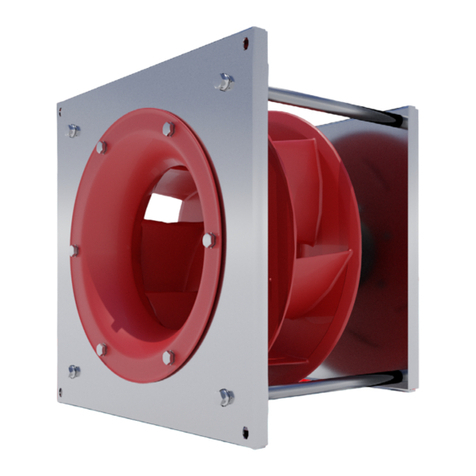

190-560 mm SR-FS-P/A Fan Sets / Operating Manual Ver. 2023-08-01 EN

Page 7 of 17

Additional information printed on the name plate is as follows:

•Serial number –a unique number given for each fan product to allow easy production, transportation, delivery and

operation traceability.

•Quality control date - date in the DD/MM/YYYY format of the quality control of the final product carried out in the

factory.

•QR Code –code with link to the Swiss Rotors service contact information.

AIR VOLUME MEASUREMENT

Fan Set are equipped with the inlet cone. Air volume measuring device with circular lead is placed on the inlet side of

the cone. Measuring device is positioned perpendicularly to the air flow direction . With the assistance of the measuring

device it is possible to control the air volume depending on the difference in pressure between the static pressure at the

inlet cone and the static pressure on the inlet area. This sensor cannot measure the dynamic pressure in the inlet area.

While Fan Set is tested it is possible to regulate air volume.

The air volume is calculated according to the following formula.

Where:

Difference between actual airflow value and value calculated

with k-factor should be less than 10%. K-factor is determined by

comparative measurement on a standard test rig under standard

test conditions –reference density 1,2 kg/m3. Airflow can be

converted to different density of air using below formula:

Where:

Value of K-factor () for Swiss Rotors Fan Set’s range is shown on below attached Table 4. K-factors were determined

during testing under standard conditions.

Table 4 - factor values of Fan Set depending on the Impeller size and motor power