4

Revision A.00

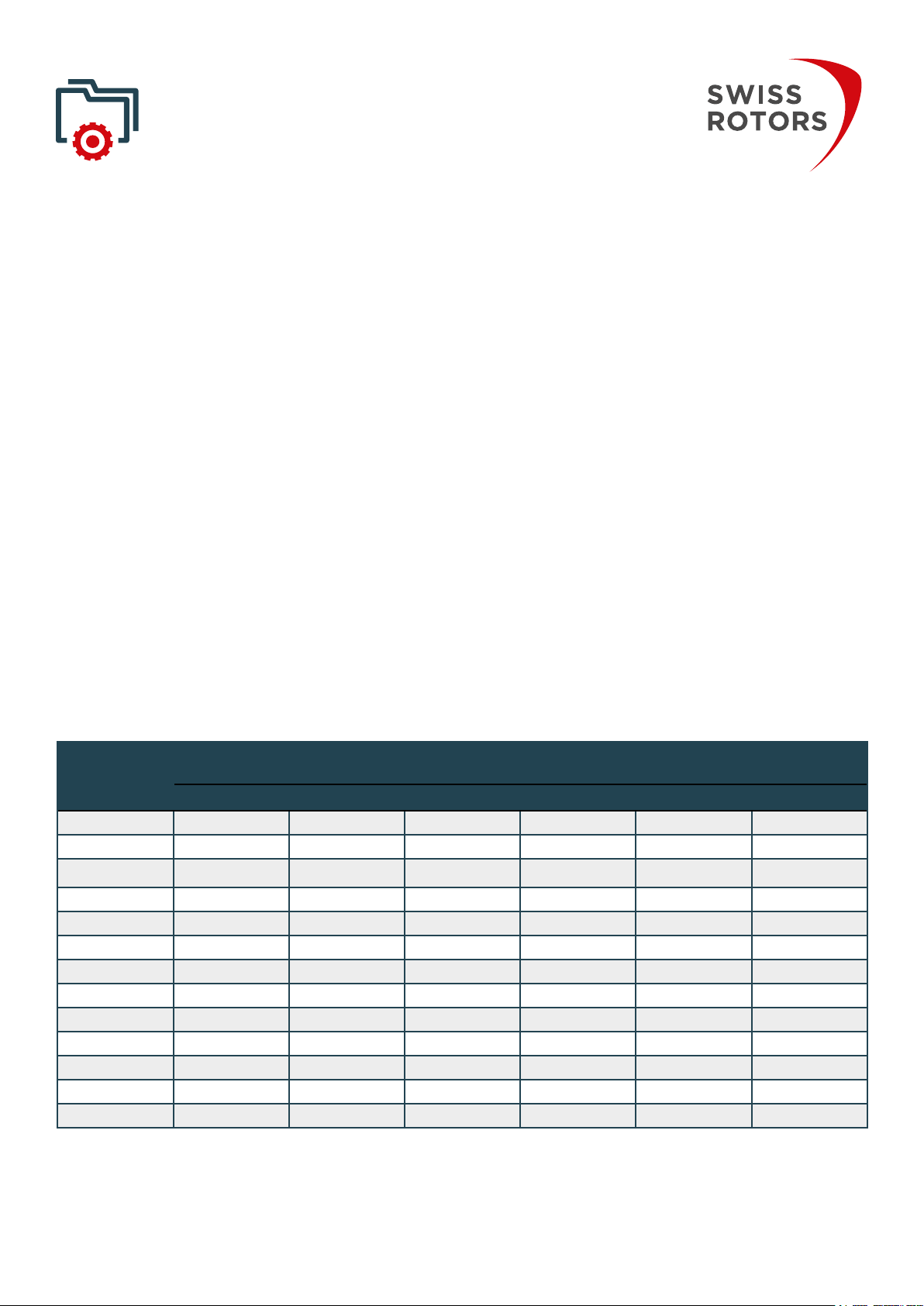

Table 1. Swiss Rotors FanSet models and dimensions

2 PRODUCT DESCRIPTION

2.1 Construction

Swiss Rotors FanSet is designed specially to replace an old fan systems solutions used in

air handling units. FanSet consist of two steel plate’s integrated by spacing sleeves. Properly

of dedicated diameter is mounted on the opposite side. Each of fans Series 225, 250 and

315 have two pressure tabs. The exception is Fan 190 Series which have one pressure tab.

All parts are made of high quality materials:

- Support bracket and plate: Sheet steel, galvanized

- Impeller: plastic

- Electronics housing: Die-cast aluminum.

All parts create perfectly optimized air supply/exhaust device. Depending on customer needs,

mounted into balancing machine. At the next step, balancing of the fan needs to be performed by

screen. FanSet is balanced and ready to operate after successful placing of the balancing weight.

FanSet models listed below:

FanSet Model Rated voltage Rated Output

Power

Rated Current Rated Speed L A

[W] [W] [A] [rpm] [mm] [mm]

SR190 230 128 1,2A 4490 120 220

SR225-03 230 349 2,3A 3600 250 300

SR225-03_UL 110/240 349 2,6A 3600 250 300

SR250-03 230 349 2,3A 3000 260 330

SR250-03_UL 110/240 349 2,6A 3000 260 330

SR315-03 230 1,5A 2060 310 400

SR315-03_UL 110/240 1,5A 2060 310 400

230 5,4A 4500 300

110/240 3,2A/230VAC 4500 300

230 5,1A 3800 290 330

110/240 3800 290 330

230 3,8A 2600 340 400

110/240 3,3A/230VAC 2600 340 400