Sureshot Dispensing Systems AC-VP1 User manual

AC-VP1

Whipped Topping

Dispenser

Operations Manual

D-19-122RevA

2

TABLE OF CONTENTS

Dispenser Components 3

Specifications 3

Overview 4

Safety Precautions 4

Electrical Requirements 5

Servicing – Electrical 5

Servicing – Refrigeration 5

Inspection for Damage 5

Reshipment 5

Uncrating the Dispenser 6

The Cup Guide 6

Insert the Catch Tray 6

Installation and Location of the Dispenser 7

Clean Before First Use of the Dispenser 7

Starting the Dispenser 8

Open the Dispenser Drawer 8

Dispenser Drawer Components 9

To Load Whipped Topping Bags 10

Reset 11

OPERATING INSTRUCTIONS

To Dispense Whipped Topping 12

Button Panel & Indicator Lights 13

Disable Button Panel 13

Remove an Empty Bag of Whipped Topping 14

Remove the Dispenser Drawer 14

Replace the Dispenser Drawer 15

Close the Dispenser Drawer 15

Remove the Motor Guard Plate 16

Replace the Motor Guard Plate 16

CLEANING

Recommended Cleaning Schedule 17

Cleaning – Catch Tray 17

Cleaning – Splash Panel, Exterior of Dispenser

& Cup Guide 17

Cleaning – Button Panel 18

Cleaning – Dispenser Drawer 18

Cleaning – Enclosure Plate, Motor Guard Plate 19

Cleaning – Dispense Tip Area 19

Cleaning – Roller 20

Cleaning – Roller Brackets 20

Cleaning – Refrigerated Compartment 20

Cleaning – Condenser 20

Document # D-19-122 RevA

REFRIGERATION SYSTEM 21

Temperature Control Adjustment 22

Side Console 22

Temperature Display Window 23

Infrared Programming Window 23

To Determine Dispenser Mode 23

Temperature Adjustments 24

Dispenser Running Too Cold 24

Dispenser Running Too Warm 24

Side Console Displays 25

MAINTENANCE

General Maintenance 26

Remove Ice Buildup 26

Drawer Difficult to Close 26

Fan 26

WIRING DIAGRAM 27

TROUBLESHOOTING

Side Console – unexpected display 28

Indicator Light flashing 28

Indicator Light solid 28

No power at the plug 28

Dispenser will not turn on 28

Dispenser will not dispense product 28

Dispenser is leaking product 28

Dispenser is unusually warm on exterior 29

Dispenser is unusually warm on interior 29

Dispenser is too cold 30

Frost buildup in refrigerated compartment 30

Dispenser is not level 30

TABLES

Dispenser Specifications 3

Button Panel Displays 13

Side Console Displays 25

WARRANTY 32

A.C.Dispensing Equipment Inc.

100 Dispensing Way

Sackville, Nova Scotia, Canada

B4C 4H2

1-888-777-9990 or 1-902-865-9602

www.sureshotdispensing.com

3

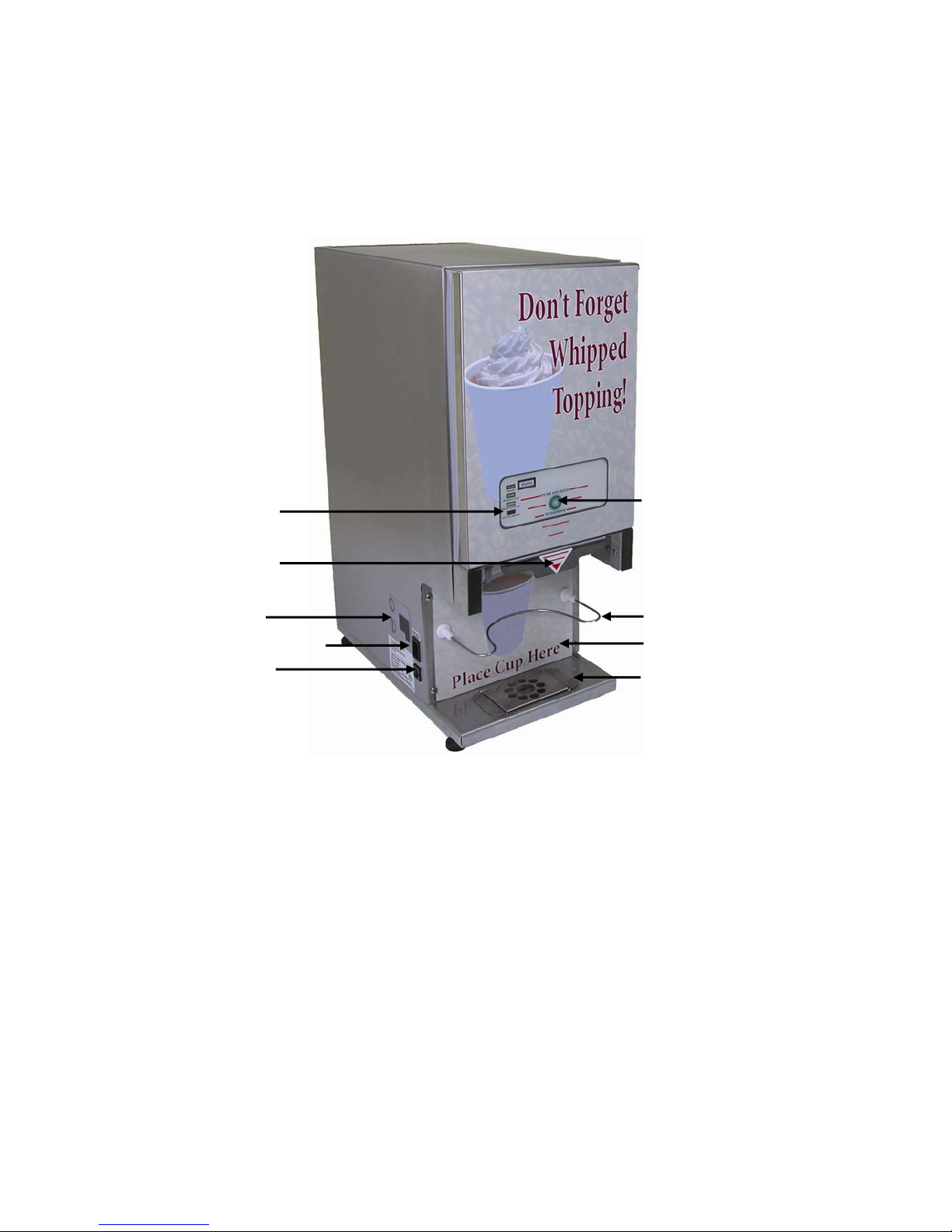

DISPENSER COMPONENTS

Specifications

Capacity: up to 20 oz. bag of whipped topping

Weight: 73 lbs / 33 Kg (empty dispenser)

Dimensions: L x W x H: 17¾” x 9½” x 24¼”

Note: height measured with 1” support feet installed.

Cup sizes up to 4¼” in diameter and 7¾” high may be used.

Dispense Button

Cup Guide

Splash Panel

Catch Tray

Indicator Lights

Handle to Open

Drawer

Side Console

ON/OFF Power Switch

Circuit Breaker

4

THE DISPENSER

The AC-VP1 Refrigerated Whipped Topping Dispenser is designed by SureShot

Dispensing Systems® to dispense Whipped Topping on coffees, teas, hot chocolate

and other specialty drinks.

Pre-packaged whipped topping is stored within the dispenser’s refrigeration compartment

and dispensed by a microprocessor-controlled roller system using a touch button on the

front of the dispenser. Our factory has configured the dispenser to deliver whipped

topping as long as the push and hold button is pressed.

Operating the dispenser

1. Place cup under the dispense tip

2. Press and hold the dispense button until the desired quantity is dispensed

Indicator Lights at the bottom left front of the dispenser drawer show the status of the

dispenser operation: Ready, Product Low, Product Empty, Out of Service.

The dispensers feature a Side Console which shows refrigeration functions for easy

monitoring and adjustment of the refrigeration system.

The dispenser is preconfigured at our factory to dispense the whipped topping to your

company’s specifications. It should not require adjustment. If you think adjustment may

be necessary, contact the SureShot Dispensing Systems® Technical Assistance Center

at 1-888-777-9990 or 1-902-865-9602) and a Service Technician will guide you through

the process.

SAFETY PRECAUTIONS

•Always plug the dispenser into an approved electrical outlet.

•The dispenser includes a microcontroller and must be operated on

grounded electrical wiring at all times.

•Unplug the dispenser from its electrical source before servicing.

•Do not immerse the dispenser in water.

•Observe all safety precautions with this dispenser that you would

with any electrical appliance.

•The dispense roller is powered by a motor. To avoid possible injury,

keep hands clear of the roller assembly during operation.

5

ELECTRICAL REQUIREMENTS

Make sure the current at the power source receptacle is: 120 VAC, 1 ph, 3 Amp, 60 Hz.

The power cord is furnished with a UL-approved 3-prong attachment plug. This plug is

designed to fit a receptacle with provisions for a grounding stud. The dispenser includes

a microcontroller and must be operated on grounded electrical wiring at all times. Failure

to do so will void the Warranty.

SERVICING - ELECTRICAL

Electrical servicing must be carried out by a qualified technician.

The Warranty will be null and void if the dispenser is serviced by unqualified personnel.

Service under Warranty must be approved and dispatched by A. C. Dispensing

Equipment Inc. before the service technician is dispatched. If you need assistance, call

the SureShot Dispensing Systems® Technical Assistance Center at 1-888-777-9990 or

1-902-865-9602.

SERVICING - REFRIGERATION

The temperature is set at the factory to maintain products within the range of 32°F to

40°F (0°C to 4.4°C).

Any servicing of the refrigeration system must be carried out by a qualified technician.

The Warranty will be null and void if the refrigeration system is serviced by unqualified

personnel. Service under Warranty must be approved and dispatched by A. C.

Dispensing Equipment Inc. before the service technician is dispatched. If you need

assistance, call the SureShot Dispensing Systems® Technical Assistance Center at

1-888-777-9990 or 1-902-865-9602.

INSPECTION FOR DAMAGE

When you receive the dispenser, inspect the exterior of the shipping container for

damage. Note any damage in detail.

Uncrate the dispenser at once. See instructions on page 6. Examine the dispenser for

damage. Report any damage to the transportation company immediately. File a claim for

damages promptly.

Your immediate inspection protects you against loss since A. C. Dispensing Equipment

Inc. is not responsible for damages incurred during shipment.

Notify A.C. Dispensing Equipment Inc. No returns will be accepted without prior approval.

Obtain an authorized return number by contacting SureShot Dispensing Systems®

Technical Assistance Center at 1-888-777-9990 or 1-902-865-9602.

RESHIPMENT

Packaging for re-shipment is done in the reverse order of uncrating. If packaging is not

available, it can be purchased locally, or from our factory by request.

Any damage occurring in transit of the returned goods caused by improper packaging is

not considered a defect covered by Warranty.

6

UNCRATING THE DISPENSER

CAUTION: Always lift the dispenser from the bottom. Do not lift dispenser by the door.

To uncrate:

1. Make sure the box is positioned with the arrow pointing upward.

2. Cut the packing straps at the top of the box.

3. Lift the top tray off the box.

4. Lift the center sleeve off the box.

5. Remove the protective corner inserts from the bottom tray.

6. Lift the dispenser by its bottom out of the tray. Use two people to lift the dispenser.

7. Remove the plastic protective covering from the stainless steel exterior of the

dispenser, by peeling it off. To peel, hold the dispenser firmly at the top and peel from

top to bottom.

8. Prior to use, read the Operations Manual. Store it for future use.

NOTE: The carton top, sleeve, and bottom tray may be stored for future shipping.

THE CUP GUIDE:

The Cup Guide is a stainless steel formed rod with plastic lugs on both ends.

It guides positioning of cups under the dispense nozzle and will accommodate a large

array of cup sizes. The dispenser is shipped with the Cup Guide attached.

INSERT THE CATCH TRAY

The Catch Tray is used to catch any whipped topping that is inadvertently spilled during

use of the dispenser. Its use helps keep the work area clean and sanitary. The Catch

Tray consists of a stainless steel screen and a stainless steel body. The Catch Tray must

be cleaned regularly, at least once daily. For Cleaning Instructions, see page 17.

To Insert the Catch Tray:

1. Remove the white plastic covering from the stainless steel screen.

2. Place the screen in the stainless steel body.

3. Place the assembled tray in the opening at the front of the dispenser.

NOTE: The Catch Tray may be removed by lifting it up and out of the opening.

23

7

INSTALLATION AND LOCATION OF THE DISPENSER

Location of Dispenser:

•This dispenser is not suitable for outdoor use.

•The ambient temperature range for dispenser operation is 50 °F to 90 °F (10 °C to

32 °C).

•Place the dispenser where it will best serve your operation.

•Leave clear space around the dispenser, approximately 1 inch (2.5 cm) on all sides.

•Do not block the vents at the top rear of the dispenser. The vents must be free and

open to ensure proper operation of the ventilation system and to prevent over-

heating and damage to the system.

•Make sure that counters, platforms, or shelves are strong enough to support the

dispenser with a full bag of whipped topping. The weight of the empty dispenser is

73 pounds.

•Place the dispenser at the appropriate serving height so that people drawing

whipped topping from the dispenser can operate the button as well as easily place

and remove cups.

•The dispenser must be placed on a level surface. The dispenser must be level to

ensure proper functioning of the refrigeration system.

oUse a bubble level to ensure accuracy.

•Do not remove the feet from the dispenser or allow the dispenser to sit flat on the

counter. Airflow and circulation under the dispenser are essential for the proper

operation of the refrigeration system. Make sure the four feet at the bottom of the

dispenser are in place. If one has loosened during shipping, re-tighten it. Removal of

the feet automatically voids the Warranty.

CLEAN BEFORE FIRST USE OF THE DISPENSER

Make sure you clean the dispenser thoroughly. See Cleaning Instructions on pages 17-

20.

•The dispenser must not be cleaned by water jet.

8

STARTING THE DISPENSER

NOTE:

•Before starting the dispenser, make certain that all Installation instructions have been

followed and that the dispenser has been sitting upright for a minimum of 3 hours.

To start the dispenser:

1. Plug the power cord into the proper electrical outlet.

2. With the dispenser drawer closed, turn the Power Switch “ON”.

•The power switch is located at the lower left side of the dispenser. For

location of the switch, see page 3.

•The Status Indicator Light on the front of the dispenser is an LED which

glows green when the dispenser is on and has reached operating

temperature.

3. Allow the dispenser to run empty for one hour to achieve a cold temperature

before placing product containers in the dispenser. The temperature control has

been pre-set at the factory. You can feel the cold temperature by placing your

hand on the top or back wall of the refrigeration compartment.

4. If the dispenser does not appear to be getting cold, check to make sure that it is

plugged in and that the power source is active. If the dispenser still does not

operate, immediately call the A. C. Dispensing Equipment Inc. Technical

Assistance Center at 1-888-777-9990 or 1-902-865-9602.

OPEN THE DISPENSER DRAWER

1. Grasp the bottom front of the dispenser drawer.

2. Pull the drawer out.

Green = ON and Ready

9

LOADING THE DISPENSER

•Ensure the dispenser has achieved proper operating temperature by running empty for

one hour before loading product to be dispensed.

•Product being placed inside the refrigerated product compartment must be between

32 °F and 40º F (0 °C and 4.4ºC).

•Whipped topping is supplied in prepackaged sanitary bags. Ensure they are the proper

temperature before being loaded into the dispenser. The product bag is disposable and

must not be reused.

•Product bags of up to 20 oz may be used in the dispenser.

•When the dispenser microprocessor determines that a bag of whipped topping is empty,

it will return the roller to the original loading position.

•Sanitize your hands or wear clean gloves to load the dispenser.

Dispenser Drawer Components

Latch

Whipped topping

bag hangs on

these 3 hooks

Roller

Dispense spout

opening

Motor Guard

Plate

Roller Plate

10

TO LOAD WHIPPED TOPPING BAGS

1. Open the dispenser: pull the drawer out from the

refrigerated compartment.

2. Remove the roller plate:

a. Undo the 2 latches that hold the plate in place

b. Move the plate forward.

c. Remove the plate by lifting it up and out

d. Set the plate aside for later re-installation

3. Remove the roller, if required:

a. Grasp the roller and slide it out of the end slots.

4. Clean the dispenser drawer interior, if required.

For cleaning instructions, see page 18.

5. Reinsert the roller, if it was removed in Step 3.

6. Remove a prepackaged bag of whipped topping

from the storage refrigerator.

Make sure the product temperature is 32 °F – 40º F

(0 °C – 4.4ºC), with no sign of ice crystals.

If ice crystals are present in the bag whipped topping,

return that bag to the storage refrigerator to thaw.

7. Prepare the bag for loading (Instructions on bag)

a. Move the coupler in the bag down to the spout portion.

b. Tear the seal off the spout.

c. Thread the dispense tip onto the nozzle.

d. Ensure that the plastic of the bag is trapped in the

threads of the two mating parts.

2a

2b

3a

11

8. Load the bag into the dispenser drawer:

a. Move the Coupler/Tip into the opening at the

drawer bottom.

b. Slide the Coupler/Tip over into the groove.

c. Snap the Coupler/Tip assembly into place.

d. Hang the bag of whipped topping over the 3 hooks

at the top of the drawer.

9. Re-insert the roller plate removed in Step 2:

a. Fit the 4 tabs on the bottom of the plate into the

4 slots in the bottom of the drawer.

b. Tilt the enclosure plate up toward the roller to

close the dispense unit/housing.

•Verify that the bag is hanging straight.

•Make sure the dispense tip has not popped

out and that it has no twists in it.

c. Fasten the two latches to secure the enclosure plate.

10. Close the dispenser: slide the drawer into the refrigerated compartment.

Verify installation: a. Place a catch container under the dispense nozzle.

b. Press the dispense button until product is released.

NOTE:

When a bag of whipped topping is emptied, the dispenser will reset automatically and

the roller will return to the top, to the full bag position, ready to have a full bag loaded into

the dispenser.

RESET – not normally required.

Reset the dispenser before a new bag of whipped topping is loaded. To be used when

roller did not automatically Reset, or for premature bag replacement.

To Reset: push and hold the Triangle Reset Button ▲(in the top right corner of the

Button Panel) for 3 seconds. This ensures the roller returns to the top and allows the

dispenser to sense when the bag is empty.

9b

8a

8d

12

OPERATING INSTRUCTIONS

•Make certain all initial Set-Up instructions have been followed before operating the

dispenser. See page 7.

TO DISPENSE WHIPPED TOPPING

1. Place cup in front of “Place Cup Here” decal, under the product dispense tip and

within the cup guide.

2. Press the dispense button and hold until the desired amount of topping is dispensed.

13

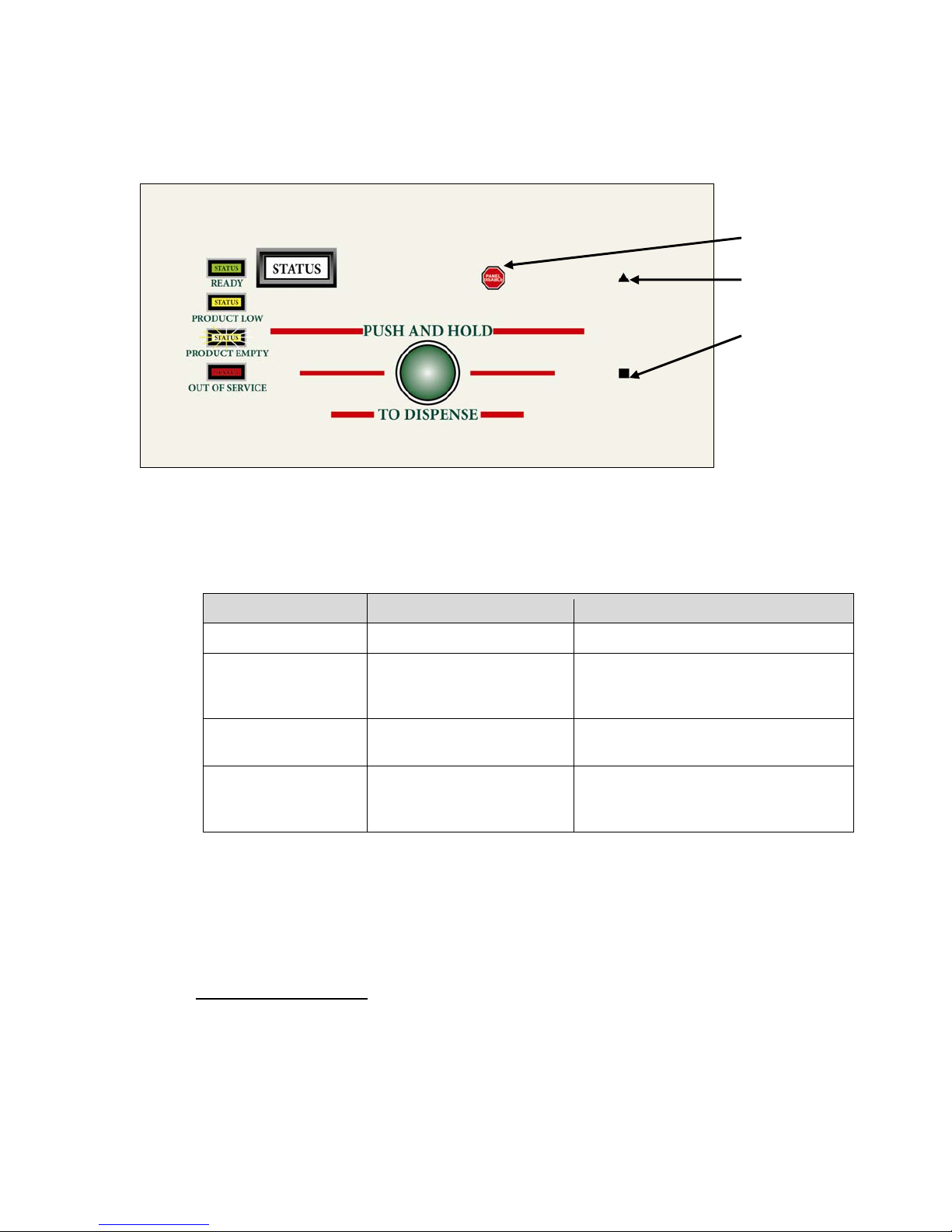

BUTTON PANEL & INDICATOR LIGHTS

The STATUS indicator light (LED) on the dispenser drawer shows the operating status:

Indicator Light - color Indicator Light – Indication Dispenser Status

Green Ready dispenser is ready to operate

Solid yellow

Product Low whipped topping is low and a new bag

must be loaded soon. The light glows

after ¾ of the bag has been dispensed.

Flashing yellow Product Empty product bag is empty and must be

replaced

Red Out of Service dispenser is out of service, i.e. topping

is too warm.

See page 24 to adjust temperature.

Panel Disable:

To prevent any unwanted dispenses during cleaning, the Button Panel can be disabled

before cleaning is started.

The Stop Sign button on the Button Panel initiates the panel disable period. It is not used

by customers and is intended for use during Button Panel cleaning.

To Disable Button Panel:

Press the Stop Sign for 3 seconds.

•The LED’s flash and the panel is disabled for 10 seconds to allow staff to wipe

down the Button Panel.

•If additional time is required, repeat this sequence.

Panel Disable

Button

Reset Button

Program Mode

Button

(Not used by customers)

14

REMOVE EMPTY BAG OF WHIPPED TOPPING

1. Open the dispenser drawer: pull the drawer out from the refrigerated compartment.

2. Remove Roller Plate.

2. Slide the dispense tip out of its groove at the bottom of the drawer.

3. Unhook the top of the bag from the 3 hooks at the top of the drawer.

4. Lift the bag up and out of the drawer.

5. Discard the empty bag.

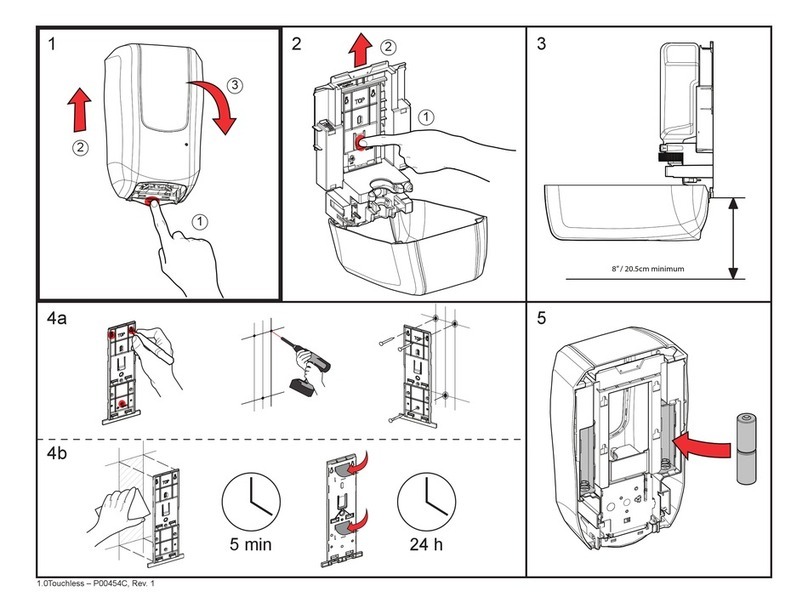

REMOVE THE DISPENSER DRAWER

The dispenser drawer may be removed for cleaning and servicing.

1. Release the door cord from the lower left corner of the drawer. Press the connector

tab to release, through the access hole, then remove the cord. The connector is

similar to a telephone jack.

2. Grasp the bottom front of the dispenser drawer – the handle with the down arrow.

3. Pull the drawer out.

4. Grasp the drawer on both sides and lift it up from the post that connects the drawer to

the drawer slides.

5. Remove the drawer from the dispenser.

1

2 & 3 4 5

15

REPLACE THE DISPENSER DRAWER

1. Grasp the drawer on both sides and move it into the dispenser, resting the back

sliders on the dispenser body.

2 a. Move the drawer slide into position so that the drawer fits onto the center post.

b. Lower the drawer onto the center post.

3. Replace the power cord (removed in step 1 of the remove drawer procedure above)

by inserting it into the tab at the lower left corner of the drawer.

4. Push the drawer in to close it.

CLOSE THE DISPENSER DRAWER

1. Grasp the bottom front of the dispenser drawer – the handle with the down arrow.

2. Push the drawer in.

1 2a

2b 3

16

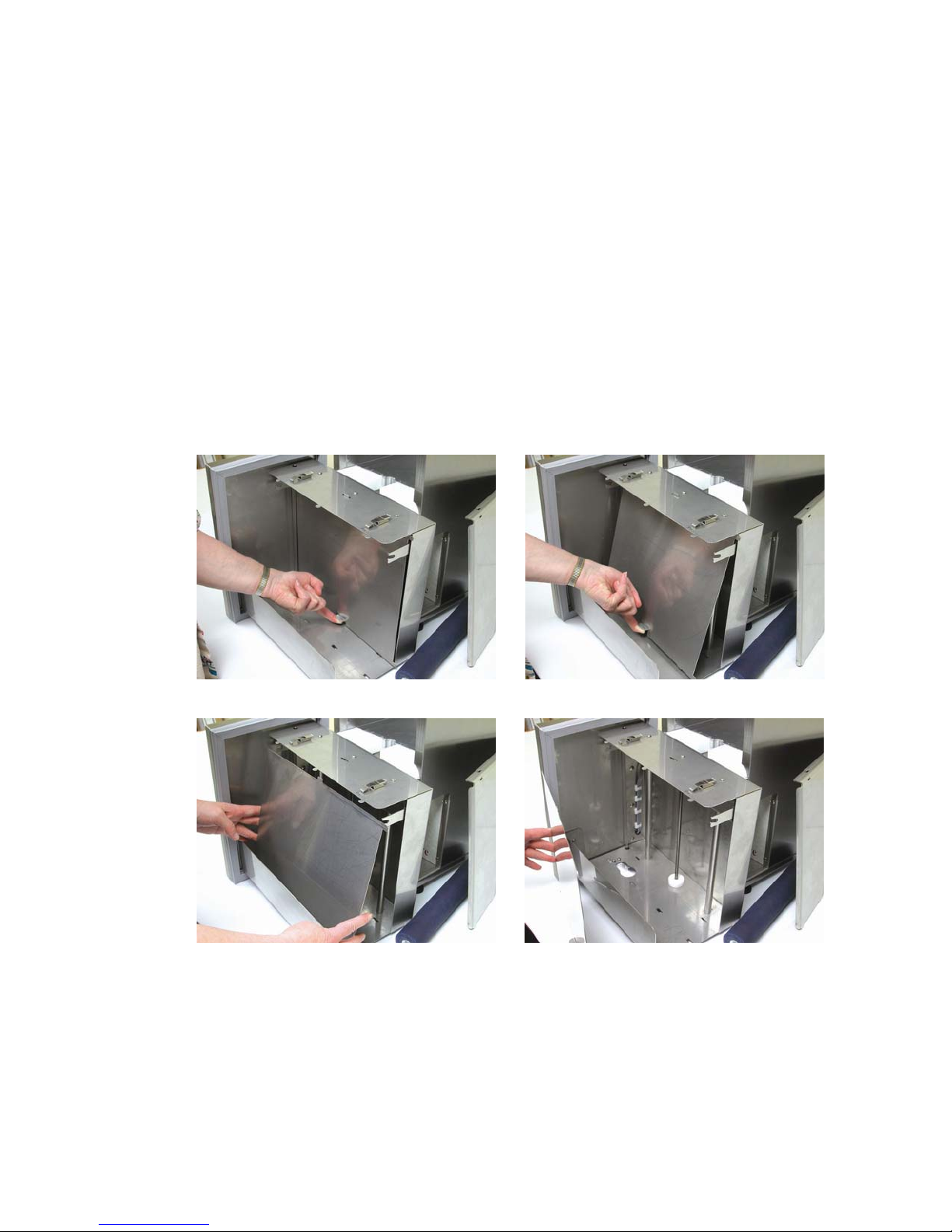

REMOVE THE MOTOR GUARD PLATE

The motor guard plate is a stainless steel plate behind the whipped topping bag that

shields the dispenser motors (see page 9). The motor guard plate should not be

removed during normal operations but, if necessary, the plate may be removed for

cleaning.

To remove the motor guard plate:

a. Lift it up by the lip at the bottom of the plate

b. Swing the plate out from the bottom.

c. Lower the plate from the top slots.

d. Remove the plate.

e. Set the plate aside to go in the dishwasher or to be washed by hand.

•Do not touch the internal rods behind the motor guard plate.

REPLACE THE MOTOR GUARD PLATE

Follow the reverse order of removal steps:

a. Move the plate into position in the drawer.

b. Insert the plate into the top slots.

c. Swing the plate into position at the bottom.

d. Use the lip at the bottom of the plate to move it securely into position.

a b

c d

17

CLEANING

RECOMMENDED CLEANING SCHEDULE:

DISPENSER PART FREQUENCY SEE PAGE

Catch Tray Daily or as needed 17

Splash Panel / Exterior / Cup Guide Daily or as needed 17

Button Panel Daily or as needed 18

Dispenser Drawer Daily or as needed 18

Roller Plate / Motor Guard Plate Daily or as needed 19

Dispense Tip Area Daily or as needed 20

Roller Every time a new product bag is loaded 19

Roller Bracket As needed 20

Refrigerated Compartment Every time a new product bag is loaded 20

Condenser Every 6 months 20

CLEANING: Catch Tray

1. Remove the catch tray.

2. Rinse the tray with lukewarm potable water.

3. Place the tray in a hot water wash at a minimum water temperature of 140ºF or 60ºC.

•A good quality general cleaner should be added to the hot wash water at the

concentrations recommended by your detergent supplier.

4. Wash thoroughly, using a bottle brush to reach all the corners and crevices.

•If a dishwasher is available, this step may be carried out by placing the tray in

the dishwasher and washing on the full wash cycle.

5. After washing, rinse the tray well with lukewarm potable water.

6. Turn the tray upside down. Drain thoroughly. Air dry thoroughly.

CLEANING: Splash Panel, Exterior of Dispenser, and Cup Guide

NOTE: Do not use any abrasive materials.

1. Use a soft, dry cloth to wipe down the exterior surfaces of the dispenser to maintain

the luster of the stainless steel finish.

2. Wash the stainless steel exterior surfaces of the dispenser with warm, soapy water.

3. Rinse with warm clear water.

•If the water is hard, wipe the dispenser dry with a soft cloth to prevent water

spotting.

•Stainless steel polish may be used if it is sprayed on a cloth before the cloth is

used to wipe down the exterior surfaces of the dispenser.

•The front of the dispenser should be wiped clean daily.

Do not spray any liquid, such as a cleaner, in or around the motor area.

Liquid could damage electrical components located in that area.

The dispenser must not be cleaned by water jet.

18

CLEANING: Button Panel

•The Button Panel can be disabled before cleaning to ensure no topping is dispensed

during the cleaning of the panel.

•The Panel Disabled mode will last for 10 seconds before the dispenser automatically

returns to normal operating conditions.

1. Disable button panel:

a. Press the Stop Sign on the button panel for 3 seconds.

b. Immediately release your finger. All LED’s embedded in the panel will flash in

sequence while the panel is disabled to allow cleaning.

2. Clean: Wipe the panel down with a cloth using warm, soapy water

3. Rinse: Rinse by wiping the panel down with a cloth using warm, clear water.

Do Not Submerge Door or Button Panel.

CLEANING: Dispenser Drawer

•The dispenser drawer may be removed from the dispenser for ease of cleaning: For

removal instructions, see page 14.

•Do not run loose water into the dispenser drawer or compartment.

•Do not immerse Dispenser drawer in water.

1. Clean any whipped topping that may have dropped into the drawer.

•Spilled topping may be cleaned easily with a damp warm or hot cloth.

•Make sure no whipped topping is left in the dispenser.

•Clean each time a new bag of whipped topping is loaded.

•Remove the enclosure plate and roller, as required, to clean spilled topping. To

clean the enclosure plate, see page 19.

•If it appears that product has spilled behind the motor guard plate, it can be lifted

up and swung out, after the roller has been removed. Clean the area behind the

motor guard plate carefully, using a damp cloth but no suds. To clean the motor

guard plate, see page 19.

•Do not wipe the internal rods and threads behind the motor guard plate. They are

lubricated with an NSF grade food lubricant. If you do wipe down the rods and

threads, they must be re-lubricated with a product similar to NSF H1 approved

food grade lubricant.

2. Wipe down the sides of the dispenser drawer with a clean cloth dipped in warm water.

3. Wipe down the sides of the dispenser drawer with a clean cloth dipped in hot, soapy

water.

4. Wipe down the sides of the dispenser drawer with a clean cloth dipped in warm water.

5. Wipe down the sides of the dispenser drawer with a clean cloth dipped in sanitizing

solution.

6. Drain thoroughly.

7. Air dry thoroughly.

19

CLEANING: Roller Plate, Motor Guard Plate

1, Remove the enclosure plate:

a. Undo the 2 latches that hold the plate in place.

b. Remove the plate by lifting it up and out from the 4 bottom slots.

c. Set the plate aside to go in dishwasher or to be washed by hand.

2. Remove the empty product bag (if one is still in dispenser):

a. Slide the dispense tip out of its groove at the bottom of the drawer.

b. Unhook the top of the bag from the 3 hooks at the top of the drawer.

c. Lift the bag up and out of the drawer.

d. Discard the empty bag.

3. Remove the roller:

a. Grasp the roller.

b. Slide the roller out of the end slots.

c. Set the roller aside to wash by hand. See Instructions below.

4. Remove the motor guard plate, if necessary:

a. Lift it up by the lip at the bottom of the plate.

b. Swing the plate out from the bottom.

c. Lower the plate from the top slots.

d. Remove the plate.

e. Set the plate aside to go in the dishwasher or to be washed by hand.

•Do not touch the rods behind the motor guard plate, if no product is spilled on

them.

5. Clean:

•The roller plate and the motor guard plate may be washed in a commercial

dishwasher on the full wash cycle.

•If your location does not have a dishwasher, the roller plate and the motor guard

plate must be washed and sanitized by hand (see below).

6. Drain thoroughly.

7. Air dry thoroughly.

Hand Wash: To wash the roller plate and the motor guard plate by hand:

1, Rinse with lukewarm water.

2. Wash thoroughly in a hot water wash at a minimum temperature of 140 °F or 60 °C.

Add a good quality general cleaner at concentrations recommended by the detergent

supplier.

3. Rinse well with lukewarm potable water.

4. Sanitize with a mild sanitizer recommended by your detergent supplier.

5. Drain thoroughly.

6. Air dry thoroughly.

CLEANING: Dispense Tip Area

NOTE: Do not use any abrasive cleaning materials.

When the drawer is removed, inspect the dispense tip area and clean if required.

Spilled topping may be removed easily with a damp warm or hot cloth.

1. Use a clean cloth dipped in warm water to wipe up the area around the dispense tip.

2. Use a clean cloth dipped in hot, soapy water to clean the area.

3. Use a clean cloth dipped in warm water to rinse the area.

4. Use a clean cloth dipped in an approved sanitizing solution to wipe down the area.

5. Air dry thoroughly.

20

CLEANING: Roller

•Do not use abrasive cleaners on the roller.

•The roller must be washed by hand.

•To remove the roller, grasp it and slide it out of the end slots.

1, Rinse the roller with lukewarm water.

2. Wash thoroughly in a hot water wash at a minimum temperature of 140 °F or 60 °C.

Add a good quality general cleaner at concentrations recommended by the detergent

supplier.

3. Rinse well with lukewarm potable water.

4. Sanitize with a mild sanitizer recommended by your detergent supplier.

5. Drain thoroughly.

6. Air dry thoroughly.

CLEANING: Roller Brackets

1. Wipe the roller brackets with a damp cloth dipped in warm, soapy water.

2. Rinse with a damp cloth dipped in warm, clear water.

3. Dry thoroughly.

CLEANING: Refrigerated Compartment

•Wipe the compartment clean each time a new whipped topping bag is loaded. This

will remove any condensation that may accumulate within the compartment.

1. Turn the dispenser OFF.

2. Remove the dispenser drawer. For removal instructions, see page 14.

Set the drawer aside to replace later.

3. Check for ice: Each time a new product bag is loaded, check the refrigerated product

compartment for ice build-up.

If ice has accumulated in the refrigerated product compartment:

Wait 10 minutes for the ice to soften.

Gently remove and discard the ice.

4. Wipe the interior down with a soft cloth.

5. Dry thoroughly.

6. Replace the dispenser drawer removed in Step 3. For replacement instructions, see

page 15.

7. Turn the dispenser back ON.

CLEANING: Condenser

Every 6 months, remove the back panel of the dispenser and inspect the condenser. If

necessary, clean the condenser using a vacuum. We suggest a vacuum be used to

prevent any damage to the condenser coil.

Table of contents

Other Sureshot Dispensing Systems Dispenser manuals