IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions

carefully. To emphasize special information, the words

WARNING, CAUTION and NOTE have special mean-

ings. Pay special attention to the messages high-

lighted by these signal words.

WARNING:

Indicates a potential hazard that could result

in death or injury.

CAUTION:

Indicates a potential hazard that could result

in vehicle damage.

NOTE:

Indicates special information to make mainte-

nance easier or instructions clearer.

WARNING:

This service manual is intended for autho-

rized SUZUKI dealers and qualified service

mechanics only. Inexperienced mechanics

or mechanics without the proper tools and

equipment may not be able to properly per-

form the services described in this manual.

Improper repair may result in injury to the

mechanic and may render the vehicle un-

safe for the driver and passengers.

WARNING:

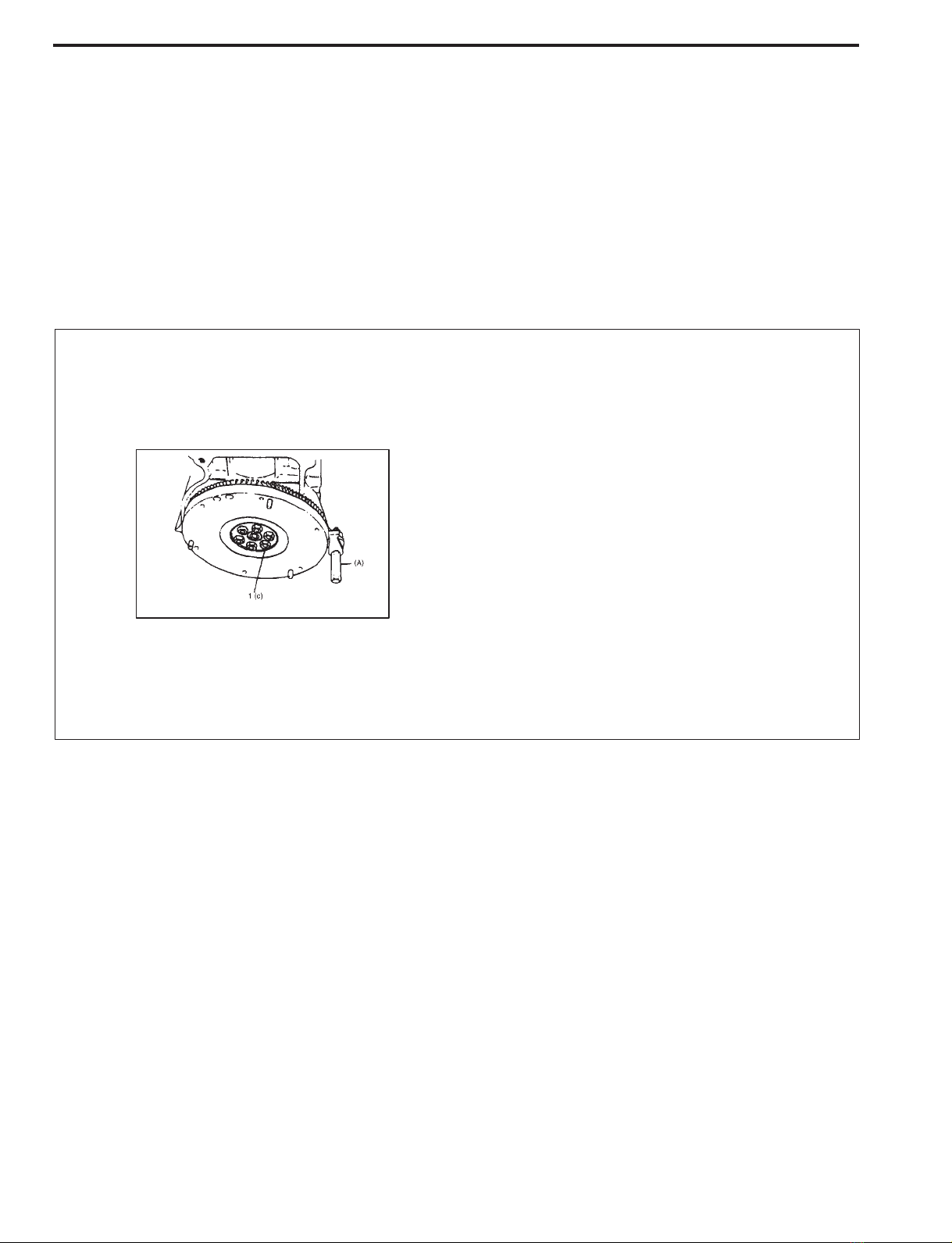

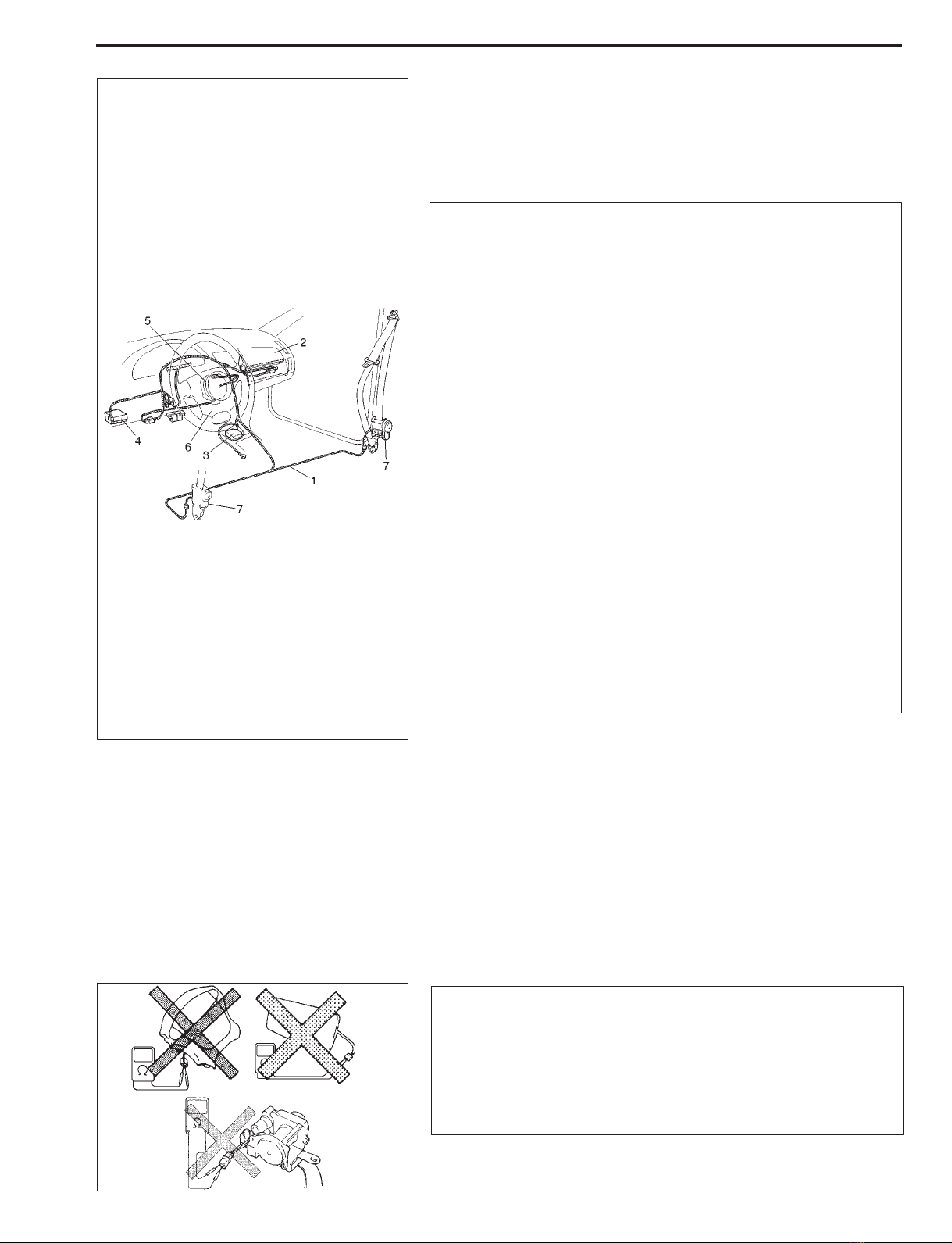

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

!Service on or around the air bag system

components must be performed only by

an authorized SUZUKI dealer. Please ob-

serve all WARNINGS, CAUTIONS and

“Service Precautions” under “On-Vehicle

Service” in SECTION 10B before perform-

ing service on or around the air bag sys-

tem components or wiring. Failure to

follow WARNINGS could result in uninten-

tional activation of the system or could

render the system inoperative. Either of

these two conditions may result in severe

injury.

!If the air bag system and another vehicle

system both need repair, SUZUKI recom-

mends that the air bag system be repaired

first, to help avoid unintentional activa-

tion of the air bag system.

!Do not modify the steering wheel, instru-

ment panel or any other air bag system

component. Modifications can adversely

affect air bag system performance and

lead to injury.

!If the vehicle will be exposed to tempera-

tures over 93!C (200!F) (for example, dur-

ing a paint baking process), remove the

air bag system components (air bag (infla-

tor) modules, SDM and seat belt preten-

sioner (if equipped)) beforehand to avoid

component damage or unintended activa-

tion of the system.