in such weather is trying and can lead to difficult situations.

Ensure that the work area is sufficiently illuminated to create a safe working

environment.

Make sure that there are no electrical cables routed in the working area.

Make sure that the work area is clear, clean and free of obstacles that can cause trips or

spills.