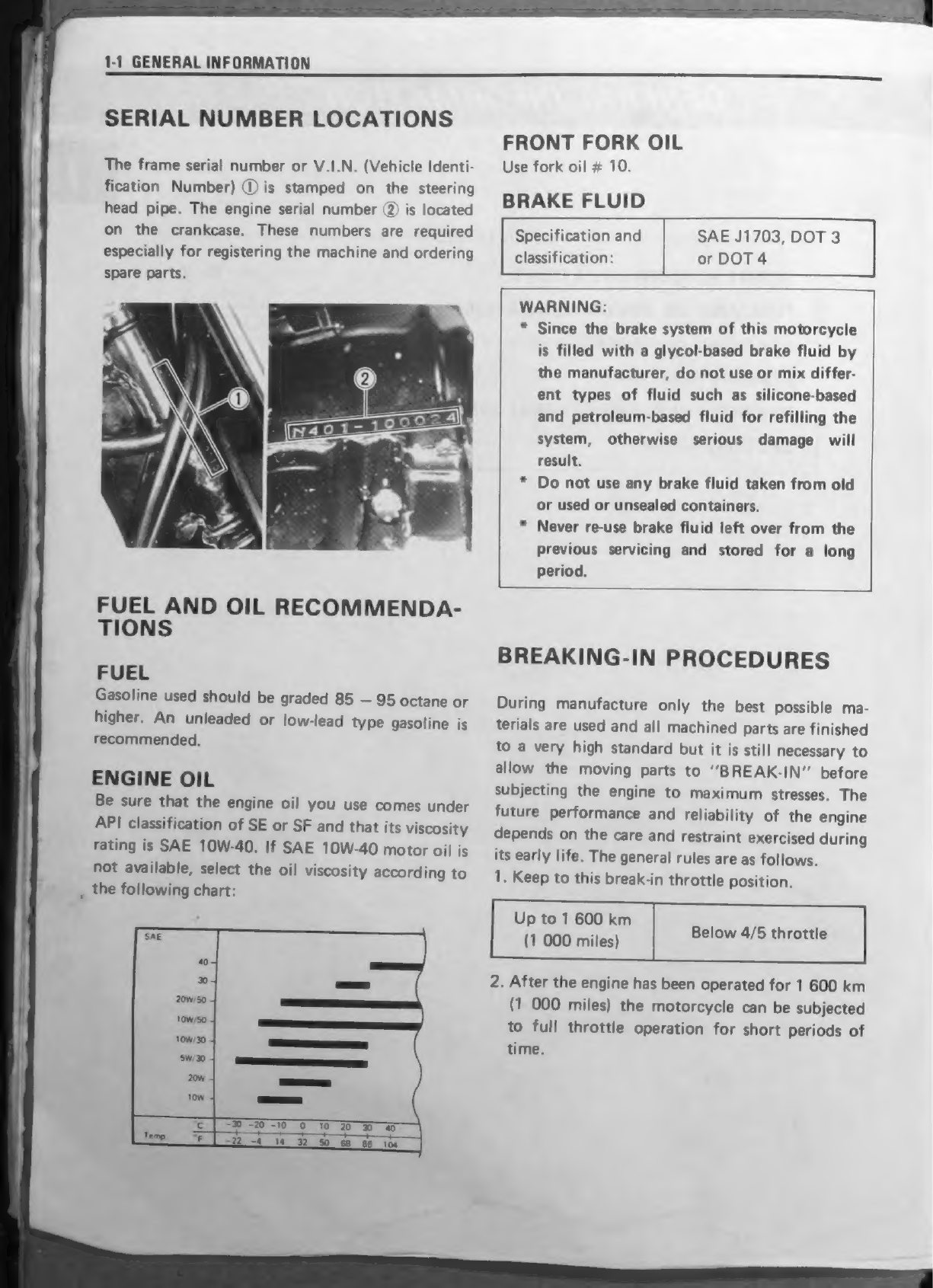

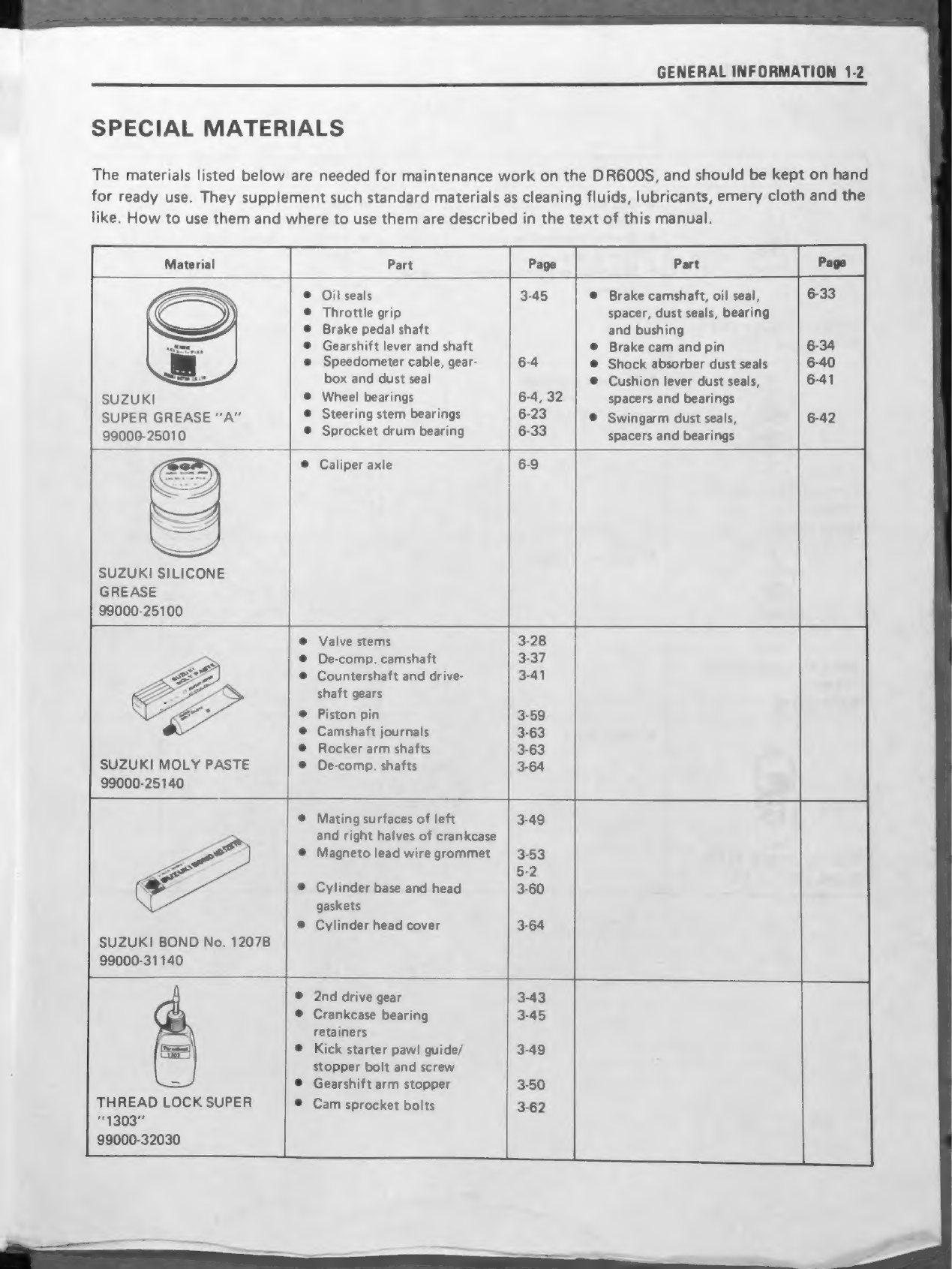

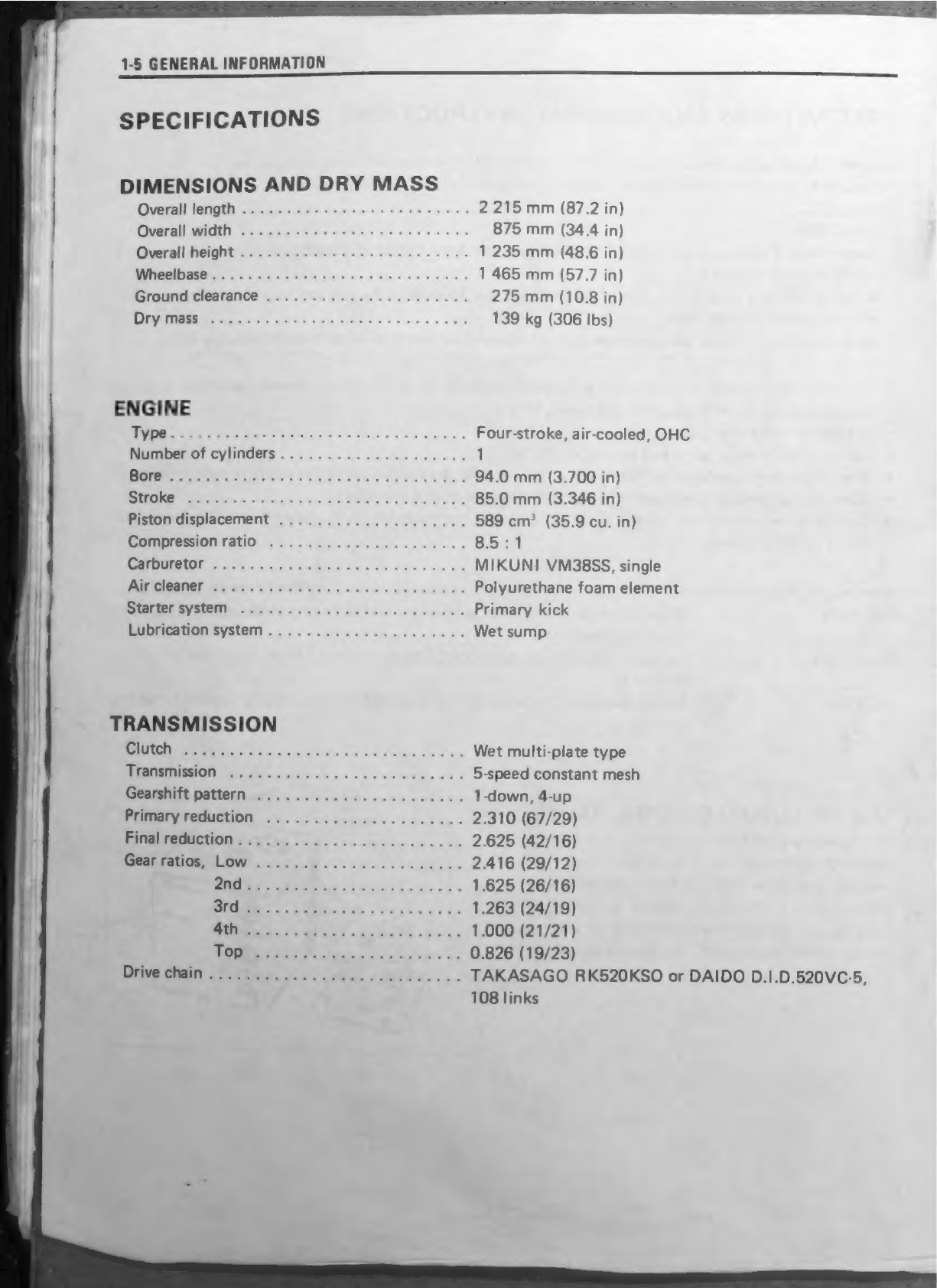

Suzuki DR600S User manual

Other Suzuki Motorcycle manuals

Suzuki

Suzuki Intruder VS700 User manual

Suzuki

Suzuki DR-Z400S 2001 User manual

Suzuki

Suzuki T250 User manual

Suzuki

Suzuki GSX-F 750 - User manual

Suzuki

Suzuki GSX-R250 User manual

Suzuki

Suzuki 1997 VZ800 User manual

Suzuki

Suzuki GSF1200S 2001 User manual

Suzuki

Suzuki 2006 GSF1200AK6 Manual

Suzuki

Suzuki RM250 Application guide

Suzuki

Suzuki GS1000 User manual

Suzuki

Suzuki Intruder VZ800 User manual

Suzuki

Suzuki GSX-R600 User manual

Suzuki

Suzuki RG50 User manual

Suzuki

Suzuki Intruder VS1400 User manual

Suzuki

Suzuki TS200R User manual

Suzuki

Suzuki Inazuma User manual

Suzuki

Suzuki AN650 2002 User manual

Suzuki

Suzuki k8 gsx1300r Reference manual

Suzuki

Suzuki 1980 GSX400 User manual

Suzuki

Suzuki Intruder VS1400 User manual