75

E

Contents

1Precautions..................................................................................................... 76

1.1 Important information ..................................................................................... 76

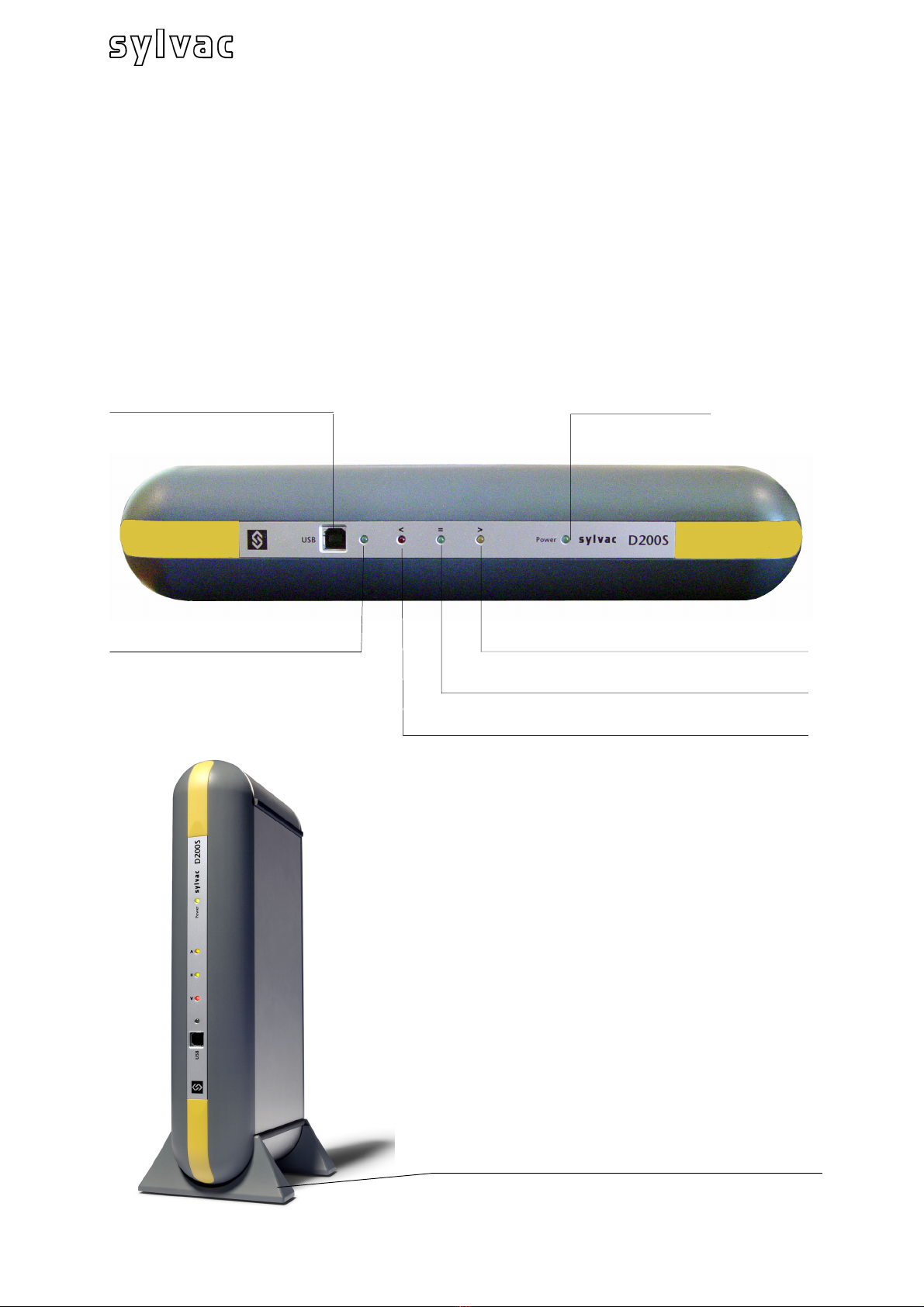

2General description of D200S unit................................................................ 77

2.1 Front of unit.................................................................................................... 77

2.2 Rear of unit .................................................................................................... 78

2.3 Functions of connectors (rear panel) ............................................................. 78

3Software D200S .............................................................................................. 81

3.1 Description of Software D200S ...................................................................... 81

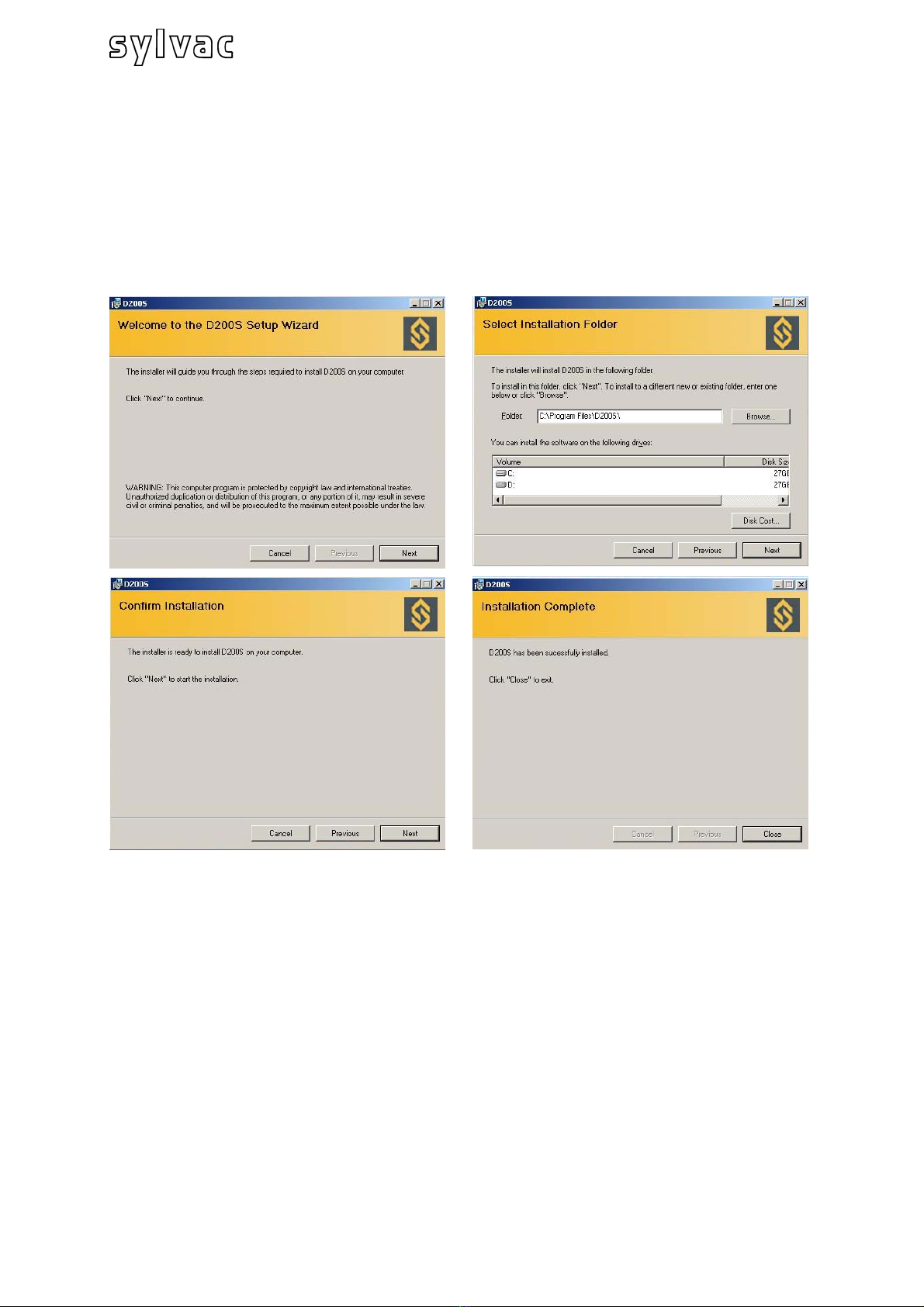

3.2 Installation of software D200S ....................................................................... 82

3.3 Hardware Connection between D200S unit and PC ...................................... 83

3.4 Installation of USB pilot.................................................................................. 83

3.5 Checking of Frontal LED indicators................................................................ 84

3.6 Connection (software) with D200S unit.......................................................... 85

4Use of software D200S .................................................................................. 86

4.1 The Main Menu .............................................................................................. 86

4.1.1 Sub-menu RS232 Setup........................................................................ 87

4.1.2 Sub-menu Channel Setup ..................................................................... 88

4.1.3 Sub-menu Sequences Configuration..................................................... 89

4.1.4 Sub-menu Foot Pedal, Switch 1 and 2 Setting ...................................... 90

4.1.5 Sub-menu Digital Output ....................................................................... 91

4.1.6 Sub-menu Simulation Mode .................................................................. 92

4.1.7 Sub-menu Send to................................................................................. 93

4.1.8 Sub-menu Open File ............................................................................. 95

4.1.9 Sub-menu Save As… ............................................................................ 95

4.1.10 Open Configuration (from D200S) ......................................................... 95

4.1.11 Transfer (to D200S)............................................................................... 96

4.1.12 Transfer + Save (to D200S)................................................................... 96

4.1.13 Reset unit .............................................................................................. 96

5Functions of the basic screen....................................................................... 97

5.1 Standard Mode .............................................................................................. 97

5.2 Bargraph Mode .............................................................................................. 98

5.3 Example of measurement with two points of measurement (2 probes).......... 99

5.4 Example of measurement with four points of measurement (4 probes) with

two D200S units............................................................................................101

6Communication protocol (remote commands)..........................................103

6.1 Example of communication with software Winwedge 32...............................103

6.2 Code for remote commands..........................................................................104

7Calibration of the unit ...................................................................................107

8Technical specifications...............................................................................108

9Sizes............................................................................Erreur ! Signet non défini.

10 Delivery ..........................................................................................................109

11 Optional accessories ....................................................................................109