diecast pegs into the top of the diecast “Keyhole” plates. Insert and tighten the socket cap

security screw from inside the dispenser through the central hole above the top shelf. Pick

the dispenser up and locate it on the lower bracket, ensuring both pegs are fully engaged.

Use the spirit level to ensure that the unit is exactly upright, then without moving it

carefully mark the position of the two upper bracket holes on the wall from inside the

dispenser through the diecast mounting peg holes (use a scribe or long thin pencil etc.).

Take the machine down from the wall, leaving the upper bracket secured in the case. Drill

and plug the two upper mounting points, then use a centre-punch or ball-point pen to

open-up the two plugged holes for easy screw entry. Lift the dispenser onto the lower

mounting bracket again and push it firmly down to fully engage the two pegs. Insert the

two securing screws from inside the machine through the upper bracket holes into the wall

plugs, and fully tighten them.

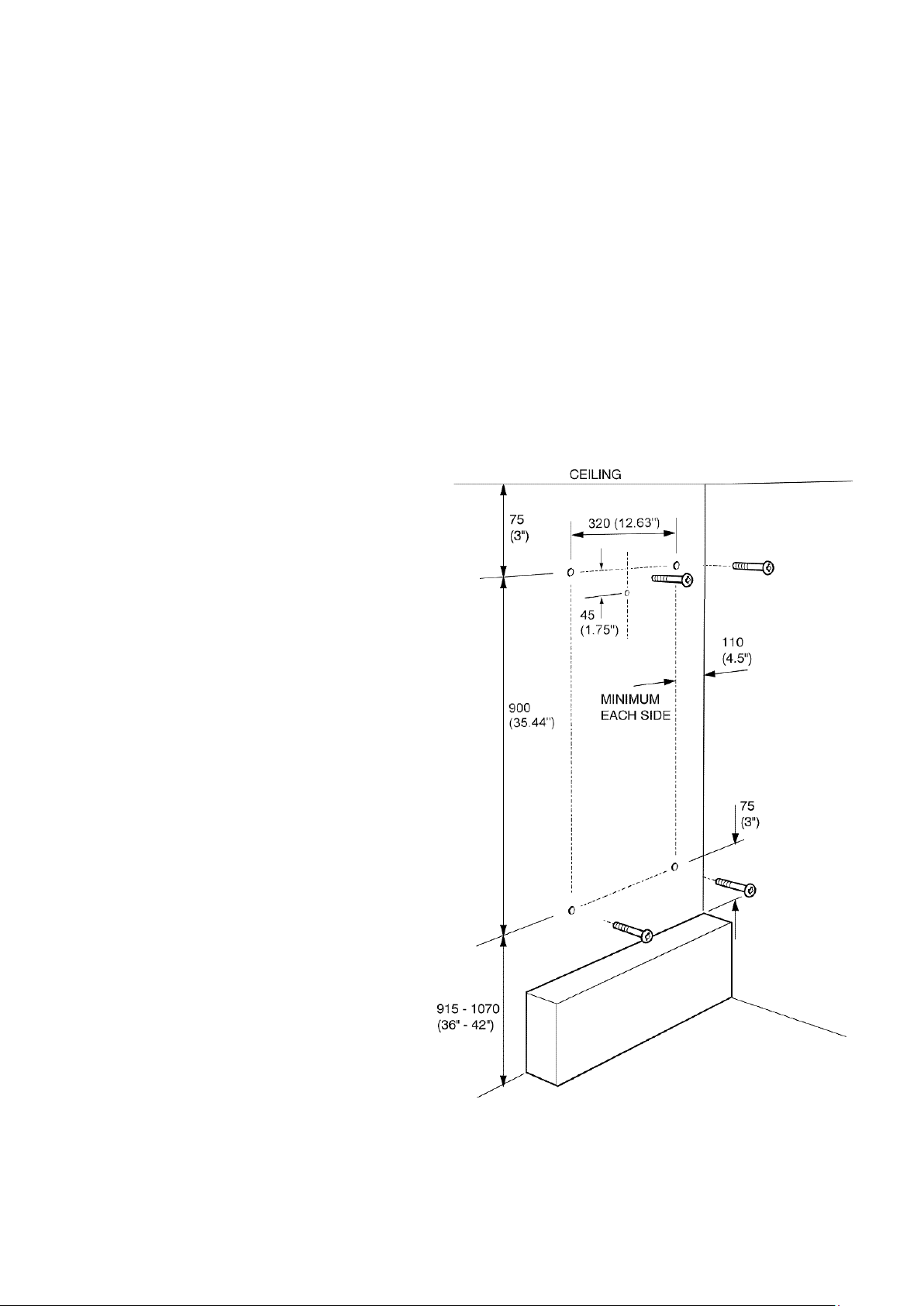

1.4.4 Fastening the dispenser to the wall (Fig 1-1 for metal m/c only)

The metal dispenser is attached

directly to the wall by four masonry

screws, inserted through the body of

the machine. This procedure should

be carried out by two people, as the

weight and size of the empty

dispenser may exceed statutory

guidelines for a single person.

Scribe the intended vertical centre-

line of the machine on the wall, and

mark a position 45mm (1 ¾”) from

the top. Drill a hole at this position

to accept a screw about 25mm (1”)

long (not supplied), plug the hole

and insert the screw until the head

is about 8mm (3/8”) clear of the wall.

Pick the machine up and hang it on

this screw with the head through

the small triangular hole at the top

in the back.

Holding the machine exactly upright,

mark the four mounting screw

positions on the wall through the

holes in the back of the dispenser

cabinet. These should be in a

rectangular pattern 320mm (12 5/8”)

apart horizontally and 900mm (35

7/16”) apart vertically. Remove the machine, drill and plug all four holes, then use a

centre-punch or ball-point pen to open them up for easy screw entry.