Foreword

This

manual

is designed

primarily

for

use by

snow-

mobile mechanics in a properly equipped shop.

However,

it

contains enough detail and basic

in-

formation

to make

it

useful to the snowmobile user

who

desires to perform his

own

basic

mainte-

nance and repair

work

. A basic knowledge

of

mechanics, the proper use

of

tools, and workshop

procedures

must

be understood in order to carry

out

maintenance and repair satisfactorily.

When-

ever the

owner

has

insufficient

experience

or

doubts his ability to do the work, the adjustments,

maintenance, and repair should be carried

out

only

by qualified mechanics.

In order to perform the

work

efficiently

and to

avoid costly mistakes, the mechanic should read

the

text, thoroughly familiarize

himself

with

the

procedures before starting work, and

then

do

the

work

carefully in a clean area.

Whenever

special

tools

or

equ ipment is specified, makeshift tools or

equipment

should

not

be used. Precision measure-

ments

can only

be

made

if

the proper

instruments

are used, and the use

of

substitute tools may

adversely affect safe operation

of

the

snowmobile.

Whenever

you see

the

symbols

shown

below, heed

their

instructionsI

Always

follow

safe operating

and maintenance practices.

IWARNINGI

This

warning

symbol

identifies

special

in-

structions

or

procedures

which

if

not

cor-

rectly

followed

,

could

result

in

personal

injury,

or

loss

of

life.

This

caution

symbol

identifies

special

in-

structions

or

procedures

which

if

not

strictly

observed,

could

result

in

damage to,

or

destruction

of

equipment

.

NOTE:

Indicates points

of

particular interest

for

more

efficient

and convenient operation.

This manual is divided

into

the

following

four

sections:

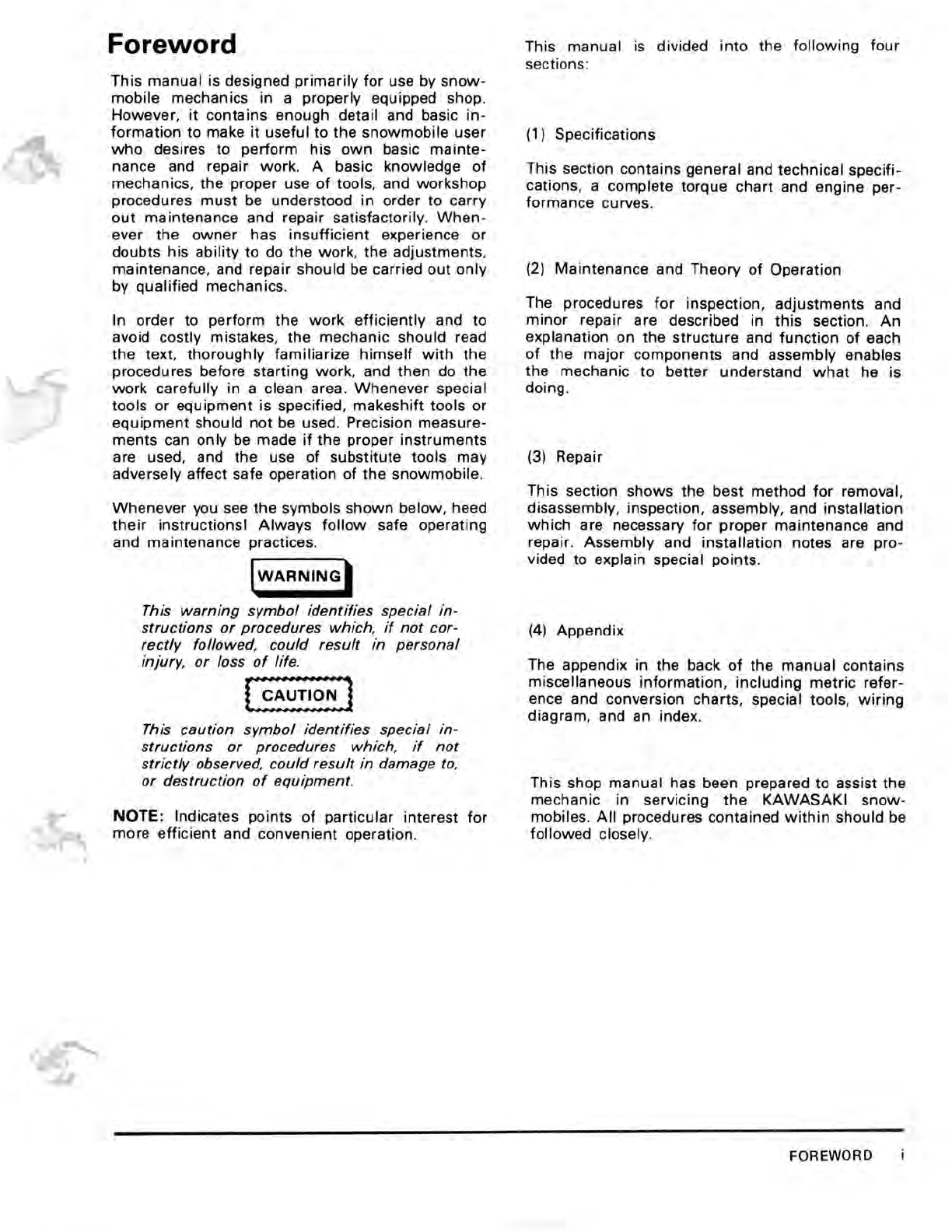

(1) Specifications

This section contains general and technical specifi-

cations, a complete torque chart and engine per-

formance

cu

rves.

(2)

Maintenance

and Theory

of

Operation

The procedures

for

inspection, adjustments and

minor

repair are described in

this

section.

An

explanation on the

structure

and

function

of each

of

the

major

components and assembly enables

the mechanic

to

better understand

what

he is

doing.

(3) Repair

This section shows the best method

for

removal,

disassembly, inspection, assembly, and installation

which

are necessary

for

proper

maintenance and

repair. Assembly and

installation

notes are pro-

vided to explain special points.

(4)

Appendix

The appendix in the back

of

the

manual

contains

miscellaneous

information,

including

metric

refer-

ence and conversion charts, special tools,

wiring

diagram, and an index.

This shop manual has been prepared to assist the

mechanic in servicing

the

KAWASAKI

snow-

mobiles.

All

procedures contained

within

should be

followed closely.

FOREWORD