4

Version 1.0.1

Table 1. Swiss Rotors FanSet models and dimensions

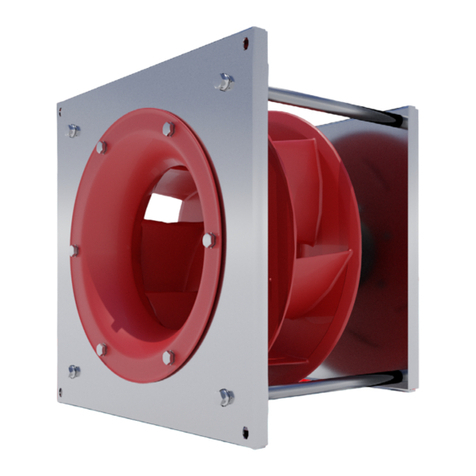

3 PRODUCT DESCRIPTION

3.1 Construction

Swiss Rotors impeller has 7 backward-curved blades in frame. Ventilating cone that are mounted

on the front plate of FanSet has it’s strictly designed shape for each size of the impeller. Series 225,

All parts are made of high quality materials:

- Front plates, inlet cones made of galvanized steel,

- Supports made of steel and painted,

- Impeller material:

o SR-A – aluminum alloy

- Electronics housing: Die-cast aluminum.

All parts create perfectly optimized air supply/exhaust device. Depending on customer needs,

before shipment.

FanSet models listed below:

Fan Set Model Rated voltage Rated Output

Power

Max Current Rated/Max

Speed

A B C D E F

[V] [W] [A] [rpm] mm [mm] [mm] [mm] [mm] [mm]

128 1,9A 96,5 2

349 224 199,1 254 15 315 228

349 221,7 199,1 254 15 315 228

349 3,5A 235,7 285 15 375 258

349 3,5A 232,4 285 15 375 258

374 3,5A 271,2 246,3 358 15 328

374 3,5A 267,8 246,3 358 15 328

735 5,4A 254 15 315 228

735 5,4A 248,1 254 15 315 228

5,1A 262 221,2 285 15 375 258

5,1A 258,7 221,2 285 15 375 258

715 3,8A 261 358 15 328

715 3,8A 298,4 261 358 15 328

SR-P-HE-315-1.5 5,3A 327,5 282 358 15 328