We reserve the right to alter specifications.

GB.FUNKRXHC.180907

www.swegon.com 5

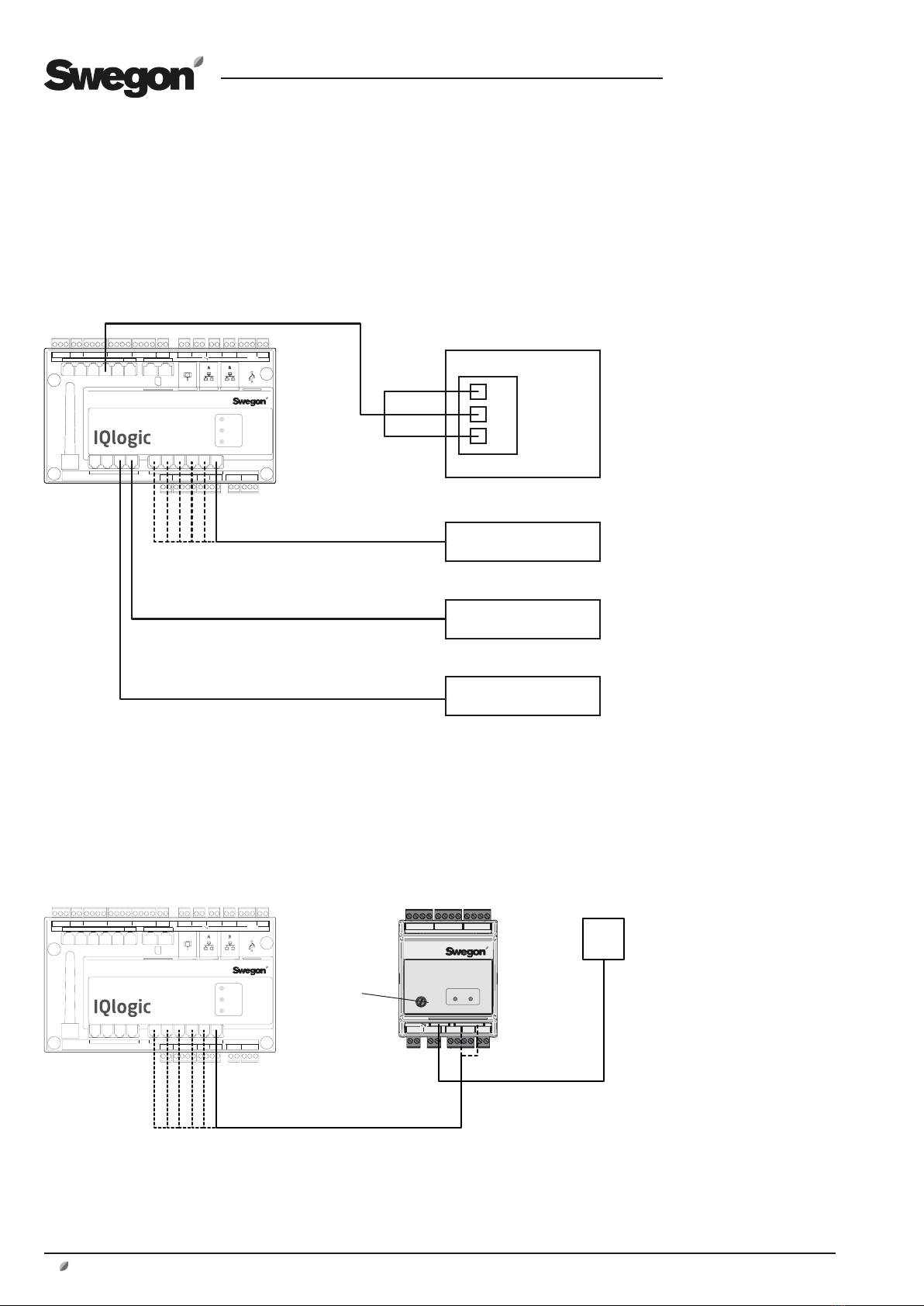

When defrosting is completed, the outdoor air damper

and the exhaust air damper open, the recirculation

damper closes and stabilization operations are run.

In order to reduce the risk of freezing, a termination

sequence is started at the same time when the recircula-

tion damper is opened and closed a number of times.

Electrical air heater RX/HC (accessory)

When there is a defrosting requirement, the electric air

heater is enabled immediately.

Overheating protection is installed. Post-cooling is car-

ried out if the air handling unit stops during or just after

defrosting.

Critical defrosting

If the evaporation temperature in the heating circuit drops

below a critical limit, defrosting starts.

If the control system discovers ongoing ordinary defrost-

ing, critical defrosting is adapted to the ordinary defrost-

ing sequence, e.g. recirculation starts.

3.10 Limitations

For operations outside the outdoor temperature limits

and/or below air limits, the reversible heat pump function

stops and the air handling unit acts as a GOLD RX.

Outdoor temperature limit, cooling

Operation of the reversible heat pump in cooling mode

is only permitted at an outdoor temperature above 15°C

(adjustable value).

Outdoor temperature limit, heating

Operation of the reversible heat pump in heating mode

is only permitted at an outdoor temperature above -25°C

(adjustable value).

Air flow limits

Operation of the reversible heat pump is only permitted

when the extract airflow and supply airflow exceed a

minimum airflow limit. Values can be set for the extract air

and supply air.

3.9 Defrosting

Freezing occurs when operations are in heating mode and

the temperature across the exhaust coil is below 0 °C.

Depending on the temperature, compressor speed, airflow

as well as moisture content in the extract air and fresh air,

freezing occurs with varying speed and behaviour.

The pressure drop across the exhaust coil is measured

to detect the defrosting requirement or stop ongoing

defrosting. Defrosting starts when the pressure drop

exceeds a specific limit. When the pressure drop falls

below another lower limit defrosting stops.

At defrosting with recirculation, the recirculation damper

have a finishing sequence for protection against freezing.

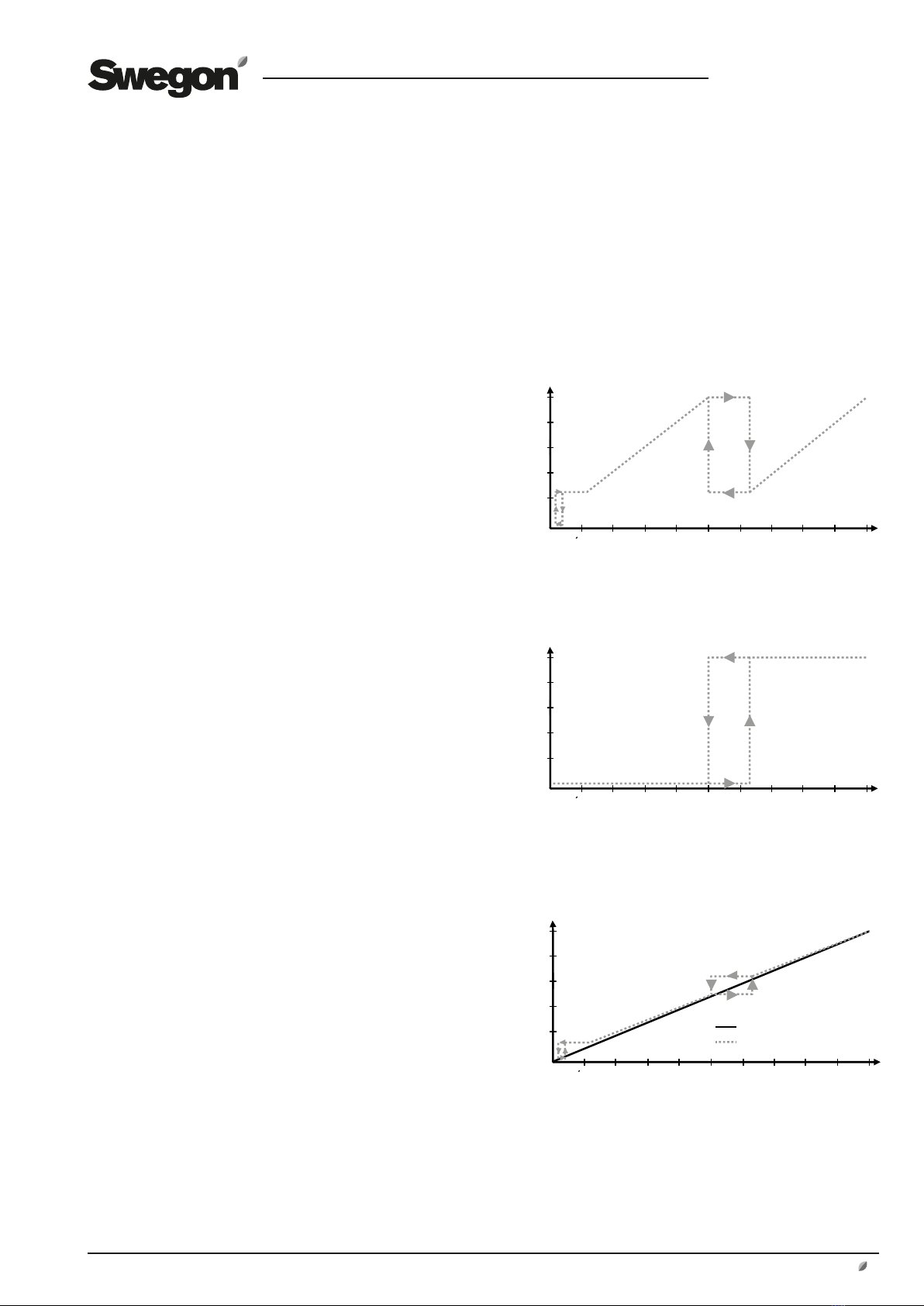

Phases

Defrosting occurs by reversing the heat pump circuit. The

exhaust coil then works as a condenser (as with the cool-

ing function) and heats.

Start delay

When the pressure drop across the exhaust air coil exceeds

the start limit, for a period longer than 60 seconds,

defrosting starts.

Initiation

When defrosting is detected the Initiation phase starts.

The recirculation damper then opens for recirculation, and

if there is an electric air heater this starts. For recirculation

the signal is sent with a delay of 60 seconds, if there is no

recirculation the signal is sent without a delay.

Pre-defrosting

When the defrosting process starts, a signal is sent to the

heating circuit which lowers the compressor speed and

turns the flow directions through the four-way valve.

Defrosting

The defrosting process continues through ramping up the

compressor speed and running until the control system

requests that defrosting stops or until the maximum

defrosting time has been reached.

Runoff

In the last part of the defrosting process, the compressor

speed drops and the flow directions through the four-way

valve are turned back.

Adaptive start and stop

Start and stop of the defrosting process is controlled by

calculations in the control system, which take a number

of different factors into consideration that are measured

continuously.

Adaptation is performed after each defrosting to optimise

the process.

Air recirculation section RX/HC (accessory)

When there is a defrosting requirement, the recircula-

tion damper opens, and the outdoor air damper and the

exhaust air damper close.

Recirculation operation is ensured before defrosting starts.