45

WARNINGS:

These warnings apply to this product, all tools and accessories, and any

chargers or power adapters you may need.

To reduce the risk of re, electric shock and injury:

- This product cannot be used by people with physical, sensory or

intellectual disabilities, or people without relevant experience (including

children), unless there is a guardian's care or guidance to ensure that

they can use this product safely.

- Do not use this product as a toy; Close attention is especially needed

when approaching children; Please take care of children to ensure that

they do not use this product as a toy.

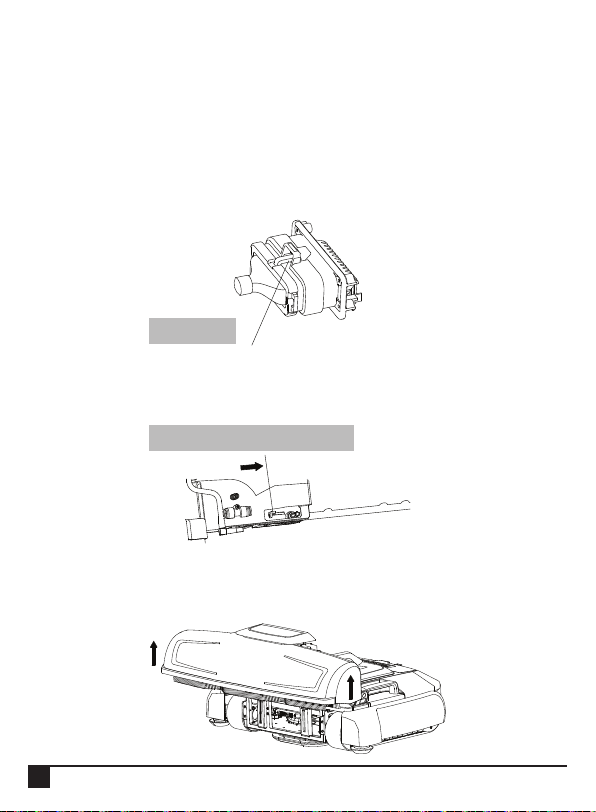

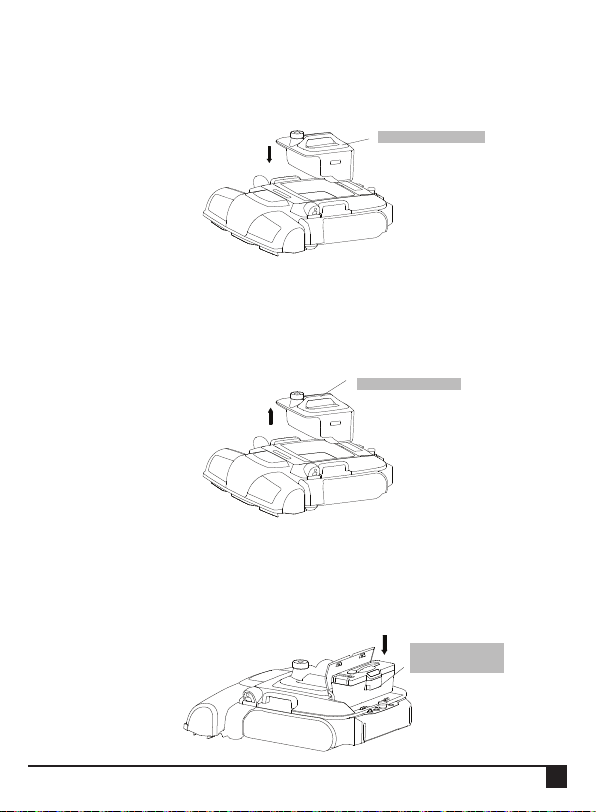

- To use the machine, please follow the instructions.

- Do not touch the connector with wet hands.

- Do not use if the cable or connector is damaged.

- Do not use this product in rainy days.

- If the product does not operate as designed, suers serious impact,

falls from high place, is damaged, or falls into water, please do not use

it, and please contact the after-sales help hotline.

- Contact the after-sales hotline for maintenance or repair. Do not

disassemble the product. Improper disassembly may cause electric

shock or re.

- Warning: Do not operate machine at temperature above 35 ℃ or below

5 ℃ , or at the surface temperature of PV module above 50 ℃ or below

5 ℃ . Otherwise, the machine may slip and fall.

- Warning: Use and store the machine with care to avoid strong impact,

which may cause vibration damage to internal structural components

and electrical components.

- Do not burn the product even if it is badly damaged. Batteries and

electrical components may explode in the re.

- It is strictly forbidden to stop the machine for cleaning operation in

situ, which may damage the panel surface.

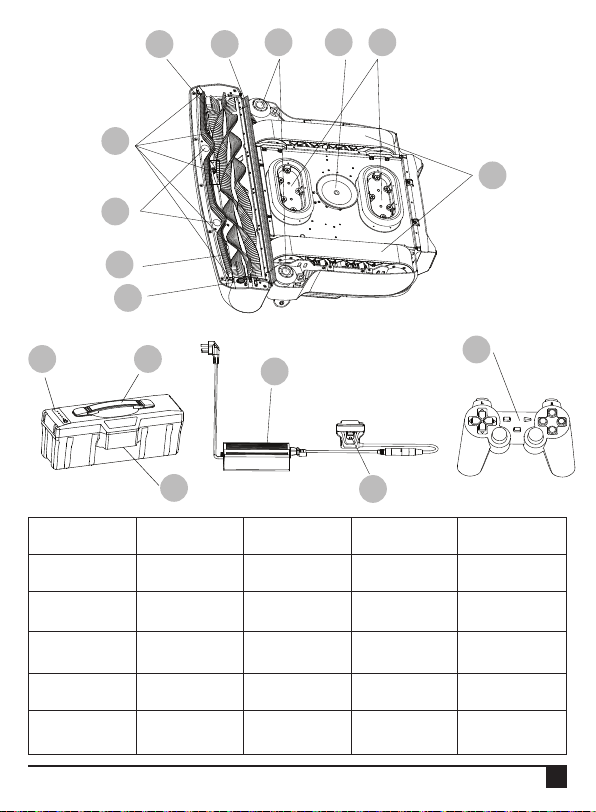

- List of product accessories and parameters of the machine.