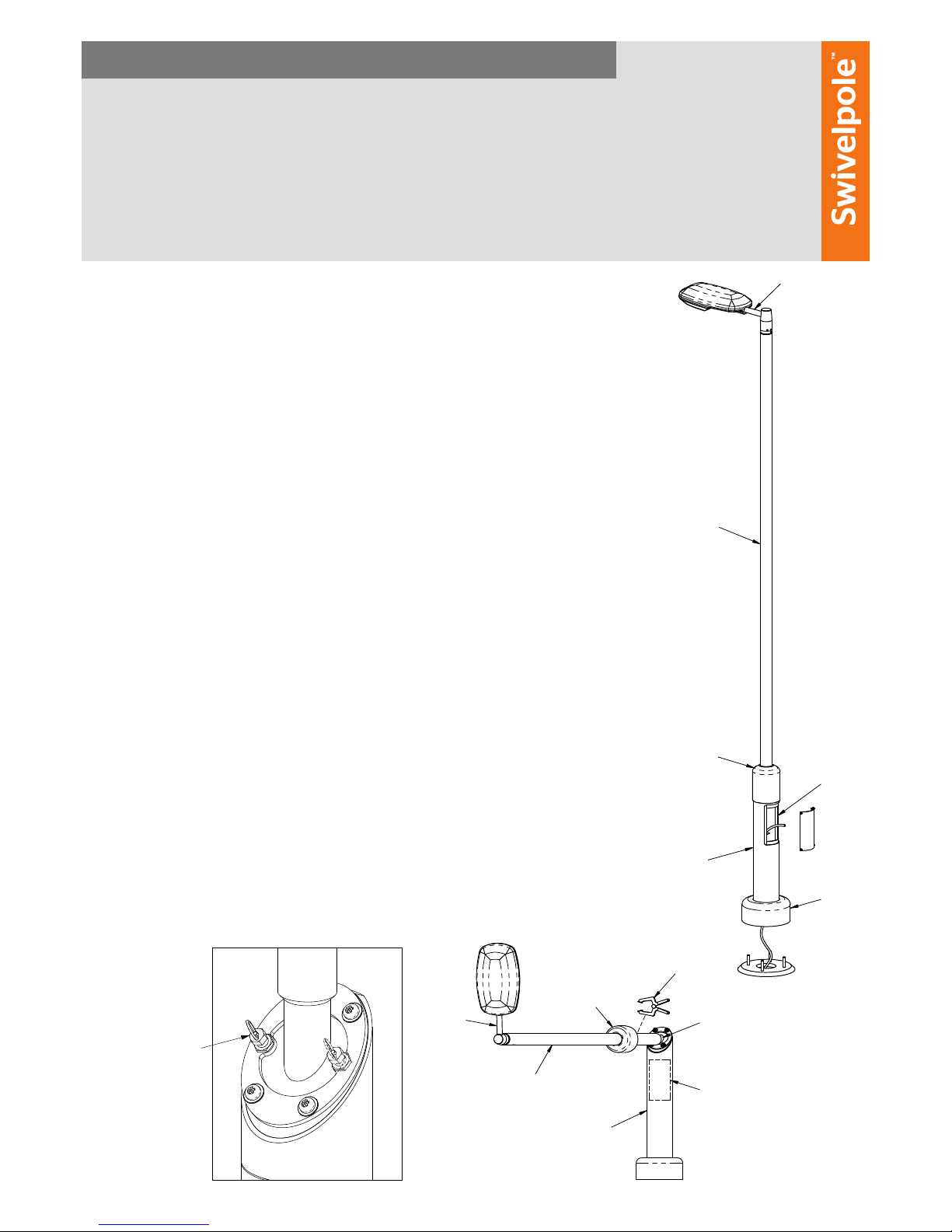

INSTALLATION & OPERATION GUIDE

NOTE: This guide should be followed in conjunction with your own worksite

Procedures, Safety Rules and Regulations to ensure the F19 Swivelpole™ is

assembled and installed safely, and correctly to optimise it’s performance.

Before installation please ensure you have read the Operation and Safety

Information.

This guide should be followed to ensure the Swivelpole™ is assembled and

installed safely and correctly.

Copies of general assembly drawings are available at

www.swivelpole.com

1. Feed the electrical cable

through the base section of the

Swivelpole™ to the access panel.

2. Position the base section over

the installed cage bolts.

3. Rotate the Swivelpole™

base section to the desired

orientation.

4. Align the base section so it is

vertical.

5. Tighten base plate bolts.

6. Slide the base cowling over the

base pole to cover the base plate.

7. Feed the electrical cable through

the pole top prior to bolting to

the swivel plate.

8. Apply multi-purpose grease to

swivel plate surfaces and bolts.

9. Slide the clamp plate onto the

pole top.

10. With one person holding the

pole top horizontally, the second

person can position the round

swivel plate locator into the hole

of the base section swivel plate.

11. Bolt the clamp plate to the swivel

plate, using the fastening kits.

Refer to Figure 1: For lowering

direction preference.

12. Tighten the bolts evenly.

13. Apply enough tension to allow

controlled raising of the pole top,

at this point the Swivelpole™ will

be self supporting.

14. To raise, use two people to guide

it as it swivels to the upright

position.

15. Insert the safety pin.

16. With the pole top in the upright

position, mark the pole in the

direction the xture is to face,

and lower it again to t the

xture.

17. Slide the joint cowling onto the

pole top using a spring clamp to

keep the joint accessible.

18. To lower, retract the safety pin

and swivel the pole top down to

a safe working height and insert

the safety pin.

19. Fit the xture mount as per

marked position on pole top.

20. Tighten the grub screws to a

torque setting of 17Nm to 20Nm.

21. Complete installation and

termination of the xture.

22. Raise the Swivelpole™ and insert

the safety pin. Tighten the

bolts evenly to a torque setting

between 40Nm and 80Nm.

23. Lower the cowling over the joint

and tighten the tamper proof

screw.

Installation of Swivelpole™ F19

SP-IEC-Installation Guide F19-20180830

Figure 1

AS SHOWN FOR

R/Hand LOWERING

DEPENDING ON SITE

CONDITIONS CLAMP

PLATE AND STOP TAB

PLUNGER CAN BE

INSTALLED ON THE

OPPOSITE SIDE TO

ALLOW FOR L/Hand

LOWERING