Suzuki DR-Z70K8 User guide

Other Suzuki Motorcycle manuals

Suzuki

Suzuki RM125 Application guide

Suzuki

Suzuki UG110 2021 User manual

Suzuki

Suzuki 2005 VL800 Manual

Suzuki

Suzuki XS 600 - SCHEMATICS 1970-1973 User manual

Suzuki

Suzuki Intruder VS1400 User manual

Suzuki

Suzuki FL125S User manual

Suzuki

Suzuki rg500 User manual

Suzuki

Suzuki DL1000AL4 User manual

Suzuki

Suzuki VL1500 User manual

Suzuki

Suzuki TS400 1971 User manual

Suzuki

Suzuki freewind User manual

Suzuki

Suzuki TU250X User manual

Suzuki

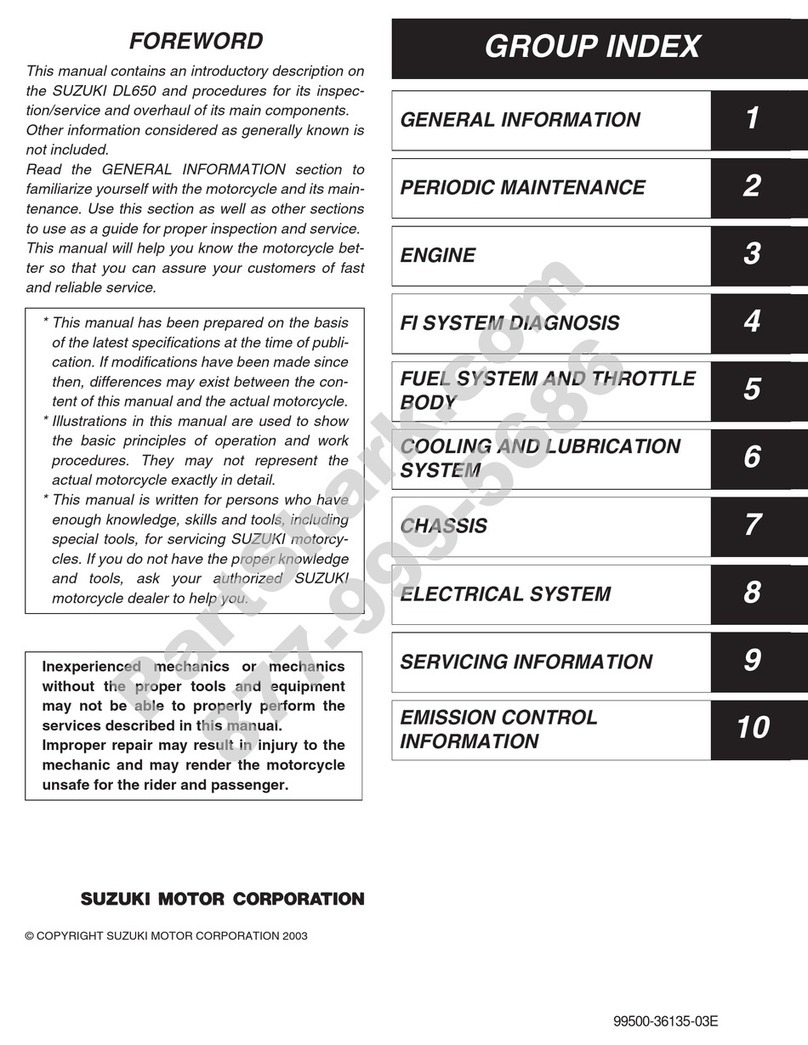

Suzuki DL650K5 User manual

Suzuki

Suzuki UK110NE 2015 User manual

Suzuki

Suzuki SV650S User manual

Suzuki

Suzuki FU150MF User manual

Suzuki

Suzuki 2007 SV650K7 Manual

Suzuki

Suzuki GSX-1300R Manual

Suzuki

Suzuki 1982 GS450GA User manual

Suzuki

Suzuki VL1500K5 Manual